ASTM B955/B955M-07

(Specification)Standard Specification for Aluminum-Alloy Centrifugal Castings

Standard Specification for Aluminum-Alloy Centrifugal Castings

SCOPE

1.1 This specification covers aluminum-alloy centrifugal castings designated as shown in Table 1.

1.2 This specification is not intended for aluminum-alloy centrifugal castings used in aerospace applications.

1.3 Alloy and temper designations are in accordance with ANSI H35.1 /H35.1 (M). The equivalent unified numbering system alloy designations are in accordance with Practice E 527.

1.4 Unless the order specifies the "M" specification designation, the material shall be furnished to the inch-pound units.

1.5 For acceptance criteria for inclusion of new aluminum and aluminum alloys and their properties in this specification, see Annex 1 and Annex 2 .

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standards. The SI units are shown in brackets or in separate tables or columns. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitation prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 955/B 955M – 07

Standard Specification for

Aluminum-Alloy Centrifugal Castings

This standard is issued under the fixed designation B 955/B 955M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope als and Alloys, Cast and Wrought

B 557 Test Methods for Tension Testing Wrought and Cast

1.1 This specification covers aluminum-alloy centrifugal

Aluminum- and Magnesium-Alloy Products

castings designated as shown in Table 1.

B 557M Test Methods for Tension Testing Wrought and

1.2 This specification is not intended for aluminum-alloy

Cast Aluminum- and Magnesium-Alloy Products [Metric]

centrifugal castings used in aerospace applications.

B 660 Practices for Packaging/Packing of Aluminum and

1.3 Alloy and temper designations are in accordance with

Magnesium Products

ANSI H35.1 / H35.1 (M). The equivalent unified numbering

B 881 Terminology Relating to Aluminum- and

system alloy designations are in accordance with Practice

Magnesium-Alloy Products

E 527.

B 917/B 917M Practice for Heat Treatment of Aluminum-

1.4 Unless the order specifies the “M” specification desig-

Alloy Castings from All Processes

nation, the material shall be furnished to the inch-pound units.

D 3951 Practice for Commercial Packaging

1.5 For acceptance criteria for inclusion of new aluminum

E29 Practice for Using Significant Digits in Test Data to

and aluminum alloys and their properties in this specification,

Determine Conformance with Specifications

see Annex A1 and Annex A2.

E34 Test Methods for ChemicalAnalysis ofAluminum and

1.6 The values stated in either inch-pound units or SI units

Aluminum-Base Alloys

are to be regarded separately as standards. The SI units are

E88 Practice for Sampling Nonferrous Metals and Alloys

shown in brackets or in separate tables or columns. The values

in Cast Form for Determination of Chemical Composition

stated in each system are not exact equivalents; therefore, each

E94 Guide for Radiographic Examination

system must be used independent of the other. Combining

E 155 Reference Radiographs for Inspection of Aluminum

values from the two systems may result in nonconformance

and Magnesium Castings

with the specification.

E 165 Test Method for Liquid Penetrant Examination

1.7 This standard does not purport to address all of the

E 527 Practice for Numbering Metals and Alloys in the

safety concerns, if any, associated with its use. It is the

Unified Numbering System (UNS)

responsibility of the user of this standard to establish appro-

E 716 Practices for Sampling Aluminum and Aluminum

priate safety and health practices and determine the applica-

Alloys for Spectrochemical Analysis

bility of regulatory limitation prior to use.

E 1251 Test Method for Analysis of Aluminum and Alumi-

2. Referenced Documents

num Alloys by Atomic Emission Spectrometry

E 2281 Practice for Process and Measurement Capability

2.1 The following documents of the issue in effect on the

Indices

date of casting purchase form a part of this specification to the

2.3 ANSI Standard:

extent referenced herein:

H35.1 / H35.1 (M) American National Standard Alloy and

2.2 ASTM Standards:

Temper Designation Systems for Aluminum

B 179 Specification for Aluminum Alloys in Ingot and

Z1.4 Sampling Procedures and Tables for Inspection by

Molten Forms for Castings from All Casting Processes

Attributes

B 275 Practice for Codification of Certain Nonferrous Met-

2.4 Military Standards:

MIL-STD-129 Marking for Shipment and Storage

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.01 on

Aluminum Alloy Ingots and Castings.

Current edition approved Oct. 1, 2007. Published November 2007. Available from Aluminum Association, Inc., 1525 Wilson Blvd., Suite 600,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Arlington, VA 22209, http://www.aluminum.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 955/B 955M – 07

A,B,C

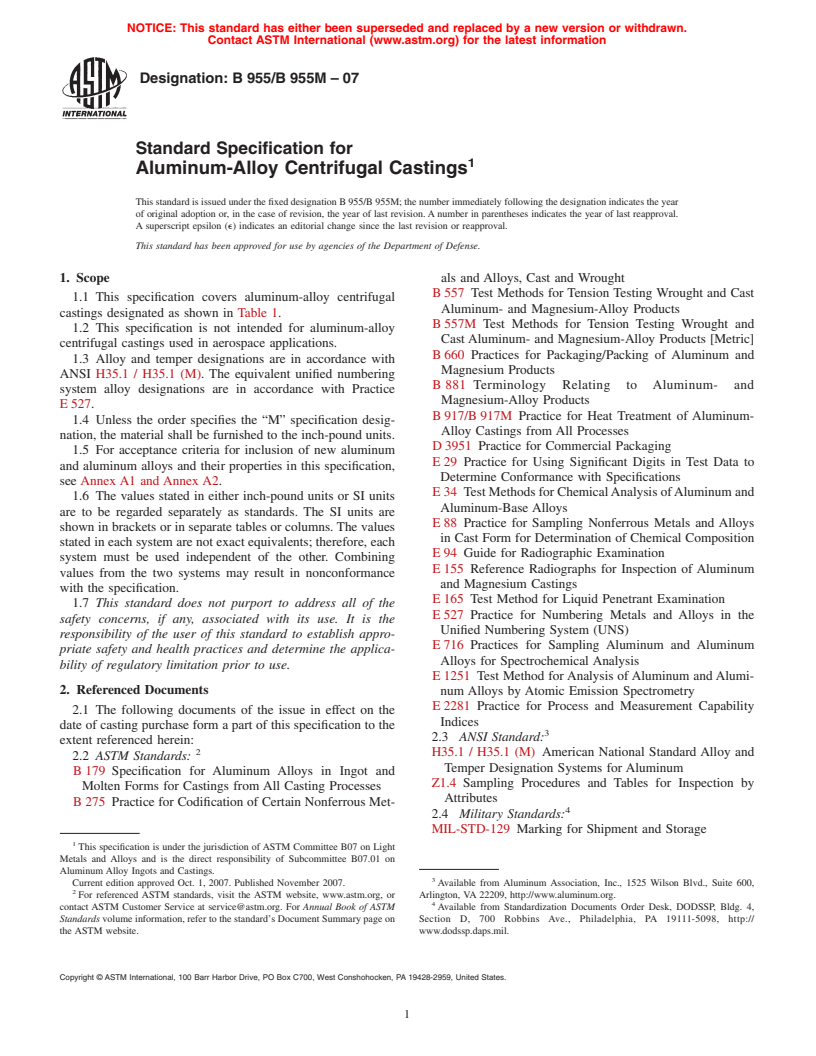

TABLE 1 Chemical Composition Limits

Alloy Composition, %

D E

ANSI UNS Silicon Iron Copper Manga- Magnesium Chromium Nickel Zinc Titanium Tin Other Elements Aluminum

nese

F

Each Total

G G

356.0 A03560 6.5–7.5 0.6 0.25 0.35 0.20–0.45 . . 0.35 0.25 . . 0.05 0.15 Remainder

505.0 0.40–0.8 0.7 0.15–0.40 0.15 0.8–1.2 0.04–0.35 … 0.25 0.15 . . 0.05 0.15 Remainder

709.0 0.40 0.50 1.2–2.0 0.30 2.1–2.9 0.18–0.28 … 5.1-6.1 0.20 … … 0.05 0.15 Remainder

850.0 A08500 0.7 0.7 0.7–1.3 0.10 0.10 . 0.7–1.3 . 0.20 5.5–7.0… … 0.30 Remainder

A

When single units are shown, these indicate the maximum amounts permitted.

B

Analysis shall be made for the elements for which limits are shown in this table.

C

The following applies to all specified limits in this table: For purposes of determining conformance to these limits, an observed value or a calculated value obtained

from analysis shall be rounded to the nearest unit in the last right-hand place of figures used in expressing the specified limit in accordance with the rounding method of

Practice E29.

D

ASTM alloy designations are defined in ANSI H35.1/H35.1 (M)

E

Others includes listed elements for which no specific limit is shown as well as unlisted metallic elements. The producer may analyze samples for trace elements not

specified in the specification. However, such analysis is not required and may not cover all metallicOthers elements. Should any analysis by the producer or the purchaser

establish that an Others element exceeds the limit of Each or that the aggregate of several Others elements exceeds the limit of Total, the material shall be considered

nonconforming.

F

2Other Elements—Total shall be the sum of unspecified metallic elements 0.010 % or more, rounded to the second decimal before determining the sum.

G

If the iron content exceeds 0.45 %, manganese content shall not be less than one half of the iron.

MIL-STD-276 Impregnation of Porous Nonferrous Metal 4. Ordering Information

Castings

4.1 Orders for material under this specification shall include

2.5 Naval Standard:

the following information:

S9074-AR-GIB-010/278 Requirements for Fabrication

4.1.1 This specification designation (which includes the

WeldingandInspection,andCastingInspectionandrepair

number, the year, and the revision letter, if applicable),

for Machinery, Piping, and Pressure Vessels

NOTE 1—For inch-pound application, specify Specification B 955 and

2.6 Federal Standard:

for metric application specify Specification B 955M. Do not mix units.

Fed Std. No. 123 Marking for Shipment (Civil Agencies)

4.1.2 Alloy (see Section 7 and Table 1),

3. Terminology

4.1.3 Temper (see Section 11 and Table 2 [Table 3]),

3.1 Definitions—RefertoTerminologyB 881fordefinitions 4.1.4 Applicable drawing or part number,

of product terms used in this specification. 4.1.5 The quantity in either pieces or pounds.

3.1.1 Hot Isostatic Processing (HIP, HIPped, and 4.2 Additionally, orders for material to this specification

HIPping)—the process of applying high pressure and tempera- shall include the following information when required by the

tures to a part through the medium of a pressurized gas, such purchaser:

as Argon or Nitrogen to remove internal porosity voids. 4.2.1 Whether chemical composition samples are to be

taken from the castings (see 7.2),

4.2.2 Whether foundry control is required (see 10.2),

4.2.3 Whether yield strength tests are required (see 11.1 and

Available from Naval Sea Systems Command (NAVSEA), 1333 Isaac Hull

Table 2, Footnote D, [Table 3], Footnote D),

Ave., SE, Washington, DC 20376, http://www.navsea.navy.mil.

A,B

TABLE 2 Tensile Requirements, (Inch-Pound Units)

Yield Elongation in Typical Brinell

Tensile

D E

Strength 2 in. or 4 3 Hardness

C

Alloy Temper Strength, min,

(0.2 % offset), Diameter, 500-kgf load,

ksi

min, ksi min, % 10-mm ball

F

ANSI UNS

356.0 A03560 T6 separately cast specimens 33.0 22.0 3.0 85

G

505.0 T61 specimens cut from castings 43.0 37.0 7.0 95

H

709.0 T61 specimens cut from castings 74.0 64.0 4.0 150

850.0 A08500 T5 separately cast specimens 18.0 . 8.0 …

A

If agreed upon by manufacturer and the purchaser, other mechanical properties may be obtained by other heat treatments such as annealing, aging, or stress relieving.

B

For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded off to the nearest 0.1 ksi, and each

value for elongation shall be rounded to the nearest 0.5 %, both in accordance with the rounding method of Practice E29.

C

Temper designations are defined in ANSI H35.1/H35.1 (M) T61 Hot Isostatic Pressed (HIP), solution heat-treated, and then artificially aged.

D

Yield strength to be evaluated only when specified in contract or purchase order.

E

Hardness values given for information only, not required for acceptance.

F

ASTM alloy designations are recorded in Practice B 275.

G

These properties apply only to castings having section thicknesses not greater than 2.5 in. Tensile specimens were taken from the casting after HIPping was completed.

The data used to calculate the minimum values came from samples taken in the axial direction. While not combinable with the axial data, tangential values are marginally

higher.

H

These properties apply only to castings having section thicknesses not greater than 2.5 in. Tensile specimens were taken from the casting after HIPping was completed.

Samples were taken in both the axial and tangential directions and the data was found to be combinable. The data represents both directions.

B 955/B 955M – 07

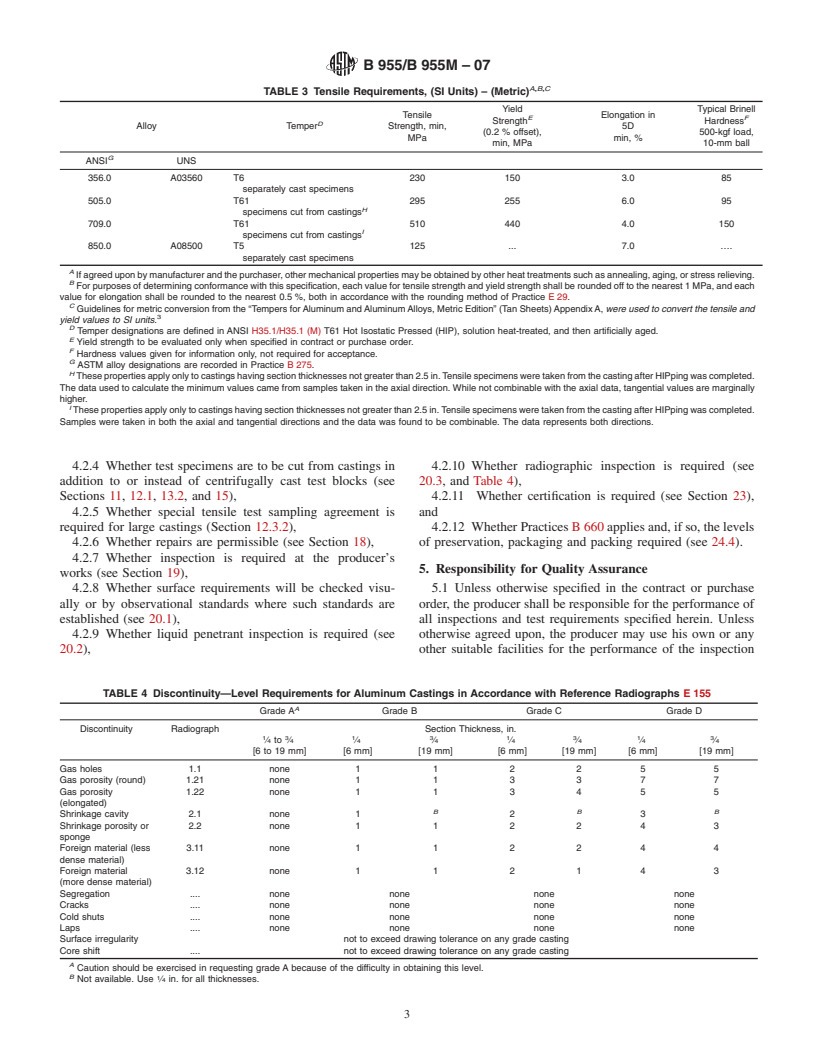

A,B,C

TABLE 3 Tensile Requirements, (SI Units) – (Metric)

Yield Typical Brinell

Tensile Elongation in

E F

Strength Hardness

D

Alloy Temper Strength, min, 5D

(0.2 % offset), 500-kgf load,

MPa min, %

min, MPa 10-mm ball

G

ANSI UNS

356.0 A03560 T6 230 150 3.0 85

separately cast specimens

505.0 T61 295 255 6.0 95

H

specimens cut from castings

709.0 T61 510 440 4.0 150

I

specimens cut from castings

850.0 A08500 T5 125 . 7.0 ….

separately cast specimens

A

If agreed upon by manufacturer and the purchaser, other mechanical properties may be obtained by other heat treatments such as annealing, aging, or stress relieving.

B

For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded off to the nearest 1 MPa, and each

value for elongation shall be rounded to the nearest 0.5 %, both in accordance with the rounding method of Practice E29.

C

Guidelines for metric conversion from the “Tempers for Aluminum and Aluminum Alloys, Metric Edition” (Tan Sheets) Appendix A, were used to convert the tensile and

yield values to SI units.

D

Temper designations are defined in ANSI H35.1/H35.1 (M) T61 Hot Isostatic Pressed (HIP), solution heat-treated, and then artificially aged.

E

Yield strength to be evaluated only when specified in contract or purchase order.

F

Hardness values given for information only, not required for acceptance.

G

ASTM alloy designations are recorded in Practice B 275.

H

These properties apply only to castings having section thicknesses not greater than 2.5 in. Tensile specimens were taken from the casting after HIPping was completed.

The data used to calculate the minimum values came from samples taken in the axial direction. While not combinable with the axial data, tangential values are marginally

higher.

I

These properties apply only to castings having section thicknesses not greater than 2.5 in. Tensile specimens were taken from the casting after HIPping was completed.

Samples were taken in both the axial and tangential directions and the data was found to be combinable. The data represents both directions.

4.2.4 Whether test specimens are to be cut from castings in 4.2.10 Whether radiographic inspection is required (see

addition to or instead of centrifugally cast test blocks (see 20.3, and Table 4),

Sections 11, 12.1, 13.2, and 15), 4.2.11 Whether certification is required (see Section 23),

4.2.5 Whether special tensile test sampling agreement is and

required for large castings (Section 12.3.2), 4.2.12 Whether Practices B 660 applies and, if so, the levels

4.2.6 Whether repairs are permissible (see Section 18), of preservation, packaging and packing required (see 24.4).

4.2.7 Whether inspection is required at the producer’s

5. Responsibility for Quality Assurance

works (see Section 19),

4.2.8 Whether surface requirements will be checked visu- 5.1 Unless otherwise specified in the contract or purchase

ally or by observational standards where such standards are order, the producer shall be responsible for the performance of

established (see 20.1), all inspections and test requirements specified herein. Unless

4.2.9 Whether liquid penetrant inspection is required (see otherwise agreed upon, the producer may use his own or any

20.2), other suitable facilities for the performance of the inspection

TABLE 4 Discontinuity—Level Requirements for Aluminum Castings in Accordance with Reference Radiographs E 155

A

Grade A Grade B Grade C Grade D

Discontinuity Radiograph Section Thickness, in.

1 3 1 3 1 3 1 3

⁄4 to ⁄4 ⁄4 ⁄4 ⁄4 ⁄4 ⁄4 ⁄4

[6 to 19 mm] [6 mm] [19 mm] [6 mm] [19 mm] [6 mm] [19 mm]

Gas holes 1.1 none 1 1 2 2 5 5

Gas porosity (round) 1.21 none 1 1 3 3 7 7

Gas porosity 1.22 none 1 1 3 4 5 5

(elongated)

B B B

Shrinkage cavity 2.1 none 1 2 3

Shrinkage porosity or 2.2 none 1 1 2 2 4 3

sponge

Foreign material (less 3.11 none 1 1 2 2 4 4

dense material)

Foreign material 3.12 none 1 1 2 1 4 3

(more dense material)

Segregation . none none none none

Cracks . none none none none

Cold shuts . none none none none

Laps . none none none none

Surface irregularity not to exceed drawing tolerance on any grade casting

Core shift . not to exceed drawing tolerance on any grade casting

A

Caution should be exercised in requesting grade A because of the difficulty in obtaining this level.

B

Not available. Use ⁄4 in. for all thicknesses.

B 955/B 955M – 07

and test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.