ASTM G139-05(2015)

(Test Method)Standard Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using Breaking Load Method

Standard Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using Breaking Load Method

SIGNIFICANCE AND USE

5.1 The test method was developed for use with high strength aluminum alloys (2XXX and Cu containing 7XXX) that are normally tested in 3.5 weight % NaCl by alternate immersion. However, the concept which uses residual strength as a measure of damage evolution (in this case environmentally-assisted cracking) can, in principle, be applied to any alloy and environmental system.

5.2 This test method has been developed for research studies of alloys and tempers with improved resistance to SCC. The test results permit different material variants to be compared with a high degree of confidence and with much more precision than the results of pass/fail tests. Thus, it is particularly useful for comparing materials with similar levels of resistance to stress-corrosion cracking. The procedure could be modified for use as a quality assurance tool but this has not been a primary purpose during its development.

5.3 The exposure periods and conditions that are described in this test method apply specifically to high strength aluminum alloys, but the statistical techniques should be valid for other alloy systems with different exposure conditions.

5.4 Although this particular procedure was primarily intended for testing products in the short-transverse stressing direction, it is useful for other stressing directions, particularly the long-transverse direction in sheet and thin plate products.

5.5 Determination of the actual serviceability of a material requires stress-corrosion testing performed in the intended service environment, under conditions relating to the end use, including protective measures such as coatings and inhibitors and is outside the scope of this test method.

5.5.1 There is no good way to compare test environments to actual service because most service environments have large inherent variability with respect to a single structure that may experience many different environments or with respect to two identical structures that serve in different l...

SCOPE

1.1 This test method covers procedures for evaluation of stress corrosion cracking (SCC) resistance by the breaking load test method, a concept which uses residual strength as the measure of damage evolution (in this case environmentally assisted cracking).

1.2 This test method covers specimen type and replication, test environment, stress levels, exposure periods, final strength determination, and statistical analysis of the raw residual strength data.

1.3 The test method was developed for use with heat-treatable aluminum alloys, that is, 2XXX alloys and 7XXX with 1.2 to 3.0 % Cu, and test specimens oriented in the short-transverse direction relative to grain structure (1, 2).2 However, the residual strength measurements and the statistics used to analyze the data are not specific to heat-treatable aluminum alloys and can be used for other specimen orientations and different types of materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G139 − 05 (Reapproved 2015)

Standard Test Method for

Determining Stress-Corrosion Cracking Resistance of Heat-

Treatable Aluminum Alloy Products Using Breaking Load

1

Method

This standard is issued under the fixed designation G139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G44PracticeforExposureofMetalsandAlloysbyAlternate

Immersion in Neutral 3.5 % Sodium Chloride Solution

1.1 This test method covers procedures for evaluation of

G47Test Method for Determining Susceptibility to Stress-

stresscorrosioncracking(SCC)resistancebythebreakingload

Corrosion Cracking of 2XXX and 7XXX Aluminum

test method, a concept which uses residual strength as the

Alloy Products

measure of damage evolution (in this case environmentally

G49Practice for Preparation and Use of Direct Tension

assisted cracking).

Stress-Corrosion Test Specimens

1.2 This test method covers specimen type and replication,

G64Classification of Resistance to Stress-Corrosion Crack-

test environment, stress levels, exposure periods, final strength

ing of Heat-Treatable Aluminum Alloys

determination, and statistical analysis of the raw residual

strength data.

3. Terminology

1.3 The test method was developed for use with heat-

3.1 Definitions of Terms Specific to This Standard:

treatable aluminum alloys, that is, 2XXX alloys and 7XXX

3.1.1 censor—a statistical term indicating that the value

with 1.2 to 3.0% Cu, and test specimens oriented in the

from an individual observation may fall outside of the range

2

short-transverse direction relative to grain structure (1, 2).

that can be measured because of test procedures or conditions.

However, the residual strength measurements and the statistics

3.1.2 sample—the nominally uniform, bulk material from

used to analyze the data are not specific to heat-treatable

which individual stress-corrosion cracking specimens are ob-

aluminum alloys and can be used for other specimen orienta-

tained.

tions and different types of materials.

1.4 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 This test method describes a procedure for using re-

responsibility of the user of this standard to establish appro-

sidual strength after exposure to a corrosive environment to

priate safety and health practices and determine the applica-

evaluate stress corrosion cracking susceptibility in heat treat-

bility of regulatory limitations prior to use.

able aluminum alloy product forms such as sheet, plate,

2. Referenced Documents

extrusions, forgings, and bar. These products generally are

3

most susceptible to SCC in the long transverse direction of

2.1 ASTM Standards:

sheet, the short transverse direction of plate, extrusions and

E8Test Methods for Tension Testing of Metallic Materials

forgings, and the transverse direction of rod and bar stock. In

E691Practice for Conducting an Interlaboratory Study to

this test, tensile bars or direct tension sheet specimens, pre-

Determine the Precision of a Test Method

pared according to Practice G49, are exposed to 3.5 weight %

aqueous sodium chloride solution (Practice G44), are removed

1

This test method is under the jurisdiction of ASTM Committee G01 on

before they fail and are tension tested to determine the amount

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

of corrosion damage that has occurred. The average retained

Environmentally Assisted Cracking.

strength is then calculated and the Box-Cox Transformation

Current edition approved Nov. 1, 2015. Published December 2015. Originally

approved in 2005. Last previous edition approved in 2011 as G139–05(2011). DOI:

can be used for statistical analysis of the results.

10.1520/G0139-05R15.

2

4.2 The procedure calls for exposure of unstressed speci-

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the standard.

mens which are used to factor out the effects of pitting,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

intergranular, and general corrosion. These phenomena de-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

grade residual strength but do not require applied stress for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. their occurrence.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G139 − 05 (2015)

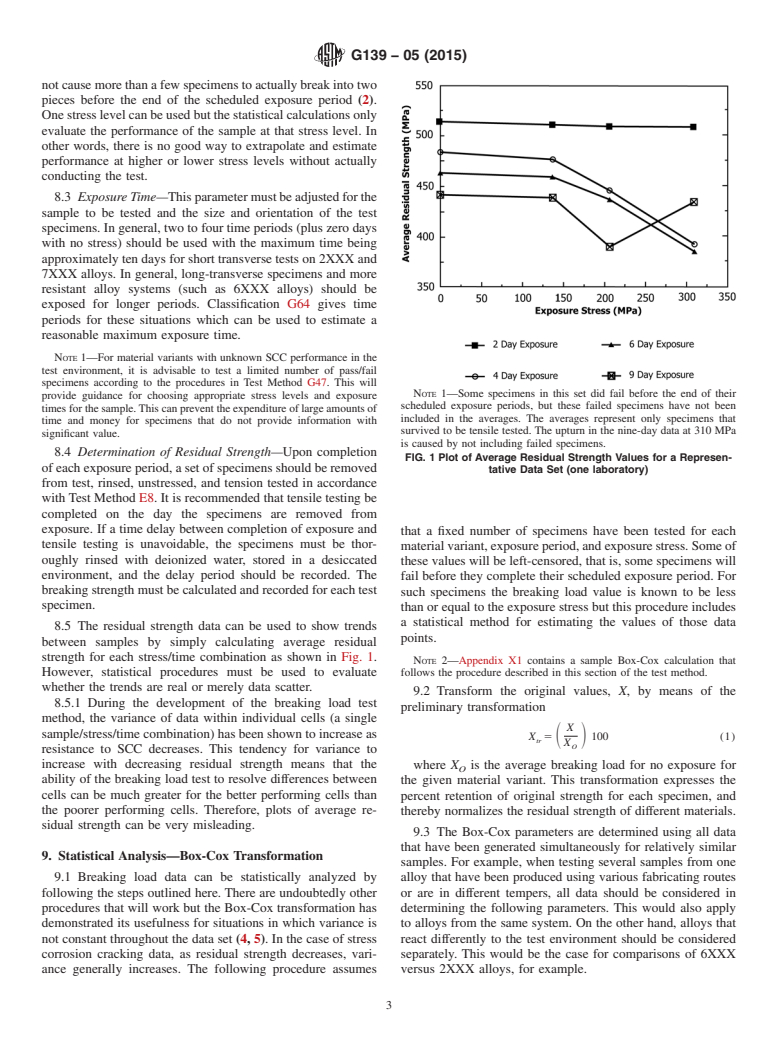

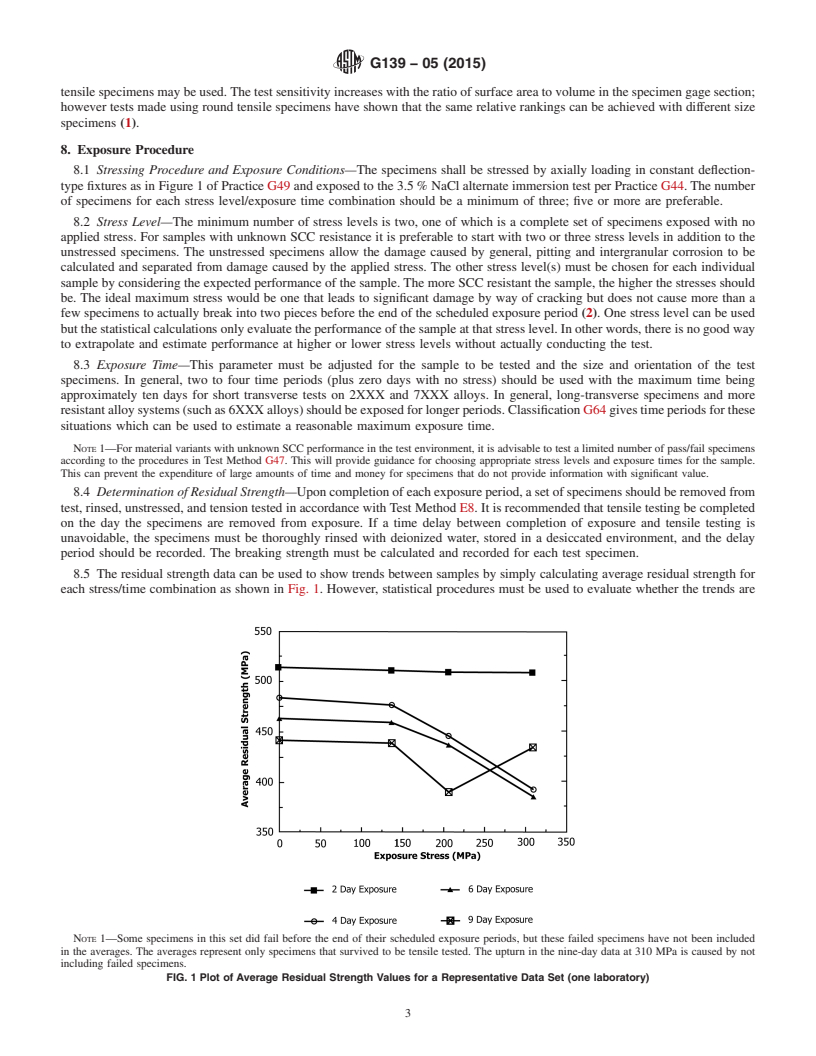

5. Significance and Use 6.2 The breaking load tes

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G139 − 05 (Reapproved 2011) G139 − 05 (Reapproved 2015)

Standard Test Method for

Determining Stress-Corrosion Cracking Resistance of Heat-

Treatable Aluminum Alloy Products Using Breaking Load

1

Method

This standard is issued under the fixed designation G139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures for evaluation of stress corrosion cracking (SCC) resistance by the breaking load test

method, a concept which uses residual strength as the measure of damage evolution (in this case environmentally assisted

cracking).

1.2 This test method covers specimen type and replication, test environment, stress levels, exposure periods, final strength

determination, and statistical analysis of the raw residual strength data.

1.3 The test method was developed for use with heat-treatable aluminum alloys, that is, 2XXX alloys and 7XXX with 1.2 to

2

3.0 % Cu, and test specimens oriented in the short-transverse direction relative to grain structure (1, 2). However, the residual

strength measurements and the statistics used to analyze the data are not specific to heat-treatable aluminum alloys and can be used

for other specimen orientations and different types of materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

E8 Test Methods for Tension Testing of Metallic Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G44 Practice for Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride Solution

G47 Test Method for Determining Susceptibility to Stress-Corrosion Cracking of 2XXX and 7XXX Aluminum Alloy Products

G49 Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

G64 Classification of Resistance to Stress-Corrosion Cracking of Heat-Treatable Aluminum Alloys

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 censor—a statistical term indicating that the value from an individual observation may fall outside of the range that can

be measured because of test procedures or conditions.

3.1.2 sample—the nominally uniform, bulk material from which individual stress-corrosion cracking specimens are obtained.

4. Summary of Test Method

4.1 This test method describes a procedure for using residual strength after exposure to a corrosive environment to evaluate

stress corrosion cracking susceptibility in heat treatable aluminum alloy product forms such as sheet, plate, extrusions, forgings,

and bar. These products generally are most susceptible to SCC in the long transverse direction of sheet, the short transverse

1

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on Environmentally

Assisted Cracking.

Current edition approved Sept. 1, 2011Nov. 1, 2015. Published September 2011December 2015. Originally approved in 2005. Last previous edition approved in 20052011

as G139G139–05(2011).–05. DOI: 10.1520/G0139-05R11.10.1520/G0139-05R15.

2

The boldface numbers in parentheses refer to the list of references at the end of the standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G139 − 05 (2015)

direction of plate, extrusions and forgings, and the transverse direction of rod and bar stock. In this test, tensile bars or direct

tension sheet specimens, prepared according to Practice G49, are exposed to 3.5 weight % aqueous sodium chloride solution

(Practice G44), are removed before they fail and are tension tested to determine the amount of corrosion damage that has occurred.

The average retained strength is then calculate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.