ASTM B925-15

(Practice)Standard Practices for Production and Preparation of Powder Metallurgy (PM) Test Specimens

Standard Practices for Production and Preparation of Powder Metallurgy (PM) Test Specimens

SIGNIFICANCE AND USE

5.1 Test specimens are used to determine the engineering properties of PM materials, for example, tensile strength, ductility, impact energy, etc.; property data that are essential to the successful use of PM material standards. Processing PM test specimens under production conditions is the most efficient method by which to obtain reliable PM material property data since in most cases it is impractical or impossible to cut test bars from sintered parts.

5.2 The performance characteristics of metal powders, for example, compressibility, green strength and dimensional changes associated with processing are evaluated using PM test specimens under controlled conditions. The data obtained are important to both metal powder producers and PM parts manufacturers.

5.3 PM test specimens play a significant role in industrial quality assurance programs. They are used to compare properties of a new lot of metal powder with an established lot in an acceptance test and are used in the part manufacturing process to establish and adjust production variables.

5.4 In those instances where it is required to present equivalent property data for a production lot of PM parts, standard test specimens compacted from the production powder mix to the same green density can be processed with the production PM parts and then tested to obtain this information.

5.5 Material property testing performed for industrial or academic research and development projects uses standard PM test specimens so the test results obtained can be compared with previous work or published data.

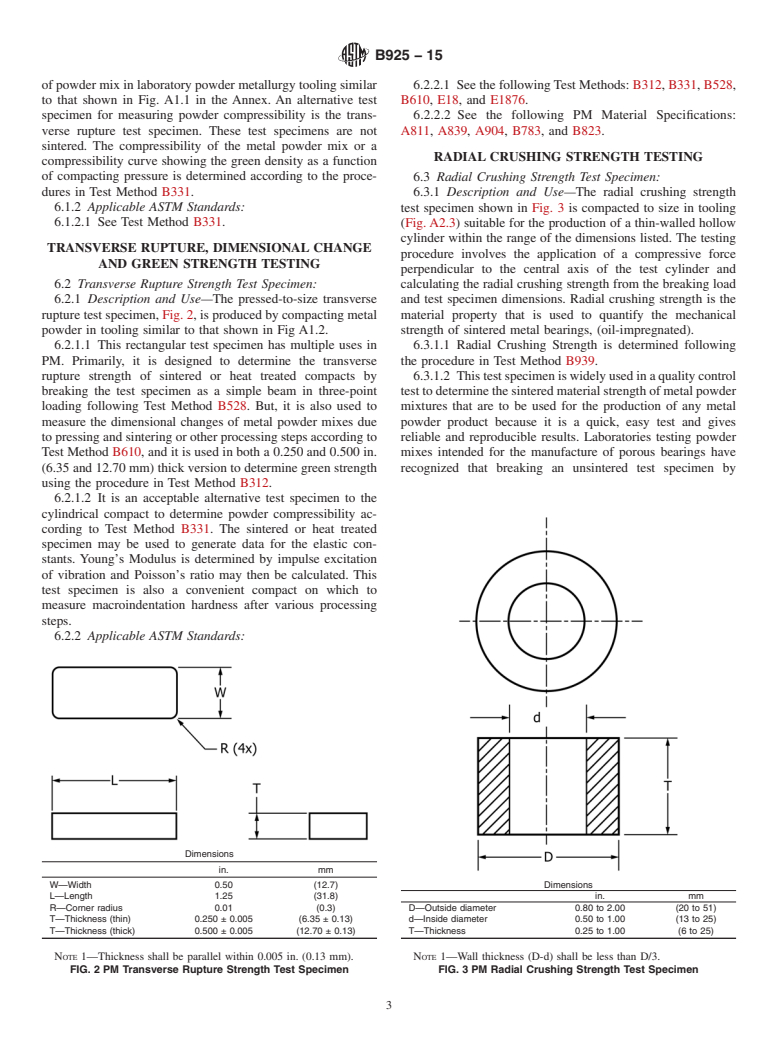

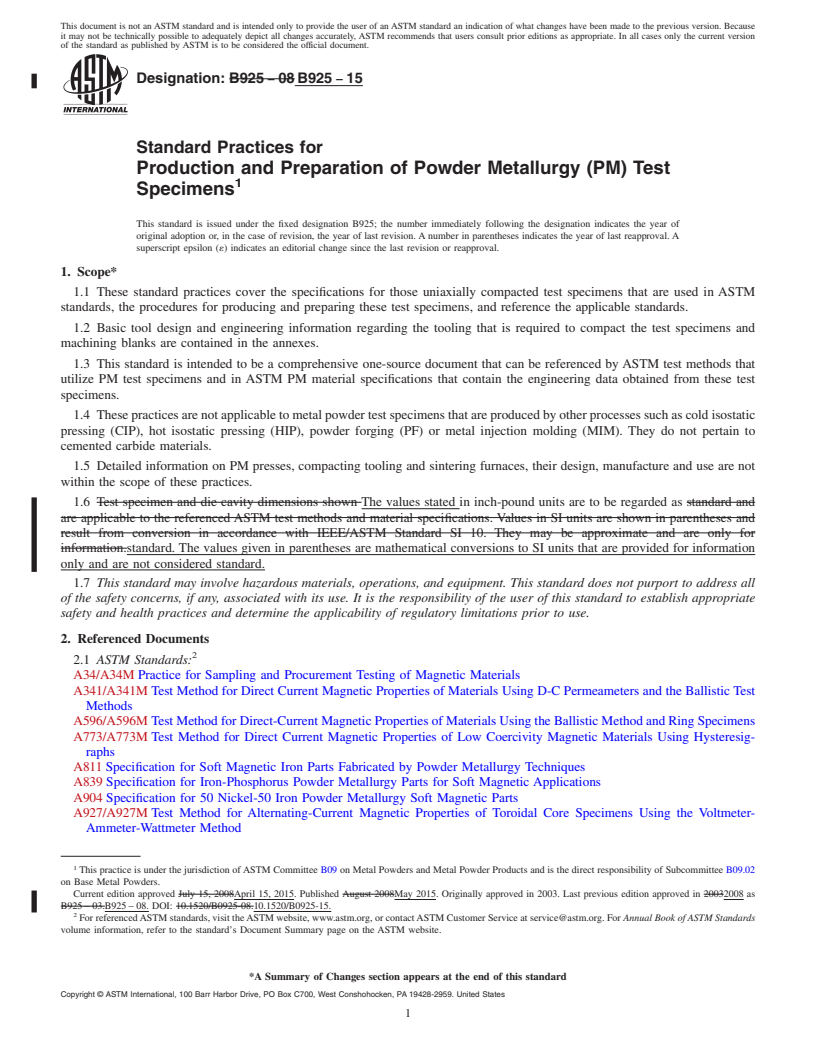

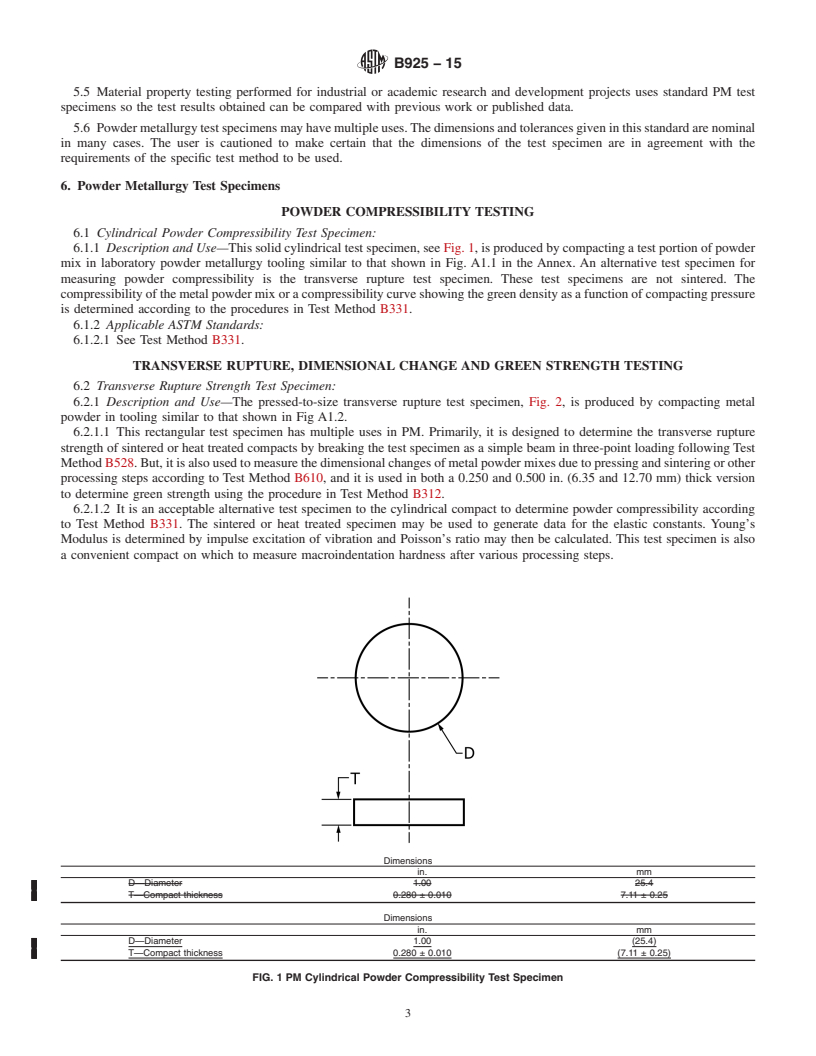

5.6 Powder metallurgy test specimens may have multiple uses. The dimensions and tolerances given in this standard are nominal in many cases. The user is cautioned to make certain that the dimensions of the test specimen are in agreement with the requirements of the specific test method to be used.

SCOPE

1.1 These standard practices cover the specifications for those uniaxially compacted test specimens that are used in ASTM standards, the procedures for producing and preparing these test specimens, and reference the applicable standards.

1.2 Basic tool design and engineering information regarding the tooling that is required to compact the test specimens and machining blanks are contained in the annexes.

1.3 This standard is intended to be a comprehensive one-source document that can be referenced by ASTM test methods that utilize PM test specimens and in ASTM PM material specifications that contain the engineering data obtained from these test specimens.

1.4 These practices are not applicable to metal powder test specimens that are produced by other processes such as cold isostatic pressing (CIP), hot isostatic pressing (HIP), powder forging (PF) or metal injection molding (MIM). They do not pertain to cemented carbide materials.

1.5 Detailed information on PM presses, compacting tooling and sintering furnaces, their design, manufacture and use are not within the scope of these practices.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B925 − 15

Standard Practices for

Production and Preparation of Powder Metallurgy (PM) Test

1

Specimens

This standard is issued under the fixed designation B925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These standard practices cover the specifications for

A34/A34M Practice for Sampling and Procurement Testing

those uniaxially compacted test specimens that are used in

of Magnetic Materials

ASTM standards, the procedures for producing and preparing

A341/A341M Test Method for Direct Current Magnetic

these test specimens, and reference the applicable standards.

Properties of Materials Using D-C Permeameters and the

1.2 Basictooldesignandengineeringinformationregarding

Ballistic Test Methods

the tooling that is required to compact the test specimens and A596/A596M Test Method for Direct-Current Magnetic

machining blanks are contained in the annexes.

Properties of Materials Using the Ballistic Method and

Ring Specimens

1.3 This standard is intended to be a comprehensive one-

A773/A773M Test Method for Direct Current Magnetic

sourcedocumentthatcanbereferencedbyASTMtestmethods

Properties of Low Coercivity Magnetic Materials Using

that utilize PM test specimens and in ASTM PM material

Hysteresigraphs

specifications that contain the engineering data obtained from

A811 Specification for Soft Magnetic Iron Parts Fabricated

these test specimens.

by Powder Metallurgy Techniques

A839 Specification for Iron-Phosphorus Powder Metallurgy

1.4 These practices are not applicable to metal powder test

Parts for Soft Magnetic Applications

specimens that are produced by other processes such as cold

A904 Specification for 50 Nickel-50 Iron Powder Metal-

isostatic pressing (CIP), hot isostatic pressing (HIP), powder

lurgy Soft Magnetic Parts

forging (PF) or metal injection molding (MIM). They do not

A927/A927M Test Method for Alternating-Current Mag-

pertain to cemented carbide materials.

netic Properties of Toroidal Core Specimens Using the

1.5 Detailed information on PM presses, compacting tool-

Voltmeter-Ammeter-Wattmeter Method

ing and sintering furnaces, their design, manufacture and use B215 Practices for Sampling Metal Powders

are not within the scope of these practices. B243 Terminology of Powder Metallurgy

B312 Test Method for Green Strength of Specimens Com-

1.6 The values stated in inch-pound units are to be regarded

pacted from Metal Powders

as standard. The values given in parentheses are mathematical

B331 Test Method for Compressibility of Metal Powders in

conversions to SI units that are provided for information only

Uniaxial Compaction

and are not considered standard.

B438 Specification for Bronze-Base Powder Metallurgy

(PM) Bearings (Oil-Impregnated)

1.7 This standard may involve hazardous materials,

B439 Specification for Iron-Base Powder Metallurgy (PM)

operations, and equipment. This standard does not purport to

Bearings (Oil-Impregnated)

address all of the safety concerns, if any, associated with its

B528 Test Method for Transverse Rupture Strength of Pow-

use. It is the responsibility of the user of this standard to

der Metallurgy (PM) Specimens

establish appropriate safety and health practices and deter-

B595 Specification for Sintered Aluminum Structural Parts

mine the applicability of regulatory limitations prior to use.

B610 Test Method for Measuring Dimensional Changes

Associated with Processing Metal Powders

1

This practice is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

2

mittee B09.02 on Base Metal Powders. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2015. Published May 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2003. Last previous edition approved in 2008 as B925 – 08. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0925-15. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B925 − 15

B783 Specification for Materials for Ferrous Powder Metal- since in most cases it is impractical or impossible to cut test

lurgy (PM) Structural Parts bars from sintered parts.

B817 Specification for Powder Metallurgy (PM) Titanium

5.2 The performance characteristics of metal powders, for

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B925 − 08 B925 − 15

Standard Practices for

Production and Preparation of Powder Metallurgy (PM) Test

1

Specimens

This standard is issued under the fixed designation B925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These standard practices cover the specifications for those uniaxially compacted test specimens that are used in ASTM

standards, the procedures for producing and preparing these test specimens, and reference the applicable standards.

1.2 Basic tool design and engineering information regarding the tooling that is required to compact the test specimens and

machining blanks are contained in the annexes.

1.3 This standard is intended to be a comprehensive one-source document that can be referenced by ASTM test methods that

utilize PM test specimens and in ASTM PM material specifications that contain the engineering data obtained from these test

specimens.

1.4 These practices are not applicable to metal powder test specimens that are produced by other processes such as cold isostatic

pressing (CIP), hot isostatic pressing (HIP), powder forging (PF) or metal injection molding (MIM). They do not pertain to

cemented carbide materials.

1.5 Detailed information on PM presses, compacting tooling and sintering furnaces, their design, manufacture and use are not

within the scope of these practices.

1.6 Test specimen and die cavity dimensions shown The values stated in inch-pound units are to be regarded as standard and

are applicable to the referenced ASTM test methods and material specifications. Values in SI units are shown in parentheses and

result from conversion in accordance with IEEE/ASTM Standard SI 10. They may be approximate and are only for

information.standard. The values given in parentheses are mathematical conversions to SI units that are provided for information

only and are not considered standard.

1.7 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic Materials

A341/A341M Test Method for Direct Current Magnetic Properties of Materials Using D-C Permeameters and the Ballistic Test

Methods

A596/A596M Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method and Ring Specimens

A773/A773M Test Method for Direct Current Magnetic Properties of Low Coercivity Magnetic Materials Using Hysteresig-

raphs

A811 Specification for Soft Magnetic Iron Parts Fabricated by Powder Metallurgy Techniques

A839 Specification for Iron-Phosphorus Powder Metallurgy Parts for Soft Magnetic Applications

A904 Specification for 50 Nickel-50 Iron Powder Metallurgy Soft Magnetic Parts

A927/A927M Test Method for Alternating-Current Magnetic Properties of Toroidal Core Specimens Using the Voltmeter-

Ammeter-Wattmeter Method

1

This practice is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee B09.02

on Base Metal Powders.

Current edition approved July 15, 2008April 15, 2015. Published August 2008May 2015. Originally approved in 2003. Last previous edition approved in 20032008 as

B925 – 03.B925 – 08. DOI: 10.1520/B0925-08.10.1520/B0925-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B925 − 15

B215 Practices for Sampling Metal Powders

B243 Terminology of Powder Metallurgy

B312 Test Method for Green Strength of Specimens Compacted from Metal Powders

B328 Test Method for Density, Oil Content, and Interconnected Porosity of Sintered Metal Structural Parts and O

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.