ASTM D1512-05(2012)

(Test Method)Standard Test Methods for Carbon Black—pH Value

Standard Test Methods for Carbon Black—pH Value

SIGNIFICANCE AND USE

3.1 The pH level of a carbon black is known to affect the vulcanization of some rubber compounds.

SCOPE

1.1 These test methods, Test Method A—Boiling Slurry and Test Method B—Sonic Slurry, are used to indicate the pH of the carbon black surface by measuring the pH of water in contact with the carbon black.Note 1—The pH of the carbon black is often used in this industry to indicate the relative acidity or alkalinity of carbon black and will be used in the remainder of these test methods to describe this property.Note 2—Test Method A and Test Method B do not always give the same results.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1512 − 05(Reapproved 2012)

Standard Test Methods for

Carbon Black—pH Value

This standard is issued under the fixed designation D1512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope TEST METHOD A—BOILING SLURRY

1.1 These test methods,Test MethodA—Boiling Slurry and

4. Apparatus

Test Method B—Sonic Slurry, are used to indicate the pH of

4.1 pH Meter, (digital is recommended) having an accuracy

the carbon black surface by measuring the pH of water in

of 60.05 pH and equipped with a combination electrode and

contact with the carbon black.

RNC connector.

NOTE 1—The pH of the carbon black is often used in this industry to

4.2 Container, stainless steel or copper, 125 cm or larger.

indicate the relative acidity or alkalinity of carbon black and will be used

in the remainder of these test methods to describe this property.

4.3 Hot Plate.

NOTE 2—Test Method A and Test Method B do not always give the

same results.

4.4 High Speed Mill, Mixer or Mortar and Pestle.

1.2 The values stated in SI units are to be regarded as the

4.5 Beakers, glass, 100 cm graduated with watch glasses.

standard. The values in parentheses are for information only.

5. Reagents

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5.1 Purity of Reagents—Reagent grade chemicals shall be

responsibility of the user of this standard to establish appro-

used in all tests. Unless otherwise indicated, it is intended that

priate safety and health practices and determine the applica-

all reagents shall conform to the specifications of the Commit-

bility of regulatory limitations prior to use.

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

2. Referenced Documents

used, provided it is first ascertained that the reagent is of

2.1 ASTM Standards:

sufficiently high purity to permit its use without lessening the

D1193 Specification for Reagent Water

accuracy of the determination.

D1799 Practice for Carbon Black—Sampling Packaged

5.2 Purity of Water—Unless otherwise indicated, references

Shipments

to water shall be understood to mean reagent water as defined

D1900 Practice for Carbon Black—Sampling Bulk Ship-

by Type 1 in Specification D1193.

ments

5.3 Distilled Water, high purity.

D4483 Practice for Evaluating Precision for Test Method

Standards in the Rubber and Carbon Black Manufacturing

5.4 Buffer Solutions, pH of 4.00, 7.00, and 10.00.

Industries

5.5 Acetone, reagent grade.

E70 Test Method for pH of Aqueous Solutions With the

Glass Electrode

6. Sampling

3. Significance and Use

6.1 Samples shall be taken in accordance with Practices

D1799 or D1900.

3.1 The pH level of a carbon black is known to affect the

vulcanization of some rubber compounds.

7. Calibration

7.1 Calibrate the pH meter using buffer solutions according

These test methods are under the jurisdiction of ASTM Committee D24 on

Carbon Black and are the direct responsibility of Subcommittee D24.31 on

to manufacturer’s instructions.

Non-Carbon Black Components of Carbon Black.

Current edition approved June 1, 2012. Published November 2012. Originally

approved in 1975. Last previous edition approved in 2005 as D1512 – 05. DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D1512-05R12. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

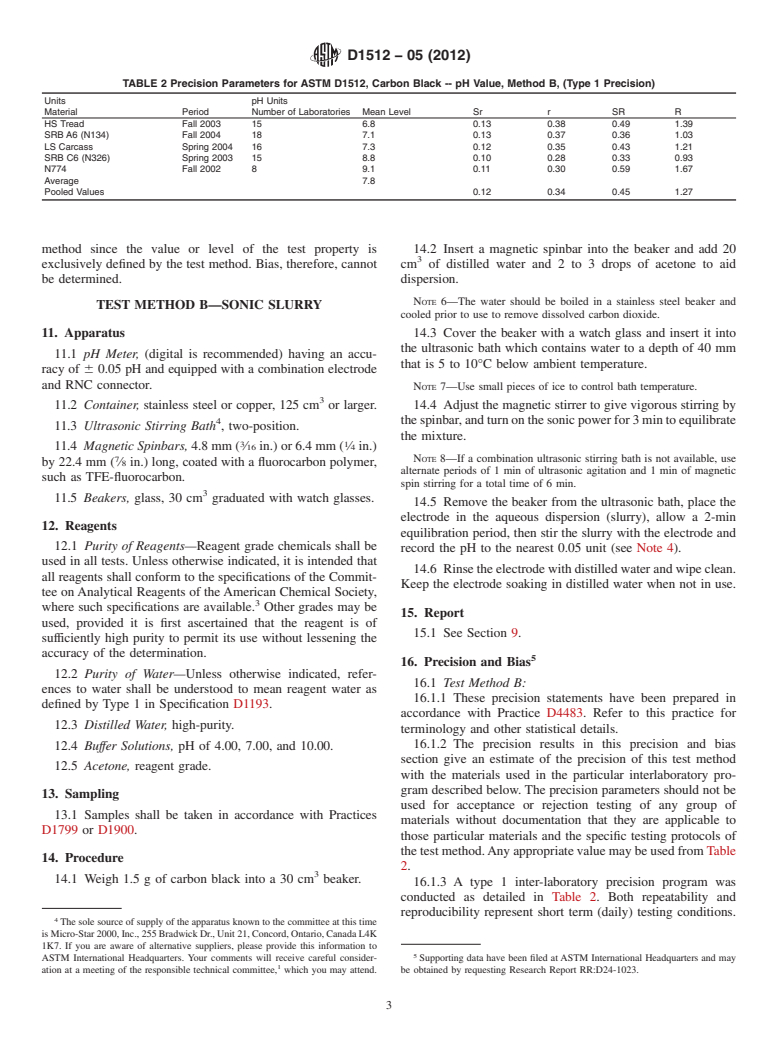

D1512 − 05 (2012)

TABLE 1 Precision Parameters for ASTM D1512, Carbon Black -- pH Value, Method A, (Type 1 Precision)

Units pH Units

Material Period Number of Laboratories Mean Level Sr r SR R

HS Tread Fall 2003 22 6.2 0.15 0.43 0.73 2.07

SRB A6 (N134) Fall 2004 23 6.5 0.15 0.41 0.53 1.49

LS Carcass Spring 2004 26 7.2 0.14 0.39 0.50 1.41

SRB C6 (N326) Spring 2003 27 8.5 0.11 0.32 0.50 1.41

N774 Fall 2002 19 8.6 0.16 0.45 0.62 1.75

Average 7.4

Pooled Values 0.14 0.40 0.58 1.65

8. Procedure those particular materials and the specific testing protocols of

thetestmethod.AnyappropriatevaluemaybeusedfromTable

8.1 Pulverize pelleted or lumpy carbon black to a fine

1.

powder, using either the high speed mixer or mortar and pestle.

10.1.3 A type 1 inter-laboratory precision program was

8.2 Weigh5gof carbon black into a 100 cm glass beaker.

conducted as detailed in Table 1. Both repeatability and

8.3 Add 50 cm of boiling, distilled water prepared in a

reproducibility represent short term (daily) testing conditions.

stainless steel beaker and 2 to 3 drops of acetone to facilitate

The testing was performed using two operators in each

wetting of the sample.

laboratoryperformingthetestonceoneachmaterialoneachof

two days (total of four tests).

NOTE 3—A stainless steel beaker is used to eliminate contamination

during boiling.

10.1.4 The results of the precision calculations for this test

8.4 Cover the glass beaker with a watch glass and boil the

are given in Table 1. The materials are arranged in ascending

mixture for 15 min, but do not allow all the liquid to evaporate. “mean level” order.

10.1.4.1 Repeatability—The pooled absolute repeatability, r,

8.5 Let the mixture cool to room temperature in an atmo-

of this test has been established as 0.40 pH units. Any other

sphere free from chemical fumes which might contaminate the

sample. value in Table 1 may be used as an estimate of repeatability, as

appropriate. The difference between two single test results (or

8.6 Standardize the pH meter with the buffer solutions.

determinations) found on identical test material under the

Rinse the electrode with distilled water and wipe clean after

repeatability conditions prescribed for this test will exceed the

each test.

repeatability on an average of not more than once in 20 cases

8.7 Place the electrode in the sludge, rotate gently in

in the normal and correct operation of the method. Two single

alternate directions until a constant pH is obtained, and record

test results that differ by more than the appropriate value from

the pH to the nearest 0.05 unit.

Table 1 must be suspected of being from different populations

NOTE 4—Refer to Test Method E70 for a definition of pH and a highly and some appropriate action taken.

detailed procedure for making pH measurements.

NOTE 5—Appropriate action may be an investigation of the test method

8.8 Rinse the electrode with distilled water and wipe clean.

procedure or apparatus for faulty operation or the declaration of a

Keep the electrode soaking in distilled water when not in use.

significant difference in the two materials, samples, etc., which generated

the two test results.

9. Report

10.1.4.2 Reproducibility—The pooled absolute

9.1 Report the following information:

reproducibility, R, of this test has been established as 1.65 pH

9.1.1 Proper identification of the sample,

units.Any other value in Table 1 may be used as an estimate of

9.1.2 Result obtained, reported to the nearest 0.05 unit, and

reproducibility, as appropriate. The difference between two

9.1.3 Test Method used, A or B.

single and independent test results found by two operators

working under the prescribed reproducibility conditions in

10. Precision and Bias

different laboratories on identical test material will exceed the

10.1 Test Method A:

reproducibilityonanaverageofnotmorethanoncein20cases

10.1.1 These precision statements have been prepared in

in the normal and correct operation of the method. Two single

accordance with Practice D4483. Refer to this practice for

test results produced in different laboratories that differ by

terminology and other statistical details.

more than the appropriate value from Table 1 must be

10.1.2 The precision results in this precision and bias

suspected of being from different populations and some appro-

section give an estimate of the precision of this test method

priate inves

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.