ASTM F2443-04

(Specification)Standard Specification for Roller, Bearing, Needle Ferrous, Solid, Spherical End

Standard Specification for Roller, Bearing, Needle Ferrous, Solid, Spherical End

ABSTRACT

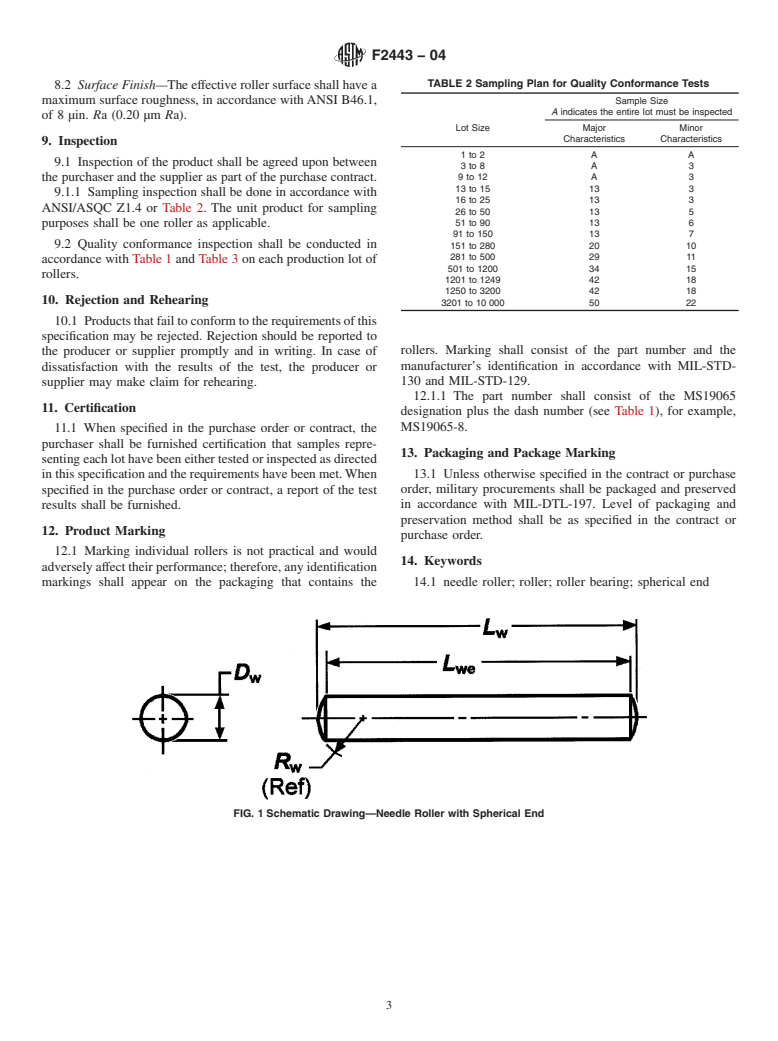

This specification covers spherical-ended ferrous needle rollers intended for use as bearing components. Rollers shall be made of chrome alloy steel E50100, E51100, E52100, and shall conform to specified requirements for heat treatment and protective coatings. Rollers shall also meet specified values for diameter, length, and effective length in accordance with MS Part No.

SCOPE

1.1 This specification covers ferrous needle rollers having spherical ends.

1.2 Spherical-ended needle rollers designed to this specification are intended for use as bearing components. A complement of rollers is run on a hardened (HRC 58-65, see Test Methods E 18) shaft and in a hardened (HRC 58-65) housing bore to form the bearing.

1.3 This specification contains many of the requirements of MS19065, which was originally developed by the Department of Defense and maintained by the Defense Supply Center Richmond. The following government activity codes may be found in the Department of Defense, Standardization Directory SD-1.Preparing activityCustodiansReview Activities DLA-GS4Army-ATNavy-MC Navy-OSAir Force-84Air Force-99DLA-GS4

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2443 −04

StandardSpecification for

1

Roller, Bearing, Needle, Ferrous, Solid, Spherical End

This standard is issued under the fixed designation F2443; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

5

1. Scope 2.3 ANSI Standard:

ANSI/ASQ Z1.4 Sampling Procedures and Tables for In-

1.1 This specification covers ferrous needle rollers having

spection of Attributes

spherical ends.

6

2.4 ASME Standards.

1.2 Spherical-ended needle rollers designed to this specifi-

ASME B46.1 SurfaceTexture, Surface RoughnessWaviness

cation are intended for use as bearing components. A comple-

and Lay

ment of rollers is run on a hardened (HRC 58-65, see Test

ASME Y14.5M Dimensioning and Tolerancing

5

Methods E18) shaft and in a hardened (HRC 58-65) housing

2.5 ISO Standard:

bore to form the bearing.

ISO 5593 Rolling Bearings–Vocabulary

7

2.6 Military Standard.

1.3 This specification contains many of the requirements of

MIL-STD-129 Marking for Shipping and Storage

MS19065, which was originally developed by the Department

MIL-STD-130 Identification Marking of U.S. Military Prop-

of Defense and maintained by the Defense Supply Center

erty

Richmond. The following government activity codes may be

MIL-DTL-197 Packaging of Bearing, Associated Parts and

foundintheDepartmentofDefense,StandardizationDirectory

2 Subassemblies

SD-1.

8

2.7 SAE Standards:

Preparing activity Custodians Review Activities

SAE J404 Chemical Compositions of SAE Alloy Steels

DLA–GS4 Army–AT Navy–MC

SAEAMS 66 Steel: Chemical Composition and Hardenabil-

Navy–OS Air Force–84

Air Force–99

ity

DLA–GS4

SAE AMS 6440 Specification for Steel Bars, Forging and

Tubing

2. Referenced Documents

SAE AMS 6444 Specification for Steel Bars, Forging and

3

2.1 ASTM Standards:

Tubing PremiumAircraft Quality for BearingApplication

A295 Specification for High-Carbon Anti-Friction Bearing

3. Terminology

Steel

E18 Test Methods for Rockwell Hardness of Metallic Ma-

3.1 Definitions—For definitions of terms used in this

terials

specification, refer to ABMA 4 and ISO 5593.

4

2.2 ABMA Standard:

4. Ordering Information

ABMA 4 Tolerance Definitions and Gauging Practices for

4.1 When ordering parts in accordance with this

Ball and Roller Bearings

specification, specify the following:

4.1.1 ASTM designation number, including year of issue,

4.1.2 Dash number (see Table 1),

1

ThisspecificationisunderthejurisdictionofASTMCommitteeF34onRolling

4.1.3 Dimensions of roller, including:

Element Bearings and is the direct responsibility of Subcommittee F34.01 on

Rolling Element. 4.1.3.1 Diameter, in. (mm),

Current edition approved Nov. 1, 2004. Published November 2004. DOI:

10.1520/F2443-04.

2 5

The Military codes that are listed in SD-1 give the address and phone numbers Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

of the DoD contacts. These are found in the DoD’s ASSIST website: http:// 4th Floor, New York, NY 10036.

6

assist.daps.dla.mil/online/start/. Available from American Society of Mechanical Engineers (ASME), ASME

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three Park Ave., New York, NY 10016-5990.

7

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available on the DOD’s ASSIST internet site located at: http://

Standards volume information, refer to the standard’s Document Summary page on assist.daps.dla.mil/online/start/.

8

the ASTM website. Available from Society of Automotive Engineers (SAE), 400 Commonwealth

4

Available from Techstreet, 1327 Jones Drive, Ann Arbor, MI 48105. Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2443−04

TABLE 1 Needle Roller with Spherical Ends Dimensions

5.3 Material certifications are required for all materials

MS Part No. D L L used. Each lot of needle rollers shall be traceable to these

w w we

Roller Roller Effective

certifications. These certifications shall be available for review

Diameter Length Length

by the purchaser and provided to the purchaser when specified

+0.0000 +0.000

in the contract or purchase order. The needle roller manufac-

−0.0002 −0.020

in. in. in.

turer shall determine conformance of materials on a periodic

MS 19065-1 0.0312 0.190 0.182 basis. These tests may be performed by the manufacturer’s

MS 19065-2 0.0312 0.250 0.242

internal laboratory or by a laboratory external to the manufac-

MS 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.