ASTM E698-01

(Test Method)Standard Test Method for Arrhenius Kinetic Constants for Thermally Unstable Materials

Standard Test Method for Arrhenius Kinetic Constants for Thermally Unstable Materials

SCOPE

1.1 This method covers the determination of the overall kinetic parameters for exothermic reactions.

1.2 The kinetic parameters are obtained from differential scanning calorimetry (DSC) curves (see Section 3).

1.3 This technique is applicable to reactions whose behavior can be described by the Arrhenius equation and the general rate law.

1.4 Limitations—There are cases where this technique is not applicable. Limitations may be indicated by curves departing from a straight line (see 11.2) or the isothermal aging test not closely agreeing with the results predicted by the calculated kinetic values. In particular, this method is not applicable to reactions that are partially inhibited. The technique may not work with reactions that include simultaneous or consecutive reaction steps. This method may not apply to materials that undergo phase transitions if the reaction rate is significant at the transition temperature.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E698–01

Standard Test Method for

Arrhenius Kinetic Constants for Thermally Unstable

1

Materials

This standard is issued under the fixed designation E698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The kinetics of exothermic reactions are important in assessing the potential of materials and

systems for thermal explosion. This method provides a means for determining Arrhenius activation

energiesandpre-exponentialfactorsusingdifferentialthermalmethods.Thismethodisoneofseveral

methodsbeingdevelopedbyASTMCommitteeE-27forchemicalreactions.Thismethodistobeused

in conjunction with other tests to characterize the hazard potential of chemicals.

1. Scope E537 Method for Assessing the Thermal Stability of

2

Chemicals by Method of Thermal Analysis

1.1 This method covers the determination of the overall

E691 Practice for Conducting an Interlaboratory Study to

kinetic parameters for exothermic reactions.

2

Determine the Precision of a Test Method

1.2 The kinetic parameters are obtained from differential

E967 Practice for Temperature Calibration of Differential

scanning calorimetry (DSC) curves (see Section 3).

Scanning Calorimeters and Differential Thermal Analyz-

1.3 Thistechniqueisapplicabletoreactionswhosebehavior

2

ers

canbedescribedbytheArrheniusequationandthegeneralrate

E968 Practice for Heat Flow Calibration of Differential

law.

2

Scanning Calorimeters

1.4 Limitations—Therearecaseswherethistechniqueisnot

E1142 Terminology Relating to Thermophysical Proper-

applicable. Limitations may be indicated by curves departing

2

ties

from a straight line (see 11.2) or the isothermal aging test not

E1445 Terminology Relating to Hazardous Potential of

closely agreeing with the results predicted by the calculated

2

Chemicals

kinetic values. In particular, this method is not applicable to

E1860 Method for Elapsed Time Calibration of Thermal

reactions that are partially inhibited. The technique may not

2

Analyzers

work with reactions that include simultaneous or consecutive

E1970 Practice for Statistical Treatment of Thermoanalyti-

reaction steps. This method may not apply to materials that

2

cal Data

undergo phase transitions if the reaction rate is significant at

the transition temperature.

3. Terminology

1.5 This standard may involve hazardous materials, opera-

3.1 Technical terms used in this test method are defined in

tions, and equipment. This standard does not purport to

Terminologies E 473, E 1142, and E 1445.

address all of the safety problems associated with its use. It is

the responsibility of whoever uses this standard to consult and

4. Summary of Test Method

establish appropriate safety and health practices and deter-

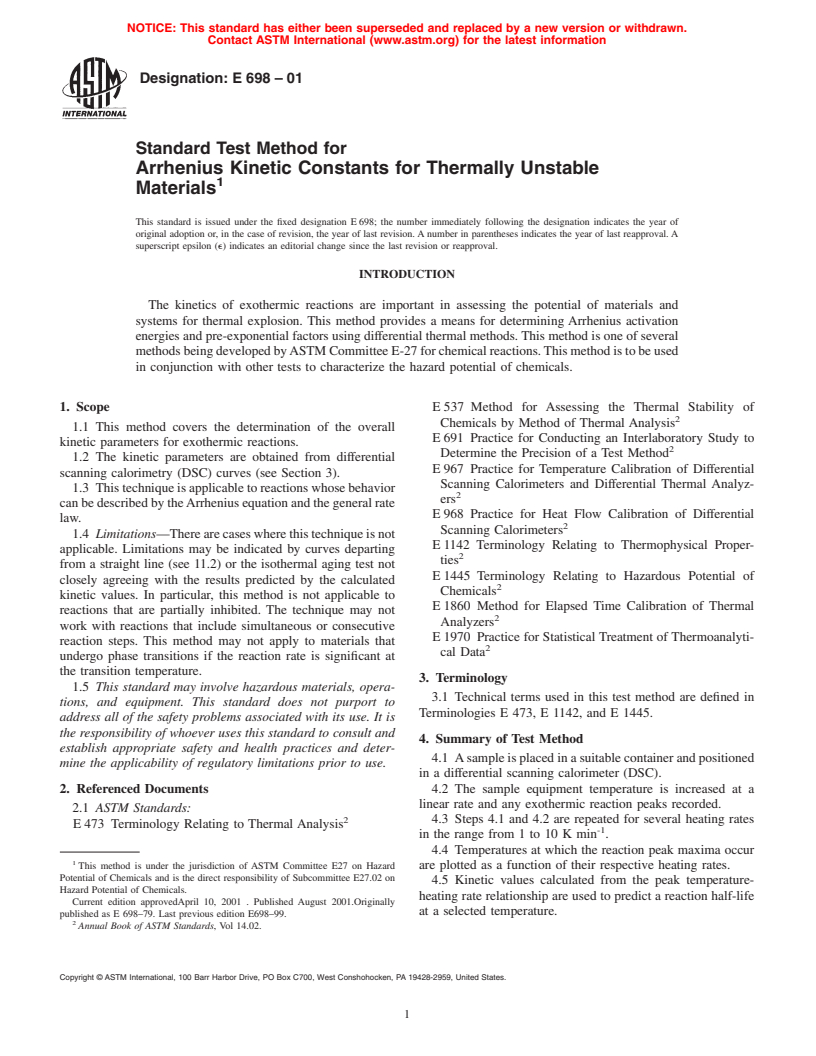

4.1 Asampleisplacedinasuitablecontainerandpositioned

mine the applicability of regulatory limitations prior to use.

in a differential scanning calorimeter (DSC).

2. Referenced Documents 4.2 The sample equipment temperature is increased at a

linear rate and any exothermic reaction peaks recorded.

2.1 ASTM Standards:

2 4.3 Steps 4.1 and 4.2 are repeated for several heating rates

E473 Terminology Relating to Thermal Analysis

-1

in the range from 1 to 10 K min .

4.4 Temperatures at which the reaction peak maxima occur

1

This method is under the jurisdiction of ASTM Committee E27 on Hazard are plotted as a function of their respective heating rates.

Potential of Chemicals and is the direct responsibility of Subcommittee E27.02 on

4.5 Kinetic values calculated from the peak temperature-

Hazard Potential of Chemicals.

heating rate relationship are used to predict a reaction half-life

Current edition approvedApril 10, 2001 . Published August 2001.Originally

at a selected temperature.

published as E 698–79. Last previous edition E698–99.

2

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E698

4.6 A sample is aged at the selected temperature for the 6.5 Auxiliary equipment useful for conducting this method

predicted half-life time. below ambient temperature.

4.7 The aged sample is temperature programmed in a 6.5.1 A coolant system, which can be directly coupled with

differntial scanning calorimetr and its reaction peak area the controller to the furnace to hasten its recovery from

compared with that for an unaged sample run under the same elevatedtemperatures,toprovideconstantcoolingrates,and/or

conditions. to sustain an isothermal subambient temperature.

4.8 If the normalized area for the aged sample is approxi-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.