ASTM D3624-85a(2005)

(Test Method)Standard Test Method for Low Concentrations of Mercury in Paint by Atomic Absorption Spectroscopy

Standard Test Method for Low Concentrations of Mercury in Paint by Atomic Absorption Spectroscopy

SIGNIFICANCE AND USE

The permissible level of heavy metals in certain coatings is specified by governmental regulatory agencies. This test method provides a fully documented procedure for determining low concentrations of mercury present in both water and solvent-reducible coatings to determine compliance.

SCOPE

1.1 This test method covers the determination of the content of mercury in the range between 10 and 1000 ppm (mg/kg) present in liquid coatings, coatings vehicles, or in dried films obtained from previously coated substrates. There is no reason to believe that higher levels could not be determined by this test method, provided that appropriate dilutions and adjustments in specimen size and reagent quantities are made.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section and .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3624–85a(Reapproved2005)

Standard Test Method for

Low Concentrations of Mercury in Paint by Atomic

Absorption Spectroscopy

This standard is issued under the fixed designation D3624; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope methodprovidesafullydocumentedprocedurefordetermining

low concentrations of mercury present in both water and

1.1 This test method covers the determination of the content

solvent-reducible coatings to determine compliance.

of mercury in the range between 10 and 1000 ppm (mg/kg)

present in liquid coatings, coatings vehicles, or in dried films

5. Apparatus

obtained from previously coated substrates. There is no reason

5.1 Atomic Absorption Spectrophotometer—Any commer-

to believe that higher levels could not be determined by this

cial instrument having an open sample presentation area in

test method, provided that appropriate dilutions and adjust-

which to mount the absorption cell or an instrument designed

ments in specimen size and reagent quantities are made.

specifically for the measurement of mercury using the cold

1.2 This standard does not purport to address all of the

vapor technique.

safety concerns, if any, associated with its use. It is the

5.2 Recorder,0to10mV.

responsibility of the user of this standard to establish appro-

5.3 Mercury Source Lamp.

priate safety and health practices and determine the applica-

5.4 Absorption Cell—Standard spectrophotometer cells 100

bility of regulatory limitations prior to use. Specific hazard

mm long, having quartz end windows may be used. Prior to

statements are given in Section 7 and 9.1.1.

use, the cell must be positioned in the optical path of the

2. Referenced Documents spectrophotometer and held in place by suitable clamps or

straps. The cell should be carefully aligned both vertically and

2.1 ASTM Standards:

horizontally to give the maximum transmittance.

D1193 Specification for Reagent Water

5.5 Reduction Vessel—Cylindrical gas washing bottle, 250-

3. Summary of Test Method mL, equipped with a coarse (40 to 60-µm) fritted glass inlet

tube and a standard-taper glass stopper. Polyethylene or poly-

3.1 The sample of liquid coating or dried film is weighed

(vinyl chloride) tubing may be used for connecting the reduc-

into a polytetrafluoroethylene (PTFE)-lined acid decomposi-

tion vessel to the absorption cell.

tion vessel and digested at an elevated temperature using

5.6 Flowmeter, capable of measuring a gas flow of 1 L/min.

sulfuric and nitric acids. Use of a sealed acid decomposition

5.7 Drying Tube—Approximately 150 by 20-mm (6 by

vessel prevents loss of mercury during the digestion. The

⁄4-in.) glass tube filled with magnesium perchlorate. The tube

digested sample is diluted to a known volume with water and

should be filled each day that it is in use, and the Mg(ClO )

the concentration of mercury is determined using a cold-vapor, 4 2

should be replaced whenever it becomes saturated (carefully

atomic absorption technique.

observe after each analysis).

4. Significance and Use

NOTE 1—Use of an indicator desiccant at the exit end of the tube will

4.1 The permissible level of heavy metals in certain coat-

make this observation easier.

ingsisspecifiedbygovernmentalregulatoryagencies.Thistest

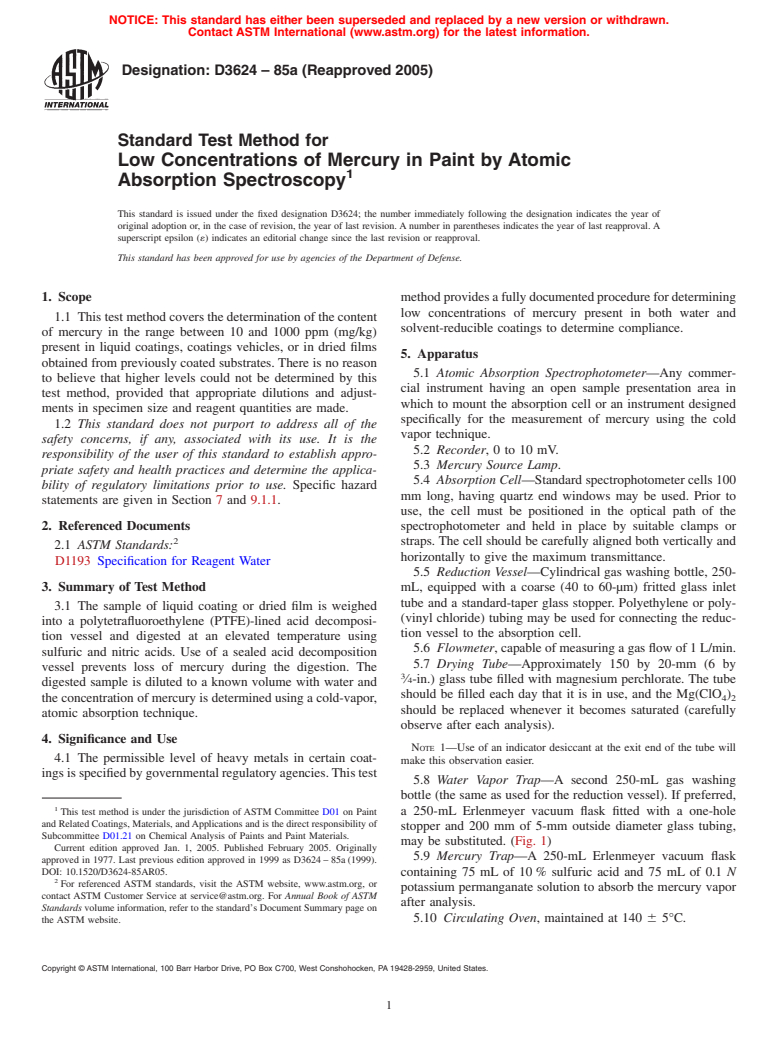

5.8 Water Vapor Trap—A second 250-mL gas washing

bottle (the same as used for the reduction vessel). If preferred,

This test method is under the jurisdiction of ASTM Committee D01 on Paint a 250-mL Erlenmeyer vacuum flask fitted with a one-hole

and Related Coatings, Materials, andApplications and is the direct responsibility of

stopper and 200 mm of 5-mm outside diameter glass tubing,

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

may be substituted. (Fig. 1)

Current edition approved Jan. 1, 2005. Published February 2005. Originally

5.9 Mercury Trap—A 250-mL Erlenmeyer vacuum flask

approved in 1977. Last previous edition approved in 1999 as D3624 – 85a (1999).

DOI: 10.1520/D3624-85AR05.

containing 75 mL of 10 % sulfuric acid and 75 mL of 0.1 N

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

potassium permanganate solution to absorb the mercury vapor

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

after analysis.

Standards volume information, refer to the standard’s Document Summary page on

5.10 Circulating Oven, maintained at 140 6 5°C.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3624–85a (2005)

FIG. 1 Apparatus

5.11 Acid Decomposition Vessel, with 25-mL PTFE diges- 6.6 Nitric Acid (sp gr 1.42) Concentrated nitric acid

tion cup. (HNO ).

5.12 Volumetric Flasks, 100, 250, and 1000-mL. 6.7 Nitrogen.

5.13 Paint Shaker. 6.8 Potassium Permanganate Solution (0.1 N)—Dissolve

5.14 Paint Draw-Down Bar. 15.8 g of KMnO in water and dilute to 1 L.

6.9 Stannous Chloride Solution (100 g/L) Dissolve 25 g of

6. Reagents

tin (II) chloride (SnCl ) by adding it to 60 mL of concentrated

6.1 Purity of Reagents—Reagent grade chemicals shall be HCl (sp gr 1.19) and warming on a hotplate. When all of the

used in all tests. Unless otherwise indicated, it is intended that

SnCl has dissolved, transfer to a 250-mLvolumetric flask and

all reagents shall conform to the specifications of the Commit- dilute to volume with water. Mix well. This solution should be

tee onAnalytical Reagents of theAmerican Chemical Society,

prepared fresh each week that it is used.

where such specifications are available. Other grades may be 6.10 Sulfuric Acid (sp gr 1.84) Concentrated sulfuric acid

used, provided it is first ascertained that the reagent is of

(H SO ).

2 4

sufficiently high purity to permit its use without lessening the 6.11 Sulfuric Acid (1+9) Carefully mix 1 volume of

accuracy of the determination.

H SO (sp gr 1.84) into 9 volumes of water.

2 4

6.2 Purity of Water—Unless otherwise indicated, references

7. Hazards

to water shall be understood to mean reagent water conforming

7.1 Concentrated nitric and sulfuric acids are corrosive and

to Type II of Specification D1193.

may cause severe burns of the skin or eyes. The vapor from

6.3 Hydroxylamine Hydrochloride Solution (100 g/L)—

concentratednitricacidisirritatingtomucousmembranes.Use

Dissolve 10 g of NH OH·HCl in 100 mL of water. Transfer a

care in handling these acidic substances. Refer to suppliers’

portion of this solution to a small dropping bottle.

Material Safety Data Sheet.

6.4 Mercury Solution, Stock (1 mg/mL)—Dissolve 0.1354 g

7.2 Mercury and its compounds are harmful and accumulate

of HgCl in 50 mL of water. Carefully add 5 mL of concen-

in the aquatic environment. Mixtures containing mercury

trated H SO and 3 mL of concentrated HNO and dilute to

2 4 3

compoundsshouldnotbeflusheddownadrain,butdisposedof

100 mL. This solution contains 1000 µg/mL of mercury.

as hazardous waste.

6.5 Mercury Standard, Working (0.1 µg/mL)—Makesucces-

7.3 Use only a rubber bulb aspirator for pipetting liquids.

sivedilutionsofthestockmercurysolutiontoobtainaworking

standard containing 0.1 mg/L (0.1 µg/mL), maintaining a

8. Calibration and Standardization

concentration of 5 % H SO and 3 % HNO by volume, in the

2 4 3

8.1 Assemble the various components, as illustrated in Fig.

diluted solutions. The working mercury standard and the

1 if an atomic absorption spectrophotometer is used, or prepare

dilutions of the stock mercury solution should be prepared

the instrument for operation if a commercial mercury analyzer

fresh each day that it is used.

is being used.

NOTE 2—Be sure that all glassware has been thoroughly cleaned and

The sole source of supply of an acid decomposition vessel, Catalog No. 4745,

rinsed with reagent water prior to use.

known to the committee at this time is the Parr Instrument Co., 211 Fifty-third St.,

Moline, IL 61265. If you are aware of alternative suppliers, please provide this

8.2 Operational instructions for atomic absorption spectro-

information to ASTM International Headquarters. Your comments will receive

photometers and commercial mercury analyzers vary with

careful consideration at a meeting of the responsible technical committee, which

different models. Consult the manufacturer’s literature for

you may attend

establishing optimum conditions for the specific instrument

Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

used.

listed by the American Chemical Society, see Analar Standards for Laboratory

8.3 With the apparatus empty, stabilize the recorder base

Chemicals, BDH Ltd., Poole, Dorset, U.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.