ASTM D5929-96(2004)

(Test Method)Standard Test Method for Determining Biodegradability of Materials Exposed to Municipal Solid Waste Composting Conditions by Compost Respirometry

Standard Test Method for Determining Biodegradability of Materials Exposed to Municipal Solid Waste Composting Conditions by Compost Respirometry

SIGNIFICANCE AND USE

As the crisis in solid waste continues to grow, MSW composting is increasingly being considered as one component in the overall solid waste management strategy. The volume reduction achieved by composting, combined with the production of a usable end product, is resulting in increasing numbers of municipalities analyzing and selecting MSW composting as an alternative to incineration or to reduce reliance on landfill disposal. This test method will help determine the effect of materials on the compost process and establish if the material can be properly disposed through solid waste composting facilities.5

This test method attempts to provide a simulation of the overall compost process while maintaining reproducibility. Exposing the test material with several other types of materials that are typically in MSW provides an environment which provides the key characteristics of composting: material not in a sole carbon source environment which allows co-metabolism, compost system is self heating, and provides a direct measurement of organism respiration.

SCOPE

1.1 This test method covers the biodegradation properties of a material by reproducibly exposing materials to conditions typical of municipal solid waste (MSW) composting. A material is composted under controlled conditions using a synthetic compost matrix and determining the acclimation time, cumulative oxygen uptake, cumulative carbon dioxide production, and percent of theoretical biodegradation over the period of the test. This test method does not establish the suitability of the composted product for any use.

1.2 The values stated in both inch-pound and SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5929–96(Reapproved2004)

Standard Test Method for

Determining Biodegradability of Materials Exposed to

Municipal Solid Waste Composting Conditions by Compost

Respirometry

This standard is issued under the fixed designation D5929; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the biodegradation properties of 3.1 Definitions—Definitions of terms applying to this test

a material by reproducibly exposing materials to conditions method appear in Terminology D1129.

typical of municipal solid waste (MSW) composting. A mate- 3.2 Definitions of Terms Specific to This Standard:

rial is composted under controlled conditions using a synthetic 3.2.1 acclimation time, n—the time required for the oxygen

compost matrix and determining the acclimation time, cumu- uptake to reach 10 % of the total measured cumulative oxygen

lative oxygen uptake, cumulative carbon dioxide production, uptake.

and percent of theoretical biodegradation over the period of the 3.2.2 oxygen uptake, n—the cumulative oxygen consumed

test. This test method does not establish the suitability of the by the organisms during the test.

composted product for any use. 3.2.3 theoretical carbon dioxide production (ThCDP),

1.2 The values stated in both inch-pound and SI units are to n—the maximum carbon dioxide that can be produced by a

be regarded separately as the standard. The values given in material as calculated by the carbon content of the material.

parentheses are for information only. 3.2.4 theoretical oxygen uptake (ThOU), n— the maximum

1.3 This standard does not purport to address all of the oxygen consumption required to fully oxidize a material based

safety concerns, if any, associated with its use. It is the on the elemental content of the material.

responsibility of the user of this standard to establish appro- 3.2.5 virgin newsprint—nonprinted newspaper roll stock.

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 This test method consists of the following:

2. Referenced Documents

4.1.1 The samples are prepared by cutting or forming the

2.1 ASTM Standards: material into the form it would most likely be seen in the waste

D513 Test Methods for Total and Dissolved Carbon Diox- stream.Atheoretical maximum carbon dioxide production and

ide in Water oxygen uptake are determined from an elemental analysis.

D1129 Terminology Relating to Water 4.1.2 An inoculum is obtained from a municipal MSW or

D1293 Test Methods for pH of Water yard waste compost facility. It is procured from a static pile

D2908 Practice for Measuring Volatile Organic Matter in that has been composting for at least two months.

Water by Aqueous-Injection Gas Chromatography 4.1.3 ThesyntheticMSWispreparedfromvirginnewsprint,

2.2 APHA-AWWA-WEF Standard Methods: pine bark or wood chips, corn starch, corn oil, bovine casein,

2540G Total, Fixed, and Volatile Solids in Solid and Semi- and urea.Abuffer/dilution water is prepared from magnesium,

solid Samples calcium, iron and a phosphate buffer.

4.1.4 The test material, synthetic compost, inoculum, and

dilution water are combined and placed in a highly insulated

reactor which monitors oxygen consumption and temperature

This test method is under the jurisdiction of ASTM Committee D34 on Waste

and captures all evolved carbon dioxide.

Management and is the direct responsibility of Subcommittee D34.03 onTreatment,

Recovery and Reuse. 4.1.5 The system is monitored, and oxygen uptake rates,

Current edition approved March 10, 1996. Published May 1996. DOI: 10.1520/

temperature profiles, and total carbon dioxide produced are

D5929-96R04.

recorded.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American Public Health Assoc., 1015 15th Street, NW, Tabak, Henry H. and Lewis, Ronald F., CEC/OECD Ring Test of Respiration

Washington, DC 20005, Standard Methods for the Examination of Water and Waste Method for Determination of Biodegradability, U. S. Environmental Protection

Water, 18th ed., 1992. Agency, pp. 1–3.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5929–96 (2004)

4.1.6 The total oxygen uptake and carbon dioxide produced 6.2.3 Computer Control of Peristaltic Pump, for automatic

are compared with the theoretical values obtained from the recirculation flow control (optional).

elemental analysis, and a percent of biodegradation is gener- 6.3 Suitable devices for the measurement of pH, dry solids

ated. Possible negative effects of the material are evaluated by (105°C),elementalanalysisofmaterial,carbondioxidecontent

observing the acclimation time of the synthetic MSW and ofscrubbers,weight,andvolumeofthefinalcompostmaterial.

evaluating the oxygen uptake rate.

7. Test Materials

5. Significance and Use

5.1 As the crisis in solid waste continues to grow, MSW

composting is increasingly being considered as one component

in the overall solid waste management strategy. The volume

reduction achieved by composting, combined with the produc-

tion of a usable end product, is resulting in increasing numbers

of municipalities analyzing and selecting MSW composting as

an alternative to incineration or to reduce reliance on landfill

disposal. This test method will help determine the effect of

materials on the compost process and establish if the material

can be properly disposed through solid waste composting

facilities.

5.2 This test method attempts to provide a simulation of the

overall compost process while maintaining reproducibility.

Exposing the test material with several other types of materials

that are typically in MSW provides an environment which

provides the key characteristics of composting: material not in

a sole carbon source environment which allows co-

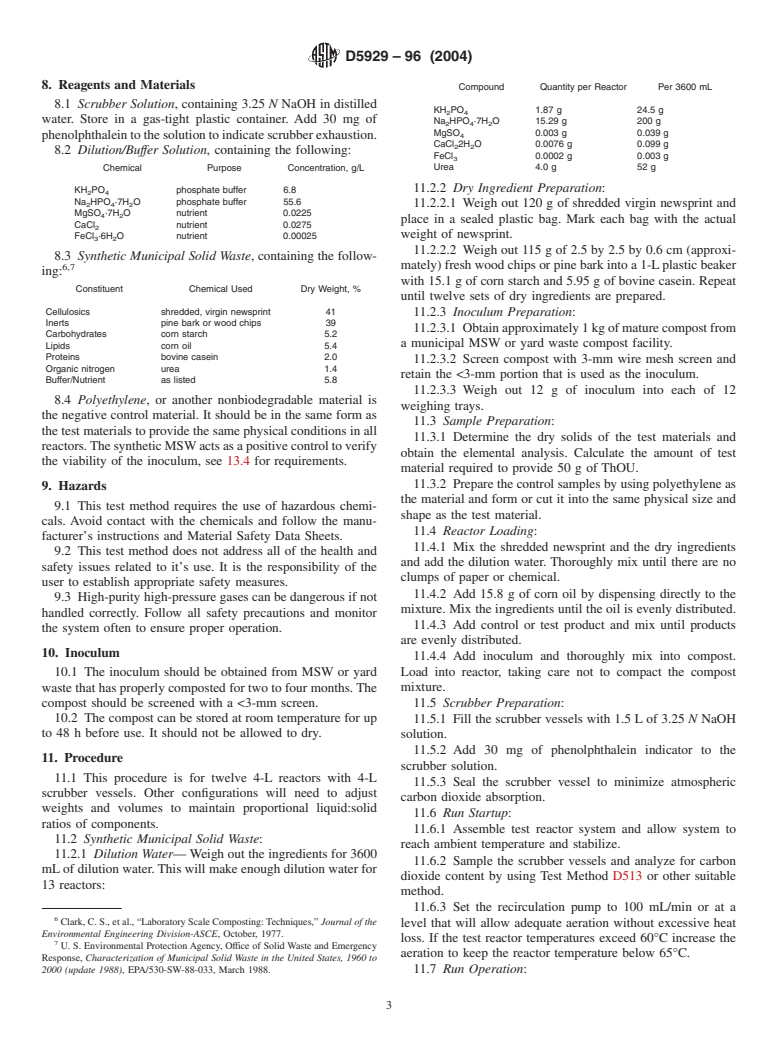

NOTE 1—The compost respirometer features a 4-L reactor vessel (A)

metabolism, compost system is self heating, and provides a

insulated with 8 cm of urethane foam. The atmosphere is drawn through

direct measurement of organism respiration.

the reactor by a peristaltic pump (B) to maintain aeration. The effluent

gases are passed through a 4-L scrubber vessel (C) containing 1.5 L of 5

6. Apparatus M NaOH to remove any carbon dioxide from the effluent gas stream.

Samples are drawn from this scrubber solution during the evaluation to

6.1 Compost Respirometry Apparatus (see Fig. 1):

determine the carbon dioxide released by the compost. As the microor-

6.1.1 Aminimum of six reactors, 2 to 6-L volume, with the

ganisms consume the oxygen in the system, a pressure drop occurs and is

test material in triplicate and the controls in triplicate. The

detected by a highly sensitive pressure switch (D). This signals the data

reactors should be surrounded with efficient insulation to

acquisition and control system (G) and the oxygen is replaced with pure

minimize heat loss and be gastight. Insulation should be 8 cm bottled oxygen by a solenoid (E) and the amount added is measured by a

mass flowmeter (F). The gasses are then returned to the reactor. A

of urethane foam or equivalent.

thermocouple(H)iscenteredinthetestreactortomonitorthetemperature

6.1.2 Tubing, with high resistance to gas permeation.

of the compost. The system is sealed to prevent interference from

6.1.3 Peristaltic Pump, to control and maintain gas flow

barometric fluctuations.

through each reactor.

FIG. 1 Compost Respirometer Functional Diagram

6.1.4 4-L Scrubber Vessel, for each reactor fitted with a

scrubber solution sampling port.

6.1.5 Differential Pressure Switch, for each reactor that

7.1 The test materials can be in any form as long as it’s

actuates between 2 and 5 in. (51 and 127 mm) of water.

dimensions do not exceed 3 by 3 by 12 cm. The test materials

6.1.6 Solenoid and Mass Flowmeter, to control and measure

should be in the form that they would be seen in the waste

the addition of pure (99.997 + ) oxygen to system.

stream. A representative sample must be obtained by using

6.1.7 Temperature Probe, situated in the middle of the

appropriate ASTM methods or other documented method.

compost.

7.2 Analyze the test materials for carbon, hydrogen, nitro-

6.1.8 DataAcquisitionandControlSystem,forthemeasure-

gen, oxygen, phosphorus, sulfur, and any other elements that

ment of temperature and the control and measurement of the

are suspected to be present at a level to effect oxygen uptake.

oxygen addition.

The ThOU must be calculated for each material.

6.2 Miscellaneous:

7.3 Calculate theThCDPfrom the carbon content of the test

6.2.1 Temperature Control Room, or hood to maintain the

material.

external temperature of the apparatus at 40°C.

7.4 The nitrogen content of the synthetic MSW should be

6.2.2 Flow Meter, to measure recirculation flow in each

adjusted if the C/N ratio is greater than 40:1. This is accom-

reactor (optional).

plished by adjusting the urea content of the synthetic MSW.

The synthetic MSW has adequate nitrogen to support the

addition of up to 35 g of carbon before the ratio exceeds 40:1.

If the urea content is adjusted, all reactors including controls

Biocycle: Journal of Waste Recycling Staff, eds., The Biocycle Guide to

Composting Municipal Wastes, JG Press, Inc., 1989. must contain the same concentration of urea.

D5929–96 (2004)

8. Reagents and Materials

Compound Quantity per Reactor Per 3600 mL

8.1 Scrubber Solution, containing 3.25 N NaOH in distilled

KH PO 1.87 g 24.5 g

2 4

water. Store in a gas-tight plastic container. Add 30 mg of

Na HPO ·7H O 15.29 g 200 g

2 4 2

MgSO 0.003 g 0.039 g

phenolphthaleintothesolutiontoindicatescrubberexhaustion.

CaCl 2H O 0.0076 g 0.099 g

2 2

8.2 Dilution/Buffer Solution, containing the following:

FeCl 0.0002 g 0.003 g

Urea 4.0 g 52 g

Chemical Purpose Concentration, g/L

11.2.2 Dry Ingredient Preparation:

KH PO phosphate buffer 6.8

2 4

Na HPO ·7H O phosphate buffer 55.6

2 4 2 11.2.2.1 Weigh out 120 g of shredded virgin newsprint and

MgSO ·7H O nutrient 0.0225

4 2

place in a sealed plastic bag. Mark each bag with the actual

CaCl nutrient 0.0275

weight of newsprint.

FeCl ·6H O nutrient 0.00025

3 2

11.2.2.2 Weigh out 115 g of 2.5 by 2.5 by 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.