ASTM A535-85(1992)

(Specification)Specification for Special-Quality Ball and Roller Bearing Steel

Specification for Special-Quality Ball and Roller Bearing Steel

General Information

Standards Content (Sample)

IND-STD ASTM A535-85 VALID NOTICE 1 'lb E 9999998 01104247 2 m

NOTICE OF

VALIDATION NO'l'lCE 1

VALIDATION

22 June 1990 for

ASTM A535-85

20 May 13Uci

MTM A53545 adopted on 20 May 1986 has been reviewed and determined to be

current.

Custodians: Military Coordinating activity:

Army - MR Army - MR

Navy - OS

Air Force - 99

Review activities:

Army - AT

User activities: .

Army - AR, ME

Navy - SH, Y-D

DIS'YHIBUTION STATEMENT A

Approved for public release; distributicln ut1.L

---------------------- Page: 1 ----------------------

ASTM A535 85 W 0759530 0529083 151 W

Designation: A 535 - 85 (Reapproved 1992)

4Tb

Standard Specification for

Special-Quality Ball and Roller Bearing Steel’

This standard is issued under the fixed designation A 535: the number immediately following the designation indicates the year of

original adoption or. in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

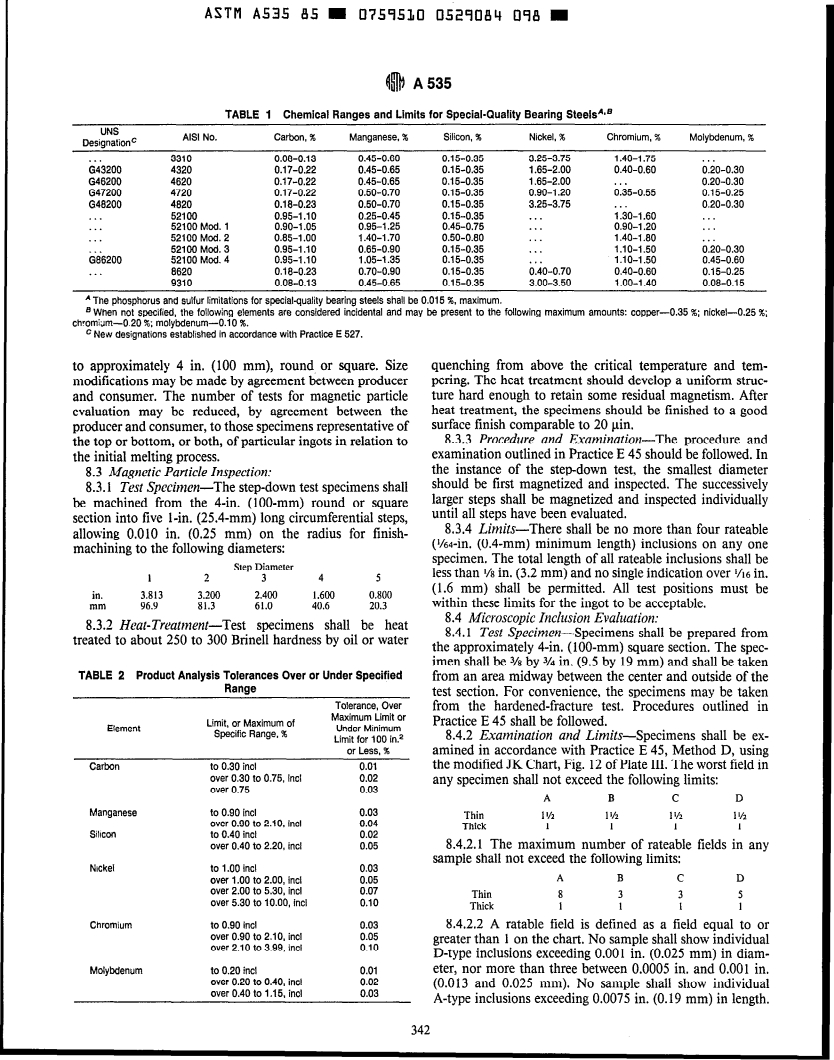

determined shall conform to the requirements in Table 1 or

1. Scope

to the other chemical requirements as specified in the order.

1.1 This specification covers special-quality steel billets

for rolling or forging bars. tube rounds. rods, coils and tubes

6. Product Analysis

to be used in the manufacture of ball and roller bearings.

1.2 The values stated in inch-pound units are to be

6.1 Analyses may be made by the purchaser from the

regarded as the standard.

finished material as ordered, representing each heat. The

chemical composition thus determined shall not vary from

2. Referenced Documents

the ranges or limits specified in Table 1, or from other

chemical requirements as specified in the order, by more

2. I AST3f Standards:

than the amounts specified in Table 2, but the several

A 29/A29M Specification for Steel Bars, Carbon and

determinations of any element in a heat may not vary, either

Alloy, Hot-Wrought and Cold-Finished, General Re-

above or below the specified range.

quirements for”

E 30 Methods for Chemical Analysis of Steel, Cast Iron,

7. Dimensions and Permissible Variations

Open-Hearth Iron, and Wrought Iron3

E 45 Practice for Determining the Inclusion Content of

7.1 The physical size and shape of the material shall be a

Steel;

matter of agreement between the manufacturer and con-

E 112 Test Methods for Determining the Average Grain

sumer.

Size4

7.2 Dimensional tolerances for hot-rolled or hot-rolled

E 527 Practice for Numbering Metals and Alloys (UNS)5

annealed bars, in straight lengths or coils, and cold-finished

bars 0.500 in. (12.7 mm) and larger which are furnished to

3. Process

this specification shall conform to tables shown in the

3.1 The steel shall be produced by the consumable- current edition of Specification A 29/A 29M.

electrode or induction vacuum-melting process or any other 7.3 Dimensional tolerances for cold-finished coils for ball

steel-making process which produces steel capable of and roller material are shown as follows:

meeting the requirements of this specification.

Size Range Total Tolerance

in. mm in. mm

4. Chemical Composition

To 0.096 incl to 2.44 incl 0.002 0.05 I

Over 0.096 to over 2.44 to

0.003 0.076

4.1 The steel shall conform to the requirements as to

0.270, incl 6.86. incl

chemical composition prescribed in Table 1 or to other

Over 0.270 to over 6.86 to 0.004 0. IO’

chemical requirements as specified in the order. For referee 0.750, incl 19.1, incl

purposes, Methods E 30 shall be used.

A These tolerances also apply to cold-finished straight lengths under 0.500 in.

(12.7 mm) in diameter. For straight lengths 0.500 in. and over. the limits specified

in Specification A 29/A 39M apply.

5. Heat Analysis

5.1 For the purpose of this specification. a heat is consid-

8. Quality Tests

ered to be the product of the initial melting process. The

analysis of each heat is determined by the producer from 8.1 The producer shall be held responsible for the quality

representative samples taken from final melted test ingots, or of the steel furnished and shall make the necessary tests to

rolled or forged blooms or billets of the final melting after the ensure this special quality. Reports shall be required on the

necessary discards are taken. The chemical composition thus results of the following four tests:

8.1.1 Magnetic particle evaluation,

8. I .2 Microscopic inclusion evaluation,

t This spcakation is under the jurisdiction of ASTM Committee A-l on Steel.

8.1.3 Grain size:

Stainless Steel and Related Alloy and is the direct responsibility of Subcommittee

8.1.3.1 Austenitic grain size (carburizing),

AtJl.28 in Rearing Steels.

8. I .3.2 Fracture grain size and indications (through-hard-

Current edition approved Dec. 27, 1985. Published February 1985. Originally

published as A 535 - 65. Last previous edition A 535 - 79”.

ening), or

2 :lt:t:d Ed r~!~.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.