ASTM F2480-06(2017)

(Guide)Standard Guide for In-ground Concrete Skatepark

Standard Guide for In-ground Concrete Skatepark

ABSTRACT

This guide covers safety and performance guidelines pertaining to in-ground skatepark facilities built primarily out of concrete and other designed materials. Any concrete materials and other designed materials intended to be used in the performance of the sports including skateboarding, inline skating and BMX biking shall be discussed. Other materials present in skatepark facilities include steel reinforcing and synthetic fibers. Physical properties such as concrete finish, surface flatness, and levelness shall be considered. In addition, expansion joints, filled control joints, and tooled control joints shall be discussed. Expansion joints should be placed where they are least likely to interfere with a wheel. Careful consideration to expansion joints location must be given, using the flow of skaters as critical design criteria. Size of control joint is not important. It must be a rigid control joint filler, which must be flush with the skating surface and close the joint completely. Also, joints should be placed where they are least likely to interfere with skate wheels, and a cut control joint is not possible. The placement of concrete on sloped radii or any areas incorporating a change in elevation is critical to the stability of the exposed steel material or concrete coping. The difficulty of achieving proper consolidation around the steel material and their reinforced attachments through the use of standard air removal consolidation techniques can lead to slumping and the creation of an air pocket around the steel material, which may not be visible during construction and may result in concrete failure on the riding surface. Skatepark signage, free standing or fixed fence, shall be provided and shall indicate the following: adult supervision of minors is or is not present; owner-operator emergency telephone numbers; emergency telephone numbers for medical, ambulance, and police; applicable regulations regarding the use of safety gear; presence of inherent risk in the participitation of skatepark activities; and drunk or users under the influence of drugs shall not participate in any skatepark activities.

SCOPE

1.1 This guide covers safety and performance guidelines pertaining to in-ground skatepark facilities built primarily out of concrete and other designed materials. This guide pertains to any concrete materials and other designed materials intended to be used in the performance of the sports including skateboarding, inline skating and BMX biking. Items such as fencing, lighting, and operational structures are not intended to be a part of this guide.

1.2 Tolerance: General Measures, Tolerances, and Conversions—General dimensional tolerances for this guide (unless otherwise noted) follow. These tolerances still apply to a dimension even when terms like greater than, less than, minimum, or maximum are used.

Dimension

Tolerance

X in. or ft

±0.5 in.

X.X in.

±0.05 in.

X.XX in.

±0.005 in.

1.3 The values stated in inch-pound units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2480 − 06 (Reapproved 2017) An American National Standard

Standard Guide for

In-ground Concrete Skatepark

This standard is issued under the fixed designation F2480; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A184/A184M Specification for Welded Deformed Steel Bar

Mats for Concrete Reinforcement

1.1 This guide covers safety and performance guidelines

A185/A185M Specification for Steel Welded Wire

pertaining to in-ground skatepark facilities built primarily out

Reinforcement, Plain, for Concrete (Withdrawn 2013)

ofconcreteandotherdesignedmaterials.Thisguidepertainsto

A497/A497M Specification for Steel Welded Wire

anyconcretematerialsandotherdesignedmaterialsintendedto

Reinforcement, Deformed, for Concrete (Withdrawn

be used in the performance of the sports including

2013)

skateboarding, inline skating and BMX biking. Items such as

A615/A615M Specification for Deformed and Plain Carbon-

fencing, lighting, and operational structures are not intended to

Steel Bars for Concrete Reinforcement

be a part of this guide.

A616/A616M Specification for Rail-Steel Deformed and

1.2 Tolerance: General Measures, Tolerances, and

Plain Bars for Concrete Reinforcement (Withdrawn

Conversions—General dimensional tolerances for this guide

1999)

(unless otherwise noted) follow. These tolerances still apply to

A617/A617M Specification for Axle-Steel Deformed and

a dimension even when terms like greater than, less than,

Plain Bars for Concrete Reinforcement (Withdrawn

minimum, or maximum are used.

1999)

Dimension Tolerance

C33 Specification for Concrete Aggregates

X in. or ft ±0.5 in.

C94/C94M Specification for Ready-Mixed Concrete

X.X in. ±0.05 in.

C125 Terminology Relating to Concrete and Concrete Ag-

X.XX in. ±0.005 in.

gregates

1.3 The values stated in inch-pound units are to be regarded

C150 Specification for Portland Cement

as standard.

C260 Specification for Air-Entraining Admixtures for Con-

1.4 This standard does not purport to address all of the

crete

safety concerns, if any, associated with its use. It is the

C494/C494M Specification for Chemical Admixtures for

responsibility of the user of this standard to establish appro-

Concrete

priate safety and health practices and determine the applica-

C1116 Specification for Fiber-Reinforced Concrete and

bility of regulatory limitations prior to use.

Shotcrete

1.5 This international standard was developed in accor-

C1141 Specification for Admixtures for Shotcrete

dance with internationally recognized principles on standard-

C1436 Specification for Materials for Shotcrete

ization established in the Decision on Principles for the

C1480 Specification for Packaged, Pre-Blended, Dry, Com-

Development of International Standards, Guides and Recom-

bined Materials for Use in Wet or Dry Shotcrete Applica-

mendations issued by the World Trade Organization Technical

tion

Barriers to Trade (TBT) Committee.

C1582/C1582M Specification for Admixtures to Inhibit

Chloride-Induced Corrosion of Reinforcing Steel in Con-

2. Referenced Documents

crete

2.1 ASTM Standards:

E1155 Test Method for Determining F Floor Flatness and

F

F Floor Levelness Numbers

L

1 2.2 ACI Standards:

This guide is under the jurisdiction of ASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

ACI 117–90 Specifications forTolerances for Concrete Con-

Subcommittee F08.66 on Sports Facilities.

struction and Materials

Current edition approved April 1, 2017. Published April 2017. Originally

approved in 2006. Last previous edition approved in 2012 as F2480 – 06 (2012).

DOI: 10.1520/F2480-06R17.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333-9094, http://www.aci-int.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2480 − 06 (2017)

ACI 302.1R-04 Guide for Concrete Floor and Slab Con- 3.1.18 specified surface, plane, or line—surface, plane, or

struction line specified by the contract documents; specified planes and

ACI 309R Guide for Consolidation of Concrete lines may slope and specified surfaces may have curvature.

2.3 ANSI Standards:

3.1.19 tolerance—(1) the permitted variation from a given

ANSI 2535.4 Product Safety Signs and Labels

dimension or quantity; (2) the range of variation permitted in

maintaining a specified dimension; and (3) A permitted varia-

3. Terminology

tion from location or alignment.

3.1 Definitions:

3.1.20 vert—vertical part of the riding surface.

3.1.1 bowl—fully enclosed or partially enclosed free-

3.1.21 vertical alignment—location relative to specified ver-

flowing form with specific transitions.

tical plane or a specified vertical line or from a line or plane

3.1.2 coping—circular pipe or other material installed on

reference to a vertical line or plane. When applied to battered

some features.

walls, abutments, or other nearly vertical surfaces, vertical

3.1.3 extension—additional elevation of the top-riding sur- alignment is defined as the horizontal location of the surface

face within the platform area. relative to the specified profile.

3.1.4 features—sections of the skate surface, which is level,

4. Materials

inclined, or curved solid surface on which the user of

skateboards, inline skates, and BMX bicycles can maneuver.

4.1 General—All materials used shall fulfill the sport-

specific requirements for skatepark facilities.

3.1.5 flat bottom—horizontal part of the riding surface

between the transitions.

4.2 Steel Elements—All exposed steel shall be inherently

corrosion resistant or be provided with a corrosion resistant

3.1.6 flat ground —flat, horizontal space, which is greater

coating.

than 12 in. long.

3.1.7 flatness—degree to which a line or surface approxi- 4.3 Concrete:

mates a plane and is a measurement of local surface 4.3.1 All concrete should consider the following, which is

bumpiness/undulation. not necessarily all-inclusive: compressive strength, flexural

strength,orboth,andfinishability;maximumsize,grading,and

3.1.8 free falling height—perpendicular distance between

type of coarse aggregate; grading and type of fine aggregate;

the floor space and an adjacent low-lying space.

combined aggregate grading; air content of concrete, if appli-

3.1.9 in-ground concrete skatepark—any concrete structure

cable; slump of concrete; water-cement ratio or water-

placed in ground that is to be used for skateboarding, inline

cementitious material ratio; and preplacement soaking require-

skating, and BMX bicycles.

ment for lightweight aggregates; and should conform to but are

3.1.10 levelness—degree to which a line or surface parallels

not limited to the requirements of Specifications C33 and

horizontal or design grade; and is a measurement of local

C94/C94M, Terminology C125, Specifications C150, C260,

conformance to design grade over a distance.

C494/C494M, C1116,C1141,C1436,C1480,C1582/C1582M,

3.1.11 performance edging—durable material installed on and ACI 302.1R-04.

4.3.2 Design details, site preparation, type of concrete and

the accessible edges or surfaces of intersecting and terminating

planes on features for performance purposes. related materials should be provided by the designer of the

concrete skatepark prior to bid documents and be applicable to

3.1.12 pool coping—manufactured masonry product similar

the local environmental conditions. Design details should

in shape and function to that typically manufactured for

reference specifications for concrete strength characteristics,

swimming pools. (See coping in 3.1.2.)

use of admixtures for freezing exposure, use of reinforcing

3.1.13 protective edging—durable material that protects ac-

steel, testing and inspection requirements. Concrete shall be

cessible edges of intersecting and terminating planes on the

manufactured to meet the specifications of the designer,

riding surfaces for the purposes of reducing wear.

method of concrete construction-ready-mix, precast or shot-

3.1.14 transition/radius—radial change in slope between

crete concrete should comply with applicable specifications.

two elevations.

4.4 Steel Reinforcing—Steel reinforcing should conform to

3.1.15 resting area—sport-functional clearance required for

but are not limited to the following specifications: deformed

standingoutoftheflowofactiveskatersandclearingtheactive

bars should conform to the requir

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2480 − 06 (Reapproved 2012) F2480 − 06 (Reapproved 2017)An American National Standard

Standard Guide for

In-ground Concrete Skatepark

This standard is issued under the fixed designation F2480; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers safety and performance guidelines pertaining to in-ground skatepark facilities built primarily out of

concrete and other designed materials. This guide pertains to any concrete materials and other designed materials intended to be

used in the performance of the sports including skateboarding, inline skating and BMX biking. Items such as fencing, lighting, and

operational structures are not intended to be a part of this guide.

1.2 Tolerance: General Measures, Tolerances, and Conversions—General dimensional tolerances for this guide (unless

otherwise noted) follow. These tolerances still apply to a dimension even when terms like greater than, less than, minimum, or

maximum are used.

Dimension Tolerance

X in. or ft ±0.5 in.

X.X in. ±0.05 in.

X.XX in. ±0.005 in.

1.3 The values stated in inch-pound units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A184/A184M Specification for Welded Deformed Steel Bar Mats for Concrete Reinforcement

A185/A185M Specification for Steel Welded Wire Reinforcement, Plain, for Concrete (Withdrawn 2013)

A497/A497M Specification for Steel Welded Wire Reinforcement, Deformed, for Concrete (Withdrawn 2013)

A615/A615M Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

A616/A616M Specification for Rail-Steel Deformed and Plain Bars for Concrete Reinforcement (Withdrawn 1999)

A617/A617M Specification for Axle-Steel Deformed and Plain Bars for Concrete Reinforcement (Withdrawn 1999)

C33 Specification for Concrete Aggregates

C94/C94M Specification for Ready-Mixed Concrete

C125 Terminology Relating to Concrete and Concrete Aggregates

C150 Specification for Portland Cement

C260 Specification for Air-Entraining Admixtures for Concrete

C494/C494M Specification for Chemical Admixtures for Concrete

C1116 Specification for Fiber-Reinforced Concrete and Shotcrete

C1141 Specification for Admixtures for Shotcrete

C1436 Specification for Materials for Shotcrete

This guide is under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilities and is the direct responsibility of Subcommittee

F08.66 on Sports Facilities.

Current edition approved July 1, 2012April 1, 2017. Published August 2012April 2017. Originally approved in 2006. Last previous edition approved in 20062012 as

F2480 – 06.F2480 – 06 (2012). DOI: 10.1520/F2480-06R12.10.1520/F2480-06R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2480 − 06 (2017)

C1480 Specification for Packaged, Pre-Blended, Dry, Combined Materials for Use in Wet or Dry Shotcrete Application

C1582/C1582M Specification for Admixtures to Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concrete

E1155 Test Method for Determining F Floor Flatness and F Floor Levelness Numbers

F L

2.2 ACI Standards:

ACI 117–90 Specifications for Tolerances for Concrete Construction and Materials

ACI 302.1R-04 Guide for Concrete Floor and Slab Construction

ACI 309R Guide for Consolidation of Concrete

2.3 ANSI Standards:

ANSI 2535.4 Product Safety Signs and Labels

3. Terminology

3.1 Definitions:

3.1.1 bowl—fully enclosed or partially enclosed free-flowing form with specific transitions.

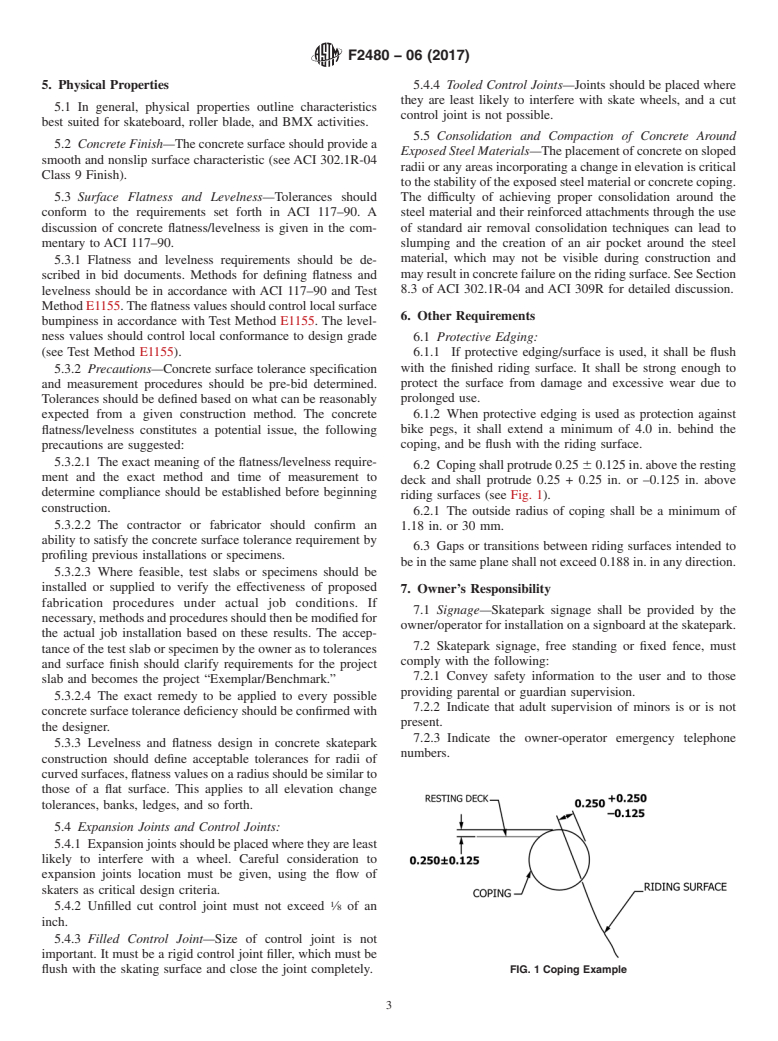

3.1.2 coping—circular pipe or other material installed on some features.

3.1.3 extension—additional elevation of the top-riding surface within the platform area.

3.1.4 features—sections of the skate surface, which is level, inclined, or curved solid surface on which the user of skateboards,

inline skates, and BMX bicycles can maneuver.

3.1.5 flat bottom—horizontal part of the riding surface between the transitions.

3.1.6 flat ground —flat, horizontal space, which is greater than 12 in. long.

3.1.7 flatness—degree to which a line or surface approximates a plane and is a measurement of local surface bumpiness/

undulation.

3.1.8 free falling height—perpendicular distance between the floor space and an adjacent low-lying space.

3.1.9 in-ground concrete skatepark—any concrete structure placed in ground that is to be used for skateboarding, inline skating,

and BMX bicycles.

3.1.10 levelness—degree to which a line or surface parallels horizontal or design grade; and is a measurement of local

conformance to design grade over a distance.

3.1.11 performance edging—durable material installed on the accessible edges or surfaces of intersecting and terminating planes

on features for performance purposes.

3.1.12 pool coping—manufactured masonry product similar in shape and function to that typically manufactured for swimming

pools. (See coping in 3.1.2.)

3.1.13 protective edging—durable material that protects accessible edges of intersecting and terminating planes on the riding

surfaces for the purposes of reducing wear.

3.1.14 transition/radius—radial change in slope between two elevations.

3.1.15 resting area—sport-functional clearance required for standing out of the flow of active skaters and clearing the active

skating zone to avoid a collision.

3.1.16 riding surface—part of skatepark structure on which the skater will be in contact.

3.1.17 skatepark —element, feature, structure, or group of elements, features, structures within a defined boundary for use by

skateboarders, inline skaters, or BMX bikers.

3.1.18 specified surface, plane, or line—surface, plane, or line specified by the contract documents; specified planes and lines

may slope and specified surfaces may have curvature.

3.1.19 tolerance—(1) the permitted variation from a given dimension or quantity; (2) the range of variation permitted in

maintaining a specified dimension; and (3) A permitted variation from location or alignment.

3.1.20 vert—vertical part of the riding surface.

3.1.21 vertical alignment—location relative to specified vertical plane or a specified vertical line or from a line or plane

reference to a vertical line or plane. When applied to battered walls, abutments, or other nearly vertical surfaces, vertical alignment

is defined as the horizontal location of the surface relative to the specified profile.

4. Materials

4.1 General—All materials used shall fulfill the sport-specific requirements for skatepark facilities.

4.2 Steel Elements—All exposed steel shall be inherently corrosion resistant or be provided with a corrosion resistant coating.

Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333-9094, http://www.aci-int.org.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

F2480 − 06 (2017)

4.3 Concrete:

4.3.1 All concrete should consider the following, which is not necessarily all-inclusive: compressive strength, flexural strength,

or both, and finishability; maximum size, grading, and type of coarse aggregate; grading and type of fine aggregate; combined

aggregate grading; air content of concrete, if applicable; slump of concrete; water-cement ratio or water-cementitious material

ratio; and preplacement soaking requirement for lightweight aggregates; and should conform to but are not limited to the

requirements of Specifications C33 and C94/C94M, Terminology C125, Specifications C150, C260, C494/C494M, C1116, C1141,

C1436, C1480, C1582/C1582M, and ACI 302.1R-04.

4.3.2 Design details, site preparation, type of concrete and related materials should be provided by the designer of the concrete

skatepark prior to bid doc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.