ASTM E18-00

(Test Method)Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

SCOPE

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C).

1.2 Values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See Note 6.)Note 1—The National Institute of Standards and Technology (NIST) maintains the national Rockwell hardness standards for the United States. In June 1998, NIST released new Rockwell C scale (HRC) test blocks as Standard Reference Materials (SRMs). The blocks were calibrated using NIST's primary reference standardizing machine. The major benefit of the NIST standards is that their HRC levels are in line with the other industrialized countries around the world. The NIST HRC levels establish the hardness of materials slightly harder than the historical standards used in the United States for the past 75 years. The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell standards maintained by NIST. This can be accomplished through the use of commercial test blocks calibrated traceable to the NIST standards or by directly using the NIST SRMs. This requirement will apply only to the Rockwell scale(s) for which NIST supplies primary reference test blocks

Note 2—In previous editions of this standard, ball indenters were required to be of hard steel. Beginning with this edition, tungsten-carbide balls are also allowed. This change is a first step in a planned future transition to eliminate steel balls and allow only the use of tungsten carbide balls. The elimination of steel ball indenters is scheduled to occur in about two years. The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously elevated hardness value. In addition, NIST is planning to standardize the HRB scale using tungsten-carbide balls. As a result of this change, this edition also requires that when a ball indenter is used, the Rockwell hardness value must be reported with the scale designation followed by the letter "S" to indicate the use of a steel ball or the letter "W" to indicate the use of a tungsten carbide ball. The user is cautioned that Rockwell hardness tests comparing the use of steel and tungsten carbide balls have been shown to give different results. For example, depending on the material tested and its hardness level, Rockwell B scale tests using a tungsten carbide ball indenter have given results up to one Rockwell point lower than when a steel ball indenter is used.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 18 – 00 An American National Standard

Standard Test Methods for

Rockwell Hardness and Rockwell Superficial Hardness of

1,2

Metallic Materials

This standard is issued under the fixed designation E 18; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B 19 Specification for Cartridge Brass Sheet, Strip, Plate,

Bar, and Disks (Blanks)

1.1 These test methods cover the determination of the

B 36/B36 M Specification for Brass Plate, Sheet, Strip, and

Rockwell hardness and the Rockwell superficial hardness of

Rolled Bar

metallic materials, including test methods for the verification

B 96 Specification for Copper-Silicon Alloy Plate, Sheet,

of machines for Rockwell hardness testing (Part B) and the

Strip, and Rolled Bar for General Purposes and Pressure

calibration of standardized hardness test blocks (Part C).

Vessels

1.2 Values stated in inch-pound units are to be regarded as

B 97 Specification for Copper-Silicon Alloy Plate, Sheet,

the standard. SI units are provided for information only.

Strip, and Rolled Bar for General Purposes

1.3 This standard does not purport to address all of the

B 103/B 103 M Specification for Phosphor Bronze Plate,

safety concerns, if any, associated with its use. It is the

Sheet, Strip, and Rolled Bar

responsibility of the user of this standard to establish appro-

B 121/B 121 M Specification for Leaded Brass Plate,

priate safety and health practices and determine the applica-

Sheet, Strip, and Rolled Bar

bility of regulatory limitations prior to use. (See Note 5.)

B 122/B 122 M Specification for Copper-Nickel-Tin Alloy,

NOTE 1—The National Institute of Standards and Technology (NIST)

Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-

maintains the national Rockwell hardness standards for the United States.

Nickel Alloy Plate, Sheet, Strip, and Rolled Bar

In June 1998, NIST released new Rockwell C scale (HRC) test blocks as

B 130 Specification for Commercial Bronze Strip for Bullet

Standard Reference Materials (SRMs). The blocks were calibrated using

Jackets

NIST’s primary reference standardizing machine. The major benefit of the

B 134 Specification for Brass Wire

NIST standards is that their HRC levels are in line with the other

industrialized countries around the world. The NIST HRC levels establish

B 152 Specification for Copper Sheet, Strip, Plate, and

the hardness of materials slightly harder than the historical standards used

Rolled Bar

in the United States for the past 75 years. The revision of E 18 requires

B 291 Specification for Copper-Zinc-Manganese Alloy

that all performance verifications of Rockwell hardness indenters and

(Manganese Brass) Sheet and Strip

hardness machines must be made using test blocks calibrated traceable to

B 370 Specification for Copper Sheet and Strip for Building

the Rockwell standards maintained by NIST. This can be accomplished

Construction

through the use of commercial test blocks calibrated traceable to the NIST

standards or by directly using the NIST SRMs. This requirement will E 4 Practices for Force Verification of Testing Machines

apply only to the Rockwell scale(s) for which NIST supplies primary

E 29 Practice for Using Significant Digits in Test Data to

reference test blocks 7

Determine Conformance with Specifications

E 140 Hardness Conversion Tables for Metals

2. Referenced Documents

2.1 ASTM Standards: 3. Terminology

A 370 Test Methods and Definitions for Mechanical Testing

3.1 Definitions:

of Steel Products

3.1.1 calibration—determination of the values of the sig-

nificant parameters by comparison with values indicated by a

reference instrument or by a set of reference standards.

These test methods are under the jurisdiction of ASTM Committee E-28 on

3.1.2 Rockwell hardness number, HR—a number derived

Mechanical Testing and are the direct responsibility of Subcommittee E28.06 on

from the net increase in the depth of indentation as the force on

Indentation Hardness Testing.

Current edition approved May 10, 2000. Published August 2000. Originally

published as E 18 – 32 T. Last previous edition E 18 – 98.

2 4

In this test method, the term Rockwell refers to an internationally recognized Annual Book of ASTM Standards, Vol 02.01.

type of indentation hardness test as defined in Section 3, and not to the hardness Discontinued, see 1981 Annual Book of ASTM Standards, Part 6.

testing equipment of a particular manufacturer. Annual Book of ASTM Standards, Vol 03.01.

3 7

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E18

an indenter is increased from a specified preliminary test force 3.1.5 verification—checking or testing to assure conform-

to a specified total test force and then returned to the prelimi-

ance with the specification.

nary test force.

3.1.2.1 Discussion—Indenters—Indenters for the Rockwell

4. Significance and Use

hardness test include a diamond spheroconical indenter and

4.1 The Rockwell hardness test is an empirical indentation

steel ball indenters of several specified diameters.

hardness test. Rockwell hardness tests provide useful informa-

3.1.2.2 Discussion—Rockwell hardness numbers are al-

tion about metallic materials. This information may correlate to

ways quoted with a scale symbol representing the indenter and

tensile strength, wear resistance, ductility, and other physical

forces used. The hardness number is followed by the symbol

characteristics of metallic materials, and may be useful in

HR and the scale designation.

quality control and selection of materials.

3.1.2.3 Examples—64 HRC = Rockwell hardness number

of 64 on Rockwell C scale. 81 HR30N = Rockwell superficial

4.2 Rockwell hardness testing at a specific location on a part

hardness number of 81 on Rockwell 30N scale.

may not represent the physical characteristics of the whole part

3.1.3 Rockwell hardness test—an indentation hardness test

or end product.

using a verified machine to force a diamond spheroconical

4.3 Rockwell hardness tests are considered satisfactory for

indenter (diamond indenter), or hard steel ball indenter under

acceptance testing of commercial shipments, and have been

specified conditions, into the surface of the material under test

used extensively in industry for this purpose.

in two operations, and to measure the difference in depth of the

4.4 Performance verifications of Rockwell hardness indent-

indentation under the specified conditions of preliminary and

ers and hardness machines shall be made using test blocks

total test forces (minor and major loads, respectively).

calibrated traceable to the Rockwell standards maintained by

3.1.4 Rockwell superficial hardness test—same as the Rock-

NIST when primary reference test blocks are available from

well hardness test except that smaller preliminary and total test

NIST for the specific Rockwell scale.

forces are used.

A. GENERAL DESCRIPTION AND TEST PROCEDURE FOR ROCKWELL HARDNESS AND ROCKWELL

SUPERFICIAL HARDNESS TESTS

5. Principles of Test and Apparatus

5.1 General Principles—The general principles of the

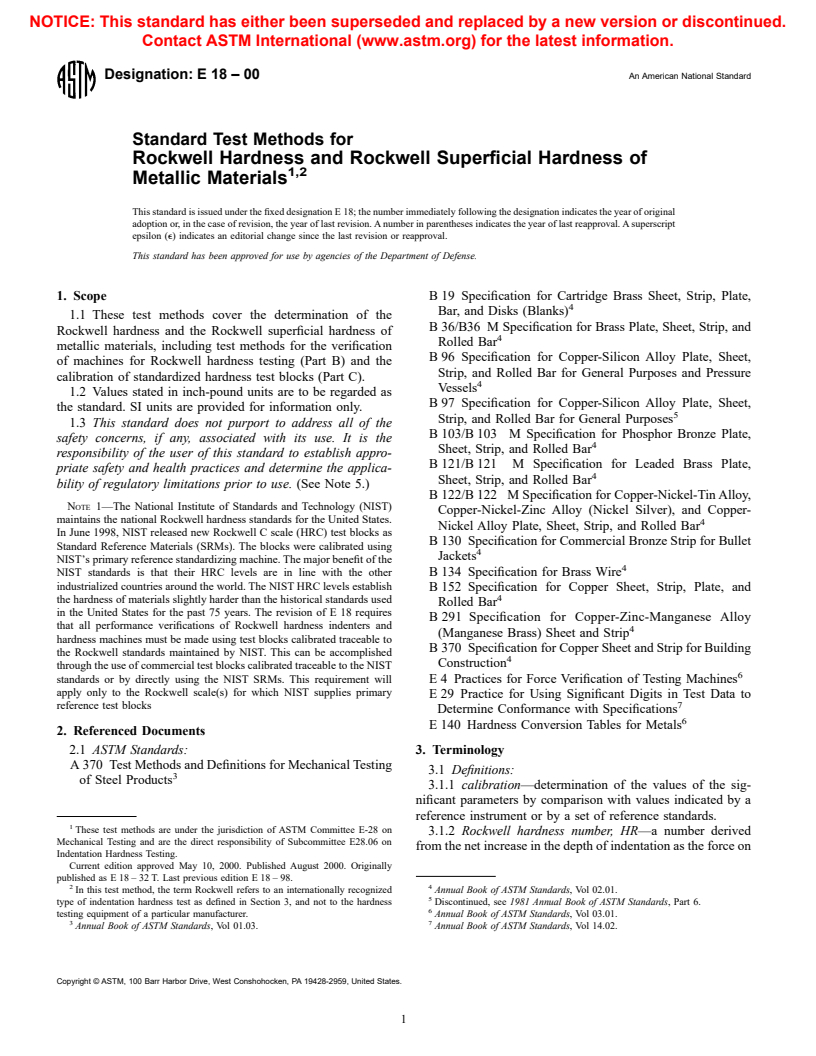

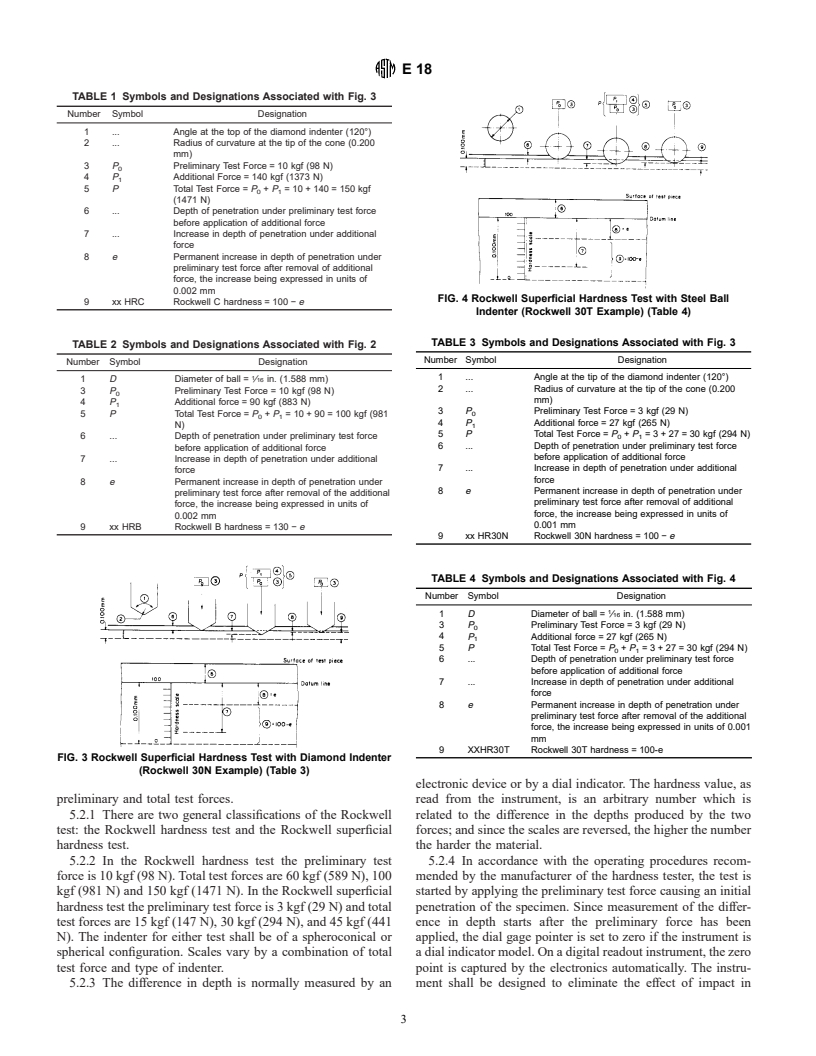

Rockwell hardness test are illustrated in Fig. 1 (diamond

indenter) and Fig. 2 (ball indenters) and the accompanying

Table 1 and Table 2. In the case of the Rockwell superficial test

the general principles are illustrated in Fig. 3 (diamond

indenter) and Fig. 4 (ball indenter) and the accompanying

Table 3 and Table 4.

5.1.1 See Equipment Manufacturer’s Instruction Manual

for a description of the machine’s characteristics, limitations,

and respective operating procedures. Typical applications of

the various hardness scales are shown in Tables 5 and 6.

Rockwell hardness values are usually determined and reported

in accordance with one of these standard scales. An indenter

FIG. 2 Rockwell Hardness Test with Steel Ball Indenter (Rockwell

B Example) (Table 2)

(diamond cone or steel ball) is forced into the surface of a test

piece in two steps under specified conditions (see Section 7)

and the difference in depth of indentation is measured as e.

5.1.2 The unit measurement for e is 0.002 mm and 0.001

mm for the Rockwell hardness test and Rockwell superficial

hardness test, respectively. From the value of e, a number

known as the Rockwell hardness is derived. There is no

Rockwell hardness value designated by a number alone be-

cause it is necessary to indicate which indenter and force have

been employed in making the test (see Table 5 and Table 6).

5.2 Description of Machine and Method of Test—The tester

for making Rockwell hardness determinations is a machine that

measures hardness by determining the difference in penetration

FIG. 1 Rockwell Hardness Test with Diamond Indenter

(Rockwell C Example) (Table 1) depths of an indenter under two specified forces, called

E18

TABLE 1 Symbols and Designations Associated with Fig. 3

Number Symbol Designation

1 . Angle at the top of the diamond indenter (120°)

2 . Radius of curvature at the tip of the cone (0.200

mm)

3 P Preliminary Test Force = 10 kgf (98 N)

4 P Additional Force = 140 kgf (1373 N)

5 P Total Test Force = P + P = 10 + 140 = 150 kgf

0 1

(1471 N)

6 . Depth of penetration under preliminary test force

before application of additional force

7 . Increase in depth of penetration under additional

force

8 e Permanent increase in depth of penetration under

preliminary test force after removal of additional

force, the increase being expressed in units of

0.002 mm

FIG. 4 Rockwell Superficial Hardness Test with Steel Ball

9 xx HRC Rockwell C hardness = 100 − e

Indenter (Rockwell 30T Example) (Table 4)

TABLE 3 Symbols and Designations Associated with Fig. 3

TABLE 2 Symbols and Designations Associated with Fig. 2

Number Symbol Designation

Number Symbol Designation

1 . Angle at the tip of the diamond indenter (120°)

1 D Diameter of ball = ⁄16 in. (1.588 mm)

2 . Radius of curvature at the tip of the cone (0.200

3 P Preliminary Test Force = 10 kgf (98 N)

mm)

4 P Additional force = 90 kgf (883 N)

3 P Preliminary Test Force = 3 kgf (29 N)

5 P Total Test Force = P + P = 10 + 90 = 100 kgf (981 0

0 1

4 P Additional force = 27 kgf (265 N)

N) 1

5 P Total Test Force = P + P =3+27=30 kgf (294 N)

6 . Depth of penetration under preliminary test force 0 1

6 . Depth of penetration under preliminary test force

before application of additional force

before application of additional force

7 . Increase in depth of penetration under additional

7 . Increase in depth of penetration under additional

force

force

8 e Permanent increase in depth of penetration under

8 e Permanent increase in depth of penetration under

preliminary test force after removal of the additional

preliminary test force after removal of additional

force, the increase being expressed in units of

force, the increase being expressed in units of

0.002 mm

0.001 mm

9 xx HRB Rockwell B hardness = 130 − e

9 xx HR30N Rockwell 30N hardness = 100 − e

TABLE 4 Symbols and Designations Associated with Fig. 4

Number Symbol Designation

1 D Diameter of ball = ⁄16 in. (1.588 mm)

3 P Preliminary Test Force = 3 kgf (29 N)

4 P Additional force = 27 kgf (265 N)

5 P Total Test Force = P + P =3+27=30 kgf (294 N)

0 1

6 . Depth of penetration under preliminary test force

before application of additional force

7 . Increase in depth of penetration under additional

force

8 e Permanent increase in depth of penetration under

preliminary test force after removal of the additional

force, the increase being expressed in units of 0.001

mm

9 XXHR30T Rockwell 30T hardness = 100-e

FIG. 3 Rockwell Superficial Hardness Test with Diamond Indenter

(Rockwell 30N Example) (Table 3)

electronic device or by a dial indicator. The hardness value, as

preliminary and total test forces. read from the instrument, is an arbitrary number which is

5.2.1 There are two general classifications of the Rockwell related to the difference in the depths produced by the two

test: the Rockwell hardness test and the Rockwell superficial forces; and since the scales are reversed, the higher the number

hardness test.

the harder the material.

5.2.2 In the Rockwell hardness test the preliminary test 5.2.4 In accordance with the operating procedures recom-

force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 mended by the manufacturer of the hardness tester, the test is

kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial started by applying the preliminary test force causing an initial

hardness test the preliminary test force is 3 kgf (29 N) and total penetration of the specimen. Since measurement of the differ-

test forces are 15 kgf (147 N), 30 kgf (294 N), and 45 kgf (441 ence in depth starts after the preliminary force has been

N). The indenter for either test shall be of a spheroconical or applied, the dial gage pointer is set to zero if the instrument is

spherical configuration. Scales vary by a combination of total a dial indicator model. On a digital readout instrument, the zero

test force and type of indenter. point is captured by the electronics automatically. The instru-

5.2.3 The difference in depth is normally measured by an ment shall be designed to eliminate the effect of impact in

E18

TABLE 5 Rockwell Hardness Scales

Scale Total Test Dial

Indenter Typical Applications of Scales

Symbol Force, kgf Figures

B ⁄16-in. (1.588-mm) ball 100 red Copper alloys, soft steels, aluminum alloys, malleable iron, etc.

C diamond 150 black Steel, hard cast irons, pearlitic malleable iron, titanium, deep case hardened steel, and other

materials harder than B100.

A diamond 60 black Cemented carbides, thin steel, and shallow case-hardened steel.

D diamond 100 black Thin steel and medium case hardened steel, and pearlitic malleable iron.

E ⁄8-in. (3.175-mm) ball 100 red Cast iron, aluminum and magnesium alloys, bearing metals.

F ⁄16-in. (1.588-mm) ball 60 red Annealed copper alloys, thin soft sheet metals.

G ⁄16-in. (1.588-mm) ball 150 red Malleable irons, copper-nickel-zinc and cupro-nickel alloys. Upper limit G92 to avoid possible

flattening of ball.

H ⁄8-in. (3.175-mm) ball 60 red Aluminum, zinc, lead.

K ⁄8-in. (3.175-mm) ball 150 red

L ⁄4-in. (6.350-mm) ball 60 red

M ⁄4-in. (6.350-mm) ball 100 red } Bearing metals and other very soft or thin materials. Use smallest ball and heaviest load that does

P ⁄4-i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.