ASTM A787-01

(Specification)Standard Specification for Electric-Resistance-Welded Metallic-Coated Carbon Steel Mechanical Tubing

Standard Specification for Electric-Resistance-Welded Metallic-Coated Carbon Steel Mechanical Tubing

SCOPE

1.1 This specification covers round, square, rectangular, and special shape, electric-resistance-welded mechanical tubing, either zinc-coated (galvanized) after welding or produced from aluminum-coated, zinc-coated (galvanized), zinc-iron alloy-coated (galvannealed), or 55 % aluminum-zinc alloy-coated steel sheet. Tubing for use as electrical conduit (EMT) or intermediate metallic conduit (IMC) is not covered by this specification.

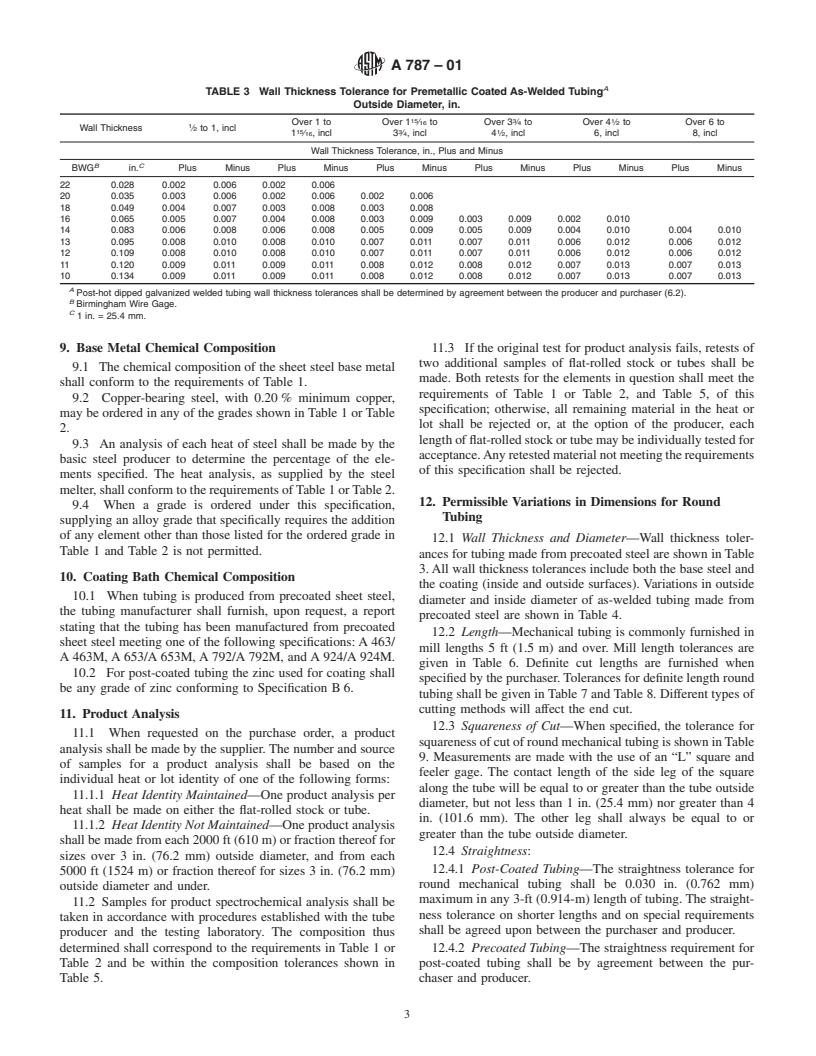

1.2 This specification covers mechanical tubing with outside diameters or maximum outside dimensions ranging from 1/2 to 8 in. (12.7 to 203.2 mm) and wall thickness from 0.028 to 0.134 in. (0.71 to 3.40 mm).

1.3 Sizes outside the ranges listed above may be ordered provided all other requirements of the specification are met.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 787 – 01

Standard Specification for

Electric-Resistance-Welded Metallic-Coated Carbon Steel

1

Mechanical Tubing

This standard is issued under the fixed designation A 787; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4

1. Scope B 6 Specification for Zinc

1.1 This specification covers round, square, rectangular, and

3. Classification

special shape, electric-resistance-welded mechanical tubing,

3.1 The types of tubing covered by this specification are:

either zinc-coated (galvanized) after welding or produced from

Type Code Description

aluminum-coated, zinc-coated (galvanized), zinc-iron alloy-

Number Letters

coated (galvannealed), or 55 % aluminum-zinc alloy-coated

steel sheet. Tubing for use as electrical conduit (EMT) or 1 AWAC electric-resistance-welded aluminum-

coated carbon steel mechanical tubing

intermediate metallic conduit (IMC) is not covered by this

2 AWG electric-resistance-welded galvanized car-

specification.

bon steel mechanical tubing

1.2 This specification covers mechanical tubing with out- 3 AWPG electric-resistance-welded carbon steel

mechanical tubing, post-hot dipped gal-

side diameters or maximum outside dimensions ranging from

vanized

1

⁄2 to 8 in. (12.7 to 203.2 mm) and wall thickness from 0.028

4 AWGA electric-resistance-welded carbon steel

mechanical tubing, zinc-iron alloy-

to 0.134 in. (0.71 to 3.40 mm).

coated (galvannealed)

1.3 Sizes outside the ranges listed above may be ordered

5 AWGZ electric-resistance-welded carbon steel

provided all other requirements of the specification are met.

mechanical tubing, 55 % aluminum-zinc

alloy-coated

1.4 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

4. Ordering Information

information only.

4.1 The ordered wall thickness of the tubing shall be the

2. Referenced Documents total of the base metal and the metallic coating.

4.2 Orders for material under this specification shall in-

2.1 ASTM Standards:

clude the following:

A 90/A 90M Test Method for Weight [Mass] of Coating on

2

4.2.1 Quantity (feet, metres, or number of lengths),

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

4.2.2 Type, code letters, and description (Sections 1 and 3),

A 370 Test Methods and Definitions for MechanicalTesting

3

4.2.3 Applicable ASTM designation number(s),

of Steel Products

4.2.4 Coating designation and type of coating,

A 428/A 428M Test Method for Weight of Coating on

2

4.2.5 Chemically treated or not chemically treated raw

Aluminum-Coated Iron or Steel Articles

material,

A 463/A 463M Specification for Steel Sheet, Aluminum-

2

4.2.6 Oiled or dry (Section 16),

Coated by the Hot-Dip Process

4.2.7 Extra smooth coating (if required),

A 653/A 653M Specification for Steel Sheet, Zinc-Coated

4.2.8 Customer application, including fabrication,

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

2 4.2.9 Flash condition (7.1),

by the Hot-Dip Process

4.2.10 Steel grade designation (Sections 5 and 9),

A 792/A 792M Specification for Steel Sheet, 55 %

2

4.2.11 Report of chemical analysis if required (Sections 10

Aluminum-Zinc Alloy-Coated by the Hot-Dip Process

and 11),

A 924/A 924M Specification for General Requirements for

2

4.2.12 Shape (round, square, rectangular, or special),

Steel Sheet, Metallic-Coated by the Hot-Dip Process

4.2.12.1 Dimensions: round—any two of the following:

inside diameter, outside diameter, or wall thickness; square or

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

rectangular—outside dimension, wall thickness, and corner

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

radii, if required. (See 12.1 and 13.1 and 13.2.)

A01.09 on Carbon Steel Tubular Products.

Current edition approved March 10, 2001. Published May 2001. Originally

published as A 787 – 81. Last previous edition A 787 – 00.

2

Annual Book of ASTM Standards, Vol 01.06.

3 4

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 02.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A787–01

A

TABLE 2 Chemical Requirements for Other Carbon Steels

4.2.13 Length: round tubing—mill lengths or definite cut

lengths (see 12.2); square and rectangular tubing—mill cut Composition, %

Grade

lengths and specified length (see 13.4).

Phos-

Designa-

Sulfur,

Carbon Manganese phorus,

4.2.14 Squareness of cut: round tubing, if required (see tion

max

max

12.3); square and rectangular tubing, if required (se

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.