ASTM G39-99

(Practice)Standard Practice for Preparation and Use of Bent-Beam Stress-Corrosion Test Specimens

Standard Practice for Preparation and Use of Bent-Beam Stress-Corrosion Test Specimens

SCOPE

1.1 This practice covers procedures for designing, preparing, and using bent-beam stress-corrosion specimens.

1.2 Different specimen configurations are given for use with different product forms, such as sheet or plate. This practice applicable to specimens of any metal that are stressed to levels less than the elastic limit of the material, and therefore the applied stress can be accurately calculated or measured (Note 1). Stress calculations by this practice are not applicable to plastically stressed specimens. Note 1-It is the nature of these methods that only the applied stress can be calculated. Since stress-corrosion cracking is a function of the total stress, for critical applications and proper interpretation of results, the residual stress (before applying external stress) or the total elastic stress (after applying external stress) should be determined by appropriate nondestructive methods, such as X-ray diffraction (1).

1.3 Test procedures are given for stress-corrosion testing by exposure to gaseous and liquid environments.

1.4 The bent-beam test is best suited for flat product forms such as sheet, strip, and plate. For plate material the bent-beam specimen is more difficult to use, because more rugged specimen holders must be built to accommodate the specimens. A double-beam modification of a four-point specimen to utilize heavier materials is described in 10.5.

1.5 The exposure of specimens in a corrosive environment is treated only briefly, since other methods deal with this aspect, for example, Specification D1141, Practices G30, G36, G44, and G50, and Method G43. The experimenter is referred to ASTM Special Technical Publication 425 (2).

1.6 The bent-beam method generally constitutes a constant strain (deflection) test. Once cracking has initiated, the state of stress at the tip of the crack as well as in uncracked areas has changed, and therefore the known or calculated stress or strain values discussed in this method apply only to the state of stress existing before initiation of cracks.

1.7 The values stated in SI units are to be regarded as standard. The inch-pound equivalents in parentheses are provided for information.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety hazard information see Section 8 and 12.1.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 39 – 99

Standard Practice for

Preparation and Use of Bent-Beam Stress-Corrosion Test

Specimens

ThisstandardisissuedunderthefixeddesignationG39;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The values stated in SI units are to be regarded as

standard. The inch-pound equivalents in parentheses are pro-

1.1 This practice covers procedures for designing, prepar-

vided for information.

ing, and using bent-beam stress-corrosion specimens.

1.8 This standard does not purport to address all of the

1.2 Differentspecimenconfigurationsaregivenforusewith

safety concerns, if any, associated with its use. It is the

different product forms, such as sheet or plate. This practice

responsibility of the user of this standard to establish appro-

applicable to specimens of any metal that are stressed to levels

priate safety and health practices and determine the applica-

less than the elastic limit of the material, and therefore, the

bility of regulatory limitations prior to use. (For more specific

applied stress can be accurately calculated or measured (see

safety hazard information see Section 7 and 12.1.)

Note 1). Stress calculations by this practice are not applicable

to plastically stressed specimens.

2. Referenced Documents

NOTE 1—It is the nature of these practices that only the applied stress

2.1 ASTM Standards:

canbecalculated.Sincestress-corrosioncrackingisafunctionofthetotal

D1141 Specification for Substitute Ocean Water

stress, for critical applications and proper interpretation of results, the

G30 Practice for Making and Using U-Bend Stress Corro-

residual stress (before applying external stress) or the total elastic stress

sion Test Specimens

(after applying external stress) should be determined by appropriate

G36 Practice for Performing Stress-Corrosion Cracking

nondestructive methods, such as X ray diffraction (1).

Tests in a Boiling Magnesium Chloride Solution

1.3 Test procedures are given for stress-corrosion testing by

G44 Practice for Evaluating Stress Corrosion Cracking

exposure to gaseous and liquid environments.

ResistanceofMetalsandAlloysbyAlternateImmersionin

1.4 The bent-beam test is best suited for flat product forms,

3.5% Sodium Chloride Solution

suchassheet,strip,andplate.Forplatematerialthebent-beam

G50 Practice for ConductingAtmospheric Corrosion Tests

specimen is more difficult to use because more rugged speci-

on Metals

men holders must be built to accommodate the specimens. A

G85 Practice for Modified Salt Spray (Fog) Testing

double-beam modification of a four-point loaded specimen to

2.2 NACE Documents:

utilize heavier materials is described in 10.5.

NACETM0177-96 LaboratoryTesting of Metals for Resis-

1.5 The exposure of specimens in a corrosive environment

tancetoSpecificFormsofEnvironmentalCrackinginH S

is treated only briefly since other practices deal with this

Environments

aspect, for example, Specification D1141, and Practices G30,

G36, G44, G50, and G85. The experimenter is referred to

3. Terminology

ASTM Special Technical Publication 425 (2).

3.1 Definitions of Terms Specific to This Standard:

1.6 The bent-beam practice generally constitutes a constant

3.1.1 stress-corrosion cracking—a cracking process requir-

strain (deflection) test. Once cracking has initiated, the state of

ingthesimultaneousactionofacorrodentandsustainedtensile

stress at the tip of the crack as well as in uncracked areas has

stress. This excludes corrosion-reduced sections that fail by

changed,andtherefore,theknownorcalculatedstressorstrain

fastfracture.Italsoexcludesintercrystallineortranscrystalline

valuesdiscussedinthispracticeapplyonlytothestateofstress

corrosion which can disintegrate an alloy without either

existing before initiation of cracks.

applied or residual stress.

3.1.2 cracking time—thetimeelapsedfromtheinceptionof

test until the appearance of cracking.

This practice is under the jurisdiction ofASTM Committee G-1 on Corrosion

of Metals, and is the direct responsibility of Subcommittee G01.06 on Stress

Corrosion Cracking and Corrosion Fatigue.

Current edition approved Jan. 10, 1999. Published April 1999. Originally Annual Book of ASTM Standards, Vol 11.02.

e1 4

published as G39–73. Last previous edition G39–90 (1994) . Annual Book of ASTM Standards, Vol 03.02.

2 5

The boldface numbers in parentheses refer to the list of references appended to Available from National Association of Corrosion Engineers, Int., P. O. Box

this practice. 218340, Houston, TX 77218–8340.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G39

3.1.2.1 Discussion—1 The test begins when the stress is

applied and the stressed specimen is exposed to the corrosive

environment, whichever occurs later.

3.1.2.2 Discussion—2 The specimen is considered to have

failed when cracks are detected. Presence of cracks can be

determined with or without optical, mechanical, or electronic

aids. However, for meaningful interpretation, comparisons

should be made only among tests employing crack detection

methods of equivalent sensitivity.

4. Summary of Practice

4.1 This practice involves the quantitative stressing of a

beamspecimenbyapplicationofabendingstress.Theapplied

stress is determined from the size of the specimen and the

bendingdeflection.Thestressedspecimensthenareexposedto

the test environment and the time required for cracks to

developisdetermined.Thiscrackingtimeisusedasameasure

of the stress-corrosion resistance of the material in the test

environment at the stress level utilized.

5. Significance and Use

5.1 The bent-beam specimen is designed for determining

the stress-corrosion behavior of alloy sheets and plates in a

variety of environments. The bent-beam specimens are de-

signed for testing at stress levels below the elastic limit of the

alloy.FortestingintheplasticrangeU-bendspecimensshould

be employed (see Practice G30). Although it is possible to

stress bent-beam specimens into the plastic range, the stress

level cannot be calculated for plastically stressed three- and

four-point loaded specimens as well as the double-beam

specimens. Therefore, the use of bent-beam specimens in the FIG. 1 Schematic Specimen and Holder Configurations

plastic range is not recommended for general use.

(see Note 4), (3) making the entire holder out of a nonmetallic

6. Apparatus

material (see Note 4), or ( 4) coating the holder with an

6.1 Specimen Holders—Bent-beam specimens require a

electrically nonconducting coating that effectively prevents

specimen holder for each specimen, designed to retain the

contact between holder and electrolyte.

applied stress on the specimen. Typical specimen holder

6.1.3 Crevice corrosion may occur in an electrolyte at

configurations are shown schematically in Fig. 1.

contact points between specimen and holder (or spacer). In

these instances the critical areas should be packed with a

NOTE 2—The double-beam specimen, more fully described in 10.5, is

self-contained and does not require a holder.

hydrophobic filler (such as grease or wax).

NOTE 3—Specimen holders can be modified from the constant defor-

NOTE 5—In atmospheres (gas) galvanic action between specimen and

mation type shown in Fig. 1 to give a constant-load type of stressing. For

holder either does not exist or is confined to a very small area as

instance, the loading bolt can be supplanted by a spring or dead-weight

experienced in outdoor exposure tests.

arrangement to change the mode of loading.

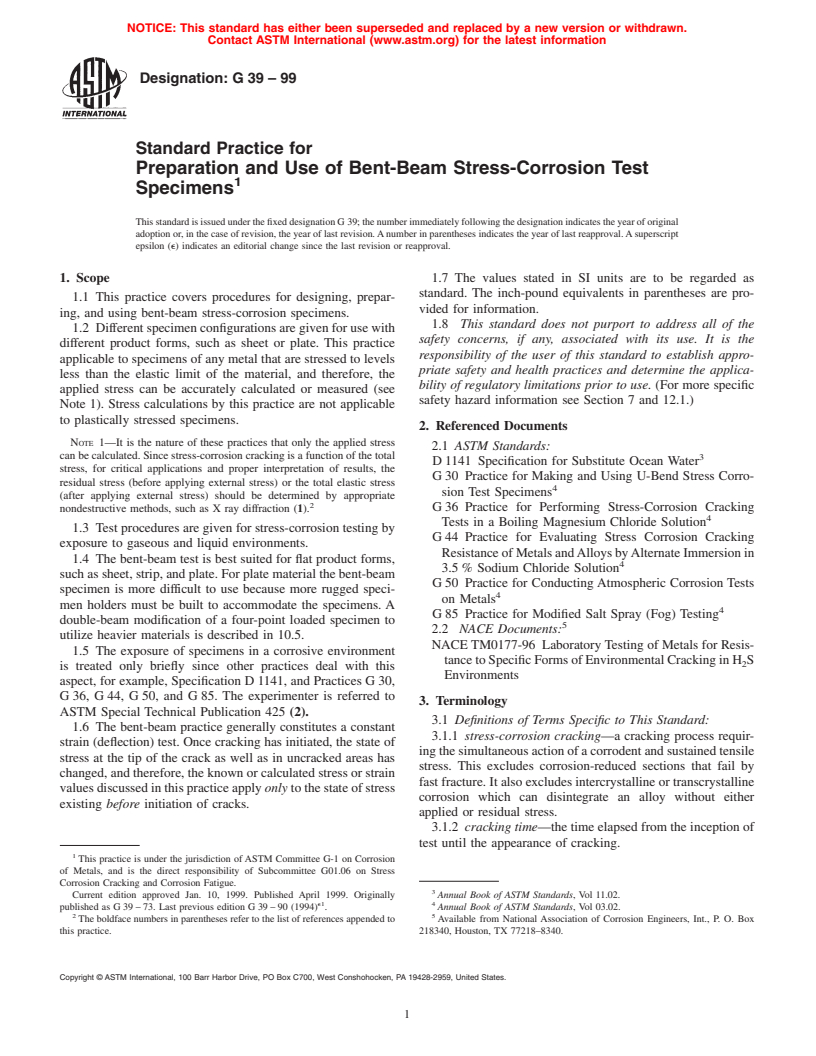

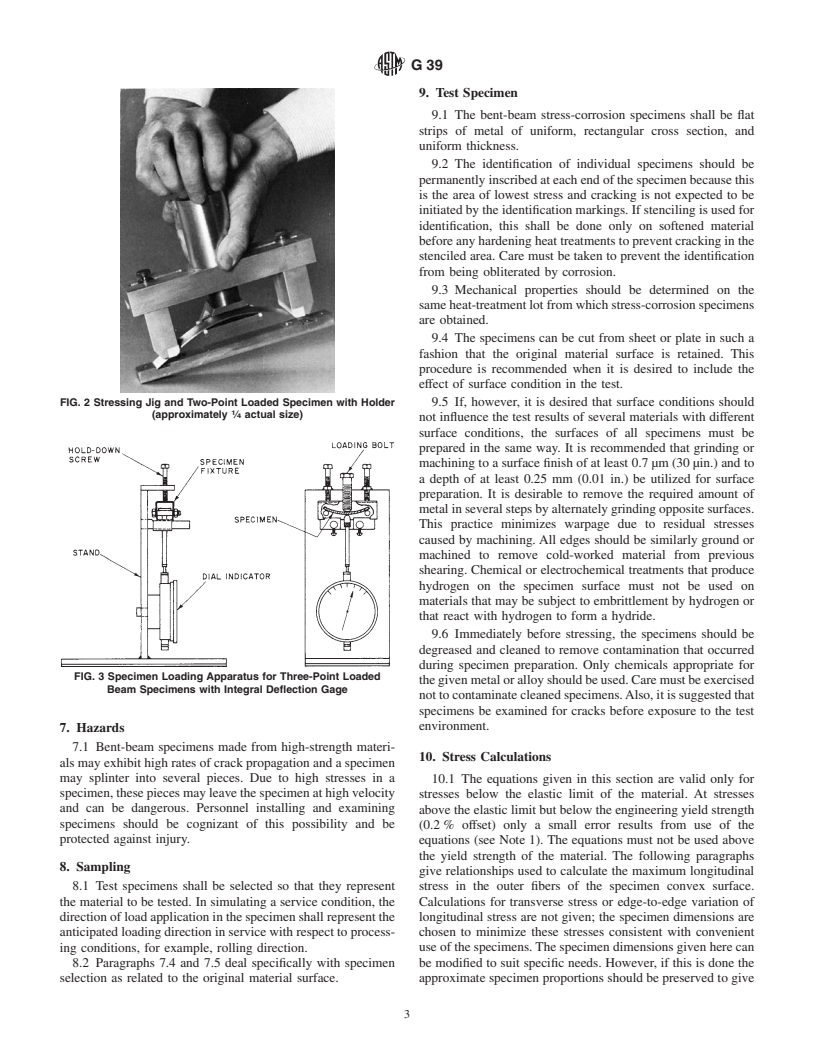

6.2 Stressing Jigs—Three-point and four-point loaded

6.1.1 The holder shall be made of a material that would

specimen holders, Fig. 1 ( b and c), contain a stressing feature

withstand the influence of the environment without deteriora-

in the form of a loading screw. To stress two-point loaded

tion or change in shape.

specimens (Fig. 1(a)), a separate stressing jig shall be used.A

NOTE 4—Itshouldberecognizedthatmanyplasticstendtocreepwhen

convenient stressing jig is shown in Fig. 2.

subjectedtosustainedloads.Ifspecimenholdersorinsulatorsaremadeof

suchmaterials,theappliedstressonthespecimenmaychangeappreciably NOTE 6—The double-beam specimen, described in 10.5, requires a

with time. By proper choice of holder and insulator materials, however, mechanical or hydraulic stressing frame (a universal tension testing

many plastics can be used, especially in short-time tests. machine can also be used) as well as welding equipment.

6.1.2 Whenthestress-corrosiontestisconductedbyimmer- 6.3 Deflection Gages—Deflection of specimens is deter-

sion in an electrolyte, galvanic action between specimen and mined by separate gages or by gages incorporated in a loading

holder (or spacer) shall be prevented (see Note 5). This is apparatus as shown in Fig. 3. In designing a deflection gage to

accomplishedby(1)makingtheholderofthesamematerialas suit individual circumstances care must be taken to reference

the individual specimens, (2) inserting electrically insulating the deflection to the proper support distance as defined in

materials between specimen and holder at all points of contact 10.2-10.5.

G39

9. Test Specimen

9.1 The bent-beam stress-corrosion specimens shall be flat

strips of metal of uniform, rectangular cross section, and

uniform thickness.

9.2 The identification of individual specimens should be

permanentlyinscribedateachendofthespecimenbecausethis

is the area of lowest stress and cracking is not expected to be

initiatedbytheidentificationmarkings.Ifstencilingisusedfor

identification, this shall be done only on softened material

beforeanyhardeningheattreatmentstopreventcrackinginthe

stenciled area. Care must be taken to prevent the identification

from being obliterated by corrosion.

9.3 Mechanical properties should be determined on the

sameheat-treatmentlotfromwhichstress-corrosionspecimens

are obtained.

9.4 The specimens can be cut from sheet or plate in such a

fashion that the original material surface is retained. This

procedure is recommended when it is desired to include the

effect of surface condition in the test.

FIG. 2 Stressing Jig and Two-Point Loaded Specimen with Holder 9.5 If, however, it is desired that surface conditions should

(approximately ⁄4 actual size)

not influence the test results of several materials with different

surface conditions, the surfaces of all specimens must be

prepared in the same way. It is recommended that grinding or

machiningtoasurfacefinishofatleast0.7µm(30µin.)andto

a depth of at least 0.25 mm (0.01 in.) be utilized for surface

preparation. It is desirable to remove the required amount of

metalinseveralstepsbyalternatelygrindingoppositesurfaces.

This practice minimizes warpage due to residual stresses

caused by machining.All edges should be similarly ground or

machined to remove cold-worked material from previous

shearing. Chemical or electrochemical treatments that produce

hydrogen on the specimen surface must not be used on

materials that may be subject to embrittlement by hydrogen or

that react with hydrogen to form a hydride.

9.6 Immediately before stressing, the specimens should be

degreased and cleaned to remove contamination that occurred

during specimen preparation. Only chemicals appropriate for

FIG. 3 Specimen Loading Apparatus for Three-Point Loaded

thegivenmetaloralloyshouldbeused.Caremustbeexercised

Beam Specimens with Integral Deflection Gage

nottocontaminatecleanedspecimens.Also,itissuggestedthat

specimens be examined for cracks before exposure to the test

environment.

7. Hazards

7.1 Bent-beam specimens made from high-strength materi-

10. Stress Calculations

alsmayexhibithighratesofcrackpropagationandaspecimen

may splinter into several pieces. Due to high stresses in a

10.1 The equations given in this section are valid only for

specimen,thesepiecesmayleavethespecimenathighvelocity

stresses below the elastic limit of the material. At stresses

and can be dangerous. Personnel installing and examining

abovetheelasticlimitbutbelowtheengineeringyieldstrength

specimens should be cognizant of this possibility and be

(0.2% offset) only a small error results from use of the

protected against injury.

equations (see Note 1). The equations must not be used above

the yield strength of the material. The following paragraphs

8. Sampling

give relationships used to calculate the maximum longitudinal

8.1 Test specimens shall be selected so that they represent stress in the outer fibers of the specimen convex surface.

the material to be tested. In simulating a service condition, the Calculations for transverse stress or edge-to-edge variation of

directionofloadapplicationinthespecimenshallrepresentthe longitudinal stress are not given; the specimen dimensions are

anticipatedloadingdirectioninservicewithrespecttoprocess- chosen to minimize these stresses consistent with convenient

ing conditions, for example, rolling direction. useofthespecimens.Thespecimendimensionsgivenherecan

8.2 Paragraphs 7.4 and 7.5 deal specifically with specimen be modified to suit specific needs. However, if this is done the

selection as related to the original material surface. approximatespecimenproportionsshouldbepreservedtogive

G39

a similar stress distribution (for instance, if the length is 10.2.2.3 By using appropriate values of k evaluate Eq 2 for

doubled the width should be doubled also). L.Tofacilitatecalculationsacomputercanbeusedtogenerate

a table for a range of strain e and H/t with resultant values of

10.1.1 When specimens are tested at elevated temperatures,

(L − H)/H.

the possibility of stress relaxation should be investigated.

10.2.3 Calculate the deflection of the specimen as follows:

Relaxation can be estimated from known creep data for the

specimen, holder, and insulating materials. Differences in

y/H 5 k/~2E 2 K! (3)

thermal expansion also should be considered.

where:

10.1.2 Theappliedstressisdeterminedbyspecimendimen-

y 5 maximum deflection.

sions and the amount of bending deflection.Thus, the errors in

The other quantities are given in 10.2.1.

the applied stress are related to those inherent in the use of

Thisrelationshipcanbeusedasasimplechecktoensurethat

measuring instruments (micrometers, deflection gages, strain

the maximum stress does not exceed the proportional limit. If

gages,andsoforth).Forthetwo-pointloadedspecimens,most

itshouldexceedtheproportionallimit,themeasureddeflection

measured values lie within 5% of the values calculated in

will be greater than that calculated from Eq 3.

accordance with the procedur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.