ASTM C617-98

(Practice)Standard Practice for Capping Cylindrical Concrete Specimens

Standard Practice for Capping Cylindrical Concrete Specimens

SCOPE

1.1 This practice covers apparatus, materials, and procedures for capping freshly molded concrete cylinders with neat cement and hardened cylinders and drilled concrete cores with high-strength gypsum plaster or sulfur mortar.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents of inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precaution statements see 4.3 and 6.2.3.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 617 – 98

Standard Practice for

Capping Cylindrical Concrete Specimens

This standard is issued under the fixed designation C 617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope hardened cylinders, or drilled concrete cores when the end

surfaces do not conform with the planeness and perpendicu-

1.1 This practice covers apparatus, materials, and proce-

larity requirements of applicable standards. Practice C 1231

dures for capping freshly molded concrete cylinders with neat

describes alternative procedures using unbonded caps or pad

cement and hardened cylinders and drilled concrete cores with

caps.

high-strength gypsum plaster or sulfur mortar.

1.2 The values stated in inch-pound units are to be regarded

4. Capping Equipment

as the standard.The SI equivalents of inch-pound units may be

4.1 Capping Plates—Neat cement caps and high-strength

approximate.

gypsum-plaster caps shall be formed against a glass plate at

1.3 This standard does not purport to address all of the

least ⁄4 in. (6 mm) thick, a machined metal plate at least 0.45

safety concerns, if any, associated with its use. It is the

in. (11 mm) thick, or a polished plate of granite or diabase at

responsibility of the user of this standard to establish appro-

least 3 in. (76 mm) thick. Sulfur mortar caps shall be formed

priate safety and health practices and determine the applica-

against similar metal or stone plates except that the recessed

bility of regulatory limitations prior to use. For specific

area which receives molten sulfur shall not be deeper than

precaution statements see 4.3 and 6.2.3.1.

⁄2 in. (12 mm). In all cases, plates shall be at least 1 in. (25

2. Referenced Documents mm) greater in diameter than the test specimen and the

working surfaces shall not depart from a plane by more than

2.1 ASTM Standards:

0.002 in. (0.05 mm) in 6 in. (152 mm). The surface roughness

C 109/C 109M Test Method for Compressive Strength of

of newly finished metal plates shall not exceed that set forth in

Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube

Table 4 ofAmerican National Standard B46.1, or 125 µin. (3.2

Specimens)

µm) for any type of surface and direction of lay. The surface,

C 150 Specification for Portland Cement

when new, shall be free of gouges, grooves, or indentations

C 472 Test Methods for Physical Testing of Gypsum, Gyp-

beyond those caused by the finishing operation. Metal plates

sum Plasters and Gypsum Concrete

that have been in use shall be free of gouges, grooves, and

C 595M Specification for Blended Hydraulic Cements

indentations greater than 0.010 in. (0.25 mm) deep or greater

C 1231 Practice for Use of Unbounded Caps in Determina-

2 2

than 0.05 in. (32 mm ) in surface area.

tion of Compressive Strength of Hardened Concrete Cyl-

inders

NOTE 1—A Rockwell hardness of 48 HRC is suggested for capping

2.2 ANSI Standard: plates of devices used to form sulfur mortar caps.

B46.1 Standard for Surface Texture (Surface, Roughness,

4.2 Alignment Devices—Suitable alignment devices, such

Waviness and Lay)

as guide bars or bull’s-eye levels, shall be used in conjunction

with capping plates to ensure that no single cap will depart

3. Significance and Use

from perpendicularity to the axis of a cylindrical specimen by

3.1 This practice describes procedures for providing plane

more than 0.5° (approximately equivalent to ⁄8 in. in 12 in.

surfaces on the ends of freshly molded concrete cylinders,

(3.2 mm in 305 mm)). The same requirement is applicable to

the relationship between the axis of the alignment device and

1 the surface of a capping plate when guide bars are used. In

This practice is under the jurisdiction of ASTM Committee C-9 on Concrete

addition, the location of each bar with respect to its plate must

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.61on

Testing Concrete for Strength.

be such that no cap will be off-centered on a test specimen by

CurrenteditionapprovedAugust10,1998.PublishedDecember1998.Originally

more than ⁄16 in. (2 mm).

published as C 617 – 68. Last previous edition C 617 – 94.

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 04.02.

Available fromAmerican Society of Mechanical Engineers, 345 E. 47th Street,

New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 617

4.3 Melting Pots for Sulfur Mortars—Pots used for melting conforming to these requirements is permitted to be used for

sulfur mortars shall be equipped with automatic temperature cylinders with strengths up to 20 percent greater than the

controlsandshallbemadeofmetalorlinedwithamaterialthat concrete tested in these qualification tests. The manufacturer

is nonreactive with molten sulfur. mustrequalifylotsofmaterialmanufacturedonanannualbasis

4.3.1 Caution: Meltingpotsequippedwithperipheralheat- or whenever there is a change in the formulation or the raw

ing will ensure against accidents during reheating of cooled materials. The user of the material must retain a copy of the

sulfur mixture that have a crusted-over surface. When using qualification results, and the dates of manufacture of material

melting pots not so equipped, a build-up of pressure under the qualified and of the material currently being used. See Table 2.

hardened surface crust on subsequent reheating may be 5.1.3 The compressive strength of capping materials shall

avoided by use of a metal rod that contacts the bottom of the be determined by testing 2 in. cubes following the procedure

pot and projects above the surface of the fluid sulfur mix as it described in Test Method C 109. Except for sulfur mortars,

cools. The rod should be of sufficient size to conduct enough molding procedures shall be as in Test Method C 109 unless

heat to the top on reheating to melt a ring around the rod first other procedures are required to eliminate large entrapped air

andthusavoidthedevelopmentofpressure.Alargemetalladle voids. See Test Methods C 472 for alternative compaction

can be substituted for the rod. procedures. Cure cubes in the same environment for the same

4.3.1.1 Use sulfur melting pots in a hood to exhaust the length of time as the material used to cap specimens.

fumes to outdoors. Heating over an open flame is dangerous 5.1.4 The strength of the capping material shall be deter-

because the flash point of sulfur is approximately 440°F mined on receipt of a new lot and at intervals not exceeding

(227°C) and the mixture can ignite due to overheating. Should three months. If a given lot of the capping material fails to

the mixture start to burn, covering will snuff out the flame.The conform to the strength requirements, it shall not be used, and

pot should be recharged with fresh material after the flame has strengthtestsofthereplacementmaterialshallbemadeweekly

been extinguished. until four consecutive determinations conform to specification

requirements.

5. Capping Materials

5.2 Neat Hydraulic Cement Paste:

5.1 Thestrengthofthecappingmaterialandthethicknessof 5.2.1 Make qualification tests of the neat hydraulic cement

paste prior to use for capping to establish the effects of

the caps shall conform to the requirements of Table 1.

5.1.1 If sulfur mortar, high strength gypsum plaster and water-cementratioandageoncompressivestrengthof2in.(50

mm) cubes.

other materials except neat cement paste are to be used to test

concrete with a strength greater than 7000 psi (50 MPa), the

NOTE 2—The cements used generally conform to Specification C 150

manufacturer or the user of the material must provide docu-

Types I, II or III; however, Specification C 595 blended cements, calcium

mentation:

aluminate or other hydraulic cements producing acceptable strength may

5.1.1.1 That the average strength of 15 cylinders capped be used.

with the material is not less than 98 percent of the average

5.2.2 Mixtheneatcementpastetothedesiredconsistencyat

strength of 15 companion cylinders capped with neat cement

a water-cement ratio equal to or less than that required to

paste or 15 cylinders ground plane to within 0.002 in. (0.05

produce the required strength, generally 2 to 4 h before the

mm).

paste is to be used (Note 3). Remix as necessary to maintain

5.1.1.2 That the standard deviation of the strengths of the

acceptable consistency (Note 4). Some retempering of the

capped cylinders is not greater than 1.57 times that of the

paste is acceptable if the required water-cement ratio is not

standard deviation of the reference cylinders.

exceeded. Optimum consistency is generally produced at

5.1.1.3 That the cap thickness requirements were met in the

water-cement ratios of 0.32 to 0.36 by mass for Type I and

qualification tests, and

Type II cements and 0.35 to 0.39 by mass forType III cements.

5.1.1.4 Of the hardening time of the caps used in the

NOTE 3—Freshly mixed pastes tend to bleed, shrink, and make unac-

qualification tests.

ceptable caps. The 2 to 4 h period is generally appropriate for portland

5.1.2 Additionally, the qualification test report must include

cements.

thecompressivestrengthof2in.cubesofthematerialqualified

NOTE 4—The required consistency of the paste is determined by the

and of neat cement paste cubes, if used. Capping materials

appearance of the cap when it is stripped. Fluid paste results in streaks in

the cap. Stiff paste results in thick caps.

TABLE 1 Compressive Strength and Maximum Thickness of

5.3 High-Strength Gypsum Cement Paste:

Capping Materials

5.3.1 No fillers or extenders may be added to neat high-

Cylinder Maximum Maximum

strength gypsum cement paste subsequent to the manufacture

Compressive Average Thickness

of the cement. (Note 5) Qualification tests shall be made to

Strength psi Minimum Strength of Capping Thickness Any Part

(MPa) Material of Cap of Cap

determine the effects of water-cement ratio and age on com-

1 5

500 to 7000 5000 psi (35 MPa) or cylinder ⁄4 in. ⁄16 in. pressive strength of 2 in. (50 mm) cubes. Retarders may be

psi (3.5 to strength whichever is greater (6 mm) (8 mm)

used to extend working time, but their effects on required

50 MPa)

water-cement ratio and strength must be determined. (Note 6)

1 3

greater than Compressive strength not less ⁄8 in. ⁄16 in.

7000 psi than (3 mm) (5 mm)

NOTE 5—Low-strength molding plaster, plaster of paris, or mixtures of

(50 MPa) cylinder strength, except as

plaster of paris and portland cement are unsuitable for capping.

provided in 5.1.1

NOTE 6—The water-gypsum cement ratio should be between 0.26 and

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 617

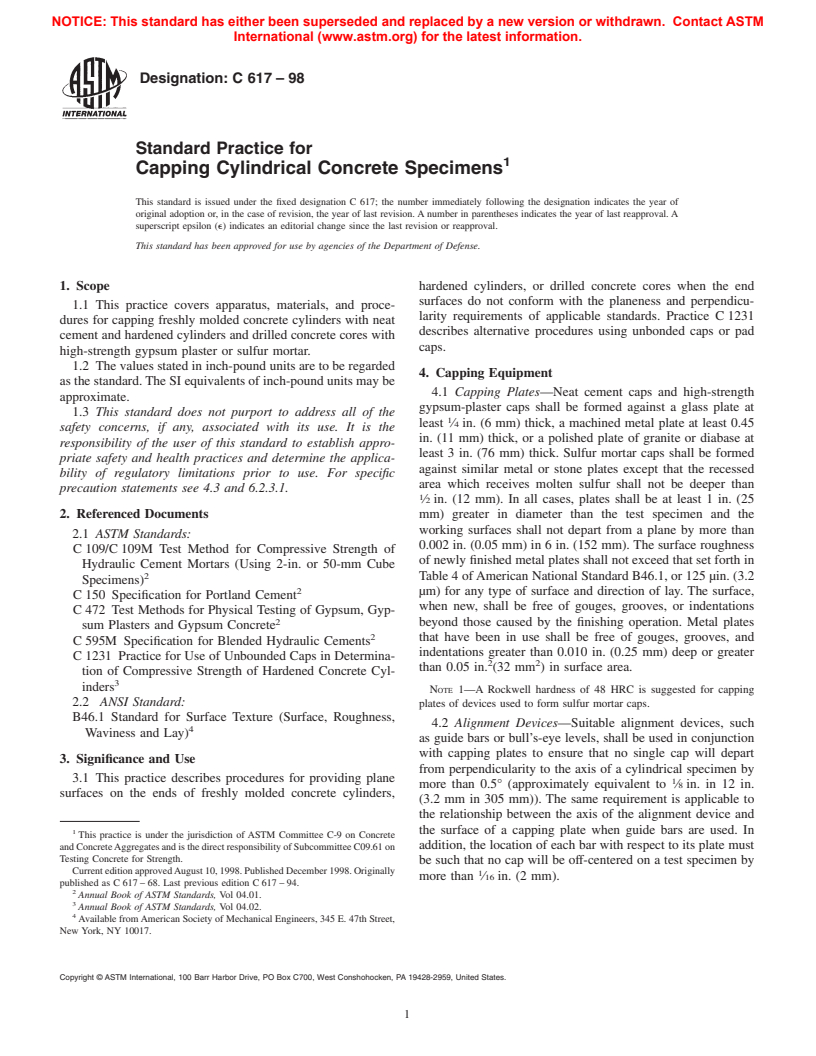

TABLE 2 Sample Report of Qualification of a Capping Material

NOTE—Manufacturer: Testing Supplies Co.

Capping Material: Super Strong AAA-Sulfor mortar

Lot: 12a45 Date Tested: 11/3/98

Signed by:______________________________ (testing agency and responsible official)

Capping

Item Material Control Cylinders Ratio Criteria Pass/Fail

Concrete Cylinder Test Data

Type of capping material Sulfur Ground

Average Concrete Strength, psi [MPa] 11 061 (76.2) 11 008 (75.9) 1.005 >0.98 Xc Pass

Standard Deviation, psi [MPa] 376 (2.59) 250 (1.72) 1.504 #1.57 C Pass

Number of cylinders tested 15 15

Cap age when cylinders tested 7 days na

Capping Material Test Data

Average cap thickness, in. [mm] 0.11 (2.8) na

Compressive strength of 2 in. [50 mm] cubes, psi (MPa) 12 195 (91)

Cube age when tested. 7 days

A

Maximum concrete strength qualified, psi (MPa) 1.2 Av. Str = 13 273 (91.5)

A

Nominally a specified strength of 11 000 psi (75 MPa) and perhaps somewhat higher.

0.30. Use of low water-cement ratios and vigorous mixing will usually

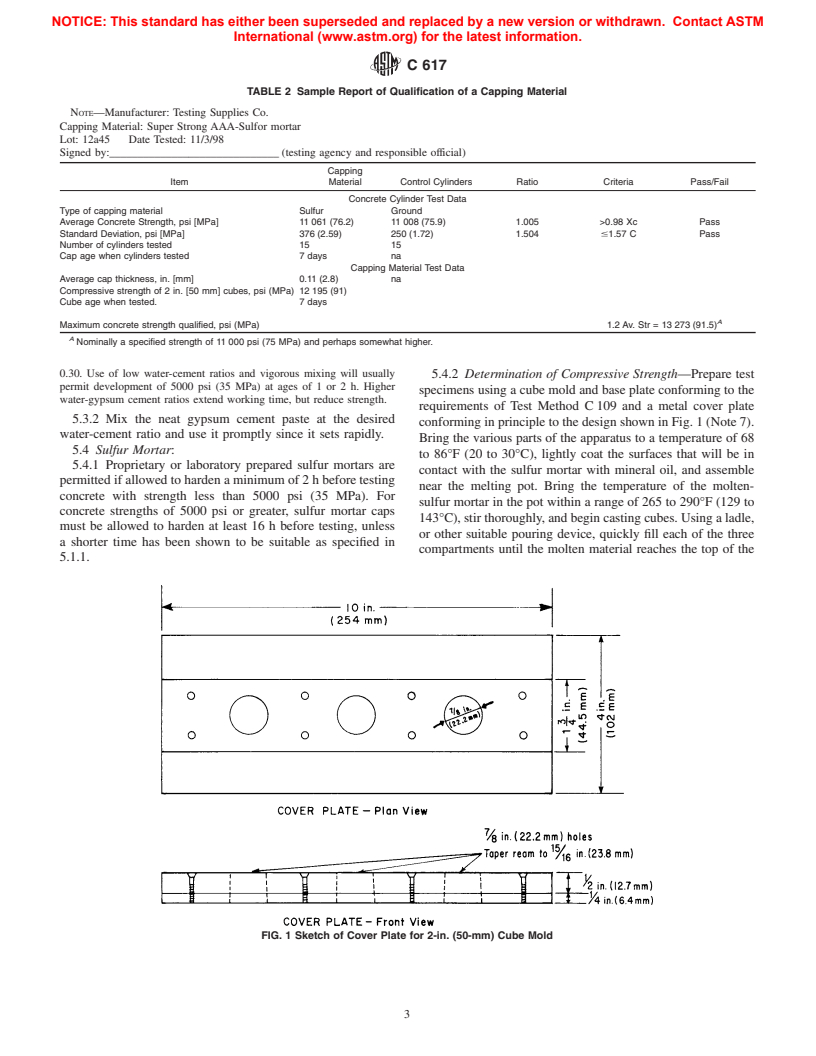

5.4.2 Determination of Compressive Strength—Prepare test

permit development of 5000 psi (35 MPa) at ages of 1 or 2 h. Higher

specimens using a cube mold and base plate conforming to the

water-gypsum cement ratios extend working time, but reduce strength.

requirements of Test Method C 109 and a metal cover plate

5.3.2 Mix the neat gypsum cement paste at the desired

conforming in principle to the design shown in Fig. 1 (Note 7).

water-cement ratio and use it promptly since it sets rapidly.

Bring the various parts of the apparatus to a temperature of 68

5.4 Sulfur Mortar:

to 86°F (20 to 30°C), lightly coat the surfaces that will be in

5.4.1 Proprietary or laboratory prepared sulfur mortars are

contact with the sulfur mortar with mineral oil, and assemble

permitted if allowed to harden a minimum of 2 h before testing

near the melting pot. Bring the temperature of the molten-

concrete with strength less than 5000 psi (35 MPa). For

sulfur mortar in the pot within a range of 265 to 290°F (129 to

concrete strengths of 5000 psi or greater, sulfur mortar caps

143°C), stir thoroughly, and begin casting cubes. Using a ladle,

must be allowed to harden at least 16 h before testing, unless

or other suitable pouring device, quickly fill each of the three

a shorter time has been shown to be suitable as specified in

compartments until the molten material reaches the top of the

5.1.1.

FIG. 1 Sketch of Cover Plate for 2-in. (50-mm) Cube Mold

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 617

filling hole.Allow sufficient time for maximum shrinkage, due 6.2.2 End Condition—The distance of any point on an

to cooling, and solidification to occur (approximately 15 min) uncapped end from a plane that passes through the highest

and refill each hole with molten material (Note 8). After

point of the end surface and is perpendicular to the axis of the

solidification is complete, remove the cubes from the mold cylinder shall not exceed ⁄8 in. (3 mm) (Note 11). If the end

without breaking off the knob formed by the filling hole in the

exceeds this limit, the end of the cylinder shall be cut, lapped

cover plate. Remove oil, sharp edges, and fins from the cubes

or ground prior to capping.

and check the planeness of the bearing surfaces in the manner

NOTE 11—This provision is to control the difference between the

described in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.