ASTM D6417-02

(Test Method)Standard Test Method for Estimation of Engine Oil Volatility by Capillary Gas Chromatography

Standard Test Method for Estimation of Engine Oil Volatility by Capillary Gas Chromatography

SCOPE

1.1 This test method covers an estimation of the amount of engine oil volatilized at 371°C (700°F).

1.1.1 This test method can also be used to estimate the amount of oil volatilized at any temperature between 126 and 371°C, if so desired.

1.2 This test method is limited to samples having an initial boiling point (IBP) greater than 126°C (259°F) or the first calibration point and to samples containing lubricant base oils with end points less than 615°C (1139°F) or the last n-paraffins in the calibration mixture. By using some instruments and columns, it is possible to extend the useful range of the test method.

1.3 This test method uses the principles of simulated distillation methodology.

1.4 This test method may be applied to both lubricant oil base stocks and finished lubricants containing additive packages. These additive packages generally contain high molecular weight, non-volatile components that do not elute from the chromatographic column under the test conditions. The calculation procedure used in this test method assumes that all of the sample elutes from the column and is detected with uniform response. This assumption is not true for samples with nonvolatile additives, and the results might be biased high relative to Test Method D 5480, which uses an internal standard to account for the uneluted material. For this reason, results by this test method are reported as area percent of oil.

1.5 The values stated in SI units are to be regarded as standard. The values stated in inch-pound units are provided for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 6417 – 02

Standard Test Method for

Estimation of Engine Oil Volatility by Capillary Gas

1

Chromatography

This standard is issued under the fixed designation D 6417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2887 Test Method for Boiling Range Distribution of

2

Petroleum Fractions by Gas Chromatography

1.1 This test method covers an estimation of the amount of

D 4626 Practice for Calculation of Gas Chromatographic

engine oil volatilized at 371°C (700°F).

3

Response Factors

1.1.1 This test method can also be used to estimate the

D 5480 Test Method for Motor Oil Volatility by Gas Chro-

amount of oil volatilized at any temperature between 126 and

4

matography

371°C, if so desired.

D 5800 Test Method for Evaporation Loss of Lubricating

1.2 This test method is limited to samples having an initial

4

Oils by the Noack Method

boiling point (IBP) greater than 126°C (259°F) or the first

E 355 Practice for Gas Chromatographic Terms and Rela-

calibration point and to samples containing lubricant base oils

5

tionships

with end points less than 615°C (1139°F) or the last n-paraffins

E 594 Practice for Testing Flame Ionization Detectors Used

in the calibration mixture. By using some instruments and

5

in Gas Chromatography

columns, it is possible to extend the useful range of the test

E 1510 Practice for Installing Fused Silica Open Tubular

method.

5

Capillary Columns in Gas Chromatographs

1.3 This test method uses the principles of simulated distil-

2.2 DIN Standard:

lation methodology.

6

DIN 51.581 Noack Evaporative Test

1.4 This test method may be applied to both lubricant oil

base stocks and finished lubricants containing additive pack-

3. Terminology

ages. These additive packages generally contain high molecu-

3.1 Definitions—This test method makes reference to many

lar weight, non-volatile components that do not elute from the

common gas chromatographic procedures, terms, and relation-

chromatographic column under the test conditions. The calcu-

ships. Detailed definitions of these can be found in Practices

lation procedure used in this test method assumes that all of the

E 355, E 594, and E 1510.

sample elutes from the column and is detected with uniform

3.2 Definitions of Terms Specific to This Standard:

response. This assumption is not true for samples with non-

3.2.1 area slice—the area resulting from the integration of

volatile additives, and the results might be biased high relative

the chromatographic detector signal within a specified reten-

to Test Method D 5480, which uses an internal standard to

tion time interval. In area slice mode (see 6.5.2), peak detection

account for the uneluted material. For this reason, results by

parameters are bypassed and the detector signal integral is

this test method are reported as area percent of oil.

recorded as area slices of consecutive, fixed duration time

1.5 The values stated in SI units are to be regarded as

intervals.

standard. The values stated in inch-pound units are provided

3.2.2 corrected area slice—an area slice corrected for base-

for information only.

line offset by subtraction of the exactly corresponding area

1.6 This standard does not purport to address all of the

slice in a previously recorded blank (nonsample) analysis.

safety concerns, if any, associated with its use. It is the

3.2.3 cumulative corrected area—the accumulated sum of

responsibility of the user of this standard to establish appro-

corrected area slices from the beginning of the analysis through

priate safety and health practices and determine the applica-

a given retention time (RT), ignoring any nonsample area (for

bility of regulatory limitations prior to use.

example, solvent).

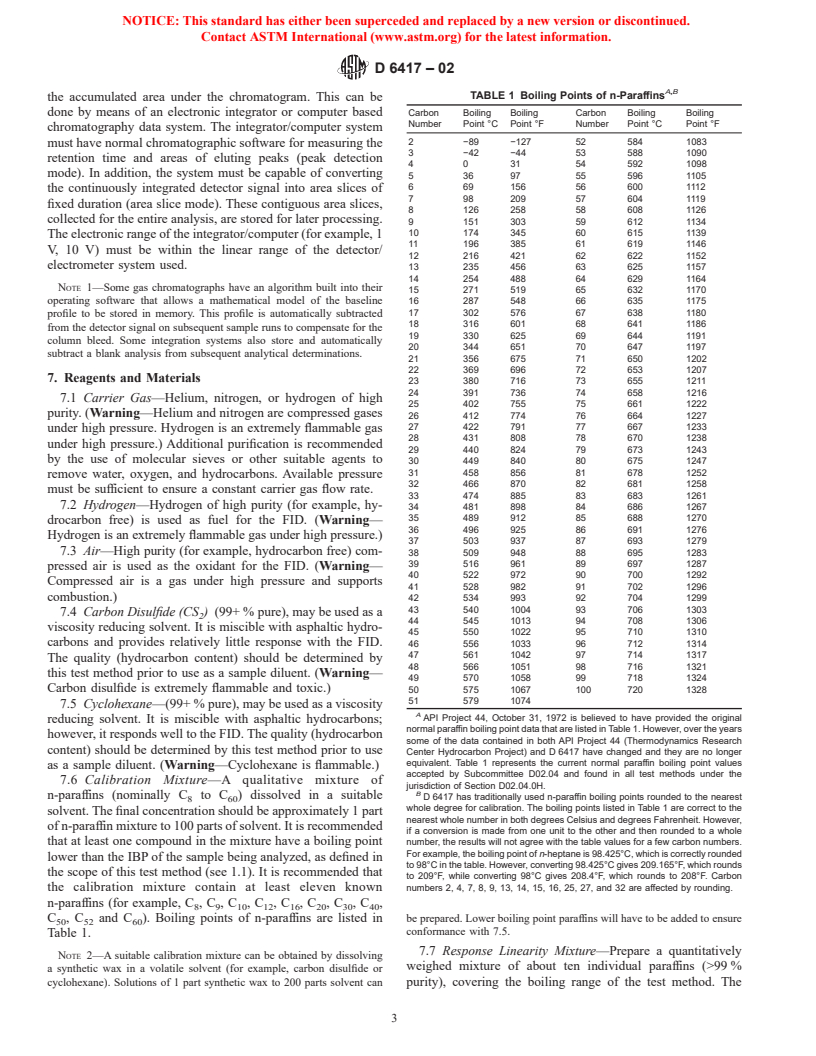

2. Referenced Documents 3.2.4 slice rate—the time interval used to integrate the

2.1 ASTM Standards:

2

Annual Book of ASTM Standards, Vol 05.01.

1 3

This test method is under the jurisdiction of ASTM Committee D02 on Annual Book of ASTM Standards, Vol 05.02.

4

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 05.03.

5

D02.04.0H on Chromatographic Distribution Methods. Annual Book of ASTM Standards, Vol 14.02.

6

Current edition approved Nov. 10, 2002. Published November 2002. Originally Published by Deutsches Institut für Normunge and available from Beuth

published as D 6417–99. Last previous edition D 6417–99. Verlag, GmbH, Burgqrafenstrasse 6, 1000 Berlin 30, Germany.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United St

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.