ASTM D129-18

(Test Method)Standard Test Method for Sulfur in Petroleum Products (General High Pressure Decomposition Device Method) (Withdrawn 2023)

Standard Test Method for Sulfur in Petroleum Products (General High Pressure Decomposition Device Method) (Withdrawn 2023)

ABSTRACT

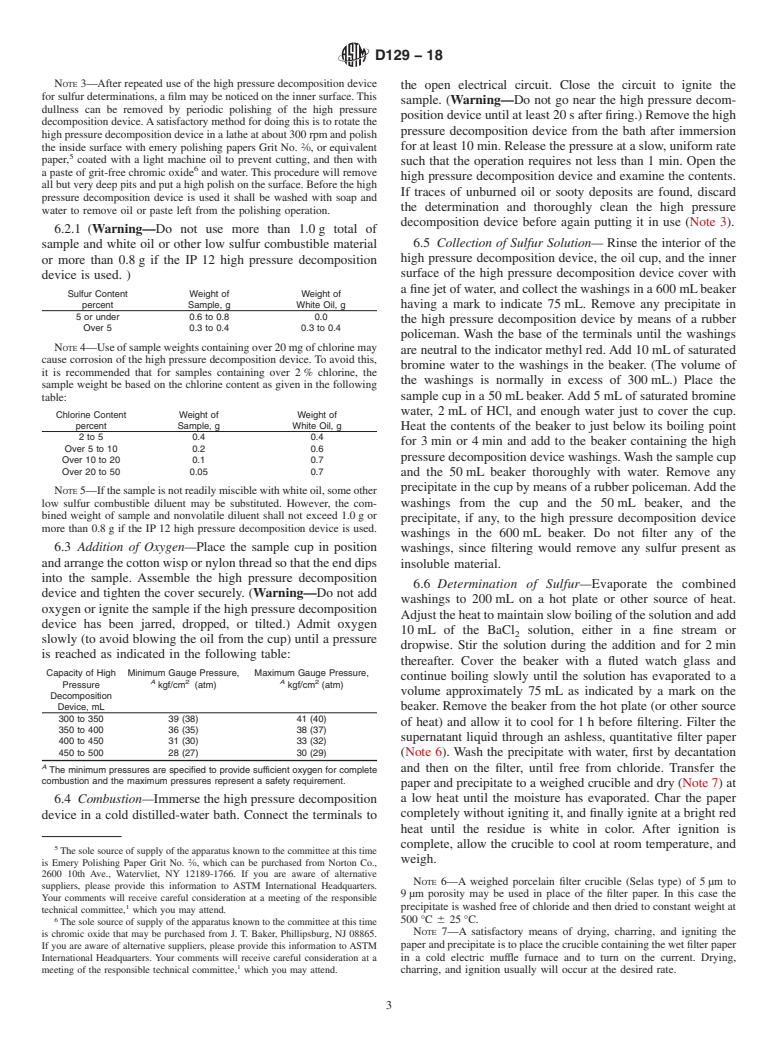

This standard details the general bomb test method for determination of the amount of sulfur in lubricating oils with additives, additive concentrates, lubricating greases, and other petroleum products with low volatilities. This test method entails oxidizing samples by combustion in a bomb containing oxygen under pressure. The amount of sulfur is determined by gravimetry. Materials needed for the test include a combustion bomb, sample cup, firing wire, ignition circuit, and a cotton wicking or nylon sewing thread. All reagents, samples, and other chemicals used for the test should conform to the required concentration and purity.

SCOPE

1.1 This test method covers the determination of sulfur in petroleum products, including lubricating oils containing additives, additive concentrates, and lubricating greases that cannot be burned completely in a wick lamp. The test method is applicable to any petroleum product sufficiently low in volatility that it can be weighed accurately in an open sample boat and containing at least 0.1 % sulfur.

Note 1: This test method is not applicable to samples containing elements that give residues, other than barium sulfate, which are insoluble in dilute hydrochloric acid and would interfere in the precipitation step. These interfering elements include iron, aluminum, calcium, silicon, and lead which are sometimes present in greases, lube oil additives, or additive oils. Other acid insoluble materials that interfere are silica, molybdenum disulfide, asbestos, mica, and so forth. The test method is not applicable to used oils containing wear metals, and lead or silicates from contamination. Samples that are excluded can be analyzed by Test Method D1552.

1.2 This test method is applicable to samples with the sulfur in the range 0.09 % to 5.5 % by mass.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

WITHDRAWN RATIONALE

This test method covered the determination of sulfur in petroleum products, including lubricating oils containing additives, additive concentrates, and lubricating greases that cannot be burned completely in a wick lamp. The test method was applicable to any petroleum product sufficiently low in volatility that it can be weighed accurately in an open sample boat and containing at least 0.1 % sulfur.

During its Test Method Revision Section Meeting held in Orlando, FL on December 06, 2022; D02.03 (Elemental Analysis) test methods that were thought to be obsolete or not being used by the petroleum community were considered. D129 was identified as possibly falling into one or both categories. D129 is a jointed test method with the Energy Institute’s test method IP 61. Energy Institute members/leadership responsible for IP 61 were contacted and agreement was found. Accordingly, this standard was balloted for withdrawal with no replacement.

D129 (first approved in 1922) is a test method with a limited scope for total sulfur in the 0.09 % to 5.5 % by mass range. The summary of the test method informs that the sample is oxidized by combustion in a high pressure decomposition device containing oxygen under pressure. The sulfur, as sulfate in the high-pressure decomposition device washings, is determined gravimetrically as barium sulfate. A suitable warning is...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D129 − 18 British Standard 4454

Designation: 61/99

Standard Test Method for

Sulfur in Petroleum Products (General High Pressure

1

Decomposition Device Method)

This standard is issued under the fixed designation D129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method covers the determination of sulfur in

petroleum products, including lubricating oils containing

2. Referenced Documents

additives, additive concentrates, and lubricating greases that

2

2.1 ASTM Standards:

cannot be burned completely in a wick lamp. The test method

D1193 Specification for Reagent Water

is applicable to any petroleum product sufficiently low in

D1552 Test Method for Sulfur in Petroleum Products by

volatility that it can be weighed accurately in an open sample

High Temperature Combustion and Infrared (IR) Detec-

boat and containing at least 0.1 % sulfur.

tion or Thermal Conductivity Detection (TCD)

NOTE 1—This test method is not applicable to samples containing

D4057 Practice for Manual Sampling of Petroleum and

elements that give residues, other than barium sulfate, which are insoluble

Petroleum Products

in dilute hydrochloric acid and would interfere in the precipitation step.

D4177 Practice for Automatic Sampling of Petroleum and

These interfering elements include iron, aluminum, calcium, silicon, and

leadwhicharesometimespresentingreases,lubeoiladditives,oradditive Petroleum Products

oils. Other acid insoluble materials that interfere are silica, molybdenum

D6299 Practice for Applying Statistical Quality Assurance

disulfide,asbestos,mica,andsoforth.Thetestmethodisnotapplicable to

and Control Charting Techniques to Evaluate Analytical

usedoilscontainingwearmetals,andleadorsilicatesfromcontamination.

Measurement System Performance

Samples that are excluded can be analyzed by Test Method D1552.

E144 Practice for Safe Use of Oxygen Combustion Vessels

1.2 This test method is applicable to samples with the sulfur

in the range 0.09 % to 5.5 % by mass.

3. Summary of Test Method

1.3 The values stated in SI units are to be regarded as

3.1 Thesampleisoxidizedbycombustioninahighpressure

standard. No other units of measurement are included in this

decomposition device containing oxygen under pressure. The

standard.

sulfur, as sulfate in the high pressure decomposition device

1.4 This standard does not purport to address all of the

washings, is determined gravimetrically as barium sulfate.

safety concerns, if any, associated with its use. It is the

3.2 (Warning—Strict adherence to all of the provisions

responsibility of the user of this standard to establish appro-

prescribed hereafter ensures against explosive rupture of the

priate safety, health, and environmental practices and deter-

high pressure decomposition device, or a blow-out, provided

mine the applicability of regulatory limitations prior to use.

the high pressure decomposition device is of proper design and

1.5 This international standard was developed in accor-

construction and in good mechanical condition. It is desirable,

dance with internationally recognized principles on standard-

however, that the high pressure decomposition device be

ization established in the Decision on Principles for the

enclosed in a shield of steel plate at least 13 mm thick, or

Development of International Standards, Guides and Recom-

equivalent protection be provided against unforeseeable con-

tingencies.)

1

This test method is under the jurisdiction of ASTM Committee D02 on

3.3 (Warning—Initial testing and periodic examination of

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

the pressure vessel is essential to ensure its fitness for service.

Subcommittee D02.03 on Elemental Analysis.

Current edition approved April 1, 2018. Published April 2018. Originally

approved in 1922. Last previous edition approved in 2013 as D129 – 13. DOI:

2

10.1520/D0129-18. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method was adopted as a joint ASTM-IP standard in 1964. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

In the IP, this test method is under the jurisdiction of the Standardization Standards volume information, refer to the stan

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D129 − 13 D129 − 18 British Standard 4454

Designation: 61/99

Standard Test Method for

Sulfur in Petroleum Products (General High Pressure

1

Decomposition Device Method)

This standard is issued under the fixed designation D129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the determination of sulfur in petroleum products, including lubricating oils containing additives,

additive concentrates, and lubricating greases that cannot be burned completely in a wick lamp. The test method is applicable to

any petroleum product sufficiently low in volatility that it can be weighed accurately in an open sample boat and containing at least

0.1 % sulfur.

NOTE 1—This test method is not applicable to samples containing elements that give residues, other than barium sulfate, which are insoluble in dilute

hydrochloric acid and would interfere in the precipitation step. These interfering elements include iron, aluminum, calcium, silicon, and lead which are

sometimes present in greases, lube oil additives, or additive oils. Other acid insoluble materials that interfere are silica, molybdenum disulfide, asbestos,

mica, and so forth. The test method is not applicable to used oils containing wear metals, and lead or silicates from contamination. Samples that are

excluded can be analyzed by Test Method D1552.

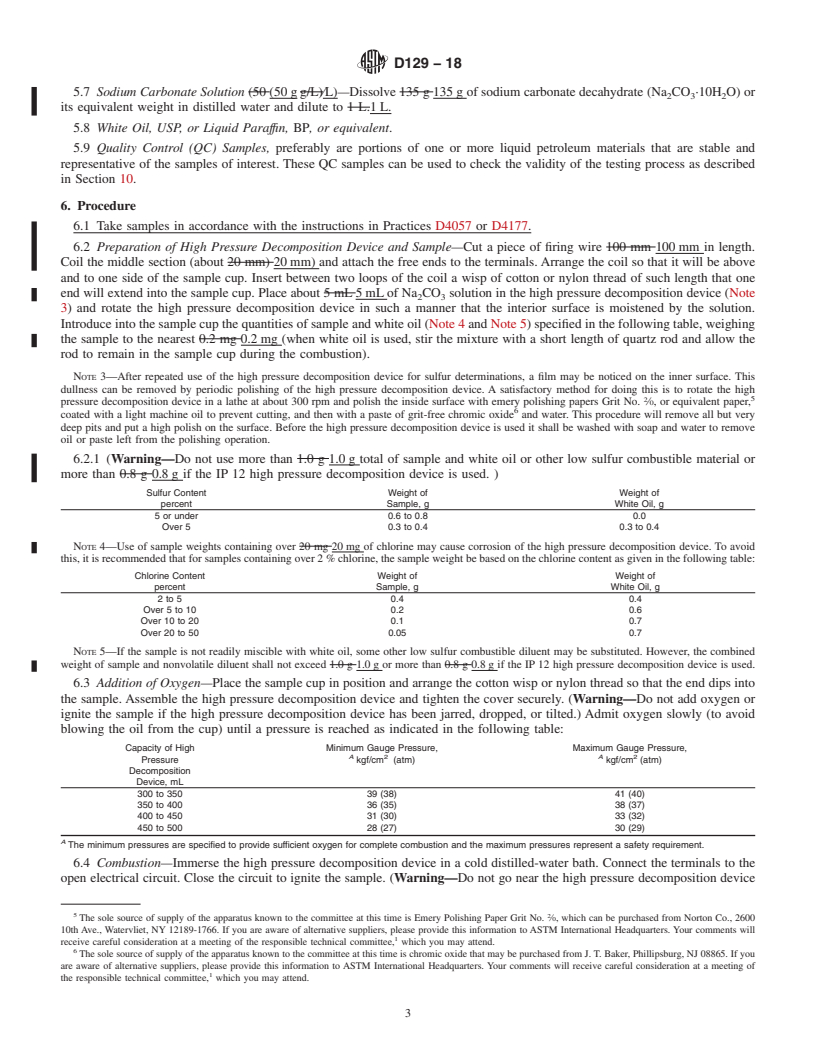

1.2 This test method is applicable to samples with the sulfur in the range 0.09 to 5.5 mass %.0.09 % to 5.5 % by mass.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1552 Test Method for Sulfur in Petroleum Products by High Temperature Combustion and Infrared (IR) Detection or Thermal

Conductivity Detection (TCD)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

E144 Practice for Safe Use of Oxygen Combustion Vessels

3. Summary of Test Method

3.1 The sample is oxidized by combustion in a high pressure decomposition device containing oxygen under pressure. The

sulfur, as sulfate in the high pressure decomposition device washings, is determined gravimetrically as barium sulfate.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved June 15, 2013April 1, 2018. Published August 2013April 2018. Originally approved in 1922. Last previous edition approved in 20112013 as

D129 – 11.D129 – 13. DOI: 10.1520/D0129-13.10.1520/D0129-18.

This test method was adopted as a joint ASTM-IP standard in 1964.

In the IP, this test method is under the jurisdiction of the Standardization Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D129 − 18

3.2 (Warning—Strict adherence to all of the pro

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D129 − 18 British Standard 4454

Designation: 61/99

Standard Test Method for

Sulfur in Petroleum Products (General High Pressure

1

Decomposition Device Method)

This standard is issued under the fixed designation D129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method covers the determination of sulfur in

petroleum products, including lubricating oils containing

2. Referenced Documents

additives, additive concentrates, and lubricating greases that

2

2.1 ASTM Standards:

cannot be burned completely in a wick lamp. The test method

D1193 Specification for Reagent Water

is applicable to any petroleum product sufficiently low in

D1552 Test Method for Sulfur in Petroleum Products by

volatility that it can be weighed accurately in an open sample

High Temperature Combustion and Infrared (IR) Detec-

boat and containing at least 0.1 % sulfur.

tion or Thermal Conductivity Detection (TCD)

NOTE 1—This test method is not applicable to samples containing

D4057 Practice for Manual Sampling of Petroleum and

elements that give residues, other than barium sulfate, which are insoluble

Petroleum Products

in dilute hydrochloric acid and would interfere in the precipitation step.

D4177 Practice for Automatic Sampling of Petroleum and

These interfering elements include iron, aluminum, calcium, silicon, and

lead which are sometimes present in greases, lube oil additives, or additive

Petroleum Products

oils. Other acid insoluble materials that interfere are silica, molybdenum

D6299 Practice for Applying Statistical Quality Assurance

disulfide, asbestos, mica, and so forth. The test method is not applicable to

and Control Charting Techniques to Evaluate Analytical

used oils containing wear metals, and lead or silicates from contamination.

Measurement System Performance

Samples that are excluded can be analyzed by Test Method D1552.

E144 Practice for Safe Use of Oxygen Combustion Vessels

1.2 This test method is applicable to samples with the sulfur

in the range 0.09 % to 5.5 % by mass.

3. Summary of Test Method

1.3 The values stated in SI units are to be regarded as

3.1 The sample is oxidized by combustion in a high pressure

standard. No other units of measurement are included in this

decomposition device containing oxygen under pressure. The

standard.

sulfur, as sulfate in the high pressure decomposition device

1.4 This standard does not purport to address all of the washings, is determined gravimetrically as barium sulfate.

safety concerns, if any, associated with its use. It is the

3.2 (Warning—Strict adherence to all of the provisions

responsibility of the user of this standard to establish appro-

prescribed hereafter ensures against explosive rupture of the

priate safety, health, and environmental practices and deter-

high pressure decomposition device, or a blow-out, provided

mine the applicability of regulatory limitations prior to use.

the high pressure decomposition device is of proper design and

1.5 This international standard was developed in accor-

construction and in good mechanical condition. It is desirable,

dance with internationally recognized principles on standard-

however, that the high pressure decomposition device be

ization established in the Decision on Principles for the

enclosed in a shield of steel plate at least 13 mm thick, or

Development of International Standards, Guides and Recom-

equivalent protection be provided against unforeseeable con-

tingencies.)

1

This test method is under the jurisdiction of ASTM Committee D02 on

3.3 (Warning—Initial testing and periodic examination of

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

the pressure vessel is essential to ensure its fitness for service.

Subcommittee D02.03 on Elemental Analysis.

Current edition approved April 1, 2018. Published April 2018. Originally

approved in 1922. Last previous edition approved in 2013 as D129 – 13. DOI:

2

10.1520/D0129-18. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method was adopted as a joint ASTM-IP standard in 1964. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

In the IP, this test method is under the jurisdiction of the Standardization Standards volume information, refer to the standard’s Document Summary page on

Committee. the ASTM website.

*A Summary of Changes section appears at the end of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.