ASTM F19-64(2000)

(Test Method)Standard Test Method for Tension and Vacuum Testing Metallized Ceramic Seals

Standard Test Method for Tension and Vacuum Testing Metallized Ceramic Seals

SCOPE

1.1 This test method covers procedures for conducting tension and vacuum tests on metal-ceramic seals to determine the bond strength of brazed, metallized ceramics. This test method is not to be considered as an absolute tension test for the ceramic.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 19–64(Reapproved2000)

Standard Test Method for

Tension and Vacuum Testing Metallized Ceramic Seals

ThisstandardisissuedunderthefixeddesignationF19;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope grips are used, care shall be taken that the axis of the test

specimenisinalignmentwiththecenterlineofthetestmachine

1.1 This test method covers procedures for conducting

heads.

tension and vacuum tests on metal-ceramic seals to determine

the bond strength of brazed, metallized ceramics. This test

5. Preparation of Specimens

method is not to be considered as an absolute tension test for

5.1 Preparethetestspecimenbybrazingtogethertwopieces

the ceramic.

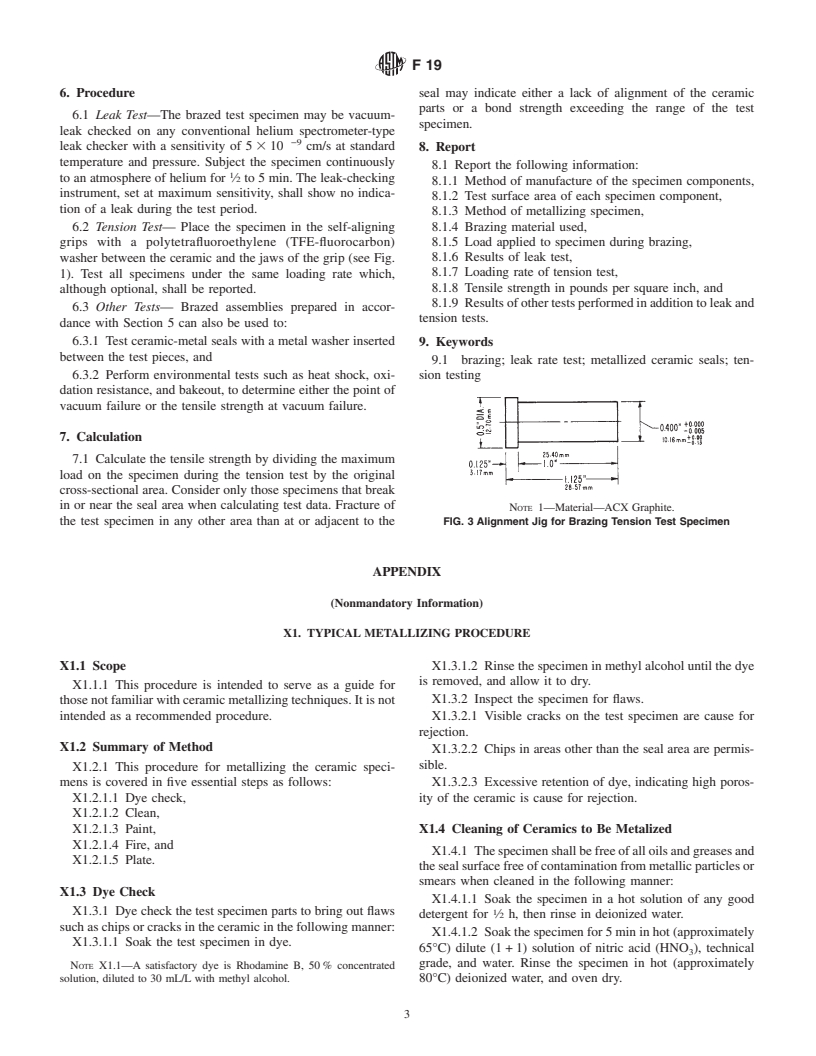

of ceramic, shown in Fig. 2, at their respective metalized

1.2 The values stated in inch-pound units are to be regarded

surfaces, as described in 5.1.1 to 5.1.3:

as the standard. The values given in parentheses are for

5.1.1 Ceramics—Grind the test surface, A, (Fig. 2) of the

information only.

two ceramic parts flat to within 0.00025 in. (0.0064 mm)

1.3 This standard does not purport to address all of the

according to good grinding practice using an abrasive passing

safety concerns, if any, associated with its use. It is the

or finer than a No. 100 (150-µm) sieve.The ground surface, A,

responsibility of the user of this standard to establish appro-

of each part shall be parallel to shoulder C, as shown in Fig. 2,

priate safety and health practices and determine the applica-

consistent with the best commercial practice. The over-all

bility of regulatory limitations prior to use.

appearance of each ceramic half of the test specimen shall

2. Referenced Documents indicate good commercial practice, and shall be free from

obvious defects. In the results of the test, report the method of

2.1 ASTM Standards:

manufacture of the specimen components, that is, slip cast,

E4 Practices for Force Verification of Testing Machines

hotpressed, hydrostatically molded, etc. Measure and record

E6 Terminology Relating to Methods of Mechanical Test-

the test surface area of each ceramic half on a projection

ing

comparator, or by other suitable means. Dye check the two

3. Terminology ceramic parts and inspect them for flaws (Note 1). Reject all

partsshowingflawsconsideredconducivetoabnormalfailures

3.1 Definitions:

of either ceramic part.

3.1.1 The definitions of terms relating to tension testing

appearing in Definitions E6, shall apply to the terms used in

NOTE 1—A suggested dye check procedure is described in the Appen-

this test method.

dix.

5.1.2 Metallized Coating—Metallize the specimen halves

4. Apparatus

under identical conditions, that is, temperature, atmosphere,

4.1 Testing Machines—Machines used for tension testing

etc. The type of metallizing used is optional, or as mutually

shall conform to the requirements of Methods E4. Only loads

agreed upon between producer and consumer. Apply the

that are within the loading range of the testing machine, as

metallizing coating only to the test surface A, Fig. 2, on the

defined in Methods E4, shall be used for determining tensile

specimen. The method of metallizing is optional, that is, silk

strengths.

screen, brush, spray, roller, etc., but should be reported.

4.2 Gripping Devices—Various types of gripping devices

NOTE 2—Atypical metallizing procedure is described in theAppendix.

may be used to apply the load to the test specimen. Those

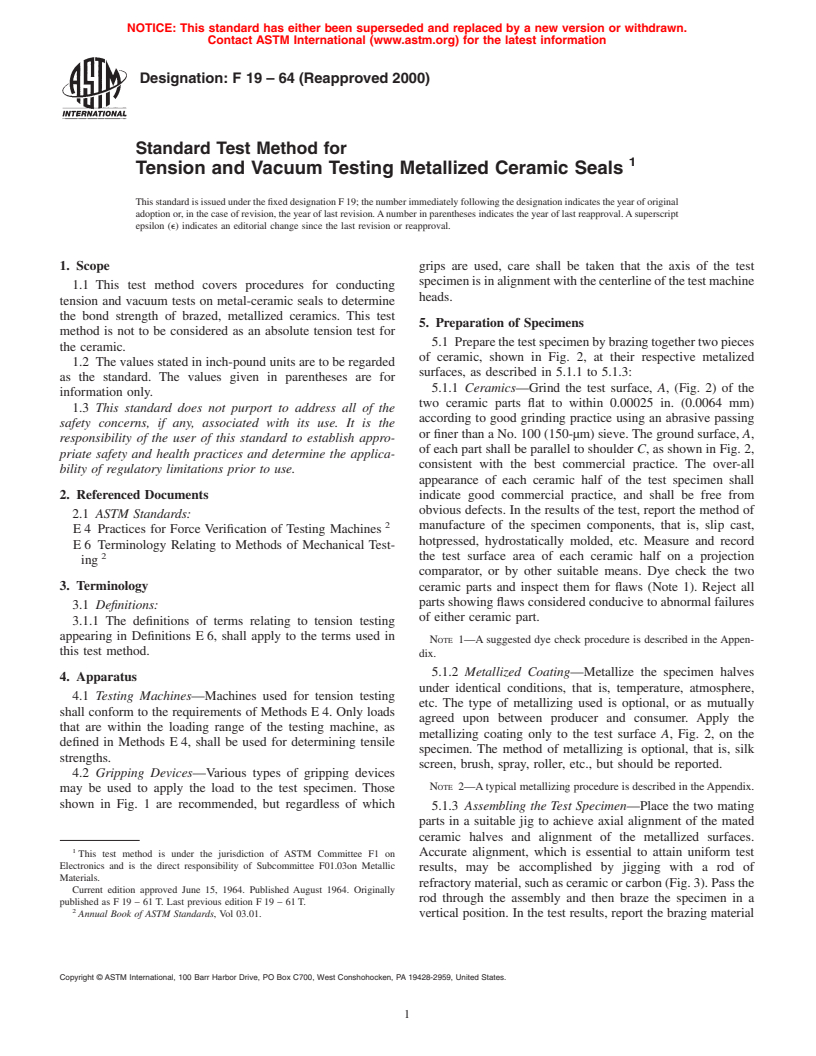

shown in Fig. 1 are recommended, but regardless of which

5.1.3 Assembling the Test Specimen—Place the two mating

parts in a suitable jig to achieve axial alignment of the mated

ceramic halves and alignment of the metallized surfaces.

Accurate alignment, which is essential to attain uniform test

This test method is under the jurisdiction of ASTM Committee F1 on

Electronics and is the direct responsibility of Subcommittee F01.03on Metallic

results, may be accomplished by jigging with a rod of

Materials.

refractorymaterial,suchasceramicorcarbon(Fig.3).Passthe

Current edition approved June 15, 1964. Published August 1964. Originally

rod through the assembly and then braze the specimen in a

published as F19 – 61T. Last previous edition F19 – 61T.

Annual Book of ASTM Standards, Vol 03.01. vertical position. In the test results, report the brazing material

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F19

NOTE 1—Tolerance on all dimensions shown, 60.016 in. (0.41 mm).

FIG. 1 Self Aligning Grip for Tension Test

A—Seal surface area to be metalized.

B—Surface inscribed with date as to ceramic batch and firing temperature.

C—Gripping shoulder.

FIG. 2 Ceramic Half of Tension Test Specimen

used; such as copper-silver eutectic, copper-gold alloy, 35 to the joint. Load the assembly to produce pressure on the seal

65%, etc. Use sufficient material to produce an even fillet at during the brazing operation and report the weight of the load.

F19

6. Procedure seal may indicate either a lack of alignment of the ceramic

parts or a bond strength exceeding the range of the test

6.1 Leak Test—The brazed test specimen may be vacuum-

specimen.

leak checked on any conventional helium spectrometer-type

−9

leak checker with a sensitivity of 5 310 cm/s at standard

8. Report

temperature and pressure. Subject the specimen continuously

8.1 Report the following information:

to an atmosphere of helium for ⁄2 to 5 min.The leak-checking

8.1.1 Method of manufacture of the specimen components,

instrument, set at maximum sensitivity, shall show no indica-

8.1.2 Test surface area of each specimen component,

tion of a leak during the test period.

8.1.3 Method of metallizing specimen,

8.1.4 Brazing material used,

6.2 Tension Test— Place the specimen in the self-aligning

grips with a polytetrafluoroethylene (TFE-fluorocarbon) 8.1.5 Load applied to specimen during brazing,

8.1.6 Results of leak test,

washer between the ceramic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.