ASTM D4742-16

(Test Method)Standard Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT)

Standard Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT)

SIGNIFICANCE AND USE

5.1 This test method is used to evaluate oxidation stability of lubricating base oils with additives in the presence of chemistries similar to those found in gasoline engine service. Test results on some ASTM reference oils have been found to correlate with sequence IIID engine test results in hours for a 375 % viscosity increase.3 The test does not constitute a substitute for engine testing, which measures wear, oxidation stability, volatility, and deposit control characteristics of lubricants. Properly interpreted, the test may provide input on the oxidation stability of lubricants under simulated engine chemistry.

5.2 This test method is intended to be used as a bench screening test and quality control tool for lubricating base oil manufacturing, especially for re-refined lubricating base oils. This test method is useful for quality control of oxidation stability of re-refined oils from batch to batch.

5.3 This test method is useful for screening formulated oils prior to engine tests. Within similar additive chemistry and base oil types, the ranking of oils in this test appears to be predictive of ranking in engine tests. When oils having completely different additive chemistry or base oil type are compared, oxidation stability results may not reflect the actual engine test result.

5.4 Other oxidation stability test methods have demonstrated that soluble metal catalyst supplies are very inconsistent and they have significant effects on the test results. Thus, for test comparisons, the same source and same batch of metal naphthenates shall be used.

Note 2: It is also recommended as a good research practice not to use different batches of the fuel component in test comparisons.

SCOPE

1.1 This test method evaluates the oxidation stability of engine oils for gasoline automotive engines. This test, run at 160 °C, utilizes a high pressure reactor pressurized with oxygen along with a metal catalyst package, a fuel catalyst, and water in a partial simulation of the conditions to which an oil may be subjected in a gasoline combustion engine. This test method can be used for engine oils with viscosity in the range from 4 mm2/s (cSt) to 21 mm2/s (cSt) at 100 °C, including re-refined oils.

1.2 This test method is not a substitute for the engine testing of an engine oil in established engine tests, such as Sequence IIID.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Pressure units are provided in psig, and dimensions are provided in inches in Annex A1, because these are the industry accepted standard and the apparatus is built according to the figures shown.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Sections 7 and 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4742 − 16

Standard Test Method for

Oxidation Stability of Gasoline Automotive Engine Oils by

1

Thin-Film Oxygen Uptake (TFOUT)

This standard is issued under the fixed designation D4742; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B211 Specification for Aluminum and Aluminum-Alloy

Rolled or Cold Finished Bar, Rod, and Wire

1.1 This test method evaluates the oxidation stability of

D664 Test Method for Acid Number of Petroleum Products

engine oils for gasoline automotive engines. This test, run at

by Potentiometric Titration

160 °C, utilizes a high pressure reactor pressurized with

D1193 Specification for Reagent Water

oxygenalongwithametalcatalystpackage,afuelcatalyst,and

D2272 Test Method for Oxidation Stability of Steam Tur-

water in a partial simulation of the conditions to which an oil

bine Oils by Rotating Pressure Vessel

may be subjected in a gasoline combustion engine. This test

D4057 Practice for Manual Sampling of Petroleum and

method can be used for engine oils with viscosity in the range

2 2 Petroleum Products

from 4 mm /s (cSt) to 21 mm /s (cSt) at 100 °C, including

E1 Specification for ASTM Liquid-in-Glass Thermometers

re-refined oils.

1.2 Thistestmethodisnotasubstitutefortheenginetesting

3. Terminology

of an engine oil in established engine tests, such as Sequence

3.1 Definitions of Terms Specific to This Standard:

IIID.

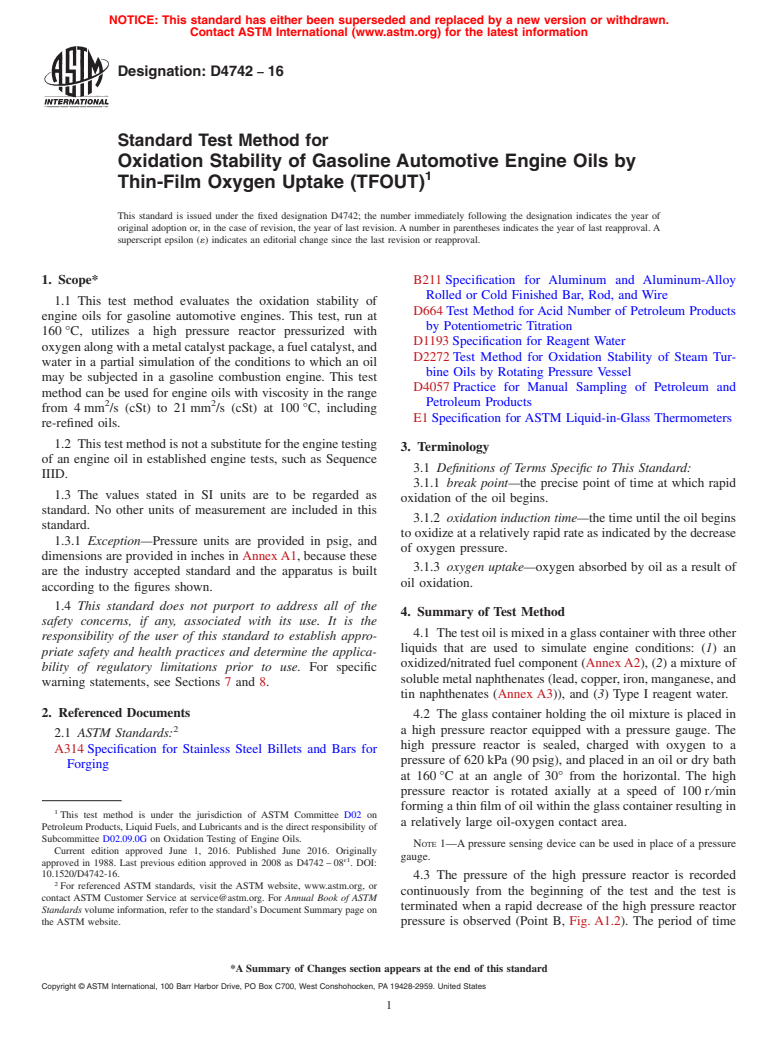

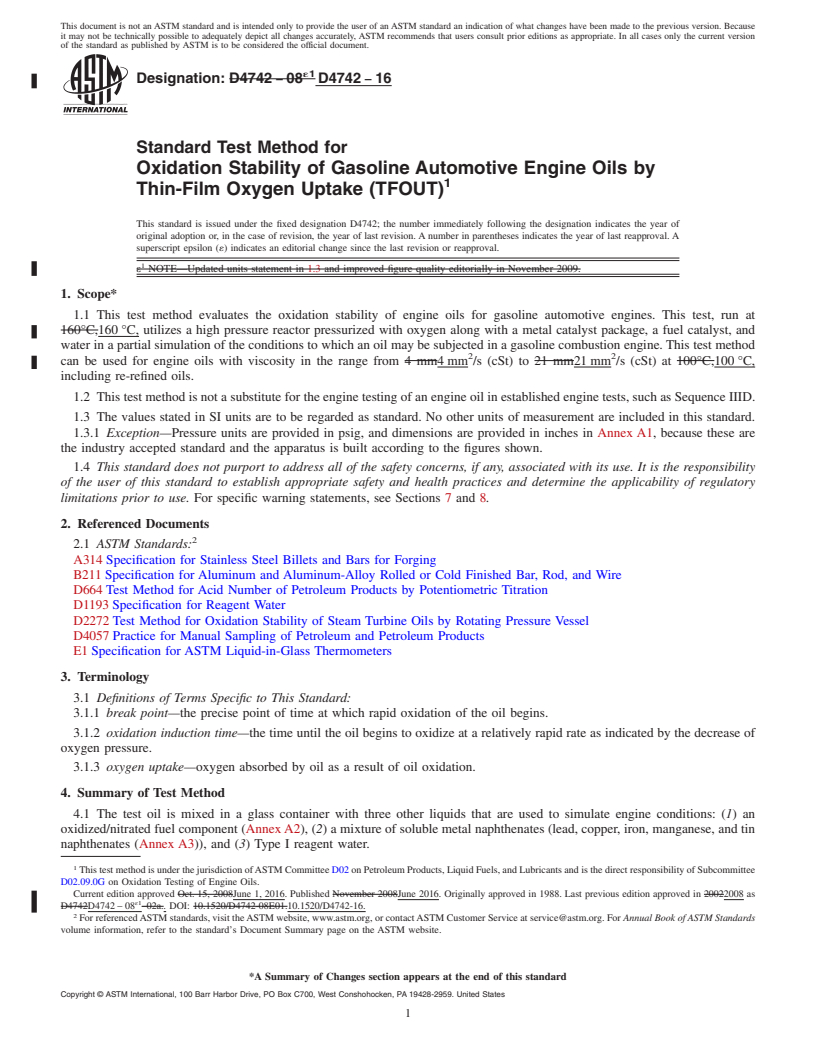

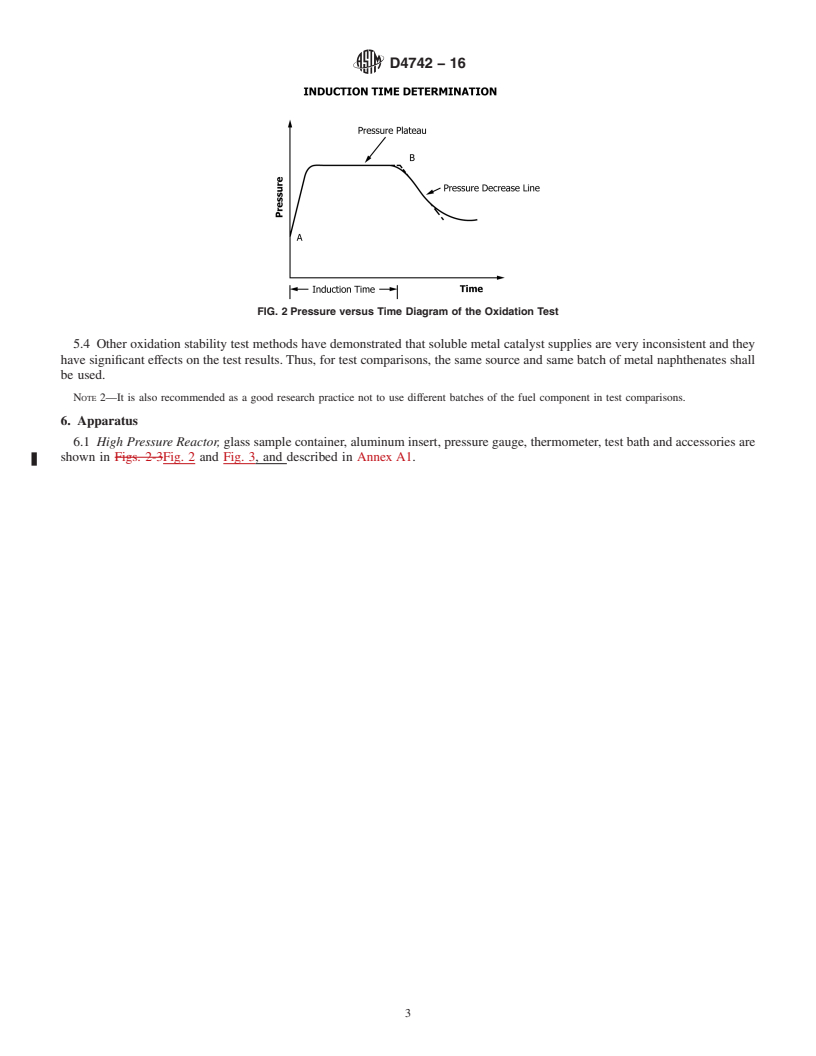

3.1.1 break point—the precise point of time at which rapid

1.3 The values stated in SI units are to be regarded as

oxidation of the oil begins.

standard. No other units of measurement are included in this

3.1.2 oxidation induction time—the time until the oil begins

standard.

to oxidize at a relatively rapid rate as indicated by the decrease

1.3.1 Exception—Pressure units are provided in psig, and

of oxygen pressure.

dimensions are provided in inches in AnnexA1, because these

3.1.3 oxygen uptake—oxygen absorbed by oil as a result of

are the industry accepted standard and the apparatus is built

oil oxidation.

according to the figures shown.

1.4 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 Thetestoilismixedinaglasscontainerwiththreeother

responsibility of the user of this standard to establish appro-

liquids that are used to simulate engine conditions: (1)an

priate safety and health practices and determine the applica-

oxidized/nitrated fuel component (AnnexA2), (2) a mixture of

bility of regulatory limitations prior to use. For specific

soluble metal naphthenates (lead, copper, iron, manganese,and

warning statements, see Sections 7 and 8.

tin naphthenates (Annex A3)), and (3) Type I reagent water.

2. Referenced Documents

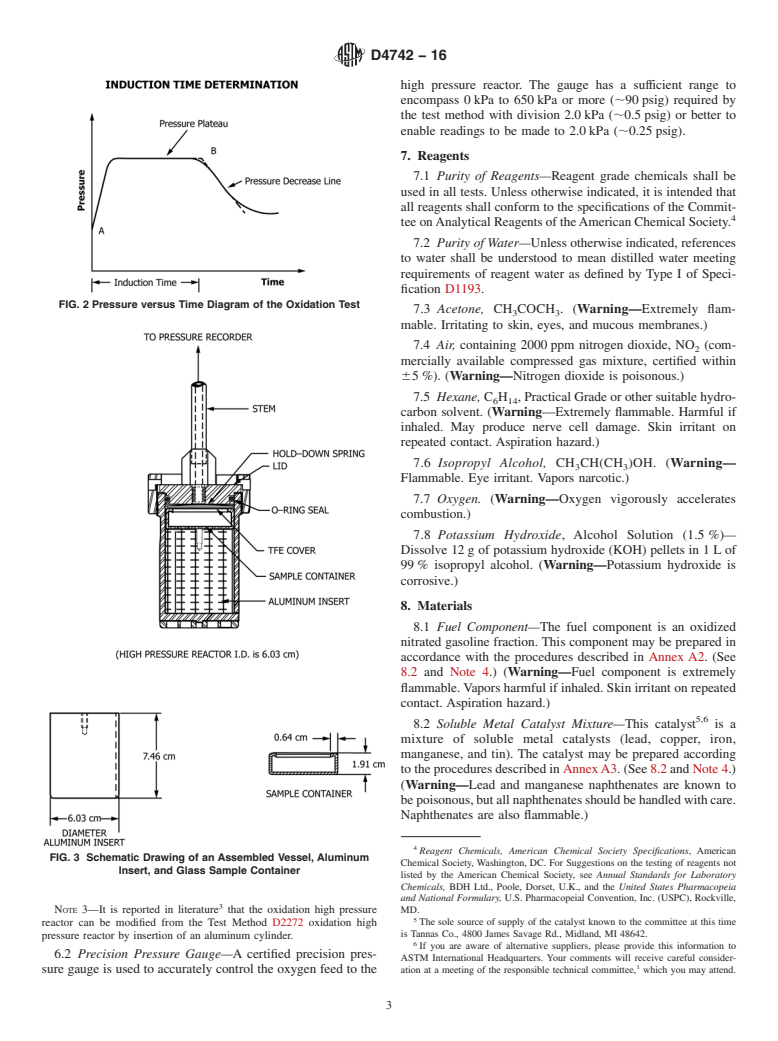

4.2 The glass container holding the oil mixture is placed in

2

a high pressure reactor equipped with a pressure gauge. The

2.1 ASTM Standards:

high pressure reactor is sealed, charged with oxygen to a

A314 Specification for Stainless Steel Billets and Bars for

pressure of 620 kPa (90 psig), and placed in an oil or dry bath

Forging

at 160 °C at an angle of 30° from the horizontal. The high

pressure reactor is rotated axially at a speed of 100 r⁄min

forming a thin film of oil within the glass container resulting in

1

This test method is under the jurisdiction of ASTM Committee D02 on

a relatively large oil-oxygen contact area.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.09.0G on Oxidation Testing of Engine Oils.

NOTE 1—A pressure sensing device can be used in place of a pressure

Current edition approved June 1, 2016. Published June 2016. Originally

gauge.

ɛ1

approved in 1988. Last previous edition approved in 2008 as D4742 – 08 . DOI:

10.1520/D4742-16.

4.3 The pressure of the high pressure reactor is recorded

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

continuously from the beginning of the test and the test is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

terminated when a rapid decrease of the high pressure reactor

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. pressure is observed (Point B, Fig. A1.2). The period of time

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4742 − 16

FIG. 1 Schematic Drawing of Oxidation Test Apparatus

that elapses between the time when the high pressure rea

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4742 − 08 D4742 − 16

Standard Test Method for

Oxidation Stability of Gasoline Automotive Engine Oils by

1

Thin-Film Oxygen Uptake (TFOUT)

This standard is issued under the fixed designation D4742; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Updated units statement in 1.3 and improved figure quality editorially in November 2009.

1. Scope*

1.1 This test method evaluates the oxidation stability of engine oils for gasoline automotive engines. This test, run at

160°C,160 °C, utilizes a high pressure reactor pressurized with oxygen along with a metal catalyst package, a fuel catalyst, and

water in a partial simulation of the conditions to which an oil may be subjected in a gasoline combustion engine. This test method

2 2

can be used for engine oils with viscosity in the range from 4 mm4 mm /s (cSt) to 21 mm21 mm /s (cSt) at 100°C,100 °C,

including re-refined oils.

1.2 This test method is not a substitute for the engine testing of an engine oil in established engine tests, such as Sequence IIID.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Pressure units are provided in psig, and dimensions are provided in inches in Annex A1, because these are

the industry accepted standard and the apparatus is built according to the figures shown.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see Sections 7 and 8.

2. Referenced Documents

2

2.1 ASTM Standards:

A314 Specification for Stainless Steel Billets and Bars for Forging

B211 Specification for Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod, and Wire

D664 Test Method for Acid Number of Petroleum Products by Potentiometric Titration

D1193 Specification for Reagent Water

D2272 Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 break point—the precise point of time at which rapid oxidation of the oil begins.

3.1.2 oxidation induction time—the time until the oil begins to oxidize at a relatively rapid rate as indicated by the decrease of

oxygen pressure.

3.1.3 oxygen uptake—oxygen absorbed by oil as a result of oil oxidation.

4. Summary of Test Method

4.1 The test oil is mixed in a glass container with three other liquids that are used to simulate engine conditions: (1) an

oxidized/nitrated fuel component (Annex A2), (2) a mixture of soluble metal naphthenates (lead, copper, iron, manganese, and tin

naphthenates (Annex A3)), and (3) Type I reagent water.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.09.0G on Oxidation Testing of Engine Oils.

Current edition approved Oct. 15, 2008June 1, 2016. Published November 2008June 2016. Originally approved in 1988. Last previous edition approved in 20022008 as

ɛ1

D4742D4742 – 08 –02a. DOI: 10.1520/D4742-08E01.10.1520/D4742-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4742 − 16

FIG. 1 Schematic Drawing of Oxidation Test Apparatus

4.2 The glass container holding the oil mixture is placed in a high pressure reactor equipped with a pressure gauge. The high

pressure reactor is sealed, charged with oxygen to a pressure of 620 kPa (90 psig), 620 kPa (90 psig), and placed in an oil or dry

bath at 160°C160 °C at an angle of 30° from the horizontal. The high pressure reactor is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.