ASTM D7078/D7078M-05

(Test Method)Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method

Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method

SIGNIFICANCE AND USE

This shear test is designed to produce shear property data for material specifications, research and development, quality assurance, and structural design and analysis. Either in-plane or interlaminar shear properties may be evaluated, depending upon the orientation of the material coordinate system relative to the loading axis. Factors that influence the shear response and should therefore be reported include: material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement.

In anisotropic materials, properties may be obtained in any of the six possible shear planes by orienting the testing plane of the specimen with the desired material plane (1-2 or 2-1, 1-3 or 3-1, 2-3 or 3-2). Only a single shear plane may be evaluated for any given specimen. Properties, in the test direction, which may be obtained from this test method, include the following:

5.2.1 Shear stress versus engineering shear strain response,

5.2.2 Ultimate shear strength,

5.2.3 Ultimate engineering shear strain,

5.2.4 Shear chord modulus of elasticity,

5.2.5 Transition strain.

SCOPE

1.1 This test method covers the determination of the shear properties of high-modulus fiber-reinforced composite materials by clamping the ends of a V-notched specimen between two pairs of loading rails. When loaded in tension, the rails introduce shear forces into the specimen through the specimen faces. In comparison, the specimen of Test Method D 5379/D 5379M is loaded through its top and bottom edges. Face loading allows higher shear forces to be applied to the specimen, if required. Additionally, the present test method utilizes a specimen with a larger gage section than the V-notched specimen of Test Method D 5379/D 5379M. In both test methods, the use of a V-notched specimen increases the gage section shear stresses in relation to the shear stresses in the vicinity of the grips, thus localizing the failure within the gage section while causing the shear stress distribution to be more uniform than in a specimen without notches. In comparison, Test Method D 4255/D 4255M utilizes an unnotched specimen clamped between two pairs of loading rails that are loaded in tension. Also in contrast to Test Method D 4255/D 4255M, the present test method provides specimen gripping without the need for holes in the specimen.

The composite materials are limited to continuous-fiber or discontinuous-fiber-reinforced composites in the following material forms:

1.1.1 Laminates composed only of unidirectional fibrous laminae, with the fiber direction oriented either parallel or perpendicular to the fixture rails.

1.1.2 Laminates of balanced and symmetric construction, with the 0 direction oriented either parallel or perpendicular to the fixture rails.

1.1.3 Laminates composed of woven, braided, or knitted fabric filamentary laminae.

1.1.4 Short-fiber-reinforced composites with a majority of the fibers being randomly distributed.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7078/D7078M − 05

StandardTest Method for

Shear Properties of Composite Materials by V-Notched Rail

Shear Method

This standard is issued under the fixed designation D7078/D7078M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope inch-pound units are shown in brackets. The values stated in

each system are not exact equivalents; therefore, each system

1.1 This test method covers the determination of the shear

must be used independently of the other. Combining values

properties of high-modulus fiber-reinforced composite materi-

from the two systems may result in nonconformance with the

alsbyclampingtheendsofaV-notchedspecimenbetweentwo

standard.

pairs of loading rails. When loaded in tension, the rails

1.3 This standard does not purport to address all of the

introduce shear forces into the specimen through the specimen

safety concerns, if any, associated with its use. It is the

faces. In comparison, the specimen of Test Method D5379/

responsibility of the user of this standard to establish appro-

D5379M is loaded through its top and bottom edges. Face

priate safety and health practices and determine the applica-

loading allows higher shear forces to be applied to the

bility of regulatory limitations prior to use.

specimen, if required. Additionally, the present test method

utilizes a specimen with a larger gage section than the

2. Referenced Documents

V-notched specimen of Test Method D5379/D5379M. In both

test methods, the use of a V-notched specimen increases the

2.1 ASTM Standards:

gage section shear stresses in relation to the shear stresses in

D792Test Methods for Density and Specific Gravity (Rela-

the vicinity of the grips, thus localizing the failure within the

tive Density) of Plastics by Displacement

gage section while causing the shear stress distribution to be

D883Terminology Relating to Plastics

more uniform than in a specimen without notches. In

D2584Test Method for Ignition Loss of Cured Reinforced

comparison, Test Method D4255/D4255M utilizes an un-

Resins

notched specimen clamped between two pairs of loading rails

D2734TestMethodsforVoidContentofReinforcedPlastics

that are loaded in tension. Also in contrast to Test Method

D3171Test Methods for Constituent Content of Composite

D4255/D4255M, the present test method provides specimen

Materials

gripping without the need for holes in the specimen.

D3878Terminology for Composite Materials

The composite materials are limited to continuous-fiber or

D4255/D4255MTest Method for In-Plane Shear Properties

discontinuous-fiber-reinforcedcompositesinthefollowingma-

of Polymer Matrix Composite Materials by the Rail Shear

terial forms:

Method

1.1.1 Laminates composed only of unidirectional fibrous

D5229/D5229MTestMethodforMoistureAbsorptionProp-

laminae, with the fiber direction oriented either parallel or

erties and Equilibrium Conditioning of Polymer Matrix

perpendicular to the fixture rails.

Composite Materials

1.1.2 Laminates of balanced and symmetric construction,

D5379/D5379MTest Method for Shear Properties of Com-

withthe0°directionorientedeitherparallelorperpendicularto

posite Materials by the V-Notched Beam Method

the fixture rails.

D6856Guide for Testing Fabric-Reinforced “Textile” Com-

1.1.3 Laminates composed of woven, braided, or knitted

posite Materials

fabric filamentary laminae.

E4Practices for Force Verification of Testing Machines

1.1.4 Short-fiber-reinforced composites with a majority of

E6Terminology Relating to Methods of Mechanical Testing

the fibers being randomly distributed.

E111Test Method for Young’s Modulus, Tangent Modulus,

and Chord Modulus

1.2 The values stated in either SI units or inch-pound units

E122PracticeforCalculatingSampleSizetoEstimate,With

are to be regarded separately as standard. Within the text the

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Lamina and Laminate Test Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 15, 2005. Published August 2005. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7078_D7078M-05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7078/D7078M − 05

Specified Precision, the Average for a Characteristic of a

Lot or Process

E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

E251Test Methods for Performance Characteristics of Me-

tallic Bonded Resistance Strain Gauges

E456Terminology Relating to Quality and Statistics

E1237Guide for Installing Bonded Resistance Strain Gages

E1309 Guide for Identification of Fiber-Reinforced

Polymer-Matrix Composite Materials in Databases

E1434Guide for Recording Mechanical Test Data of Fiber-

Reinforced Composite Materials in Databases

2.2 Other Documents:

ANSI Y14.5M-1982 Geometric Dimensioning and Toler-

ancing

ANSI/ASME B 46.1-1985 Surface Texture (Surface

Roughness, Waviness, and Lay)

2.3 ASTM Adjuncts:

V-Notched Rail Shear Fixture Machining Drawings

FIG. 1 Material Coordinate System

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating

3.2.4.1 Discussion—The offset shear strength is a measure

to high-modulus fibers and their composites. Terminology

of the extent of material stress/strain linearity. (The material

D883definestermsrelatingtoplastics.TerminologyE6defines

non-linearityinthisdefinitionneitherassumesnorprohibitsthe

terms relating to mechanical testing. Terminology E456 and

presence of damage.) When comparing material offset

Practice E177 define terms relating to statistics. In the event of

strengths the same offset strain and modulus definition should

a conflict between terms, Terminology D3878 shall have

be used. For material comparison in the absence of evidence

precedence over the other terminology standards.

suggesting the use of more appropriate values, an offset strain

of 0.2% should be used with the standard chord modulus. A

NOTE 1—If the term represents a physical quantity, its analytical

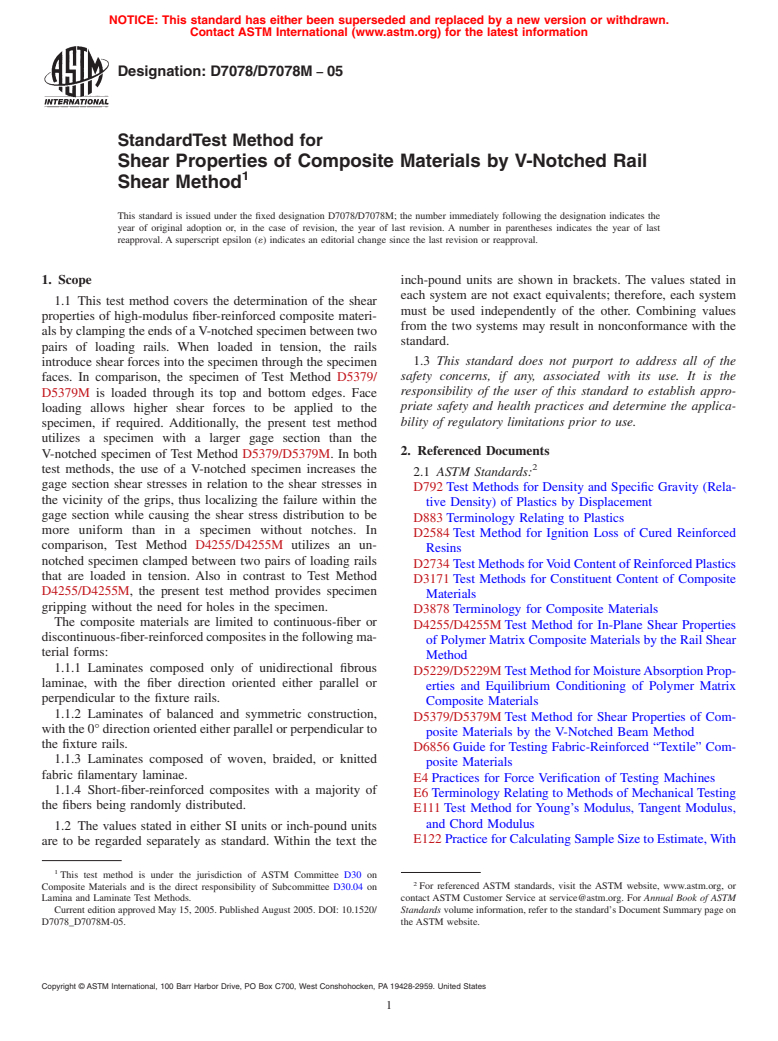

graphical example of offset shear strength is shown in Fig. 2.

dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

fundamental dimension form, using the following ASTM standard sym- For design, other offset strain and modulus definition combi-

bology for fundamental dimensions, shown within square brackets: [M]

nations may be more suitable for specific materials and

formass,[L]forlength,[T]fortime,[Θ]forthermodynamictemperature,

applications.

and [nd] for nondimensional quantities. Use of these symbols is restricted

to analytical dimensions when used with square brackets, as the symbols 3.2.5 shear strength [M/(LT )], n—the shear stress carried

may have other definitions when used without the brackets.

by a material at failure under a pure shear condition.

3.2 Definitions of Terms Specific to This Standard:

3.3 Symbols:

3.2.1 in-plane shear, n—shear associated with shear forces

A = cross-sectional area of a specimen

or deformation applied to the 1-2 material plane such that the

CV = coefficient of variation statistic of a sample

resultingsheardeformationsoccurintheplaneofthelaminate.

population for a given property (in percent)

(See also material coordinate system).

d = coupon width between notches

3.2.2 interlaminar shear, n—any of the shear properties

d = notch depth

describing the response resulting from a shear load or defor- su

F = ultimate shear strength in the test direction

mation applied to the 1-3 or 2-3 material planes. (See also u

F = ultimate strength in the test direction

material coordinate system).

F° (offset) = the value of the shear stress at the intersection

3.2.3 material coordinate system, n—a Cartesian coordinate of the shear chord modulus of elasticity and

system describing the principal material coordinate system the stress strain curve, when the modulus is

using 1, 2, and 3 for the axes, as shown in Fig. 1. offset along the shear strain axis from the

origin by the reported strain offset value

3.2.4 offset shear strength [M/(LT )], n—the shear stress a

G = shearmodulusofelasticityinthetestdirection

material sustains at the intersection of the shear stress versus

h = overall coupon thickness

engineering shear strain curve with a line parallel to a defined

L = overall coupon length

modulus and translated from the origin by a specified strain.

n = number of coupons per sample population

P = load carried by test coupon

f

P = load carried by test coupon at failure

max

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., P = maximum load carried by test coupon before

4th Floor, New York, NY 10036.

failure

AvailablefromASTMHeadquarters,100BarrHarborDr.,POBoxC700,West

r = notch radius

Conshohocken, PA 19428-2959. Order Adjunct ADJD7078.

D7078/D7078M − 05

4.3 The notches influence the shear strain distribution in the

central region of the coupon, producing a more uniform

distribution than without notches. As a result of the reduced

specimen width due to the notches, the average shear stress is

increased relative to the unnotched width.

5. Significance and Use

5.1 This shear test is designed to produce shear property

data for material specifications, research and development,

quality assurance, and structural design and analysis. Either

in-plane or interlaminar shear properties may be evaluated,

depending upon the orientation of the material coordinate

system relative to the loading axis. Factors that influence the

shear response and should therefore be reported include:

material,methodsofmaterialpreparationandlay-up,specimen

stacking sequence, specimen preparation, specimen

conditioning, environment of testing, specimen alignment and

gripping, speed of testing, time at temperature, void content,

and volume percent reinforcement.

FIG. 2 Illustration of Modulus and Offset Strength Determination

5.2 In anisotropic materials, properties may be obtained in

any of the six possible shear planes by orienting the testing

plane of the specimen with the desired material plane (1-2 or

S = standard deviation statistic of a sample popu-

n-1

2-1, 1-3 or 3-1, 2-3 or 3-2). Only a single shear plane may be

lation for a given property

evaluated for any given specimen. Properties, in the test

w = overall coupon width

direction, which may be obtained from this test method,

x = test result for an individual specimen from the

i

include the following:

sample population for a given property

5.2.1 Shear stress versus engineering shear strain response,

¯

X = mean or average (estimate of mean) of a

5.2.2 Ultimate shear strength,

sample population for a given property

5.2.3 Ultimate engineering shear strain,

γ = engineering shear strain

5.2.4 Shear chord modulus of elasticity,

ϵ = indicated normal strain from strain transducer

5.2.5 Transition strain.

or extensometer

σ = normal stress

6. Interferences

τ = shear stress

θ = ply orientation angle

6.1 Material and Specimen Preparation—Poormaterialfab-

rication practices, lack of control of fiber alignment, and

4. Summary of Test Method

damage induced by improper specimen machining are known

4.1 A material coupon in the form of a flat rectangle with

causes of high material data scatter in composites.

symmetrical centrally located V-notches, shown schematically

6.2 Elastic Modulus Measurement—Shear modulus calcula-

in Fig. 3, is clamped to two fixture halves (pictured in Fig. 4,

tionsinthistestmethodassumeauniformdistributionofshear

and shown schematically in Fig. 5 and in more detail in the

stress and shear strain in the region of the specimen between

machining drawings of ASTM Adjunct ADJD7078). When

the notch tips. The actual uniformity is dependent on the

loaded in tension using a mechanical testing machine, this

material orthotropy, the direction of loading, and the notch

fixture introduces shear forces in the specimen that produce

geometry (notch angle, notch depth, and notch radius). Refer-

failures across the notched specimen.

ring to the fiber orientations in Fig. 6, detailed stress analysis

4.2 Thespecimenisinsertedintothetwofixturehalveswith

(1) has shown that [0] specimens produce an elastic modulus

n

the notches located along the line of the applied load. The two

measurement that is too high (5-10% too high for carbon/

halves of the assembled fixture are extended by a testing

epoxy), whereas [0/90] specimens produce a relatively accu-

ns

machine while monitoring load. The relative displacement

rate elastic modulus measurement. Further, stress analysis has

between the two fixture halves produces shear stresses in the

shown that specimens with between 25% and 100% 645º

notched specimen. By placing two strain gage elements,

plies produce relatively accurate elastic laminate modulus

oriented at 645º to the loading axis, in the middle of the

measurements.

specimen and along the loading axis, the shear strain response

6.3 Specimen Geometry Modifications—Variations in the

of the material can be measured.

notch geometry (notch angle, notch depth, and notch radius)

affect the degree of nonuniformity of shear stress and shear

The fixture and specimen were developed at the University of Utah (1-3). This

work followed an earlier investigation on an improved rail shear test method at the

University of Wyoming Composite Materials Research Group (4 and 5). The Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

numbers in parentheses refer to the references listed at the end of the standard. this standard.

D7078/D7078M − 05

Nominal Specimen Dimensions

d = 31.0 mm [1.20 in.]

d = 12.7 mm [0.50 in.]

h = as required

L = 76.0 mm [3.0 in.]

r = 1.3 mm [0.05 in.]

w = 56.0 mm [2.20 in.]

FIG. 3 V-Notched Rail Shear Test Specimen Schematic

FIG. 4 Partially Assembled Fixture with Specimen and Spacer Blocks

strain in the region of the specimen between the notches. notch angle, notch depth, and notch radius for the purpose of

Recommendations for notch dimensions versus the degree of increasing the uniformity of the shear stress/shear strain

material orthotropy have not been fully developed. Thus, a distributions for a particular material and laminate are accept-

single notch geometry has been adopted. Variations to the able when the variations are clearly noted in the report.

-------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.