ASTM D4255/D4255M-20e1

(Test Method)Standard Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

Standard Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

SIGNIFICANCE AND USE

5.1 These shear tests are designed to produce in-plane shear property data for material specifications, research and development, and design. Factors that influence the shear response and should therefore be reported include: material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and fiber volume reinforcement content. Properties that may be measured by this test method include:

5.1.1 In-plane shear stress versus engineering shear strain response,

5.1.2 In-plane shear chord modulus of elasticity,

5.1.3 Offset shear stress, and

5.1.4 Maximum in-plane shear stress. In cases in which the engineering shear strain at failure is greater than 5 %, the shear stress corresponding to 5 % engineering shear strain should be reported.

SCOPE

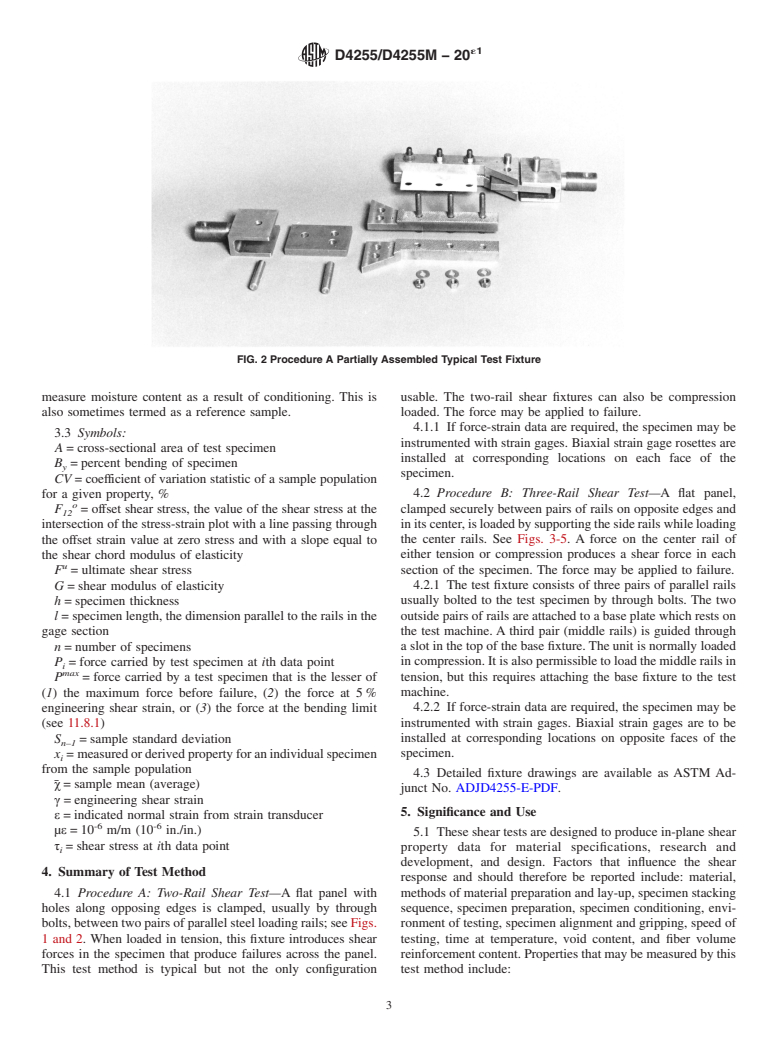

1.1 This test method determines the in-plane shear properties of high-modulus fiber-reinforced composite materials by either of two procedures. In Procedure A, laminates clamped between two pairs of loading rails are tested. When loaded in tension, the rails introduce shear forces in the specimen. In Procedure B, laminates clamped on opposite edges with a tensile or compressive force applied to a third pair of rails in the center are tested.

1.2 Application of this test method is limited to continuous-fiber or discontinuous-fiber-reinforced polymer matrix composites in the following material forms:

1.2.1 Laminates composed only of unidirectional fibrous laminae, with the fiber direction oriented either parallel or perpendicular to the fixture rails.

1.2.2 Laminates composed only of woven fabric filamentary laminae with the warp direction oriented either parallel or perpendicular to the fixture rails.

1.2.3 Laminates of balanced and symmetric construction, with the 0° direction oriented either parallel or perpendicular to the fixture rails.

1.2.4 Short-fiber-reinforced composites with a majority of the fibers being randomly distributed.

Note 1: Additional test methods for determining in-plane shear properties of polymer matrix composites may be found in Test Methods D3518/D3518M, D5379/D5379M, D5448/D5448M, and D7078/D7078M.

1.3 The reproducibility of this test method can be affected by the presence of shear stress gradients in the gage section and stress concentrations at the gripping areas. Test Methods D5379/D5379M and D7078/D7078M provide superior shear response in comparison to this test method, as their specimen configurations produce a relatively pure and uniform shear stress state in the gage section.

1.4 The technical content of this standard has been stable since 2001 without significant objection from its stakeholders. As there is limited technical support for the maintenance of this standard, changes since that date have been limited to items required to retain consistency with other ASTM D30 Committee standards, including editorial changes and incorporation of updated guidance on micrometers and calipers, strain gage requirements, speed of testing, specimen preconditioning and environmental testing. Future maintenance of the standard will only be in response to specific requests and performed only as technical support allows.

1.5 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5.1 Within the text the inch-pounds units are shown in brackets.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and envi...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D4255/D4255M − 20

Standard Test Method for

In-Plane Shear Properties of Polymer Matrix Composite

1

Materials by the Rail Shear Method

This standard is issued under the fixed designation D4255/D4255M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Adjunct stock code was updated editorially to reflect its digital code in February 2023.

1. Scope stress concentrations at the gripping areas. Test Methods

D5379/D5379M and D7078/D7078M provide superior shear

1.1 This test method determines the in-plane shear proper-

response in comparison to this test method, as their specimen

ties of high-modulus fiber-reinforced composite materials by

configurations produce a relatively pure and uniform shear

either of two procedures. In Procedure A, laminates clamped

stress state in the gage section.

between two pairs of loading rails are tested. When loaded in

tension, the rails introduce shear forces in the specimen. In 1.4 The technical content of this standard has been stable

Procedure B, laminates clamped on opposite edges with a since 2001 without significant objection from its stakeholders.

tensile or compressive force applied to a third pair of rails in As there is limited technical support for the maintenance of this

the center are tested. standard, changes since that date have been limited to items

required to retain consistency with other ASTM D30 Commit-

1.2 Application of this test method is limited to continuous-

tee standards, including editorial changes and incorporation of

fiber or discontinuous-fiber-reinforced polymer matrix com-

updated guidance on micrometers and calipers, strain gage

posites in the following material forms:

requirements, speed of testing, specimen preconditioning and

1.2.1 Laminates composed only of unidirectional fibrous

environmental testing. Future maintenance of the standard will

laminae, with the fiber direction oriented either parallel or

only be in response to specific requests and performed only as

perpendicular to the fixture rails.

technical support allows.

1.2.2 Laminates composed only of woven fabric filamentary

laminae with the warp direction oriented either parallel or 1.5 Units—The values stated in either SI units or inch-

perpendicular to the fixture rails.

pound units are to be regarded separately as standard. The

1.2.3 Laminates of balanced and symmetric construction, values stated in each system are not necessarily exact equiva-

with the 0° direction oriented either parallel or perpendicular to

lents; therefore, to ensure conformance with the standard, each

the fixture rails. system shall be used independently of the other, and values

1.2.4 Short-fiber-reinforced composites with a majority of

from the two systems shall not be combined.

the fibers being randomly distributed. 1.5.1 Within the text the inch-pounds units are shown in

brackets.

NOTE 1—Additional test methods for determining in-plane shear

properties of polymer matrix composites may be found in Test Methods

1.6 This standard does not purport to address all of the

D3518/D3518M, D5379/D5379M, D5448/D5448M, and D7078/

safety concerns, if any, associated with its use. It is the

D7078M.

responsibility of the user of this standard to establish appro-

1.3 The reproducibility of this test method can be affected

priate safety, health, and environmental practices and deter-

by the presence of shear stress gradients in the gage section and

mine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accor-

1

dance with internationally recognized principles on standard-

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.04 on

ization established in the Decision on Principles for the

Lamina and Laminate Test Methods.

Development of International Standards, Guides and Recom-

Current edition approved Oct. 1, 2020. Published October 2020. Originally

mendations issued by the World Trade Organization Technical

approved in 1983. Last previous edition approved in 2015 as D4255/D4255M – 15a.

DOI: 10.1520/D4255_D4255M-20E01. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.