ASTM F1735-02

(Specification)Standard Specification for Poly (Vinyl Chloride) (PVC) Profile Strip for PVC Liners for Rehabilitation of Existing Man-Entry Sewers and Conduits

Standard Specification for Poly (Vinyl Chloride) (PVC) Profile Strip for PVC Liners for Rehabilitation of Existing Man-Entry Sewers and Conduits

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, extrusion quality, and a form of marking for extruded poly (vinyl chloride)(PVC) profile strips used for field fabrication of PVC liners for existing man-entry (36 to 144 in. (900 to 3650 mm) in vertical dimension) sewer and conduit rehabilitation.

1.2 Profile strip produced to this specification is for use in field fabrication of PVC liners in non-pressure pipe and conduit rehabilitation where the liner is installed into the existing sewer or conduit and the annular space between the liner and the existing sewer or conduit is grouted with cementitious grout.

Note 1—The practice for the installation of PVC liner covered by this specification is Practice F 1698.

1.3 This specification includes extruded profile strips made only from materials specified in 6.1.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1735 – 02

Standard Specification for

Poly (Vinyl Chloride)(PVC) Profile Strip for PVC Liners for

1

Rehabilitation of Existing Man-Entry Sewers and Conduits

This standard is issued under the fixed designation F 1735; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2122 Test Method of Determining Dimensions of Ther-

3

moplastic Pipe and Fittings

1.1 This specification covers requirements and test methods

D 2152 Test Method for Degree of Fusion of Extruded Poly

for materials, dimensions, workmanship, extrusion quality, and

(Vinyl Chloride)(PVC) Pipe and Molded Fittings by Ac-

a form of marking for extruded poly (vinyl chloride)(PVC)

3

etone Immersion

profile strips used for field fabrication of PVC liners for

D 2240 Test Method for Rubber Property—Durometer

existing man-entry (36 to 144 in. (900 to 3650 mm) in vertical

4

Hardness

dimension) sewer and conduit rehabilitation.

F 412 Definitions Of Terms Relating To Plastic Piping

1.2 Profile strip produced to this specification is for use in

3

Systems

field fabrication of PVC liners in non-pressure pipe and conduit

F 1698 Practice for Installation of Poly (Vinyl Chlo-

rehabilitation where the liner is installed into the existing sewer

ride)(PVC) Profile Strip Liner and Cementitious Grout for

or conduit and the annular space between the liner and the

Rehabilitation of Existing Man—Entry Sewers and Con-

existing sewer or conduit is grouted with cementitious grout.

3

duits

NOTE 1—The practice for the installation of PVC liner covered by this

2.2 Federal Standard:

specification is Practice F 1698.

Federal Standard No. 123 Marking For Shipment (Civil

5

1.3 This specification includes extruded profile strips made

Agencies)

only from materials specified in 6.1.

2.3 Military Standard:

5

1.4 The values stated in inch-pound units are to be regarded

MIL-STD-129 Marking for Shipment and Storage

as the standard. The values given in parentheses are for

3. Terminology

information only.

1.5 This standard does not purport to address all of the

3.1 General—Definitions are in accordance with Terminol-

safety concerns, if any, associated with its use. It is the

ogy D 883 and Terminology F 412. Abbreviations are in

responsibility of the user of this standard to establish appro-

accordance with Terminology D 1600, unless otherwise indi-

priate safety and health practices and determine the applica-

cated.

bility of regulatory limitations prior to use.

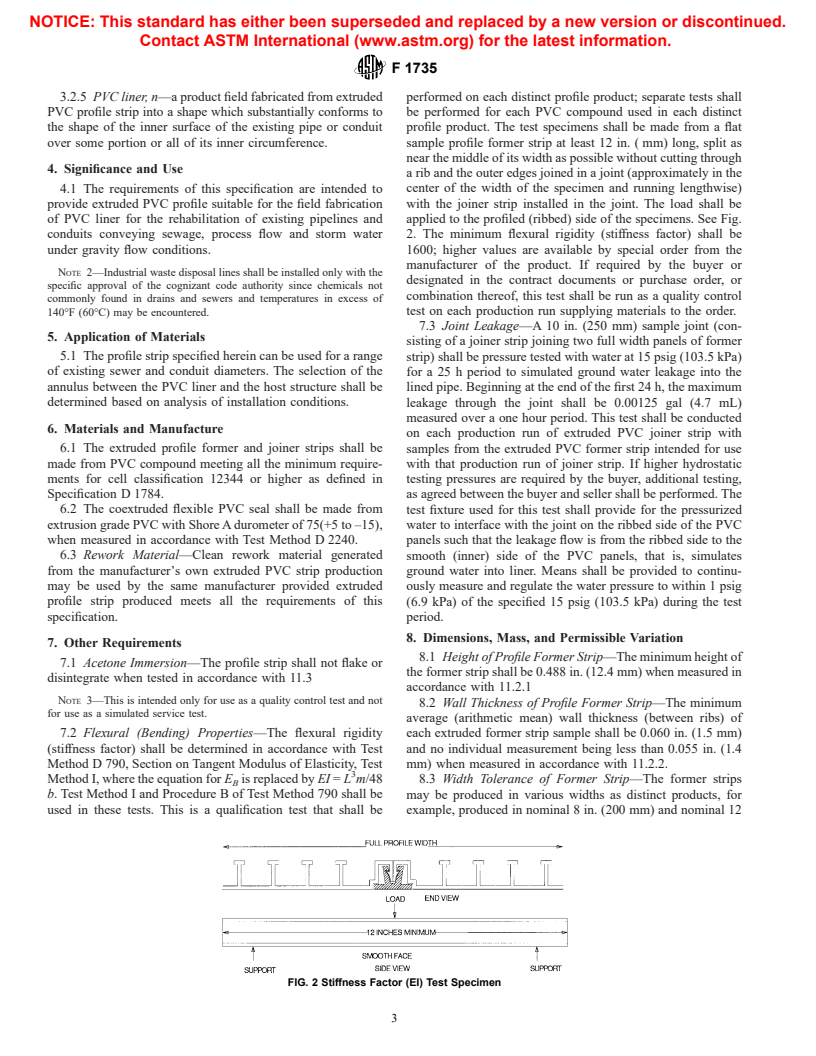

3.2 Definitions of Terms Specific to this Standard—See Fig.

1 to clarify terminology.

2. Referenced Documents

3.2.1 coextruded flexible PVC seal, n—a flexible (soft) bead

2.1 ASTM Standards:

of PVC coextruded in the joiner strip to provide compression

2

D 618 Practice for Conditioning Plastics for Testing

sealing of the mechanical joint made when the joiner strip

D 790 Test Method for Flexural Properties of Unreinforced

locks adjacent edges of former strip.

and Reinforced Plastics and Electrical Insulating Materi-

3.2.2 extruded PVC joiner strip, n—a companion product to

2

als

the profile former strip of such configuration as to provide the

2

D 883 Terminology Relating to Plastics

locking mechanism at the edges of the former strips.

2

D 1600 Abbreviations of Terms Relating to Plastics

3.2.3 extruded PVC profile former strip, n—a product,

D 1784 Specification for Rigid Poly (Vinyl Chloride)(PVC)

available in various sizes, consisting of a smooth inner surface

Compounds and Chlorinated Poly (Vinyl Chlo-

and a ribbed outer surface (profile) with edge configurations to

2

ride)(CPVC) Compounds

allow mechanical locking of adjacent strips.

3.2.4 production run, n—a continuous extrusion of a given

profile type.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

3

Trenchless Plastic Pipeline Technology. Annual Book of ASTM Standards, Vol 08.04.

4

Current edition approved Apr. 10, 2002. Published April 2002. Originally Annual Book of ASTM Standards, Vol 09.01.

5

published as F 1735 - 96. Last previous edition F 1735 - 96. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

2

Annual Book of ASTM Standards, Vol 08.01. Robbins Ave., Philadelphia, PA 19111–5098, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.