ASTM D4756-96

(Practice)Standard Practice for Installation of Rigid Poly(Vinyl Chloride) (PVC) Siding and Soffit

Standard Practice for Installation of Rigid Poly(Vinyl Chloride) (PVC) Siding and Soffit

SCOPE

1.1 This practice covers the minimum requirements for and the methods of installation of rigid vinyl siding, soffits, and accessories on the exterior wall and soffit areas of buildings. In all applications, refer also to the specific manufacturer's instructions for installation.

1.2 This practice covers aspects of installation relating to effectiveness and durability in service.

1.3 The various application systems are located in the following sections of this practice: Section 8 Substrate, Surface Preparation Section 9 Application of Horizontal Siding Section 10 Application of Vertical Siding Section 11 Application of Soffits Section 12 Special Details

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only. Note 1-There are no ISO standards covering the subject matter of this practice.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 4756 – 96

Standard Practice for

Installation of Rigid Poly(Vinyl Chloride) (PVC) Siding and

1,2

Soffit

This standard is issued under the fixed designation D 4756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 631 Terminology of Building Constructions

2.2 Council of American Building Offıcials:

1.1 This practice covers the minimum requirements for and

CABO One and Two Family Dwelling Code: Section

the methods of installation of rigid vinyl siding, soffits, and

R-707 Attic Ventilation

accessories on the exterior wall and soffit areas of buildings. In

all applications, refer also to the specific manufacturer’s

3. Terminology

instructions for installation.

3.1 General—Definitions are in accordance with Termi-

1.2 This practice covers aspects of installation relating to

nologies D 883 and E 631 and abbreviations with Terminology

effectiveness and durability in service.

D 1600 unless otherwise indicated.

1.3 The various application systems are located in the

3.2 Definitions of Terms Specific to This Standard:

following sections of this practice:

3.2.1 crimp—small protrusions, typically approximately ⁄2

Section 8 Substrate, Surface Preparation

1 1

in. (12.7 mm) long, ⁄8in. (3.2 mm) wide, and projecting ⁄8in.

Section 9 Application of Horizontal Siding

Section 10 Application of Vertical Siding

(3.2 mm) formed by a crimper (snaplock punch). (See Fig. 1.)

Section 11 Application of Soffits

3.2.2 crimper—a special hand tool designed to form crimps

Section 12 Special Details

(snaplock ears) intended to hold partial panels in place. (See

1.4 The values stated in inch-pound units are to be regarded

Fig. 1.)

as the standard. The SI units given in parentheses are for

3.2.3 fascia—the trim along the perimeter of roofs or roof

information only.

overhangs. (See Fig. 2.)

3.2.4 flashing—special membrane pieces or manufactured

NOTE 1—There are no ISO standards covering the subject matter of this

trim pieces used to supplement siding panels in weather

practice.

protection around openings, such as windows and doors.

1.5 This standard does not purport to address all of the

3.2.5 nailslot punch—a special hand tool used to create

safety concerns, if any, associated with its use. It is the

slots for attachment of field-modified siding or accessories.

responsibility of the user of this standard to establish appro-

(See Fig. 3.)

priate safety and health practices and determine the applica-

3.2.6 snaplock ears—See crimp and Fig. 1.

bility of regulatory limitations prior to use.

3.2.7 snaplock punch—See crimper and Fig. 1.

2. Referenced Documents 3.2.8 soffıt—the underside surface (typically horizontal) of

roof overhangs.

2.1 ASTM Standards:

3 3.2.9 zip tool—a special hand tool used to separate inter-

D 883 Terminology Relating to Plastics

locked siding panels. (See Fig. 4.)

D 1600 Terminology for Abbreviated Terms Relating to

Plastics

4. Delivery of Materials

D 3679 Specification for Rigid Poly(Vinyl Chloride) (PVC)

4 4.1 All manufactured materials shall be delivered in the

Siding

original packages, containers, or bundles bearing the size or

D 4477 Specification for Rigid Poly(Vinyl Chloride) (PVC)

4 type product, or both, brand name, and manufacturer (or

Soffit

supplier) identification, manufacturer’s lot number, and the

ASTM specification to which it conforms.

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.24 on Plastic Building

5. Protection of Materials

Products.

Current edition approved March 10, 1996. Published May 1996. Originally

5.1 All vinyl siding and soffit products shall be stacked off

published as D 4756 – 91. Last previous edition D 4745 – 91.

This edition contains a change to Section 1 to add an ISO equivalency

statement. Annual Book of ASTM Standards, Vol 04.07.

3 6

Annual Book of ASTM Standards, Vol 08.01. Available from Council of American Building Officials, 5203 Leesburg Pike,

Annual Book of ASTM Standards, Vol 08.04. Falls Church, VA 22041.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4756

FIG. 1 Crimper and Crimps on Siding FIG. 3 Nailslot Punch

FIG. 4 Zip Tool

FIG. 2 Panels and Accessories

for vertical siding of poly(vinyl chloride) or noncorrosive

the ground, on level supports to avoid sagging, and protected

metal.

from the weather, surface contamination, and possible damage.

7.4.2 Corner Posts—Of two types: for inside corners and

for outside corners of poly(vinyl chloride).

6. Environmental Conditions

7.4.3 Trim Channels—Produced of poly(vinyl chloride) in a

6.1 Vinyl siding and accessories will expand when heated

variety of designs and sizes for use around openings and edges

and contract when cooled. If siding is installed in hot weather

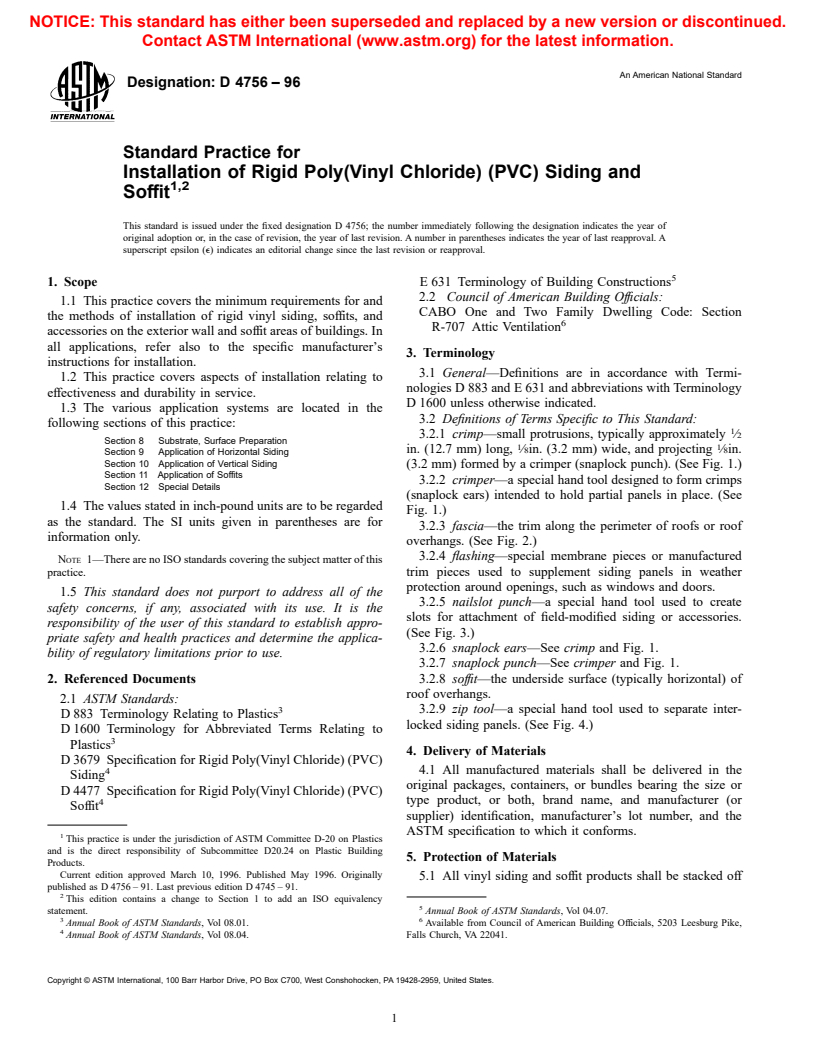

of wall and soffit surfaces. (See Fig. 5.)

and the siding is very warm it will be partially “expanded” and

7.4.4 Fascia Panels—Produced of poly(vinyl chloride),

allowance for more future “contraction” than expansion should

typically in a “J” shape with an extended flat leg, intended for

be provided. If installed during cold weather using vinyl siding

field cutting to cover roof trim.

that was stored outside, more allowance for future expansion

NOTE 2—To minimize the possibility of any color variation use

than contraction is necessary.

material from a single manufacturer’s lot number for application to one

7. Materials building.

7.1 Horizontal Wall Siding—See Specification D 3679. 7.5 Fasteners:

7.2 Vertical Wall Siding—See Specification D 3679 7.5.1 Nails—Corrosion-resistant with head diameter ⁄16 in.

7.3 Soffıt Panels—See Specification D 4477. (7.9 mm) minimum, shank diameter ⁄8 in. (3.2 mm), length

7.4 Accessories: sufficient to penetrate not less than ⁄4 in. (19 mm) into framing

7.4.1 Starter Strip—Of two types: for horizontal siding and or furring.

D 4756

on center for horizontal siding and applied horizontally and

typically spaced 12 in. (305 mm) on center for vertical siding.

9. Application of Horizontal Siding

9.1 General Requirements—Vinyl siding and accessories

expand and contract as much as ⁄4 in. (6.4 mm) over a 12-ft

(3.65-m) length with changes in temperature. For this reason

adhere to the following provisions:

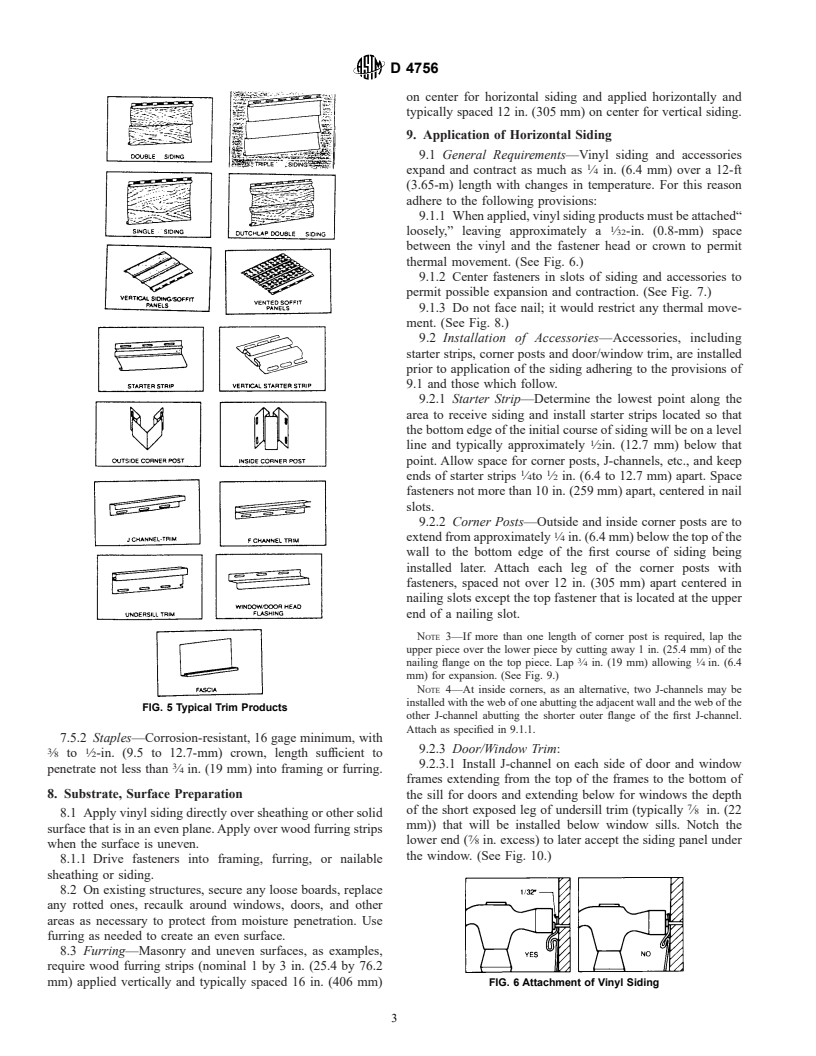

9.1.1 When applied, vinyl siding products must be attached“

loosely,” leaving approximately a ⁄32-in. (0.8-mm) space

between the vinyl and the fastener head or crown to permit

thermal movement. (See Fig. 6.)

9.1.2 Center fasteners in slots of siding and accessories to

permit possible expansion and contraction. (See Fig. 7.)

9.1.3 Do not face nail; it would restrict any thermal move-

ment. (See Fig. 8.)

9.2 Installation of Accessories—Accessories, including

starter strips, corner posts and door/window trim, are installed

prior to application of the siding adhering to the provisions of

9.1 and those which follow.

9.2.1 Starter Strip—Determine the lowest point along the

area to receive siding and install starter strips located so that

the bottom edge of the initial course of siding will be on a level

line and typically approximately ⁄2in. (12.7 mm) below that

point. Allow space for corner posts, J-channels, etc., and keep

1 1

ends of starter strips ⁄4to ⁄2 in. (6.4 to 12.7 mm) apart. Space

fasteners not more than 10 in. (259 mm) apart, centered in nail

slots.

9.2.2 Corner Posts—Outside and inside corner posts are to

extend from approximately ⁄4 in. (6.4 mm) below the top of the

wall to the bottom edge of the first course of siding being

installed later. Attach each leg of the corner posts with

fasteners, spaced not over 12 in. (305 mm) apart centered in

nailing slots except the top fastener that is located at the upper

end of a nailing slot.

NOTE 3—If more than one length of corner post is required, lap the

upper piece over the lower piece by cutting away 1 in. (25.4 mm) of the

3 1

nailing flange on the top piece. Lap ⁄4 in. (19 mm) allowing ⁄4 in. (6.4

mm) for expansion. (See Fig. 9.)

NOTE 4—At inside corners, as an alternative, two J-channels may be

installed with the web of one abutting the adjacent wall and the web of the

FIG. 5 Typical Trim Products

other J-channel abutting the shorter outer flange of the first J-channel.

Attach as specified in 9.1.1.

7.5.2 Staples—Corrosion-resistant, 16 gage minimum, with

9.2.3 Door/Window Trim:

3 1

⁄8 to ⁄2-in. (9.5 to 12.7-mm) crown, length sufficient to

9.2.3.1 Install J-channel on each side of door and window

penetrate not less than ⁄4 in. (19 mm) into framing or furring.

frames extending from the top of the frames to the bottom of

8. Substrate, Surface Preparation the sill for doors and extending below for windows the depth

of the short exposed leg of undersill trim (typically ⁄8 in. (22

8.1 Apply vinyl siding directly over sheathing or other solid

mm)) that will be installed below window sills. Notch the

surface that is in an even plane. Apply over wood furring strips

lower end ( ⁄8 in. excess) to later accept the siding panel under

when the surface is uneven.

the window. (See Fig. 10.)

8.1.1 Drive fasteners into framing, furring, or nailable

sheathing or siding.

8.2 On existing structures, secure any loose boards, replace

any rotted ones, recaulk around windows, doors, and other

areas as necessary to protect from moisture penetration. Use

furring as needed to create an even surface.

8.3 Furring—Masonry and uneven surfaces, as examples,

require wood furring strips (nominal 1 by 3 in. (25.4 by 76.2

mm) applied vertically and typically spaced 16 in. (406 mm) FIG. 6 Attachment of Vinyl Siding

D 4756

FIG. 7 Fastening Location in Siding Slots

FIG. 11 Installation of Door and Window Trim

and fasten leaving ⁄4 in. (6.4 mm) gap at the corner posts.

FIG. 8 Face Nailing of Vinyl Siding Prohibited

Space fasteners not over 16 in. (406 mm) on center. (See Fig.

12.)

9.3.3 Lap the next panel over the first by one-half of the

factory cut notch. (See Fig. 13.) Insert backerboard (if used)

and fasten.

9.3.4 To field-notch a panel where the factory notch has

been cut off, cut away 1 ⁄2in. (38 mm) of the nailing flange and

1 1

lock. Cut a ⁄8 by 1 ⁄2-in. (3.2 by 38-mm) notch from the bottom

step of the panel, cutting away the hook on the back as well.

(Field cut notches should be identical to factory notches.)

9.3.5 At the bottom of the window, install a piece of

undersill trim snugly between the side J-channels and against

the underside of the sill. Use the proper thickness of furring

behind it to keep the pitch of the panel consistent. Flash or

caulk the J-channel-undersill intersections to prevent water

FIG. 9 Joining Corner Posts

infiltration. (See Fig. 14.)

9.3.6 At a window a siding panel may have to be cut to fit

under the opening. Be sure this panel extends on both sides of

the window. Measure the panel to fit. Hold the siding panel

under the window and mark the width of the opening on it.

Allow ⁄4in. (6.4 mm) clearance at the edges for insertion into

each side of the J-channel. Measure the space between the

bottom edge of the S-lock on the previous panel and the

FIG. 10 Installation of Window and Door Trim

undersill trim, being sure to allow ⁄16 in. (14.3 mm) for

insertion into the undersill trim receiver. Remove cut section.

Punch snap locks every 6 in. (152 mm) along the horizontal cut

9.2.3.2 Across the top install head flashing (optional) and

J-channel that extends to the outer edges of the exposed legs of edge. Slide the panel up into position so the bottom locks into

the previous panel and the top snaps into the undersill trim and

the side J-channels. Cut out each end of the head flashing to

match the contour of the side J-channels and fasten in place. fasten. (See Fig. 15.)

9.3.7 Over a window or door, measure for the cuts. Mark the

Cut along the bends of the J-channel in ⁄4 in. (19 mm) from

each end, bend down the resultant tabs of the web, insert them bottom portion of the panel and cut out the unwanted section.

Install the panel. (See Fig. 16.)

into the side J-channels and fasten in place as shown in Fig. 11.

9.3 Siding Panel Installation:

NOTE 5—In some instances it may be necessary to place a piece of

9.3.1 General Considerations—To make overlapped siding

furring into the J-channel behind the cut edge of the siding to reduce wind

joints less noticeable on the sides of a building, start at the rear

corner and install toward the front. On the front and rear of

buildings start at the corners and install toward the entrance

door. Avoid use of short panel lengths under 24 in. (610 mm).

When lapping, factory-cut ends of panels should be on top of

field-cut ends for best appearance.

9.3.2 Engage the bottom of the first panel and the starter

strip. If backerboard insulation is used, drop it in behind the

panel now. Make sure the panel is locked, but not pulled tight, FIG. 12 Fastening of Initial Siding Panel

D 4756

siding panel below and slide it into J-channel allowing ⁄4-in.

(6.4-mm) expansion gap between the end of the siding and

back of the J-channel. The panel for the top of the gable may

be face nailed. Drill a hole the size of the nail shank in the

center of this triangular panel. Lock the panel in place and

drive one nail into the pre-drilled hole. Do not nail it tight!

Nailing into the panel without a pre-drilled hole may crack or

FIG. 13 Lapping Siding Panel

kink the vinyl. (See Fig. 18.)

NOTE 6—A pattern can be made from two pieces of scrap siding. (See

Fig. 19(a).) Hold one piece on the lock of the last installed panel, place the

other piece against the gable and mark the horizontal piece. Cut along the

mark and use this piece as a pattern for the remaining siding panels on that

side. (See Fig. 19(b).) Make another pattern for the other end of the panels.

9.3.9 The final panel under an eave is handled like the

portion under a window. Nail undersill trim to the top of the

sidewall (see Fig. 20), flush with the underside of the eave. If

more than one length of undersill trim is needed, splice as

shown in Fig. 21. To determine the amount of the top panel to

be cut off, measure from the bottom of the undersill trim lock

to bottom of the preceding panel lock and add ⁄16 in. (14.3

mm). (See Fig. 22.) Cut the panels accordingly. Punch snap-

locks every 6 in. (152 mm) along the cut edge and slide it up

into position. (See Fig. 22.)

FIG. 14 Installatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.