ASTM D3702-94(1999)

(Test Method)Standard Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine

Standard Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine

SCOPE

1.1 This test method covers the determination of wear rate and coefficient of friction for self-lubricated materials in rubbing contact by a testing machine that utilizes a thrust washer specimen configuration. Note 1-This machine may also be used to measure coefficient of friction.

1.2 The values in SI units are to be regarded as the standard. In cases where materials, products, or equipment are available only in inch-pound units, SI values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3702–94 (Reapproved 1999)

Standard Test Method for

Wear Rate and Coefficient of Friction of Materials in Self-

Lubricated Rubbing Contact Using a Thrust Washer Testing

Machine

This standard is issued under the fixed designation D 3702; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope example, quantity of material removed (mass, volume, thick-

ness) in unit distance of sliding or unit time.

1.1 This test method covers the determination of wear rate

2.2 Definitions of Terms Specific to This Standard:

and coefficient of friction for self-lubricated materials in

2 2.2.1 torque—reaction of a tendency to turn due to friction

rubbing contact by a testing machine that utilizes a thrust

forces between specimens traveling in a circular path. It is the

washer specimen configuration.

product of a restraining force and the radius at which it acts to

NOTE 1—This machine may also be used to measure coefficient of

balance the frictional torque.

friction.

3. Summary of Test Method

1.2 The values in SI units are to be regarded as the standard.

In cases where materials, products, or equipment are available

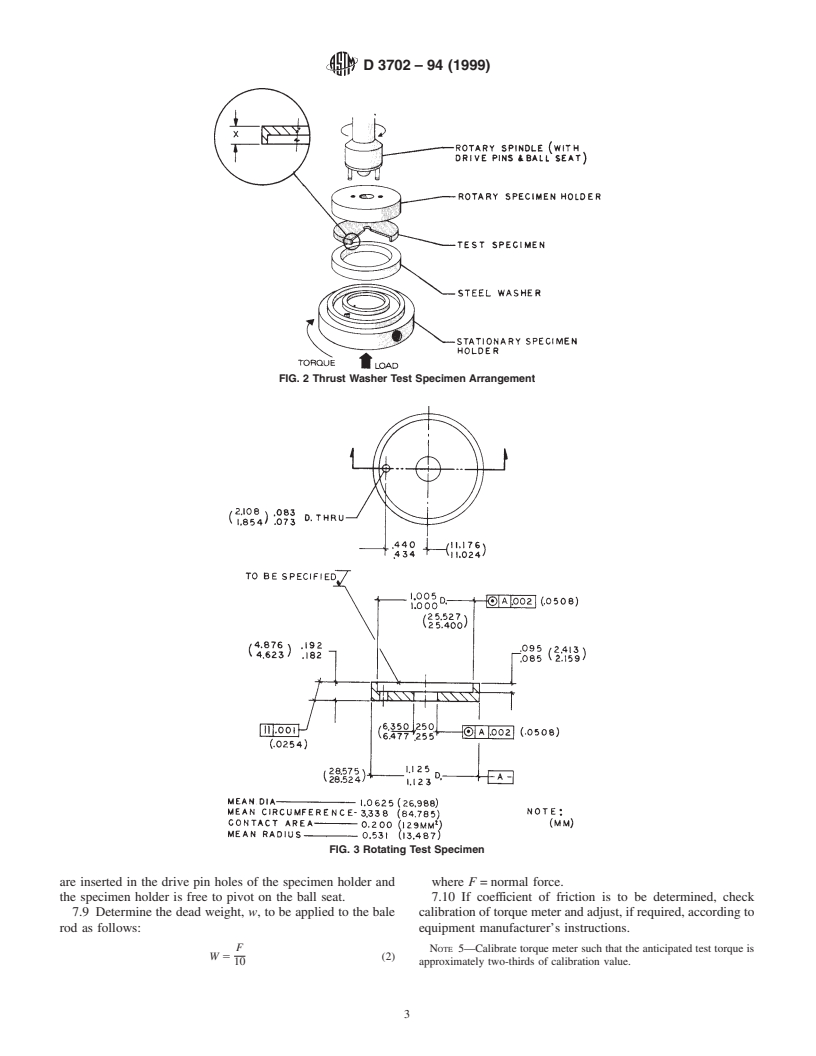

3.1 The test machine is operated with a test specimen

only in inch-pound units, SI values in parentheses are for

rotating under load against a stationary steel washer. Each test

information only.

consists of break-in for 40 h followed by a selected test

1.3 This standard does not purport to address all of the

duration, each at the same selected normal load and speed.

safety concerns, if any, associated with its use. It is the

Load is obtained by application of dead weights to the 10:1

2 2

responsibility of the user of this standard to establish appro-

lever arm. The contact area is 1.29 cm (0.20 in. ). The mean

priate safety and health practices and determine the applica-

rubbing velocity is related to spindle rotational speed: 1

bility of regulatory limitations prior to use.

rpm = 0.0848 m/min (0.278 ft/min).

3.2 The thickness change of the test specimen and torque

2. Terminology

during test are measured for each test.

2.1 Definitions:

3.3 Wear rate in centimetres per hour (inches per hour) and

2.1.1 coeffıcient of friction, µ or f—in tribology—thedimen-

coefficient of friction is reported.

sionlessratioofthefrictionforce(F)betweentwobodiestothe

4. Significance and Use

normal force (N) pressing these bodies together.

4.1 This test method is used to determine the equilibrium

µ or f 5 ~F/N! (1)

rate of wear and coefficient of friction of materials in rubbing

2.1.1.1 Discussion—A distinction is often made between

contactunderusefuloperatingconditions,thatis,combinations

static coefficient of friction and kinetic coefficient of friction.

of pressure and velocity that fall below the PV

2.1.2 wear—damage to a solid surface, generally involving

(pressure 3 velocity) limit of the test material. The user of this

progressive loss of material, due to relative motion between

test method should determine to his own satisfaction whether

that surface and a contacting substance or substances.

the results of this test procedure correlate with field perfor-

2.1.3 wear rate—the rate of material removal or dimen-

mance or other bench test machines. If the test conditions are

sional change due to wear per unit of exposure parameter; for

changed, the wear rates may change and the relative value of

one material with respect to another may also change.

4.2 Test conditions may be selected from Table 1.

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricants and is the direct responsibiltiy of Subcommittee 4.3 The precision of wear measurement is relatively inde-

D02.L 0.05 on Solid Lubricants.

pendent of test duration or amount of wear, but the precision of

Current edition approved July 15, 1994. Published September 1994. Originally

wear rate (calculation) improves with test duration and amount

e1

published as D 3702 – 78. Last previous edition D 3702 – 90 .

of wear. It is generally believed that useful wear rate precision

An example is the Falex Multispecimen Test Machine, available from Falex

Corp., 1020Airpark Drive, Sugar Grove, IL60554. This manufacturer recommends

a maximum test load of 808 lb (367 kg).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3702–94 (1999)

A

TABLE 1 Test Conditions

Rotational Rubbing Velocity, Load, lb(kg), to Obtain PV, psi 3 ft/min (kg/cm 3 m/min) at Selected Speeds

speed, rpm ft/min (m/min) PV 1250 (26.8) PV 2500 (53.6) PV 5000 (107.1) PV 10 000 (214.3)

1 2 3 4

36 10 (3.05) 25.0 (11.3) 50.0 (22.7) 100 (45.4) 200 (90.7)

180 50 (15.2) 5.0 (2.3) 10.0 (4.5) 20.0 (9.1) 40.0 (18.1)

900 250 (76.2) 1.0 (0.5) 2.0 (0.9) 4.0 (1.8) 8.0 (3.6)

A −5 −7

For many applications a wear rate exceeding 1.0 3 10 in./h (2.5 3 10 m/h) is considered excessive. Typical wear rates for some commonly used materials at

different PV levels are:

−6 −5 −7 −7

Acetal homopolymer at PV:5 3 10 to 1 3 10 in./h (1.3 3 10 to 2.5 3 10 m/h)

−5 −5 −7 −7

Acetal homopolymer at PV:1 3 10 to 3 3 10 in./h (2.5 3 10 to 7.5 3 10 m/h)

−6 −6 −8 −7

22 % PTFE-filled acetal homopolymer at PV:3 3 10 to 6 3 10 in./h (7.5 3 10 to 1.5 3 10 m/h)

−5 −5 −7 −6

Polyamide (Type 6-6) at PV:1 3 10 to 5 3 10 in./h (2.5 3 10 to 1.3 3 10 m/h)

−5 −5 −7 −7

15 % graphite filled polyimide restin at PV:1 3 10 to 2 3 10 in./h (2.5 3 10 to 5 3 10 m/h)

requires the selection of a test duration sufficient to produce 0.1 7.2 Before each test, thoroughly clean the steel washer and

mm (0.004 in.) of wear. Test durations will often be in the 50 both specimen holders using the solvent per 5.1.

to 4000-h range.

NOTE 3—Remove all solvents from the washer before testing.

5. Apparatus

7.3 Clean the test specimen as recommended by the manu-

5.1 Falex Multispecimen Test Machine, Fig. 1, shown sche-

facturer of the test material.

matically in Fig. 2 and described in Annex A1.

7.3.1 Store cleaned test specimens prior to testing in a glass

5.2 Test Specimen or Rotating Wafer, shown in Fig. 3.

jar.

5.3 Stationary Washer, AISI C-1018 steel, shown in Fig. 4.

7.3.2 Following the cleaning, do not handle the test speci-

The surface finish should be 16 6 2 µin. AA, the hardness

mens with bare hands. It is recommended that clean cotton

Rc20 6 5.

gloves or clean tweezers or tongs be used.

5.4 Micrometer (Note 4), capable of measuring to the

nearest 0.003 mm (0.0001 in.).

NOTE 4—Check compatibility of the test specimen cleaning procedure

and reagents with the specific material to be tested.

6. Reagents and Materials

7.4 Preset the speed control to provide the desired speed as

6.1 Solvent, safe, non-film forming, nonchlorinated.

measured in revolutions per minute using the built-in tachom-

NOTE 2—Petroleum distillates, formerly used as solvents, have been

eter. Refer to Table 1 to convert the specified velocity to

eliminated due to possible toxic effects. Each user should select a solvent

revolutions per minute.

that can meet applicable safety requirements and thoroughly clean

7.5 Install the test specimen in the upper specimen holder

machine parts.

with the bolt and washer provided.Torque the bolt to 2.8 6 0.6

6.2 Appropriate reagents for cleaning the test specimen as

J (25 6 5 in.·lbf).

recommended by the manufacturer of the test material.

7.6 Place the steel washer in the lower specimen holder.

7. Preparation of Apparatus 7.7 Balance the load lever arm with the bale rod att

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.