ASTM A774/A774M-00

(Specification)Standard Specification for As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and Moderate Temperatures

Standard Specification for As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and Moderate Temperatures

SCOPE

1.1 This specification covers five grades of as-welded, wrought austenitic stainless steel fittings for low-pressure piping and intended for low and moderate temperatures and general corrosive service. Users should note that certain corrosive conditions may restrict the use of one or more grades. For applications requiring a product that requires heat treatment or full pressure rating refer to Specification A403/A403M. The term "fittings" applies to butt and socket welding parts such as 45° and 90° elbows, tees, reducers, wyes, laterals, crosses, and stub ends.

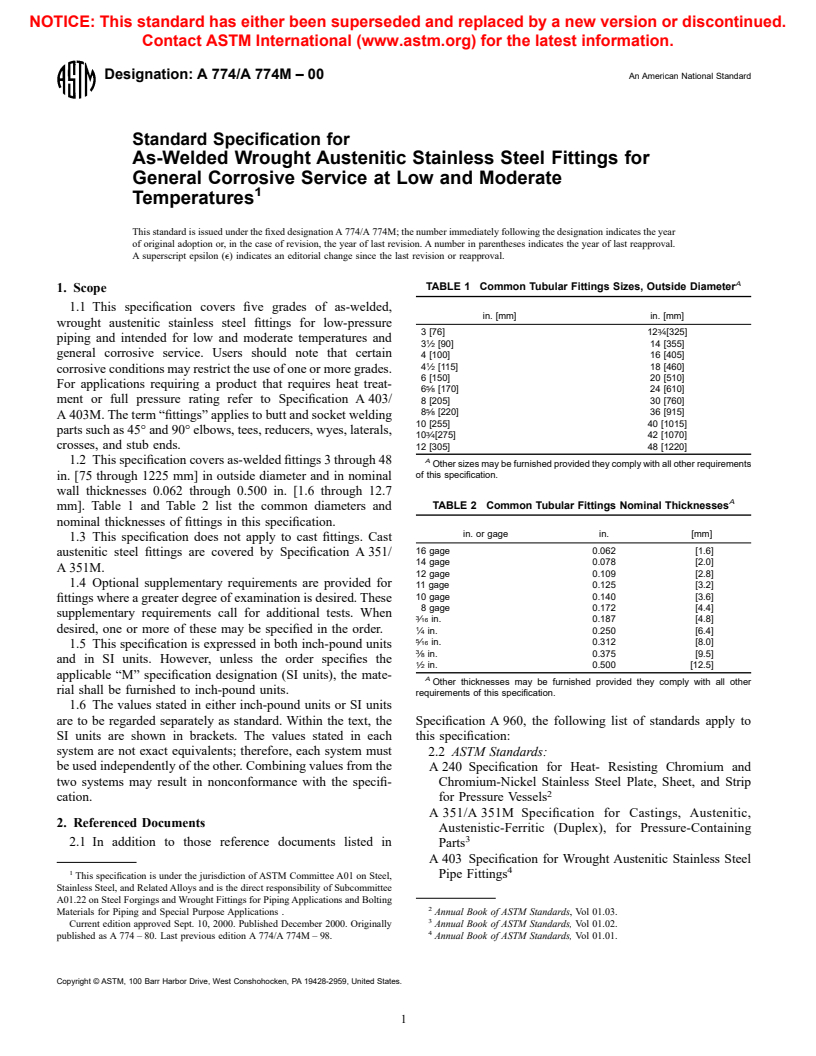

1.2 This specification covers as-welded fittings 3 through 48 in. [75 through 1225 mm] in outside diameter and in nominal wall thicknesses 0.062 through 0.500 in. [1.6 through 12.7 mm]. Table 1 and Table 2 list the common diameters and nominal thicknesses of fittings in this specification.

1.3 This specification does not apply to cast fittings. Cast austenitic steel fittings are covered by Specification A351/ A351M.

1.4 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. These supplementary requirements call for additional tests. When desired, one or more of these may be specified in the order.

1.5 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 774/A 774M – 00 An American National Standard

Standard Specification for

As-Welded Wrought Austenitic Stainless Steel Fittings for

General Corrosive Service at Low and Moderate

Temperatures

This standard is issued under the fixed designation A 774/A 774M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

A

TABLE 1 Common Tubular Fittings Sizes, Outside Diameter

1. Scope

1.1 This specification covers five grades of as-welded,

in. [mm] in. [mm]

wrought austenitic stainless steel fittings for low-pressure

3 [76] 12 ⁄4[325]

piping and intended for low and moderate temperatures and

3 ⁄2 [90] 14 [355]

general corrosive service. Users should note that certain 4 [100] 16 [405]

4 ⁄2 [115] 18 [460]

corrosive conditions may restrict the use of one or more grades.

6 [150] 20 [510]

For applications requiring a product that requires heat treat-

6 ⁄8 [170] 24 [610]

ment or full pressure rating refer to Specification A 403/ 8 [205] 30 [760]

8 ⁄8 [220] 36 [915]

A 403M. The term “fittings” applies to butt and socket welding

10 [255] 40 [1015]

parts such as 45° and 90° elbows, tees, reducers, wyes, laterals,

10 ⁄4[275] 42 [1070]

crosses, and stub ends.

12 [305] 48 [1220]

A

1.2 This specification covers as-welded fittings 3 through 48

Other sizes may be furnished provided they comply with all other requirements

of this specification.

in. [75 through 1225 mm] in outside diameter and in nominal

wall thicknesses 0.062 through 0.500 in. [1.6 through 12.7

A

TABLE 2 Common Tubular Fittings Nominal Thicknesses

mm]. Table 1 and Table 2 list the common diameters and

nominal thicknesses of fittings in this specification.

in. or gage in. [mm]

1.3 This specification does not apply to cast fittings. Cast

16 gage 0.062 [1.6]

austenitic steel fittings are covered by Specification A 351/

14 gage 0.078 [2.0]

A 351M.

12 gage 0.109 [2.8]

1.4 Optional supplementary requirements are provided for

11 gage 0.125 [3.2]

10 gage 0.140 [3.6]

fittings where a greater degree of examination is desired. These

8 gage 0.172 [4.4]

supplementary requirements call for additional tests. When

⁄16 in. 0.187 [4.8]

desired, one or more of these may be specified in the order.

⁄4 in. 0.250 [6.4]

⁄16 in. 0.312 [8.0]

1.5 This specification is expressed in both inch-pound units

⁄8 in. 0.375 [9.5]

and in SI units. However, unless the order specifies the

⁄2 in. 0.500 [12.5]

applicable “M” specification designation (SI units), the mate-

A

Other thicknesses may be furnished provided they comply with all other

rial shall be furnished to inch-pound units.

requirements of this specification.

1.6 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the Specification A 960, the following list of standards apply to

SI units are shown in brackets. The values stated in each

this specification:

system are not exact equivalents; therefore, each system must 2.2 ASTM Standards:

be used independently of the other. Combining values from the

A 240 Specification for Heat- Resisting Chromium and

two systems may result in nonconformance with the specifi- Chromium-Nickel Stainless Steel Plate, Sheet, and Strip

cation.

for Pressure Vessels

A 351/A 351M Specification for Castings, Austenitic,

2. Referenced Documents

Austenistic-Ferritic (Duplex), for Pressure-Containing

2.1 In addition to those reference documents listed in

Parts

A 403 Specification for Wrought Austenitic Stainless Steel

Pipe Fittings

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting

Materials for Piping and Special Purpose Applications . Annual Book of ASTM Standards, Vol 01.03.

Current edition approved Sept. 10, 2000. Published December 2000. Originally Annual Book of ASTM Standards, Vol 01.02.

published as A 774 – 80. Last previous edition A 774/A 774M – 98. Annual Book of ASTM Standards, Vol 01.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 774/A 774M

A 960 Specification for Common Requirements for solution annealed condition unless other heat treat conditions

Wrought Steel Piping Fittings are agreed upon by the manufacturer and the purchaser. The

E 527 Practice for Numbering Metals and Alloys (UNS) fittings shall be formed by a hot or cold process, and welded by

2.3 ASME Standard: a shielded welding process with or without the addition of filler

Section IX, Welding Qualtifications, ASME Boiler and metal.

Pressure Vessel Code 5.2 Fittings shall be furnished clean and free of scale.

2.4 MSS Standard: 5.3 Welding:

SP 43 Wrought Stainless Steel Butt Welding Fittings 5.3.1 The joints shall be full penetration double-welded or

2.5 AWS Standards: single-welded butt joints employing fusion-welding processes

A5.4 Corrosion-Resisting Chromium and Chromium- with or without the addition of filler metal as defined under

Nickel Steel Covered Welding Electrodes Definitions, ASME Boiler and Pressure Vessel Code, Section

A5.9 Corrosion-Resisting Chromium and Chromium- IX. This specification makes no provision for any difference in

Nickel Steel Welding Rods and Bare Electrodes weld quality requirements regardless of the weld joint-type

2.6 SAE Standard: employed (single or double) in making the weld. Welding

J1086 Unified Numbering System for Metals and Alloys procedures and welding operators shall be qualified in accor-

dance with ASME Boiler and Pressure Vessel Code, Section

3. Ordering Information

IX.

3.1 See Specification A 960 and the following:

5.3.2 For fittings employing multiple passes, the root-pass

3.1.1 Dimensions (outside diameter and specified wall

may be made without the addition of filler metal.

thickness, see Table 1 and Table 2),

5.3.3 The alloy content (chromium, nickel, molybdenum,

3.1.2 Grade (Table 3), columbium, and tantalum) of the deposited weld metal shall

3.1.3 End use, if known,

conform to that required of the base metal or for equivalent

weld metal as given in the AWS filler metal specification A5.4

4. General Requirements

or A5.9, except that, when welding on Types 304L base metal,

4.1 Product furnished to this specification shall conform to

the deposited weld metal shall correspond, respectively, to

the requirements of Specification A 960, including any supple-

AWS Types E308L (ER308L) and, when welding on Type 321

mentary requirements that are indicated in the purchase order.

base metal, the weld metal shall correspond to AWS Types

Failure to comply with the requirements of Specification A 960

E347 (ER347 or ER321).

constitutes non-conformance with this specification. In case of

6. Chemical Composition

a conflict between the requirements of this specification and

Specification A 960, this specification shall prevail.

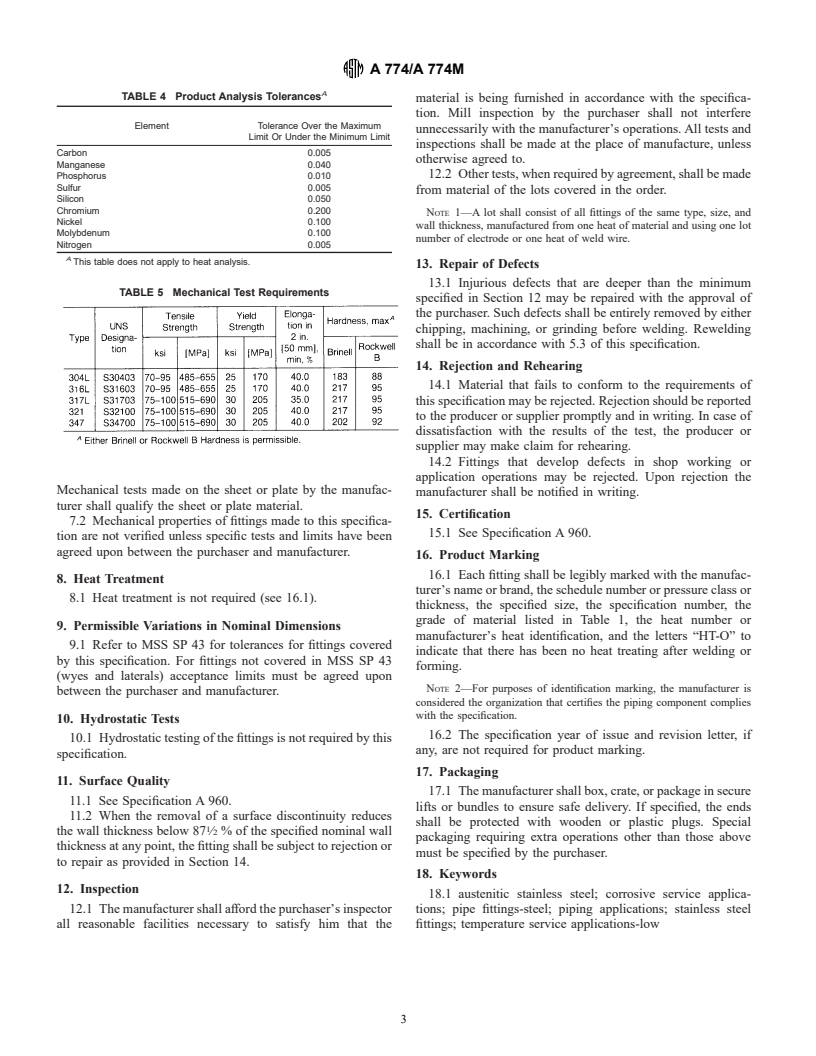

6.1 The steel shall conform to requirements of chemical

composition for the respective material prescribed in Table 3

5. Manufacture

and Table 4.

5.1 The fittings shall be made from flat-rolled steel, such as

6.2 The steel shall not contain any unspecified elements for

in Specification A 240. The flat rolled steel shall be in the

the ordered grade to the extent that it conforms to the

requirements of anothe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.