ASTM D1458-96

(Test Method)Standard Test Methods for Fully Cured Silicone Rubber-Coated Glass Fabric and Tapes for Electrical Insulation

Standard Test Methods for Fully Cured Silicone Rubber-Coated Glass Fabric and Tapes for Electrical Insulation

SCOPE

1.1 These test methods cover procedures for testing fully cured silicone rubber-coated glass fabric and tapes to be used for electrical insulation.

1.2 The procedures appear in the following order:ProcedureSectionsASTM ReferencesBreaking Strength7 D 828 Breaking Strength After Creasing8...Conditioning5 ...Dielectric Breakdown Voltage9D 149, D 295,D 6054Dielectric Proof-Voltage10D 1389 Dissipation Factor and Relative Permittivity11D 150Sampling4 ...Thermal Endurance15 D 1830 Thickness6 D 374 Thread Count14 ...Volume Resistivity12 D 257Weight13 ...

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 9.5.1 for a specific warning statement.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1458 – 96 An American National Standard

Standard Test Methods for

Fully Cured Silicone Rubber-Coated Glass Fabric and Tapes

for Electrical Insulation

This standard is issued under the fixed designation D 1458; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Paper Used for Electrical Insulation

D 257 Test Methods for D-C Resistance or Conductance of

1.1 These test methods cover procedures for testing fully

Insulating Materials

cured silicone rubber-coated glass fabric and tapes to be used

D 295 Test Methods for Varnished Cotton Fabrics Used for

for electrical insulation.

Electrical Insulation

1.2 The procedures appear in the following order:

D 374 Test Methods for Thickness of Solid Electrical Insu-

ASTM Test Method

lation

Procedure Sections References

D 618 Practice for Conditioning Plastics and Electrical

Breaking Strength 6 D 828

Insulating Materials for Testing

Breaking Strength After Creasing 7 .

D 828 Test Method for Tensile Properties of Paper and

Conditioning 4 .

Dielectric Breakdown Voltage 8 D 149, D 295,

Paperboard Using Constant-Rate-of-Elongation Appara-

D 618

tus

Dielectric Proof-Voltage 9 D 1389

Dissipation Factor and Relative Permittivity 10 D 150 D 1389 Test Method for Proof-Voltage Testing of Thin

Sampling 3 .

Solid Electrical Insulating Materials

Thermal Endurance 14 D 1830

D 1830 Test Method for Thermal Endurance of Flexible

Thickness 5 D 374

Sheet Materials Used for Electrical Insulation by the

Thread Count 13 .

Volume Resistivity 11 D 257

Curved Electrode Method

Weight 12 .

D 5032 Practice for Maintaining Constant Relative Humid-

1.3 The values stated in inch-pound units are to be regarded

ity by Means of Aqueous Glycerin Solutions

as the standard. The values given in parentheses are for

E 104 Practice for Maintaining Constant Relative Humidity

information only.

by Means of Aqueous Solutions

1.4 This standard does not purport to address all of the

3. Sampling

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Sample shipments of material as specified below, and

priate safety and health practices and determine the applica-

where possible take only one sample from any package.

bility of regulatory limitations prior to use. See 8.5.1 for a

3.1.1 Fabric—Over 3 in. (75 mm) in width.

specific warning statement.

3.1.1.1 Rolls—Select one roll from each ten rolls or fraction

thereof in a shipment of full-width fabric. Cut off not less than

2. Referenced Documents

two turns of fabric from each roll selected from sampling, and

2.1 ASTM Standards:

select sample material for the preparation of test specimens

D 149 Test Method for Dielectric Breakdown Voltage and

from the remaining layers of the roll.

Dielectric Strength of Solid Electrical Insulating Materials

3.1.1.2 Sheets—Select one sheet from each 50 sheets or

at Commercial Power Frequencies

fraction thereof in a shipment of sheeted fabric. Remove not

D 150 Test Methods for A-C Loss Characteristics and

less than six sheets from the outer layers of each package of

Permittivity (Dielectric Constant) of Solid Electrical Insu-

sheets selected from sampling, and then select sample material

lating Materials

for the preparation of test specimens from the remaining

D 202 Test Methods for Sampling and Testing Untreated

sheets.

3.1.2 Tapes and Strips—3 in. (75 mm) and less in width.

These test methods are under the jurisdiction of ASTM Committee D-9 on

Electrical and Electronic Insulating Materials and are the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved March 10, 1996. Published May 1996. Originally Annual Book of ASTM Standards, Vol 15.09.

published as D 1458 – 57 T. Last previous edition D 1458 – 91. Annual Book of ASTM Standards, Vol 10.02.

2 6

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 11.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1458

3.1.2.1 Tapes—Cut off not less than six turns of tape from linear measure will be required.

each roll selected for sampling, and then select sample material 5.3 Conditioning—It is not necessary to condition the speci-

for the preparation of test specimens from the remaining layers mens for this test. Conduct tests at the Standard Laboratory

of the roll. Select rolls of tape in accordance with the following Temperature of 23 6 1°C (73.4 6 1.8°F).

schedule: 5.4 Procedure—Make ten measurements, equally spaced

along 36 in. (910 mm) of the specimen or specimens in

Minimum Number of Sample

Number of Rolls in Shipment Rolls

accordance with Method C of Test Methods D 374 modified as

follows:

Over 10 000 1 per 1000

5.4.1 Allow the presser foot to remain on the test specimen

5001 to 10 000 10

2001 to 5000 5

for 2 s, at the end of which read the dial gage.

Less than 2000 2

5.4.2 Use a presser foot 0.250 in. (6.35 mm) in diameter,

3.1.2.2 Strips—Select three strips from each 100 strips or

and an anvil surface upon which the specimen rests at least 2

fraction thereof in a shipment of strips. Remove not less than

in. (51 mm) in diameter. The force exerted on the specimen

six strips from the outer layers of each package of strips

shall be 3 ozf (85 g).

selected for sampling, and then select sample material for the

5.4.3 Method C is not considered interchangeable with

preparation of test specimens from the remaining strips.

Method A.

3.2 Prepare the test specimens from samples selected as

5.5 Report—Report the average, maximum, and minimum

specified in 3.1, and as provided for in the individual test

thickness to the nearest 0.0001 in. (0.003 mm).

methods.

6. Breaking Strength

4. Conditioning

6.1 Significance and Use—The breaking strength of fin-

4.1 Significance and Use—The properties of the material

ished fabric or tape is of importance as a measure of the tension

described in these test methods are affected by the temperature

it will withstand without failure while being applied in service.

and moisture content of the material to a greater or lesser

6.2 Apparatus—Use a power-driven tensile testing machine

extent, depending on the specific property.

meeting the requirements specified for Tensile Properties in

4.2 Conditioning—Unless otherwise specified in the indi-

Test Methods D 202, except that the means for determining

vidual test method, condition test specimens as described in

elongation and for recording applied load and elongation are

4.2.1 or 4.2.2, and in matters of dispute, consider 4.2.1 as the

not required. The machine shall be equipped with specimen-

referee method.

gripping devices as described in 6.2.1 or 6.2.2.

4.2.1 Condition the test specimens for 48 h in the Standard

6.2.1 Provide two flat-jawed clamps, in which case crocus

Laboratory Atmosphere of 50 6 2 % relative humidity at a

cloth will be required for holding specimens between the jaws,

temperature of 23 6 1°C (73.4 6 1.8°F), and conduct the tests

or

under these conditions.

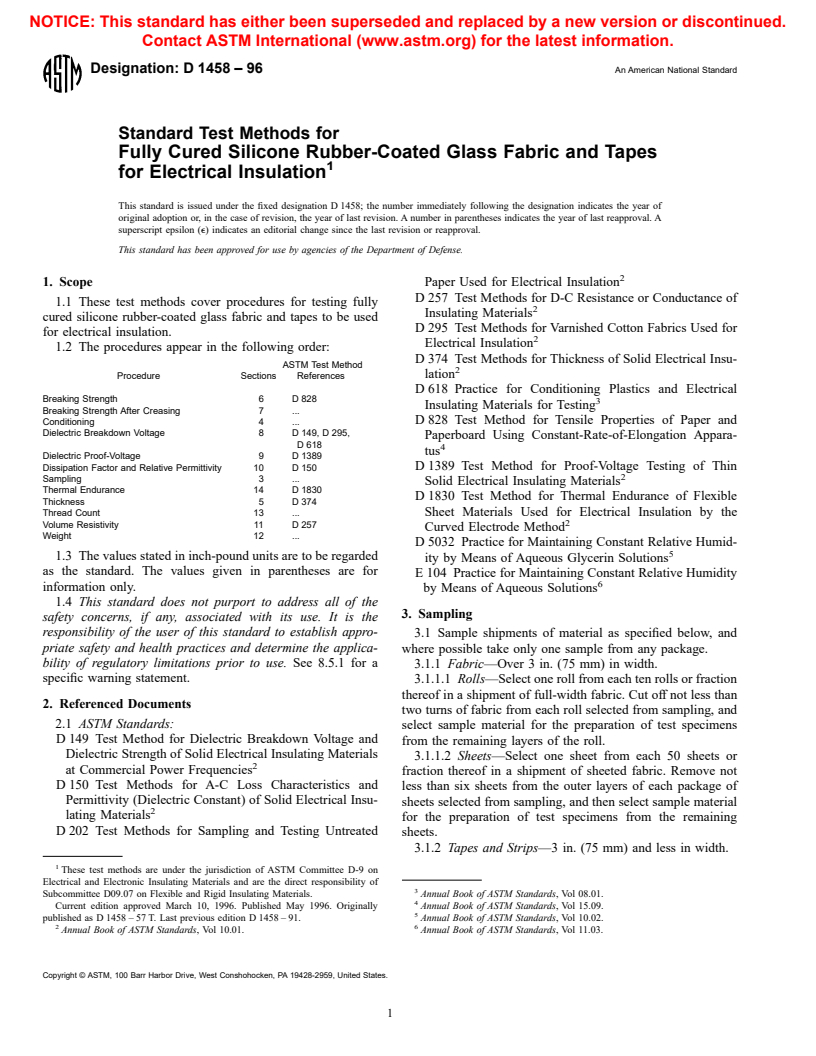

6.2.2 Provide two gripping devices of the drum type as

4.2.2 Condition the test specimens for 48 h in the Standard

described in Fig. 1, in which case pins as indicated will be

Laboratory Atmosphere of 50 6 2 % relative humidity at a

required for securing specimens on the cylinders.

temperature of 23 6 1°C (73.4 6 1.8°F), and conduct the tests

6.3 Test Specimens—The test specimen shall be of sufficient

immediately upon removal of the specimens from the condi-

length to provide positive gripping in the jaws with a separa-

tioning room or chamber.

tion of approximately 6 in. (150 mm). In the case of the

flat-jawed clamps, this will require a minimum specimen

5. Thickness

length of 8 in. (200 mm) and a desirable length of 10 in. (250

5.1 Significance and Use:

mm). Where drum-type gripping devices are used, a specimen

5.1.1 The importance of space factor in the design of

no less than 20 in. (500 mm) long will be required. Prepare the

electrical equipment makes proper determination of thickness

specimens from each sample as follows:

essential.

6.3.1 Fabrics—Cut five specimens, 1 in. (25.4 mm) wide

5.1.2 Some properties, such as dielectric strength and di-

(Note 1), with sides parallel to the warp threads, and cut five

electric breakdown, vary with the thickness of the material, and

specimens of similar width with sides perpendicular to the

certain properties, such as thermal conductivity and dielectric

warp threads (Note 2).

constant, cannot be determined without a knowledge of thick-

NOTE 1—Where specimens 1 in. (25.4 mm) in width have ultimate

ness.

breaking loads exceeding the capacity of the machine, it is permissible to

5.2 Test Specimens—Cut specimens prepared from fabric

reduce the width of the specimen to not less than 0.5 in. (13 mm).

samples 1 in. (25 mm) wide across the entire width of the

NOTE 2—Frequently the fill threads of glass fabrics used to manufac-

fabric, while specimens prepared from tape and strip samples

ture silicone rubber-coated glass fabrics do not run in a straight line and

shall be the width of the sample and 36 in. (910 mm) long. are not perpendicular to the warp threads. Breaking strength from

specimens cut perpendicular to the warp threads may, therefore, be highly

Where the specimen is 36 in. or longer (full-width fabric 36 in.

variable.

or more in width, or where the length of a strip is 36 in. or

longer), only one specimen will be required unless otherwise 6.3.2 Tapes and Strips—Cut five specimens, 1 in. (25.4 mm)

specified. Where the specimen is less than 36 in. (full-width wide (see Note 2), from each sample. Where tapes or strips are

fabric less than 36 in. wide, or strips less than 36 in. long), as manufactured in widths less than 1 in. (25.4 mm), use the

many specimens as are needed to obtain the equivalent 36 in. specimen width as manufactured.

D 1458

specimens of the same sample. Since there is no accepted

reference material suitable for determining the bias for this test

method, no statement on bias is being made.

7. Breaking Strength After Creasing

7.1 Significance and Use—Creasing of silicone rubber-

coated glass fabric is accompanied by breaking of some of the

glass fibers at the crease and a consequent reduction in

breaking strength. The extent of this damage is related to the

thickness and weave of the glass fabric and the nature and

thickness of the silicone rubber coating. The creasing simulates

to a degree the pinching action resulting from several succes-

sive layers of tape moving relative to one another while in

confined position, such as in cables.

7.2 Apparatus:

7.2.1 Use a metal weight adjustable between 2.25 and 4.50

lbf (10 and 20 N). Mount it suitably through guides over a

metal horizontal plane so that the weight may be lowered at a

uniform speed perpendicular to the horizontal plane. The

bottom of the weight shall be parallel to the top surface of the

horizontal plane at all times. The creasing surface of the weight

is a rectangle of such dimensions that the side which is

perpendicular to the crease made on the specimen is 1.5 in. (40

mm). Suitable apparatus is shown in Fig. 2.

7.2.2 Provide suitable means for lowering the weight at a

FIG. 1 Drum-Type Gripping Devices uniform rate of 12 in. (300 mm)/min and of raising the weight

at the end of a 2-s dwell. This may be accomplished by

6.4 Conditioning—It is not necessary to condition speci- utilizing the breaking strength machine, described in 6.2, in

mens for this test. Conduct tests at the Standard Laboratory combination with a system of pulleys. It may also be achieved

Temperature of 23 6 1°C (73.4 6 1.8°F). by using a motor fitted with reducing gears and a cam, or by

6.5 Procedure: other devices that accomplish the purpose.

6.5.1 Clamp the ends of the specimen in the jaws between 7.3 Test Specimens—Prepare ten specimens as described in

two pieces of crocus cloth, the abrasive side of the cloth facing 6.3 except that specimens shall be taken from samples of tape

the metal jaws. Carefully align the specimen so that the or rolls of fabric only. In the case of fabric, cut the specimens

breaking force is parallel to the length of the specimen between in the warp direction only.

the jaws. Adjust the clearance between jaws to 6 in. (150 mm). 7.4 Conditioning:

6.5.2 Alternatively, loop the specimen around a binding pin 7.4.1 It is usually not necessary to condition specimens for

of suitable diameter so that the specimen fits neither too tightly this test. When specimens are not especially conditioned, test

nor too loosely in the hole provided. Insert the looped them at the Standard Laboratory Temperature of 23 6 1°C

specimen and pin in the hole provided in the drum-type (73.4 6 1.8°F).

gripping device. Carefully align the specimen so that the 7.4.2 Where it is desired to obtain the greatest degree of

breaking force will be parallel to the length of the specimen. reproducibility, condition specimens in accordance with 4.2.

Adjust the clearance between jaws to 6 in. (150 mm). 7.5 Procedure:

6.5.3 Adjust the speed of the machine in accordance with 7.5.1 Adjust the weight so that the specimens are creased by

the requirements for Tensile Properties in Test Methods D 202. a load of 4.5 lbf (20 N)/in. of width.

6.5.4 Disregard values for breaks in or at the jaws. In these 7.5.2 Fold the specimen without creasing, and insert the

cases, continue tests so that there are five reportable breaking looped end under the weight so that the crease will be formed

strength values per sample. under the center of the weight. Lower the weight at a uniform

6.6 Report: rate of 12 in. (300 mm)/min to crease the specimen.

6.6.1 Report the average, maximum, and minimum break- 7.5.3 Allow the creased specimen to support the weight for

ing strength in pounds per inch of width (or kilograms per a period of 2 s, at the end of which period lift the weight from

millimetre of width), together with the width and nominal the specimen.

7.5.4 Determine the breaking strength of the creased speci-

thickness.

6.6.2 In the case of fabrics, report the breaking strength in men in accordance with 6.5.

the warp and fill directions separately. 7.6 Report—Report the following information:

6.7 Precision and Bias—The precision (repeatability within 7.6.1 Average, maximum, and minimum breaking strengths

a single laborator

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.