ASTM E1627-94(1998)

(Practice)Standard Practice for Sensory Evaluation of Edible Oils and Fats

Standard Practice for Sensory Evaluation of Edible Oils and Fats

SCOPE

1.1 This practice covers the recommended procedures for the sensory evaluation of edible oils and fats.

1.2 This practice covers techniques for evaluating odor and flavor in fats and oils, for determining overall odor and flavor intensity, and the intensity of individual odors or flavors.

1.3 The techniques used in this practice are applicable to oils (liquid at room temperature) and liquified fats (solid at room temperature).

1.4 The values in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1627 – 94 (Reapproved 1998)

Standard Practice for

1

Sensory Evaluation of Edible Oils and Fats

This standard is issued under the fixed designation E 1627; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope sensory panel under the supervision of a sensory professional

or for use by quality control and quality assurance personnel

1.1 This practice covers the recommended procedures for

for the sensory evaluation of edible oils and fats.

the sensory evaluation of edible oils and fats.

1.2 This practice covers techniques for evaluating odor and

3

6. Apparatus

flavor in fats and oils, for determining overall odor and flavor

6.1 Glass Vial, 30-mm outside diameter by 57-mm height,

intensity, and the intensity of individual odors or flavors.

wide-mouth threaded top. Use amber glass for odor/flavor

1.3 The techniques used in this practice are applicable to

evaluations; clear glass for visual examination.

oils (liquid at room temperature) and liquified fats (solid at

6.2 Circulating Waterbath, with automatic timer, thermo-

room temperature).

stat, and rack.

1.4 The values in SI units are to be regarded as the standard.

6.3 Waterbath Thermometer, with range from 20 to 100°C

1.5 This standard does not purport to address all of the

in 1°C divisions, calibrated for 76-mm immersion, 305 mm

safety concerns, if any, associated with its use. It is the

long.

responsibility of the user of this standard to establish appro-

6.4 Hard plastic threaded caps with liners, or tape (PFTE

priate safety and health practices and determine the applica-

pipe thread tape), to cover top of vial opening before capping

bility of regulatory limitations prior to use. Specific precau-

with new, nonmetallic screw-type caps. Tape should com-

tions are given in Section 7.

pletely cover vial opening or multiple strips of tape should be

2. Referenced Documents used.

2.1 ASTM Standards:

7. Precautions

E 1346 Practice for Bulk Sampling, Handling, and Prepar-

2

7.1 Panelists and sample servers should avoid introducing

ing Edible Vegetable Oils for Sensory Evaluation

extraneous odors during testing by use of products, such as

3. Terminology scented hand soap, hand creams, perfume, etc., or odorous

writing instruments or inks. Panelists should avoid exhaling

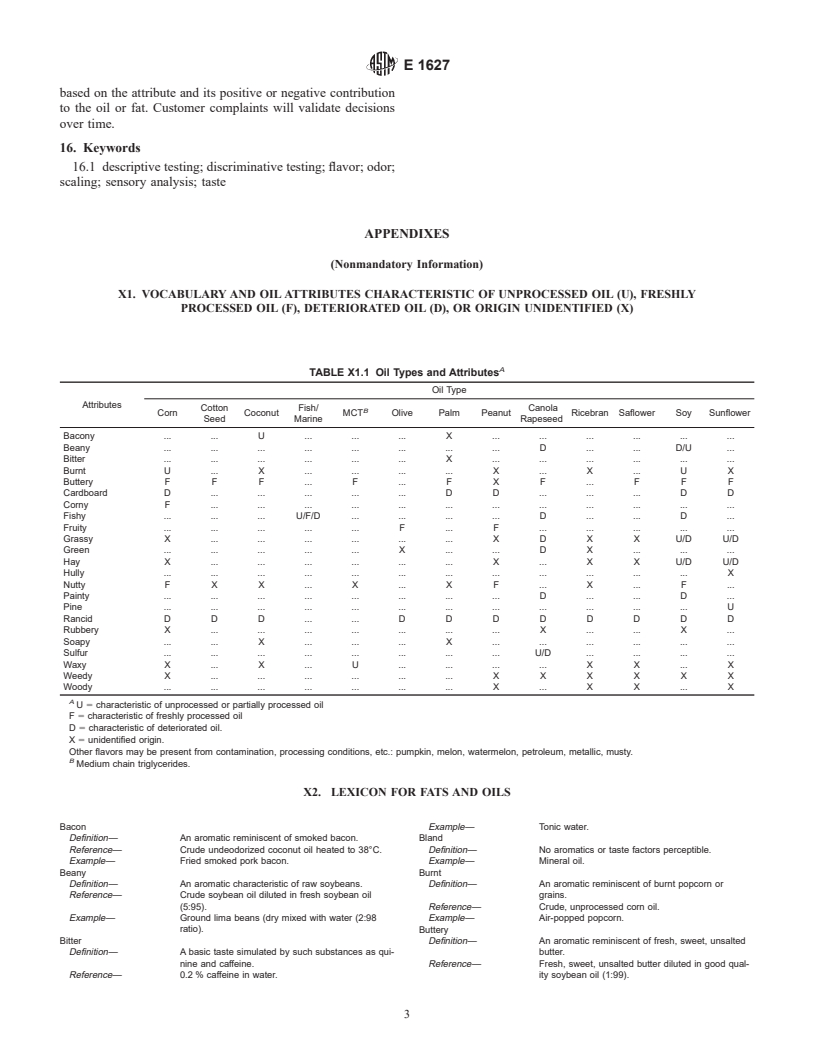

3.1 A lexicon specific for descriptors of odors and flavors in

into sample vials.

oils and fats is included in Appendix X2.

8. Procedures for Recruitment and Screening Panelists

4. Summary of Practice

8.1 For basic information on conducting sensory tests, see

4.1 This practice addresses the procedures for screening and

4 5

MNL26 and STP 758.

training of oil panelists; rating and scoring samples; and data

5

8.2 For normal sensory acuity for basic tastes, see STP 758.

collection, handling, analysis, and interpretation.

8.3 General Odor or Flavor Recognition Relating to Oils—

5. Significance and Use Present prospective panelists with a series of samples and a list

of applicable oil descriptors specific for the type of oil to be

5.1 The application of this practice will help ensure consis-

tested (see Appendix X1). Appendix X2 contains definitions,

tency in procedures used for the sensory evaluation of edible

reference standards, and examples of each descriptor. Test

oils.

prospective panelists for general discrimination and the ability

5.2 This practice is designed for use by oil processors or

to describe samples and demonstrate familiarity with terms.

research laboratories for evaluations by a trained, experienced

1 3

This practice is under the jurisdiction of ASTM Committee E-18 on Sensory Cole-Parmer Instrument Co., 7425 North Oak Park Ave., Niles, IL 60714, is

Evaluation of Materials and Products and is the direct responsibility of Subcom- one source for the apparatus and equipment given in this practice.

4

mittee E18.06 on Food, Beverage, and Tobacco Evaluation. Manual on Sensory Testing Methods, ASTM MNL26, ASTM.

5

Current edition approved Aug. 15, 1994. Published October 1994. Guidelines for Selection and Training of Sensory Panel Members, ASTM STP

2

Annual Book of ASTM Standards, Vol 15.07. 758, ASTM, 1981.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 1627

5

8.4 For general interest and availability, see STP 758. 11.6 If testing oils with weak odors, smell an empty

container to facilitate adaptation to extraneous odors and to

9. Procedures for Training Oil Panelists allow for better discrimination between oils.

5

9.1 See STP 758 for information on p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.