ASTM D1523-00

(Specification)Standard Specification for Synthetic Rubber Insulation for Wire and Cable, 90°C Operation

Standard Specification for Synthetic Rubber Insulation for Wire and Cable, 90°C Operation

SCOPE

1.1 This specification covers a crosslinked insulating compound for electrical wires and cables. The rubber polymer is primarily composed of synthetic rubber.

1.2 This type of insulation is suitable for continuous operation at conductor temperatures not exceeding 90°C in dry locations, and operating voltages not exceeding 2000 V. This insulation may have low-temperature limitations. Consult the manufacturer for specific recommendations for installation.

1.3 In many instances the insulation cannot be tested unless it has been formed around a conductor. Therefore, tests are done on insulated wire in this standard solely to determine the relevant property of the insulation and not to test the conductor or completed cable.

1.4 Whenever two sets of values are presented, in different units, the values in the first set are the standard, while those in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 1523 – 00

Standard Specification for

Synthetic Rubber Insulation for Wire and Cable, 90°C

Operation

This standard is issued under the fixed designation D 1523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

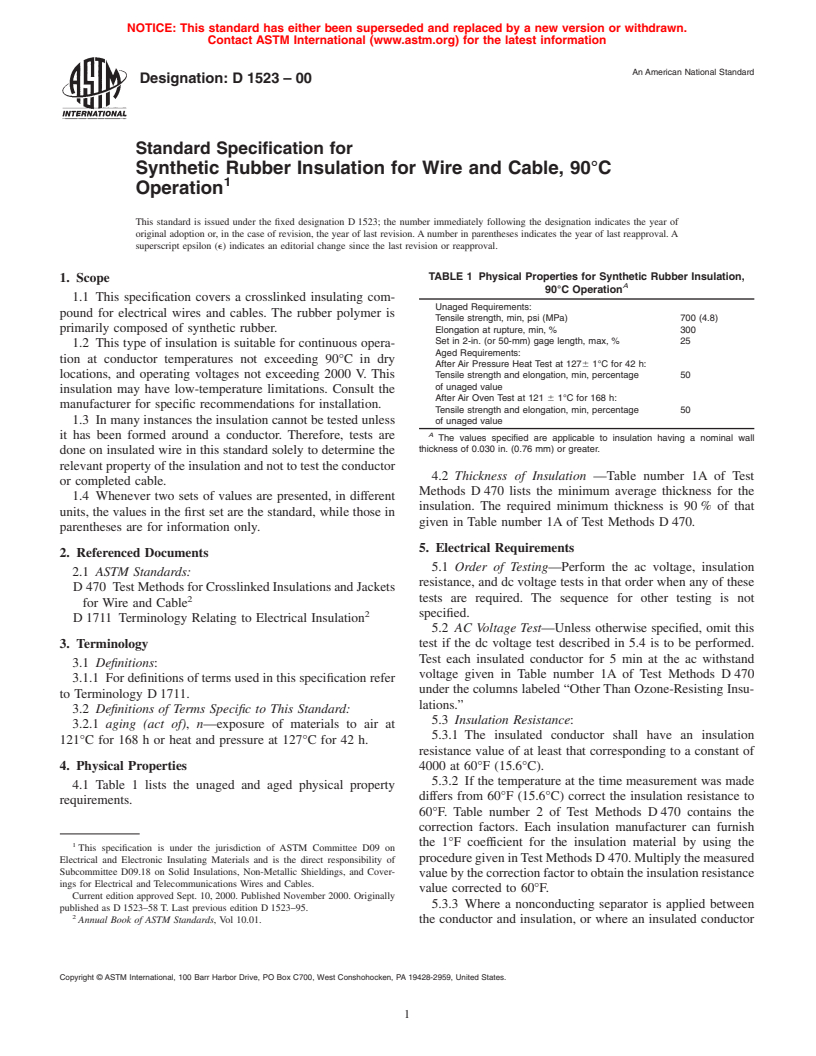

TABLE 1 Physical Properties for Synthetic Rubber Insulation,

1. Scope

A

90°C Operation

1.1 This specification covers a crosslinked insulating com-

Unaged Requirements:

pound for electrical wires and cables. The rubber polymer is

Tensile strength, min, psi (MPa) 700 (4.8)

primarily composed of synthetic rubber.

Elongation at rupture, min, % 300

Set in 2-in. (or 50-mm) gage length, max, % 25

1.2 This type of insulation is suitable for continuous opera-

Aged Requirements:

tion at conductor temperatures not exceeding 90°C in dry

After Air Pressure Heat Test at 1276 1°C for 42 h:

locations, and operating voltages not exceeding 2000 V. This Tensile strength and elongation, min, percentage 50

of unaged value

insulation may have low-temperature limitations. Consult the

After Air Oven Test at 121 6 1°C for 168 h:

manufacturer for specific recommendations for installation.

Tensile strength and elongation, min, percentage 50

1.3 In many instances the insulation cannot be tested unless of unaged value

A

it has been formed around a conductor. Therefore, tests are

The values specified are applicable to insulation having a nominal wall

thickness of 0.030 in. (0.76 mm) or greater.

done on insulated wire in this standard solely to determine the

relevant property of the insulation and not to test the conductor

4.2 Thickness of Insulation —Table number 1A of Test

or completed cable.

Methods D 470 lists the minimum average thickness for the

1.4 Whenever two sets of values are presented, in different

insulation. The required minimum thickness is 90 % of that

units, the values in the first set are the standard, while those in

given in Table number 1A of Test Methods D 470.

parentheses are for information only.

5. Electrical Requirements

2. Referenced Documents

5.1 Order of Testing—Perform the ac voltage, insulation

2.1 ASTM Standards:

resistance, and dc voltage tests in that order when any of these

D 470 Test Methods for Crosslinked Insulations and Jackets

2 tests are required. The sequence for other testing is not

for Wire and Cable

2 specified.

D 1711 Terminology Relating to Electrical Insulation

5.2 AC Voltage Test—Unless otherwise specified, omit this

3. Terminology test if the dc voltage test described in 5.4 is to be performed.

Test each insulated conductor for 5 min at the ac withstand

3.1 Definitions:

voltage given in Table number 1A of Test Methods D 470

3.1.1 For definitions of terms used in this specification refer

under the columns labeled “Other Than Ozone-Resisting Insu-

to Terminology D 1711.

lations.”

3.2 Definitions of Terms Specific to This Standard:

5.3 Insulation Resistance:

3.2.1 aging (act of), n—exposure of materials to air at

5.3.1 The insulated conductor shall have an insulation

121°C for 168 h or heat and pressure at 127°C for 42 h.

resistance value of at least that corresponding to a constant of

4. Physical Properties 4000 at 60°F (15.6°C).

5.3.2 If the temperature at the time measurement w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.