ASTM E1387-95

(Test Method)Standard Test Method for Ignitable Liquid Residues in Extracts from Fire Debris Samples by Gas Chromatography

Standard Test Method for Ignitable Liquid Residues in Extracts from Fire Debris Samples by Gas Chromatography

SCOPE

1.1 This test method covers the identification of residues of ignitable liquids in extracts from fire debris samples. Extraction procedures are described in the referenced documents.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see 6.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1387 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Ignitable Liquid Residues in Extracts from Fire Debris

Samples by Gas Chromatography

This standard is issued under the fixed designation E 1387; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method covers the identification of residues of 3.1 The sample extract or preparation is introduced into the

ignitable liquids in extracts from fire debris samples. Extrac- gas chromatographic column containing a liquid phase suitable

tion procedures are described in the referenced documents. for the separation of common ignitable liquid components. The

1.2 The values stated in SI units are to be regarded as the resulting chromatogram is interpreted by techniques of pattern

standard. The values given in parentheses are for information recognition and pattern comparison described in this test

only. method. Ignitable liquids may fall into one of five major

1.3 This standard does not purport to address all of the classifications, or into a “miscellaneous” category described

safety concerns, if any, associated with its use. It is the herein.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For a specific 4.1 The identification of an ignitable liquid residue in a

sample of fire debris can support a field investigator’s opinion

precautionary statement, see 6.3.

regarding the incendiary nature of a fire.

2. Referenced Documents

4.1.1 The identification of an ignitable liquid residue in a

2.1 ASTM Standards: fire scene does not necessarily lead to the conclusion that a fire

E 260 Practice for Packed Column Gas Chromatography was incendiary in nature. Further investigation may reveal a

E 752 Practice for Safety and Health Requirements Relating legitimate reason for the presence of ignitable liquids.

to Occupational Exposure to Carbon Disulfide 4.2 Due to the volatility of ignitable liquids and to variations

E 1385 Practice for Separation and Concentration of Ignit- in sampling technique, the absence of detectable quantities of

able Liquid Residues from Fire Debris Samples by Steam ignitable liquid residues does not necessarily lead to the

Distillation conclusion that ignitable liquids were not present at the fire

E 1386 Practice for Separation and Concentration of Ignit- scene.

able Liquid Residues from Fire Debris Samples by Solvent 4.3 When the gas chromatographic pattern is not sufficiently

Extraction complex, as described in 10.3, additional analytical techniques

E 1389 Practice for Cleanup of Fire Debris Sample Extracts are required.

by Acid Stripping

5. Apparatus

E 1412 Practice for Separation and Concentration of Ignit-

5.1 Gas Chromatograph—A chromatograph equipped with

able Liquid Residues from Fire Debris Samples by Passive

Headspace Concentration a flame ionization or mass spectral detector may be used. Other

detectors may be used if it can be shown that they have

E 1413 Practice for Separation and Concentration of Ignit-

able Liquid Residues from Fire Debris Samples by Dy- sensitivity and selectivity equal to the above detectors.

5.1.1 Sensitivity—The system shall be capable of detecting

namic Headspace Concentration

E 1618 Guide for Ignitable Liquid Residues in Extracts 0.05 volume % in carbon disulfide (or any appropriate solvent)

of any common ignitable mixtures.

from Fire Debris Samples by Gas Chromatography-Mass

Spectrometry 5.1.2 Sample Inlet System—A sample inlet system that

allows a reproducible volume of liquid to be injected.

5.1.3 Column—A non-polar capillary column is recom-

This test method is under the jurisdiction of ASTM Committee E-30 on

mended, but any column may be used provided that, under the

Forensic Sciences and is the direct responsibility of Subcommittee E30.01 on

conditions of use, the test mixture can be resolved into its

Criminalistics.

component peaks.

Current edition approved Oct. 10, 1995. Published December 1995. Originally

published as E 1387 – 90. Last previous edition E 1387 – 90. 5.1.3.1 The test mixture shall consist of equal parts by

Annual Book of ASTM Standards, Vol 14.02.

weight of the even-numbered normal alkanes ranging from

Annual Book of ASTM Standards, Vol 11.03.

E 1387

n-hexane through n-eicosane, plus the following aromatic change composition. Extracts in carbon disulfide may be

components: toluene, p-xylene, o-ethyltoluene, covered with water prior to removing the extracts from the

m-ethyltoluene, and 1,2,4-trimethylbenzene. sample preparation hood. Alternatively, septum seal vials may

5.1.3.2 If total resolution of the test mixture cannot be be used for storing any solvents or extracts.

obtained on a single column or program, changing columns or 7.2.1 If water is used as a sealant, exercise care to avoid the

programs is permitted as long as using both columns or introduction of water onto DMCS treated columns.

programs results in the complete resolution of the test mixture. 7.2.2 Avoid the use of water as a sealant if the presence of

5.2 Column Oven—A column oven capable of reproducible water soluble compounds is suspected.

temperature and temperature program settings in the range of

8. Calibration

50 to 300°C should be used.

5.3 Strip Chart Recorder—A recording potentiometer with 8.1 Calibrate the chromatographic instrument frequently

using standards of known concentrations of known ignitable

a full scale deflection of 10 mV or less should be used. The full

scale response of the recorder should not exceed 1 s. An liquids as well as blanks. Optimize gas flows periodically.

Refer to Practice E 260 for detailed instructions on operation of

integrator, or computerized data station and printer which

meets or exceeds these requirements, is acceptable. the gas chromatograph.

8.1.1 Run appropriate blanks and controls periodically.

5.4 Syringes:

5.4.1 For liquid samples—a microsyringe, capable of repro- 8.1.1.1 Clean syringes thoroughly between injections.

8.1.2 Run known standards as necessary.

ducibly introducing sample sizes in the range of 0.1 to 10.0

mL. 8.1.2.1 Standard chromatograms must be run under the

5.4.2 For gas samples—a gas-tight syringe capable of same chromatographic conditions as those used to produce the

sample chromatogram.

reproducibly introducing sample sizes in the range of 0.5 to 5

mL. 8.1.2.2 Every case file that includes a positive identification

of an ignitable liquid or residue must include the standard

6. Reagents and Materials

chromatogram used to confirm the identification.

8.2 Chromatogram Evaluation—A good chromatogram for

6.1 Purity of Reagents—Reagent grade chemicals shall be

comparison work is one in which the peaks of interest are 50

used in all tests. Unless otherwise indicated, it is intended that

to 100 % of full scale. Rerun samples, or replot chromatogram,

all reagents conform to the specifications of the Committee on

Analytical Reagents of the American Chemical Society where using different parameters (attenuation or sample size) to

achieve a good chromatogram.

such specifications are available. Other grades may be used,

provided it is first ascertained that the reagent is of sufficiently 8.2.1 In addition to the chromatogram described above, it is

sometimes necessary to produce other, off-scale plots, in order

high purity to permit its use without lessening the accuracy of

the determination. to bring some features into view for comparison. Such off-scale

plots may be required when there are one or more components

6.2 Solvents—The solvent in which the extract is dissolved

will depend upon the extraction technique employed. Fre- present at a significantly higher concentration than the other

components in the residue.

quently check solvents for purity by running appropriate

blanks, both neat and evaporated, to at least twice the extent

9. Petroleum Distillate Classification System

used in the analysis.

9.1 Six major classes of complex liquid products are recog-

6.2.1 If Carbon disulfide is used, read and follow the safety

nized as usually identifiable by GC patterning alone when

precautions described in Practice E 752.

recovered from fire debris.

6.3 Carrier Gas—Caution: hydrogen, helium, and nitrogen

9.1.1 This test method is only intended to allow isolated

are compressed under high pressure, and hydrogen is an

residues to be characterized as to one of the types of products

extremely flammable gas.

listed in Table 1. Other characterizations of samples may be

6.4 Combustion Gases—Air and hydrogen (if a flame ion-

possible, but are not within the scope of this test method.

ization detector is used).

6.5 Activated Charcoal.

10. Procedure

7. Sample Handling

10.1 Obtain a chromatogram of the fire debris sample

extract.

7.1 Methods of obtaining the extracts or preparations for

10.2 Obtain a chromatogram of a matching, or nearly

analysis are described in Practices E 1385, E 1386, E 1389,

matching, standard, and compare the pattern of peaks visually.

E 1412, and E 1413.

10.2.1 The essential requirement for making a classification

7.2 Due to the volatility of the solvents and the analytes,

using this procedure is the matching of the sample chromato-

take care to ensure that samples do not evaporate or otherwise

gram with a known standard chromatogram obtained under

similar conditions, noting sufficient significant points of corre-

lation or similarities. Make all comparisons using only good

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

chromatograms, as described in 8.2.

listed by the American Chemical Society, see Analar Standards for Laboratory

10.2.2 Pattern matching requires that the entire pattern used

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

for comparison be displayed at the same sensitivity.

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD. 10.2.2.1 To provide sufficient detail for some comparisons,

E 1387

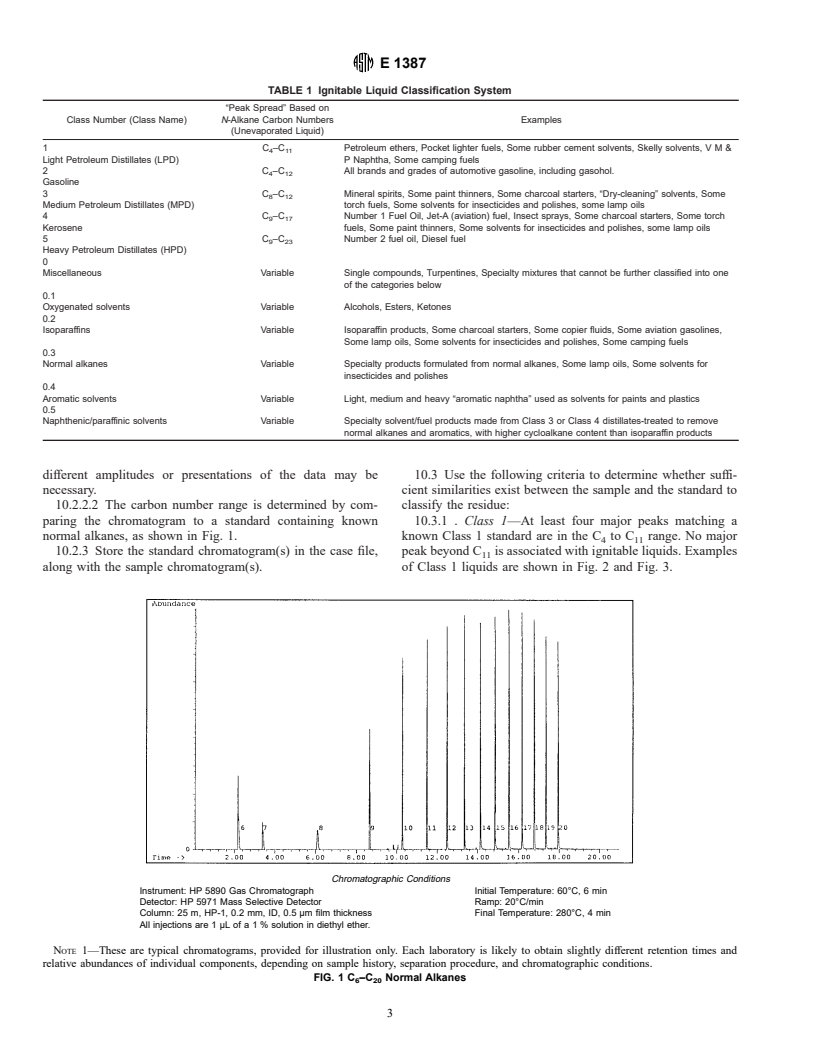

TABLE 1 Ignitable Liquid Classification System

“Peak Spread” Based on

Class Number (Class Name) N-Alkane Carbon Numbers Examples

(Unevaporated Liquid)

1 C –C Petroleum ethers, Pocket lighter fuels, Some rubber cement solvents, Skelly solvents,VM&

4 11

Light Petroleum Distillates (LPD) P Naphtha, Some camping fuels

2 C –C All brands and grades of automotive gasoline, including gasohol.

4 12

Gasoline

3 C –C Mineral spirits, Some paint thinners, Some charcoal starters, “Dry-cleaning” solvents, Some

8 12

Medium Petroleum Distillates (MPD) torch fuels, Some solvents for insecticides and polishes, some lamp oils

4 C –C Number 1 Fuel Oil, Jet-A (aviation) fuel, Insect sprays, Some charcoal starters, Some torch

9 17

Kerosene fuels, Some paint thinners, Some solvents for insecticides and polishes, some lamp oils

5 C –C Number 2 fuel oil, Diesel fuel

9 23

Heavy Petroleum Distillates (HPD)

Miscellaneous Variable Single compounds, Turpentines, Specialty mixtures that cannot be further classified into one

of the categories below

0.1

Oxygenated solvents Variable Alcohols, Esters, Ketones

0.2

Isoparaffins Variable Isoparaffin products, Some charcoal starters, Some copier fluids, Some aviation gasolines,

Some lamp oils, Some solvents for insecticides and polishes, Some camping fuels

0.3

Normal alkanes Variable Specialty products formulated from normal alkanes, Some lamp oils, Some solvents for

insecticides and polishes

0.4

Aromatic solvents Variable Light, medium and heavy “aromatic naphtha” used as solvents for paints and plastics

0.5

Naphthenic/paraffinic solvents Variable Specialty solvent/fuel products made from Class 3 or Class 4 distillates-treated to remove

normal alkanes and aromatics, with higher cycloalkane content than isoparaffin products

different amplitudes or presentations of the data may be 10.3 Use the following criteria to determine whether suffi-

necessary. cient similarities exist between the sample and the standard to

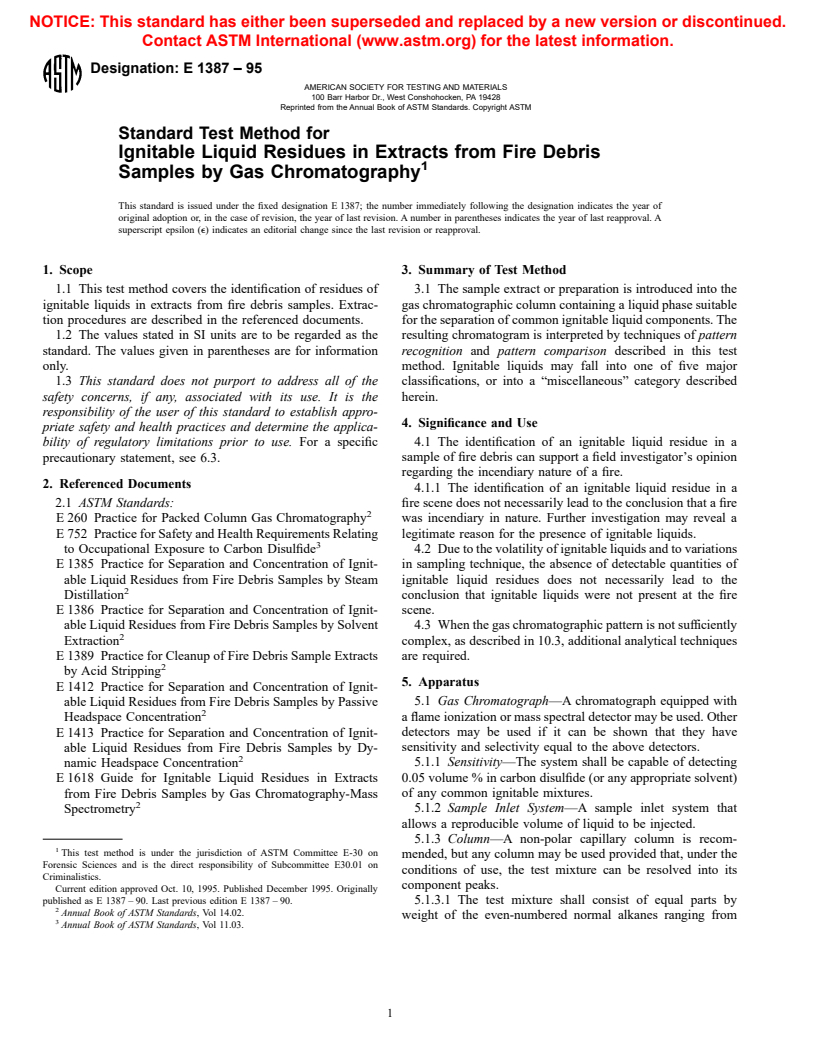

10.2.2.2 The carbon number range is determined by com- classify the residue:

paring the chromatogram to a standard containing known 10.3.1 . Class 1—At least four major peaks matching a

normal alkanes, as shown in Fig. 1. known Class 1 standard are in the C to C range. No major

4 11

10.2.3 Store the standard chromatogram(s) in the case file, peak beyond C is associated with ignitable liquids. Examples

along with the sample chromatogram(s). of Class 1 liquids are shown in Fig. 2 and Fig. 3.

Chromatographic Conditions

Instrument: HP 5890 Gas Chromatograph Initial Temperature: 60°C, 6 min

Detector: HP 5971 Mass Selective Detector Ramp: 20°C/min

Column: 25 m, HP-1, 0.2 mm, ID, 0.5 μm film thickness Final Temperature: 280°C, 4 min

All injections are 1 μL of a 1 % solution in diethyl ether.

NOTE 1—These are typical chromatograms, provided for illustration only. Each laboratory is likely to obtain slightly different retention times and

relative abundances of individual components, depending on sample history, separation procedure, and chromatographic conditions.

FIG. 1 C –C Normal Alkanes

6 20

E 1387

Chromatographic Conditions

Instrument: HP 5890 Gas Chromatograph Initial Temperature: 60°C, 6 min

Detector: HP 5971 Mass Selective Detector Ramp: 20°C/min

Column: 25 m, HP-1, 0.2 mm, ID, 0.5 μm film thickness Final Temperature: 280°C, 4 min

All injections are 1 μL of a 1 % solution in diethyl ether.

NOTE 1—These are typical chromatograms, provided for illustration only. Each laboratory is likely to obtain slightly different retention times and

relative abundances of individual components, depending on sample history, separation procedure, and chromatographic conditions.

FIG. 2 Example of a Class 1 Pattern; Brand A Cigarette Lighter Fluid

Chromatographic Conditions

Instrument: HP 5890 Gas Chromatograph Initial Temperature: 60°C, 6 min

Detector: HP 5971 Mass Selective Detector Ramp: 20°C/min

Column: 25 m, HP-1, 0.2 mm, ID, 0.5 μm film thickness Final Temperature: 280°C, 4 min

All injections are 1 μL of a 1 % solution in diethyl ether.

NOTE 1—These are typical chromatograms, provided for illustration only. Each laboratory is likely to obtain slightly different retention times and

relat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.