ASTM E826-08(2013)

(Practice)Standard Practice for Testing Homogeneity of a Metal Lot or Batch in Solid Form by Spark Atomic Emission Spectrometry

Standard Practice for Testing Homogeneity of a Metal Lot or Batch in Solid Form by Spark Atomic Emission Spectrometry

SIGNIFICANCE AND USE

5.1 The purpose of this practice is to evaluate the homogeneity of a lot of material selected as a candidate for development as a reference material or certified reference material, or for a L/B selected for some other purpose (see Appendix X1-Appendix X4 for examples).

5.2 This practice is applicable to the testing of samples taken at various stages during production. For example, continuous cast materials, ingots, rolled bars, wire, etc., could be sampled at various stages during the production process and tested.

SCOPE

1.1 This practice is suitable for testing the homogeneity of a metal lot or batch (L/B) in solid form by spark atomic emission spectrometry (Spark-AES). It is compliant with ISO Guide 35—Certification of Reference Materials: General and Statistical Principles. It is primarily intended for use in the development of reference materials but may be used in any other application where a L/B is to be tested for homogeneity. It is designed to provide a combined study of within-unit and between-unit homogeneity of such a L/B.

1.2 This practice is designed primarily to test for elemental homogeneity of a metal L/B by Spark-AES. However, it can be adapted for use with other instrumental techniques such as X-ray fluorescence spectrometry (XRF) or atomic absorption spectrometry (AAS).Note 1—This practice is not limited to elemental analysis or techniques. This practice can be applied to any property that can be measured, for example, the property of hardness as measured by the Rockwell technique.

1.3 The criteria for acceptance of the test specimens must be previously determined. That is, the maximum acceptable level of heterogeneity must be determined on the basis of the intended use of the L/B.

1.4 It is assumed that the analyst is trained in Spark-AES techniques including the specimen preparation procedures needed to make specimens ready for measurements. It is further assumed that the analyst is versed in and has access to computer-based data capture and analysis. The methodology of this practice is best utilized in a computer based spreadsheet.

1.5 This practice can be applied to one or more elements in a specimen provided the signal-to-background ratio is not a limiting factor.

1.6 This practice includes methods to correct for systematic drift of the instrument with time. (Warning—If drift occurs, erroneous conclusions will be obtained from the data analysis.)

1.7 This practice also includes methods to refine estimates of composition and uncertainty through the use of a type standard or multiple calibrants.

1.8 It further provides a means of reducing a nonhomogeneous set to a homogeneous subset.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E826 − 08(Reapproved 2013)

Standard Practice for

Testing Homogeneity of a Metal Lot or Batch in Solid Form

by Spark Atomic Emission Spectrometry

This standard is issued under the fixed designation E826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This practice also includes methods to refine estimates

of composition and uncertainty through the use of a type

1.1 Thispracticeissuitablefortestingthehomogeneityofa

standard or multiple calibrants.

metallotorbatch(L/B)insolidformbysparkatomicemission

spectrometry (Spark-AES). It is compliant with ISO Guide

1.8 It further provides a means of reducing a nonhomoge-

35—Certification of Reference Materials: General and Statis-

neous set to a homogeneous subset.

tical Principles. It is primarily intended for use in the devel-

1.9 This standard does not purport to address all of the

opment of reference materials but may be used in any other

safety concerns, if any, associated with its use. It is the

application where a L/B is to be tested for homogeneity. It is

responsibility of the user of this standard to establish appro-

designed to provide a combined study of within-unit and

priate safety and health practices and determine the applica-

between-unit homogeneity of such a L/B.

bility of regulatory limitations prior to use.

1.2 This practice is designed primarily to test for elemental

homogeneityofametalL/BbySpark-AES.However,itcanbe

2. Referenced Documents

adapted for use with other instrumental techniques such as

X-ray fluorescence spectrometry (XRF) or atomic absorption

2.1 ASTM Standards:

spectrometry (AAS).

E135Terminology Relating to Analytical Chemistry for

NOTE 1—This practice is not limited to elemental analysis or tech-

Metals, Ores, and Related Materials

niques.Thispracticecanbeappliedtoanypropertythatcanbemeasured,

E177Practice for Use of the Terms Precision and Bias in

for example, the property of hardness as measured by the Rockwell

ASTM Test Methods

technique.

E178Practice for Dealing With Outlying Observations

1.3 Thecriteriaforacceptanceofthetestspecimensmustbe

E634Practice for Sampling of Zinc and Zinc Alloys by

previously determined. That is, the maximum acceptable level

Spark Atomic Emission Spectrometry

of heterogeneity must be determined on the basis of the

E716Practices for Sampling and Sample Preparation of

intended use of the L/B.

Aluminum and Aluminum Alloys for Determination of

1.4 It is assumed that the analyst is trained in Spark-AES

Chemical Composition by Spectrochemical Analysis

techniques including the specimen preparation procedures

E1329PracticeforVerificationandUseofControlChartsin

needed to make specimens ready for measurements. It is

Spectrochemical Analysis

further assumed that the analyst is versed in and has access to

E1601Practice for Conducting an Interlaboratory Study to

computer-baseddatacaptureandanalysis.Themethodologyof

Evaluate the Performance of an Analytical Method

this practice is best utilized in a computer based spreadsheet.

E1806Practice for Sampling Steel and Iron for Determina-

1.5 This practice can be applied to one or more elements in

tion of Chemical Composition

a specimen provided the signal-to-background ratio is not a

2.2 ISO Standard:

limiting factor.

ISO Guide 35Certification of Reference Materials: General

1.6 This practice includes methods to correct for systematic

and Statistical Principles

drift of the instrument with time. (Warning—If drift occurs,

erroneousconclusionswillbeobtainedfromthedataanalysis.)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This practice is under the jurisdiction ofASTM Committee E01 on Analytical contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ChemistryforMetals,Ores,andRelatedMaterialsandisthedirectresponsibilityof Standards volume information, refer to the standard’s Document Summary page on

Subcommittee E01.22 on Laboratory Quality. the ASTM website.

Current edition approved April 1, 2013. Published August 2013. Originally Available from International Organization for Standardization (ISO), 1, ch. de

approved in 1981. Last previous edition approved in 2008 as E826–08. DOI: la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

10.1520/E0826-08R13. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E826 − 08 (2013)

3. Terminology 4.4 This practice requires that there be an absence of

outliers in the data (Practice E178). (Warning—The use of

3.1 Definitions—For definitions of terms used in this

Practice E178 dealing with outliers should be done with

practice,refertoTerminologyE135,andPracticesE177,E178,

extreme care to ensure that values are not discarded that may

E1329, and E1806.

be valid for the analysis.)

3.2 Definitions of Terms Specific to This Standard:

4.5 Variability introduced by sample preparation may influ-

3.2.1 ANOVA (analysis of variance)—a statistical means of

ence the findings of this practice.

partitioning the variance of a data set into contributing com-

ponents.

5. Significance and Use

3.2.2 batch—a set of specimens to be tested for

homogeneity, often a subset of a lot.

5.1 The purpose of this practice is to evaluate the homoge-

neity of a lot of material selected as a candidate for develop-

3.2.3 between-unit homogeneity—homogeneitywithrespect

ment as a reference material or certified reference material, or

to the various specimens in the candidate L/B (see Section 8).

for a L/B selected for some other purpose (see Appendix

3.2.4 drift—a gradual, systematic change in instrument

X1-Appendix X4 for examples).

readings with time.

5.2 This practice is applicable to the testing of samples

3.2.5 fair (fairness)—the assurance for a participant in a

taken at various stages during production. For example, con-

proficiencytestprogramthatallofthematerialfromwhichthe

tinuous cast materials, ingots, rolled bars, wire, etc., could be

participants’ test materials are taken is sufficiently homoge-

sampled at various stages during the production process and

neous so that any results later identified as outliers should not

tested.

be attributed to any significant test item variability.

3.2.6 homogeneity—as defined in this practice, statistically

6. Summary of the Test Method

acceptable differences between means in the test.

6.1 General—This practice is based on J. W. Tukey’s HSD

3.2.7 solid form—specimensareinaformequivalenttothat

(honestly significant difference) procedure for pairwise com-

described in 6.4.4 of Practice E1806.

parisons among means (8). It uses the ANOVA technique to

3.2.8 type standard—as defined in this practice, calibrant

partition the variation into contributing components, then

similar in composition to the candidate for homogeneity

eliminates contributions from sources other than heterogeneity

testing.

and random processes. The model used is:

3.2.9 unit—specimen to be tested, referred to as a disk,

x 5 µ1β 1τ 1ε (1)

ij i j ij

regardless of the actual shape.

where:

3.2.10 within-unit homogeneity—homogeneity with respect

to an individual specimen (see Section 8). x = the result of the ith burn on the jth P/S,

ij

µ = the “true” mean of the population of all possible burn

4. Summary of Practice

results,

β = the variation in the ith burn due to the measurement

4.1 This practice, which is based on statistical methods

i

process,

(1-8), consists of stepwise instructions for testing the homo-

τ = the variation in the jth P/S due to heterogeneity, and

geneity of a candidate L/B. The candidate specimens are j

ε = the variation due to random or randomized processes.

selected as described in Section 10, and then measured by ij

Spark-AES (Section 11). The resultant data are corrected for

6.1.1 The data are then arranged inabbyt matrix (where b

instrumental drift, if desired (see Sections 13-15), and then

isthenumberofburnsperP/Sandtisthenumberofpositions

tabulated (see Tables2, X1.3, and X1.4) to facilitate the

or specimens) and rowwise statistics taken. These statistics

statistical calculations that are performed according to Section

allowtheestimationandeliminationofthevariationduetothe

12.

measurement process, leaving only the contributions from

heterogeneity and random processes. The maximum contribu-

4.2 The homogeneity of the L/B is determined from the

results of the data analysis consisting of a one-way analysis of tion of random error is estimated and a critical value (w)

determined. If the difference between any two pairs of means

variance (ANOVA).

is less than the critical value, then the set of positions or

4.3 This practice requires that repeated measurements on

specimens is considered homogeneous. In practice, the “ best”

the same position or specimen (P/S) have sufficient precision

difference is between the maximum and the minimum. If we

(that is, repeatability) through appropriate selection of instru-

call this value T, then if T is less than or equal to w, the set is

mental parameters so that any significant difference within or

considered homogeneous at the selected level of confidence

between positions or specimens can be detected with confi-

(usually 95% or 99%). If T is greater than w, then the set is

dence. This is best done through the use of drift management:

considered heterogeneous.

standardization, control charts (Practice E1329),

normalization, and drift monitoring.

6.2 Multiple Determinations—The reason for taking mul-

tiple determinations on each P/S is to obtain a gage of the

variation associated with the measurement process and the

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this standard. material being tested.

E826 − 08 (2013)

6.3 Randomized Testing—Randomizing the measurement 7.3 Regardless of shape, individual specimens must be

sequences randomizes any systematic error(s) not accounted dimensionally compatible with common analytical methods.

for with instrument, process, and drift controls. 7.3.1 Mostsolidformtechniquesrequireaspecimentohave

NOTE 2—It is possible to extend this to any population that can be put

at least one flat analytical face.

in this form. This means that this technique can be applied to lab data

7.3.2 If the shape of a specimen is too irregular, it will be

generated by an interlaboratory study. Currently, interlaboratory studies,

too difficult to “clamp” to Spark-AES spark stand.

even with the aid of h and k statistics (Practice E1601), only allow the

7.3.3 The preferred form is cylindrical, but any form that

administrator to request corrections or perhaps eliminate certain data

based on judgement calls. The application of this approach would allow satisfies the above criteria is acceptable.

the option of systematic elimination through the use of an accepted

7.3.4 Typical forms are round, elliptical, rectangular, or

statistical method.

hexagonal disks, truncated cones, etc.

7.3.5 Spark-AES requires a specimen to be at least 6 mm

7. Lot or Batch Forms

thick to minimize heating effects.

7.1 Lots or batches may be cast or wrought.

NOTE 3—When considering the use of cast material, the analyst must

7.1.1 Acastmateriallotisgenerallypresentedintheformof

consider the possibility that microscopic cast structures may cause

ingot(s) or linked pieces.

problems with the measurement technique. It is best to use a casting

7.1.2 A wrought material lot is generally presented in the

technique that will produce “well behaved” specimens such as chill

form of bar stock.

casting.

7.2 Lots or batches may be contiguous, piecewise, or a

8. The Sampling Model

combination.

7.2.1 A contiguous lot might be a single ingot or bar. 8.1 General—The proposed sampling system is based on

7.2.2 A piecewise lot might be a set of pieces having been cylindrical geometry. That is, most lots or batches tested

cut from bar(s), ingot(s), or linked piece casting(s). In this last present themselves in some variant of cylindrical geometry.

case, even if the pieces have not been separated, it can be Roundbarstockisfairlyobvious.Butevensquare,rectangular,

considered a piecewise lot since they are already defined. hexagonal,orothersuchgeometriesworkunderthisapproach.

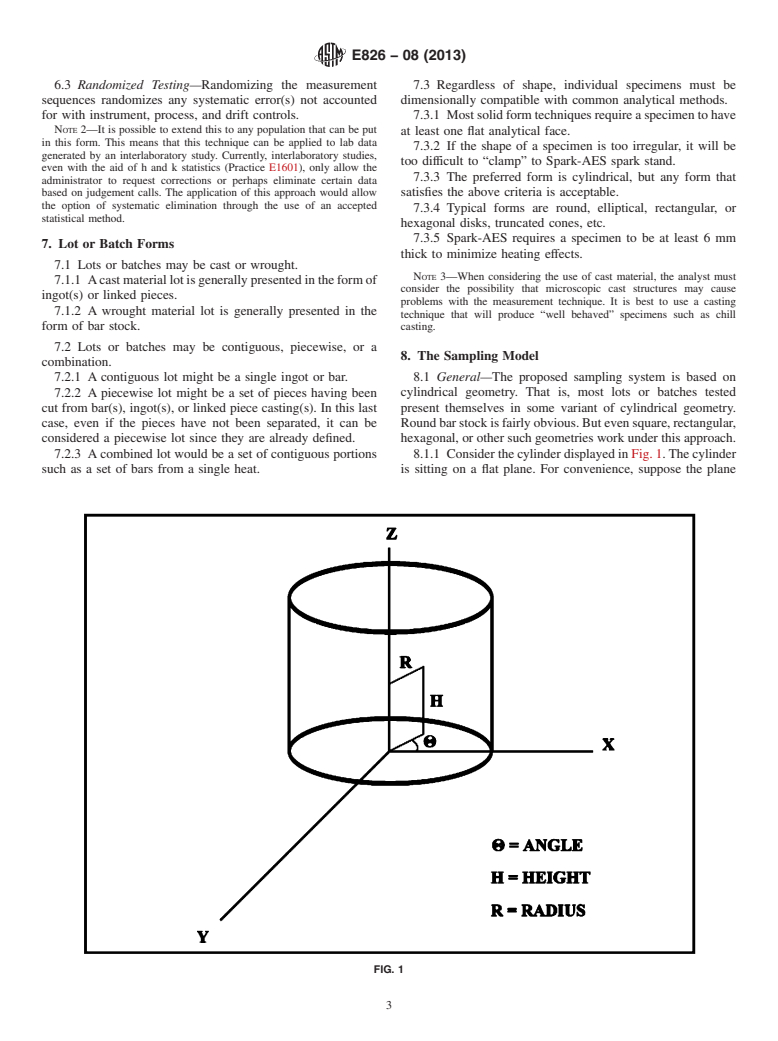

7.2.3 Acombined lot would be a set of contiguous portions 8.1.1 ConsiderthecylinderdisplayedinFig.1.Thecylinder

such as a set of bars from a single heat. is sitting on a flat plane. For convenience, suppose the plane

FIG. 1

E826 − 08 (2013)

corresponds to zero height. Further, suppose the axis of the

cylinder defines the origin of an XYZ coordinate system. The

zaxiscorrespondstothecylinderaxis.The xand yaxescanbe

oriented as one chooses. Let the x axis correspond to an angle

of zero degrees. Then, every point in the cylinder can be

described by its height from the plane (H ≥ Z), its distance

fromthecentralaxis(R),anditsanglewithrespecttothe xaxis

(Θ).

8.1.2 Given the cylindrical geometry described in 8.1.1

(Fig. 1), homogeneity can be defined in axial, radial, and

circumferential terms.Axial homogeneity refers to the unifor-

mity of the material from one end to another. Radial homoge-

neity refers to the uniformity of the material from the center

outward.Circumferentialhomogeneityreferstotheuniformity

of the material around a concentric circle.

8.1.3 At any level (Z) the latter two are measured by

selecting a number of positions on the analytical face of each

sampletobesocharacterized.Thenumberandpositionofeach

isarationalizationbetweenthesizeandshapeoftheanalytical

face and the size of Spark-AES burn spot.Asufficient number

of spots are chosen to represent a reasonable sampling of the

surface.

FIG. 3

8.1.4 Two common forms encountered are demonstrated in

Figs. 2 and 3.Arationalization of sample size versus spot size

total number of positions. Four such sequences are run. The

dictates a seven-position strategy for round samples in the

resultant data are derandomized and presented as a 4×n

range of 25 mm to 50 mm in diameter and a nine-position

matrix. The resultant matrix is processed in accordance with

strategy for square samples in the range of 25 mm to 50 mm

Section 12.

across.Fortheroundgeometry,circumferentialhomogeneityis

8.1.6 If this process is applied at any level (Z), then the

covered with Positions 1–6. Comparisons of these to Position

entire solid can be characterized.

7coversradialhomogeneity.Forthesquaregeometry,circum-

ferentialhomogeneityiscoveredwithPositions1–8.Compari-

8.2 Within-Unit Homogeneity (R, Θ)—For

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.