ASTM F788-12

(Specification)Standard Specification for Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric Series

Standard Specification for Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric Series

ABSTRACT

This specification establishes allowable limits for the various types of surface discontinuities that may occur during the manufacture and processing of bolts, screws, and studs, including heat-treated machine screws, tapping screws, and sems. Types of surface discontinuities are: crack; burst; seam; fold; thread lap; void; tool marks; and gouge and nick. These surface discontinuities shall be inspected in accordance with the specified requirements.

SCOPE

1.1 This specification establishes allowable limits for the various types of surface discontinuities that may occur during the manufacture and processing of bolts, screws, and studs, including heat-treated machine screws, tapping screws, and sems (the washers of screw-washer assemblies are excluded). This specification covers metric series products with nominal diameters of 4 mm and larger and with specified minimum tensile strengths of 420 MPa and higher; and inch series products with nominal diameters of No. 5 (0.1250 in.) and larger and with specified minimum tensile strengths of 60 000 psi and higher.

1.2 When the engineering requirements of the application necessitate control of surface discontinuities on bolts, screws, or studs, the purchaser shall specify conformance to ASTM Specification F788, in the original inquiry and purchase order.

1.2.1 When the engineering requirements of the application necessitate that surface discontinuities on bolts, screws, and studs be controlled within limits closer than those specified in this specification, the purchaser shall specify the applicable limits in the original inquiry and purchase order.

1.3 The allowable limits established in this specification for metric bolts, screws, and studs with nominal diameters from 4 to 24 mm inclusive, are essentially identical with requirements given in ISO 6157/I. There are no ISO standards for surface discontinuities on any inch-series products.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F788 −12

StandardSpecification for

Surface Discontinuities of Bolts, Screws, and Studs, Inch

1

and Metric Series

ThisstandardisissuedunderthefixeddesignationF788;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification establishes allowable limits for the

E340Test Method for Macroetching Metals and Alloys

various types of surface discontinuities that may occur during

F1470Practice for Fastener Sampling for Specified Me-

the manufacture and processing of bolts, screws, and studs,

chanical Properties and Performance Inspection

including heat-treated machine screws, tapping screws, and

F1789Terminology for F16 Mechanical Fasteners

sems (the washers of screw-washer assemblies are excluded).

3

This specification covers metric series products with nominal

2.2 ISO Standard:

diameters of 4 mm and larger and with specified minimum ISO6157/IFasteners, Surface Discontinuities on Bolts,

tensile strengths of 420 MPa and higher; and inch series Screws and Studs

products with nominal diameters of No. 5 (0.1250 in.) and

larger and with specified minimum tensile strengths of 60000 3. Ordering Information

psi and higher.

3.1 Orders for bolts, screws, and studs requiring disconti-

nuity control shall include the following:

1.2 When the engineering requirements of the application

3.1.1 ASTM designation and date of issue of this specifica-

necessitate control of surface discontinuities on bolts, screws,

tion.

or studs, the purchaser shall specify conformance to ASTM

3.1.2 Special requirements, for example, closer discontinu-

Specification F788, in the original inquiry and purchase order.

ity limits (1.2.1) and inspection sampling plan (6.2).

1.2.1 When the engineering requirements of the application

necessitate that surface discontinuities on bolts, screws, and

4. Types of Surface Discontinuities (see Terminology

studs be controlled within limits closer than those specified in

F1789 for definitions not provided)

this specification, the purchaser shall specify the applicable

4.1 Crack

limits in the original inquiry and purchase order.

4.1.1 Quench Cracks—Typical quench cracks are shown in

1.3 The allowable limits established in this specification for

Fig. 1. Limits are specified in 5.2.

metric bolts, screws, and studs with nominal diameters from 4

4.1.2 Forging Cracks—Typical forging cracks are shown in

to 24 mm inclusive, are essentially identical with requirements

Fig. 2. Limits are specified in 5.3.

given in ISO6157/I. There are no ISO standards for surface

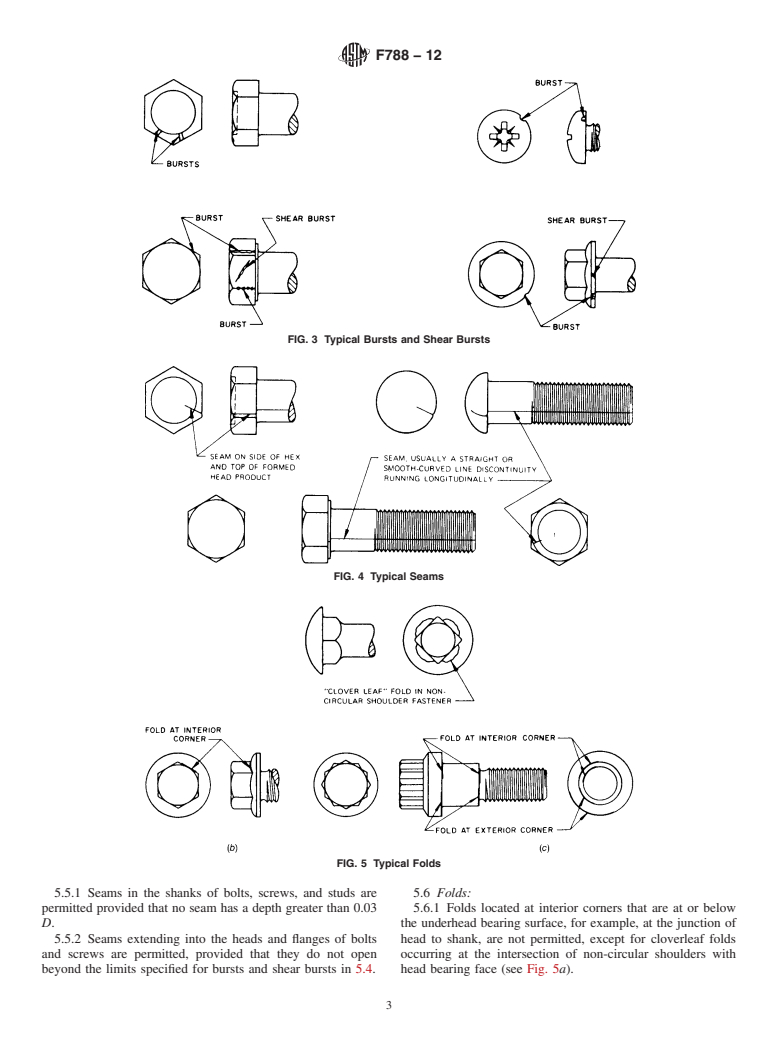

4.2 Burst—Typical bursts are shown in Fig. 3. Limits are

discontinuities on any inch-series products.

specified in 5.4.

1.4 The values stated in either SI units or inch-pound units

4.2.1 Shear Burst—A shear burst is an open break in the

are to be regarded separately as standard. The values stated in

metal located at approximately a 45° angle to the product axis.

each system may not be exact equivalents; therefore, each

Shearburstsoccurmostfrequentlyattheperipheryofproducts

system shall be used independently of the other. Combining

having flanged or circular heads. Shear bursts may also occur

values from the two systems may result in non-conformance

on the sides of hex-head products. Typical shear bursts are

with the standard.

shown in Fig. 3. Limits are specified in 5.4.

1 2

This specification is under the jurisdiction of ASTM Committee F16 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fasteners and is the direct responsibility of Subcommittee F16.93 on Quality contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Assurance Provisions for Fasteners. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2012. Published November 2012. Originally the ASTM website.

3

approved in 1982. Last previous edition approved in 2008 as F788/F788M–08. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/F0788-12. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F788−12

FIG. 1 Typical Quench Cracks

shoulder diameter; and Dc designates flange diameter (speci-

fied maximum) or head diameter (specified maximum) of

circular head products. For metric series products, D and Dc

are in millimetres;

...

Designation: F788/F788M − 08 F788 − 12

Standard Specification for

Surface Discontinuities of Bolts, Screws, and Studs, Inch

1

and Metric Series

This standard is issued under the fixed designation F788/F788M;F788; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification establishes allowable limits for the various types of surface discontinuities that may occur during the

manufacture and processing of bolts, screws, and studs, including heat-treated machine screws, tapping screws, and sems (the

washers of screw-washer assemblies are excluded). This specification covers metric series products with nominal diameters of 4

mm and larger and with specified minimum tensile strengths of 420 MPa and higher; and inch series products with nominal

diameters of No. 5 (0.1250 in.) and larger and with specified minimum tensile strengths of 60 000 psi and higher.

1.2 When the engineering requirements of the application necessitate control of surface discontinuities on bolts, screws, or

studs, the purchaser shall specify conformance to ASTM Specification F788/F 788M,, in the original inquiry and purchase order.

1.2.1 When the engineering requirements of the application necessitate that surface discontinuities on bolts, screws, and studs

be controlled within limits closer than those specified in this specification, the purchaser shall specify the applicable limits in the

original inquiry and purchase order.

1.3 The allowable limits established in this specification for metric bolts, screws, and studs with nominal diameters from 4 to

24 mm inclusive, are essentially identical with requirements given in ISO 6157/I. There are no ISO standards for surface

discontinuities on any inch-series products.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

E340 Test Method for Macroetching Metals and Alloys

F1470 Practice for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

F1789 Terminology for F16 Mechanical Fasteners

3

2.2 ISO Standard:

ISO 6157/I Fasteners, Surface Discontinuities on Bolts, Screws and Studs

3. Ordering Information

3.1 Orders for bolts, screws, and studs requiring discontinuity control shall include the following:

3.1.1 ASTM designation and date of issue of this specification.

3.1.2 Special requirements, for example, closer discontinuity limits (1.2.1) and inspection sampling plan (6.2).

4. Types of Surface Discontinuities (see Terminology F1789 for definitions not provided)

4.1 Crack

4.1.1 Quench Cracks—Typical quench cracks are shown in Fig. 1. Limits are specified in 5.2.

4.1.2 Forging Cracks—Typical forging cracks are shown in Fig. 2. Limits are specified in 5.3.

4.2 Burst—Typical bursts are shown in Fig. 3. Limits are specified in 5.4.

4.2.1 Shear Burst—A shear burst is an open break in the metal located at approximately a 45° angle to the product axis. Shear

bursts occur most frequently at the periphery of products having flanged or circular heads. Shear bursts may also occur on the sides

of hex-head products. Typical shear bursts are shown in Fig. 3. Limits are specified in 5.4.

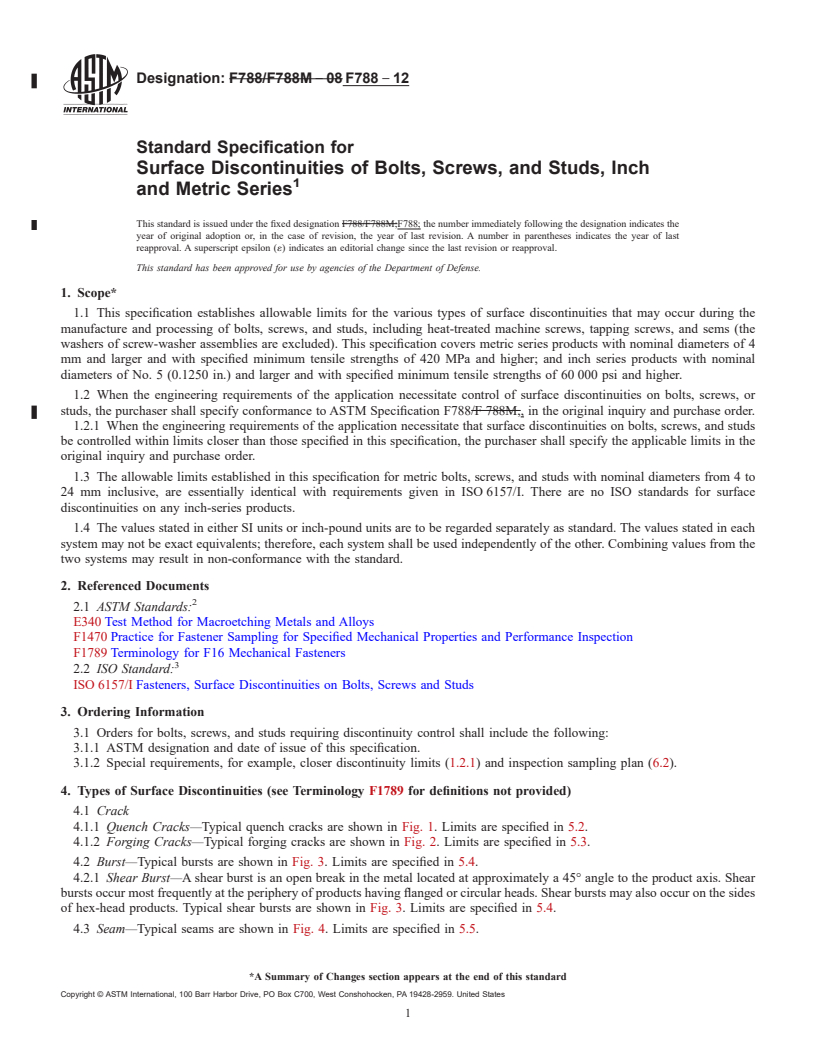

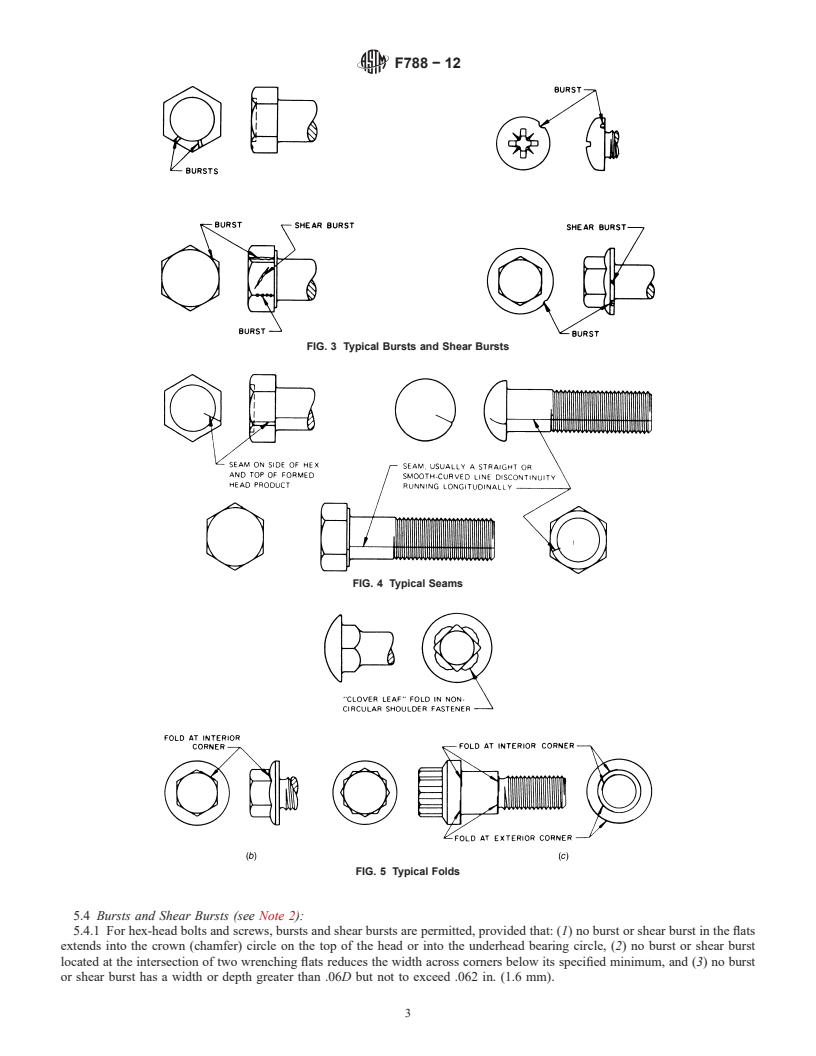

4.3 Seam—Typical seams are shown in Fig. 4. Limits are specified in 5.5.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F788 − 12

FIG. 1 Typical Quench Cracks

FIG. 2 Typical Forging Cracks

4.4 Fold—Typical folds are shown in Fig. 5 a,b, and c. Limits are specified in 5.6.

4.5 Thread Lap—Limits are specified in Supplementary Requirement S.1.1.

4.6 Void—A void is a shallow pocket or hollow on the surface of a bolt or screw due to nonfilling of metal during forging. Voids

are produced by marks or impressions of chips (shear burrs) or by rust formation on the raw material. They are not planished during

forging. Typical voids are shown in Fig. 6. Limits are specified in 5.7.

4.7 Tool Marks—Tool marks are longitudinal or circumferential grooves of shallow depth produced by the movement of

manufacturing tools over the surface of the bolt or screw. Typical tool marks are shown in Fig. 7. Limits are specified in 5.8.

4.8 Gouge and Nick—an indentation on the surface of a fastener produced by impact with another fastener, or from processing

equipment during manufacture, handling or t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.