ASTM B577-93(2004)e1

(Test Method)Standard Test Methods for Detection of Cuprous Oxide (Hydrogen Embrittlement Susceptibility) in Copper

Standard Test Methods for Detection of Cuprous Oxide (Hydrogen Embrittlement Susceptibility) in Copper

SIGNIFICANCE AND USE

These test methods determine whether copper products will be resistant to embrittlement when exposed to elevated temperatures in a reducing atmosphere.

5.1.1 It is assumed that all who use these test methods will be trained personnel capable of performing these procedures skillfully and safely. It is expected that work will be performed in a properly equipped facility.

SCOPE

1.1 These test methods describe procedures for determining the presence of cuprous oxide (Cu2O) in products made from deoxidized and oxygen-free copper.

1.2 Units Inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The test methods appear in the following order:SectionsMicroscopical Examination without Thermal TreatmentMicroscopical Examination after Thermal TreatmentClosed Bend Test after Thermal TreatmentReverse Bend Test after Thermal Treatment

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:B577–93 (Reapproved2004)

Standard Test Methods for

Detection of Cuprous Oxide (Hydrogen Embrittlement

Susceptibility) in Copper

This standard is issued under the fixed designation B577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Editorial changes were made throughout in October 2004.

1. Scope* deoxidizers, as determined by metallographic examination at

753 under polarized light. Oxygen may be present as residual

1.1 These test methods describe procedures for determining

deoxidation products.

the presence of cuprous oxide (Cu O) in products made from

3.1.2 embrittlement—the reduction of the normal ductility

deoxidized and oxygen-free copper.

in a metal as a result of a physical or chemical change. As it

1.2 Units—Inch-pound units are to be regarded as standard.

relates to these test methods, embrittlement is the loss of

The values given in parentheses are mathematical conversions

ductility caused by the reaction of cuprous oxide in the copper

to SI units that are provided for information only and are not

material when exposed at elevated temperatures to a reducing

considered standard.

atmosphere.

1.3 This standard does not purport to address all of the

3.1.3 oxygen-free copper—electrolytic copper produced

safety concerns, if any, associated with its use. It is the

substantially free of cuprous oxide without the use of metallic

responsibility of the user of this standard to establish appro-

or metalloidal deoxidizers as determined by metallographic

priate safety and health practices and determine the applica-

examination at 753 under polarized light. Oxygen may be

bility of regulatory limitations prior to use.

present up to a maximum of 5 ppm in Copper UNS No.

1.4 The test methods appear in the following order:

C10100 and 10 ppm in Copper UNS No. C10200.

Sections

4. Summary of Test Methods

Microscopical Examination without Thermal Treatment 9-11

Microscopical Examination after Thermal Treatment 13-15

4.1 The presence of cuprous oxide is determined either by

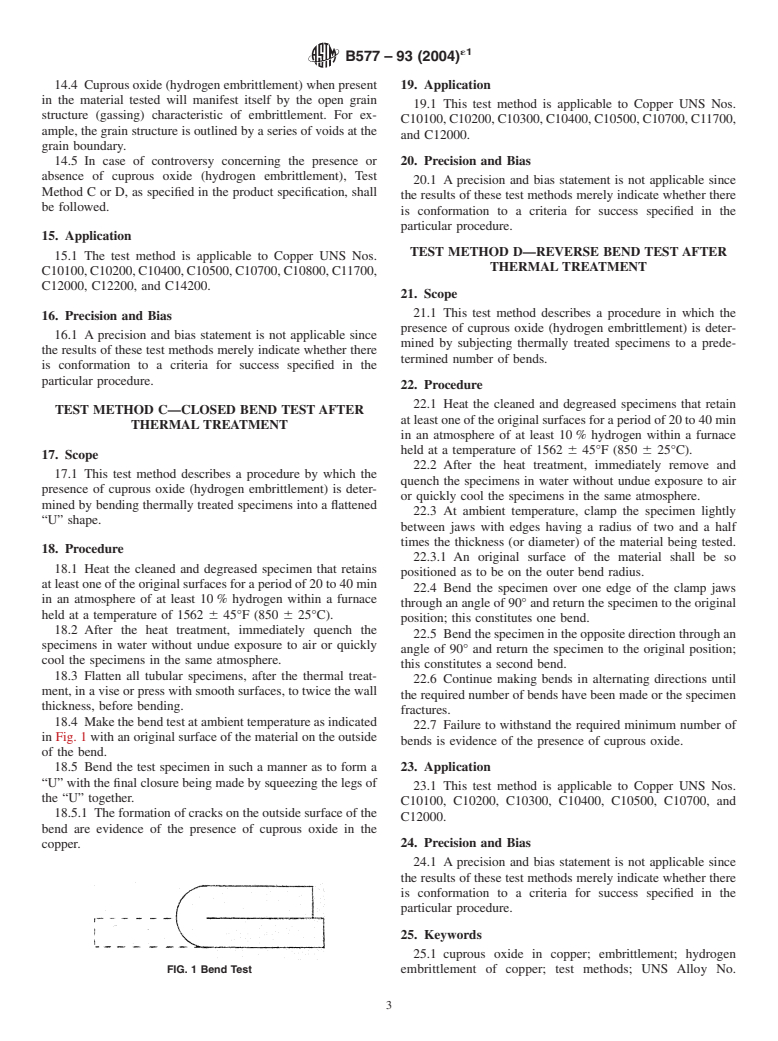

Closed Bend Test after Thermal Treatment 17-19

microscopicalexaminationunderpolarizedlightorbymethods

Reverse Bend Test after Thermal Treatment 21-23

that involve heating the test specimens in a hydrogen-rich

2. Referenced Documents

atmosphere and rapidly cooling the specimens without undue

2.1 ASTM Standards: exposure to air followed by a microscopical examination or a

E3 Guide for Preparation of Metallographic Specimens

suitable bend test.

E883 Guide for Reflected−Light Photomicrography

5. Significance and Use

3. Terminology

5.1 These test methods determine whether copper products

3.1 Definitions:

will be resistant to embrittlement when exposed to elevated

3.1.1 deoxidized copper—material produced substantially

temperatures in a reducing atmosphere.

free of cuprous oxide, by the use of metallic or metalloidal

5.1.1 It is assumed that all who use these test methods will

be trained personnel capable of performing these procedures

skillfullyandsafely.Itisexpectedthatworkwillbeperformed

These test methods are under the jurisdiction of ASTM Committee B05 on

Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.06

in a properly equipped facility.

on Methods of Test.

Current edition approved May 1, 2004. Published May 2004. Originally

6. Apparatus

approved in 1973. Last previous edition approved in 1998 as B577–93 (1998).

6.1 Test Method A—Metallographic equipment of the type

DOI: 10.1520/B0577-93R04E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

described in Practice E3 and Guide E883 suitably equipped

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

with a polarized light illuminating device.

Standards volume information, refer to the standard’s Document Summary page on

6.2 Test Methods B, C, and D:

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

B577–93 (2004)

6.2.1 Metallographic equipment of the type described in TEST METHOD A—MICROSCOPICAL

Practice E3 and Guide E883 provided with normal illumina- EXAMINATION WITHOUT THERMAL TREATMENT

tion.

9. Scope

6.2.2 A furnace of sufficient capacity, capable of maintain-

ing the required reducing atmosphere while the specimens are 9.1 This test method describes a procedure by which the

presence of cuprous oxide is determined by polarized light

being heated. A rapid cooling device using either water or a

reducing atmosphere is required. microscopy examination at a minimum magnification of 753.

6.2.3 A machinist vise with replaceable matching pairs of

10. Procedure

jaw mandrels of various radii contours.

10.1 Thetestspecimenstakentransversetoandboundedby

an original surface of the material are mounted and polished in

7. Sampling

accordance with Practice E3.

7.1 Sampling shall be in accordance with the requirements

10.1.1 Photomicrographs, when taken, are prepared in ac-

of the specification under which the material was ordered.

cordance with Guide E883.

10.2 The polished, but unetched, surface of the specimens

8. Test Specimens

are examined under reflected polarized light at a minimum

8.1 Longitudinal specimens, that is, specimens whose axes

magnification of 753.

are parallel to the direction of working are preferable. How-

10.2.1 Cuprous oxide will appear as ruby-red particles.

ever,equallyreliableresultscanbeobtainedwithspecimensin

10.2.2 Cuprous oxide will appear as blue particles under

which the axis is perpendicular to the directions of working.

white light.

8.2 Specimens shall be of dimensions suitable for the

performance of the required tests. Where necessary to cut a

11. Application

specimenfromanoversizepieceofmaterial,atleastoneofthe

11.1 This test method is applicable to Copper UNS Nos.

original surfaces of the material shall be retained in the test

C10100,C10200,C10300,C10400,C10500,C10700,C11700,

specimen. Suggested dimensions for test specimens are given

and C12000.

in the following table (for Procedures C or D):

Wrought Products Suggested Dimensions for 12. Precision and Bias

Test Specimens

12.1 A precision and bias statement is not applicable since

Flats (wire, strip, sheets, bar, thickness—that of the product but should not

the results of these test methods merely indicate whether there

and plate) exceed ⁄2 in. (13 mm)

is conformation to a criteria for success specified in the

width—approx. ⁄2 in. (13 mm)

particular procedure.

length—approx. 6 in. (152 mm)

Shapes and forgings To the extent that the dimensions of the ma-

terial permit, the dimensions of the test TEST METHOD B—MICROSCOPICAL

specimens are those suggested for the flat

EXAMINATION AFTER THERMAL TREATMENT

products specimens.

(Where the product dimensions, particularly

13. Scope

length, as in the case of forgings, do not

permit taking a specimen, the total

13.1 This test method describes a procedure by which the

product may then become the test spec-

presence of cuprous oxide is determined by microscopical

imen for examination by Procedures A

or B.) examination under normal illumination at a minimum magni-

Wire or rod diameter or distance between parallel

fica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.