ASTM F1386-92(2021)

(Guide)Standard Guide for Construction of Sounding Tube and Striker Plate for Tank Sounding

Standard Guide for Construction of Sounding Tube and Striker Plate for Tank Sounding

SIGNIFICANCE AND USE

5.1 Sounding tubes may be fabricated from 11/2 NPS or larger. Only when otherwise specified, Schedule 40 components, manufactured from the list of material indicated in Practice F1155 and Specification A53/A53M, Grade S or Grade ERW. In addition, sounding tubes may be fabricated in stainless steel for stainless steel tanks.

5.1.1 Sounding tubes passing through or terminating in fuel tanks, potable water tanks, or clean salt water ballast tanks should be constructed of 70-30 copper nickel, but other suitable material is acceptable.

5.2 Striker plates shall be fabricated in accordance with Specification A36/A36M.

5.3 The fittings shall be designed in accordance with ASME B16.5, ASME B16.9, ASME B16.28, or ASME B16.11 as applicable (see Table 21 in Practice F1155), and the installation shall be in accordance with ASME B31.1 as modified by Specification F722. These standards cover the fitting tolerances.

5.4 Some cargo may preclude the use of materials specified in this guide. However, configuration examples are applicable for all applications.

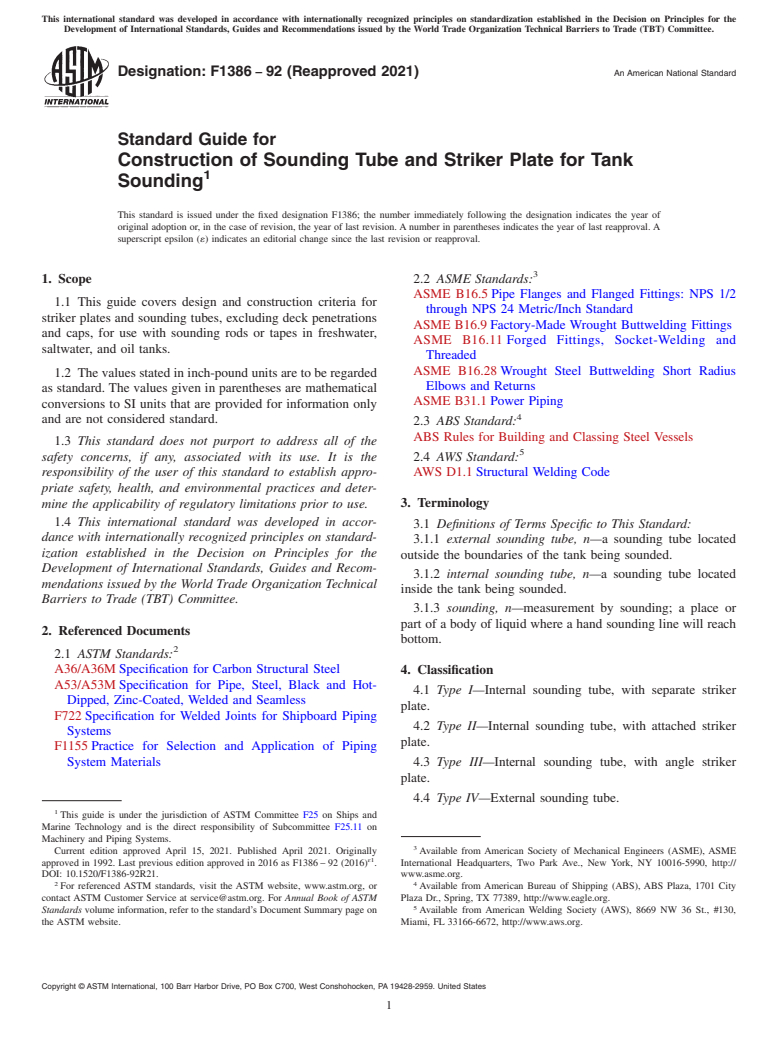

5.5 When a sounding tube is combined with the air escape, either three 11/4-in. (approximately 30-mm) diameter holes approximately 12 in. (305 mm) from the tank top equally spaced or six 1/2-in. (approximately 15-mm) diameter holes approximately 6 in. (150 mm) from the tank top equally spaced can be used for perforations. See Fig. 2.

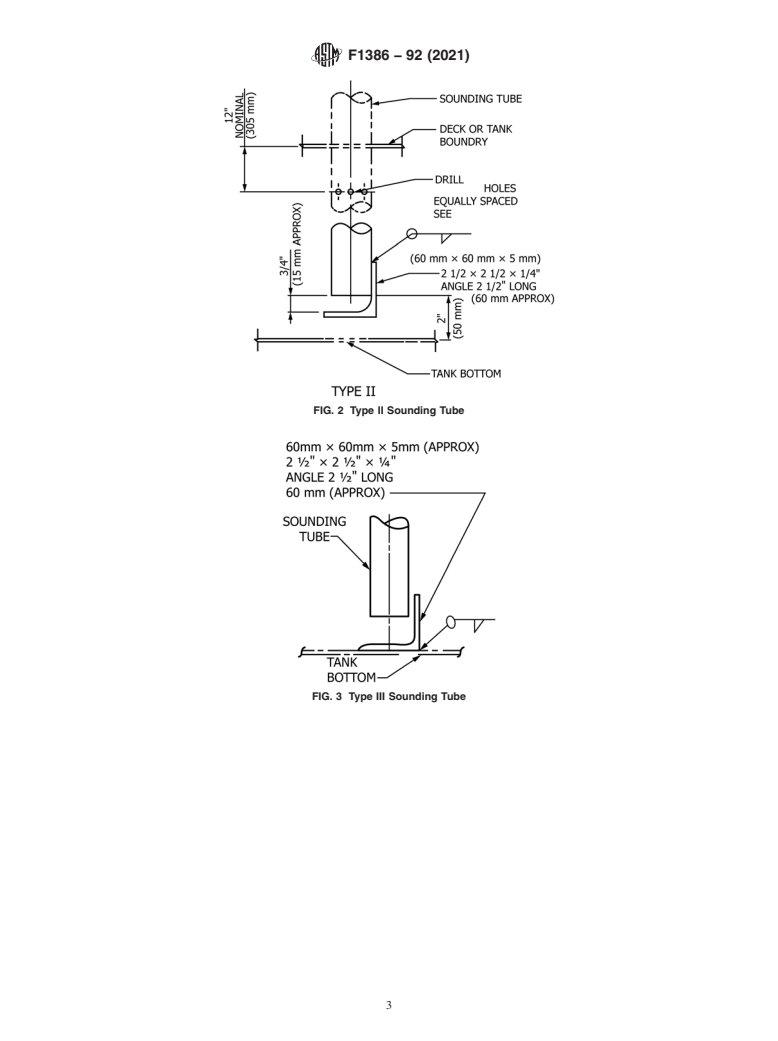

5.6 Figs. 1-4 are guidance details.

FIG. 1 Type I Sounding Tube

FIG. 2 Type II Sounding Tube

FIG. 3 Type III Sounding Tube

FIG. 4 Type IV Sounding Tube

SCOPE

1.1 This guide covers design and construction criteria for striker plates and sounding tubes, excluding deck penetrations and caps, for use with sounding rods or tapes in freshwater, saltwater, and oil tanks.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1386 − 92 (Reapproved 2021) An American National Standard

Standard Guide for

Construction of Sounding Tube and Striker Plate for Tank

Sounding

This standard is issued under the fixed designation F1386; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASME Standards:

ASME B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2

1.1 This guide covers design and construction criteria for

through NPS 24 Metric/Inch Standard

striker plates and sounding tubes, excluding deck penetrations

ASME B16.9 Factory-Made Wrought Buttwelding Fittings

and caps, for use with sounding rods or tapes in freshwater,

ASME B16.11 Forged Fittings, Socket-Welding and

saltwater, and oil tanks.

Threaded

ASME B16.28 Wrought Steel Buttwelding Short Radius

1.2 The values stated in inch-pound units are to be regarded

Elbows and Returns

as standard. The values given in parentheses are mathematical

ASME B31.1 Power Piping

conversions to SI units that are provided for information only

and are not considered standard.

2.3 ABS Standard:

ABS Rules for Building and Classing Steel Vessels

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 2.4 AWS Standard:

responsibility of the user of this standard to establish appro- AWS D1.1 Structural Welding Code

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3.1 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard-

3.1.1 external sounding tube, n—a sounding tube located

ization established in the Decision on Principles for the

outside the boundaries of the tank being sounded.

Development of International Standards, Guides and Recom-

3.1.2 internal sounding tube, n—a sounding tube located

mendations issued by the World Trade Organization Technical

inside the tank being sounded.

Barriers to Trade (TBT) Committee.

3.1.3 sounding, n—measurement by sounding; a place or

part of a body of liquid where a hand sounding line will reach

2. Referenced Documents

bottom.

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel 4. Classification

A53/A53M Specification for Pipe, Steel, Black and Hot-

4.1 Type I—Internal sounding tube, with separate striker

Dipped, Zinc-Coated, Welded and Seamless

plate.

F722 Specification for Welded Joints for Shipboard Piping

4.2 Type II—Internal sounding tube, with attached striker

Systems

plate.

F1155 Practice for Selection and Application of Piping

System Materials 4.3 Type III—Internal sounding tube, with angle striker

plate.

4.4 Type IV—External sounding tube.

This guide is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved April 15, 2021. Published April 2021. Originally Available from American Society of Mechanical Engineers (ASME), ASME

ɛ1

approved in 1992. Last previous edition approved in 2016 as F1386 – 92 (2016) . International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

DOI: 10.1520/F1386-92R21. www.asme.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Bureau of Shipping (ABS), ABS Plaza, 1701 City

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Plaza Dr., Spring, TX 77389, http://www.eagle.org.

Standards volume information, refer to the standard’s Document Summary page on Available from American Welding Society (AWS), 8669 NW 36 St., #130,

the ASTM website. Miami, FL 33166-6672, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1386 − 92 (2021)

5. Significance and Use

5.1 Sounding tubes may be fabricated from 1 ⁄2 NPS or

larger. Only when otherwise specified, Schedule 40

components, manufactured from the list of material indicated

in Practic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.