ASTM E685-93

(Practice)Standard Practice for Testing Fixed-Wavelength Photometric Detectors Used in Liquid Chromatography

Standard Practice for Testing Fixed-Wavelength Photometric Detectors Used in Liquid Chromatography

SCOPE

1.1 This practice is intended to serve as a guide for the testing of the performance of a photometric detector (PD) used as the detection component of a liquid-chromatographic (LC) system operating at one or more fixed wavelengths in the range 210 to 800 nm. Measurements are made at 254 nm, if possible, and are optional at other wavelengths.

1.2 This practice is intended to describe the performance of the detector both independently of the chromatographic system (static conditions) and with flowing solvent (dynamic conditions).

1.3 For general liquid chromatographic procedures, consult Refs (1-9).

1.4 For general information concerning the principles, construction, operation, and evaluation of liquid-chromatography detectors, see Refs (10 and 11) in addition to the sections devoted to detectors in Refs (1-7).

1.5 The values stated in SI units are to be regarded as standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 685 – 93 An American National Standard

Standard Practice for

Testing Fixed-Wavelength Photometric Detectors Used in

Liquid Chromatography

This standard is issued under the fixed designation E 685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 absorbance calibration—the procedure that verifies

that the absorbance scale is correct within 65%.

1.1 This practice is intended to serve as a guide for the

3.1.2 drift—the average slope of the noise envelope ex-

testing of the performance of a photometric detector (PD) used

pressed in absorbance units per hour (AU/h) as measured over

as the detection component of a liquid-chromatographic (LC)

a period of 1 h.

system operating at one or more fixed wavelengths in the range

3.1.3 dynamic—under conditions of a flow rate of 1.0

210 to 800 nm. Measurements are made at 254 nm, if possible,

mL/min.

and are optional at other wavelengths.

3.1.4 linear range—ofaPD, the range of concentrations of

1.2 This practice is intended to describe the performance of

a test substance in a mobile phase over which the response of

the detector both independently of the chromatographic system

the detector is constant to within5%as determined from the

(static conditions) and with flowing solvent (dynamic condi-

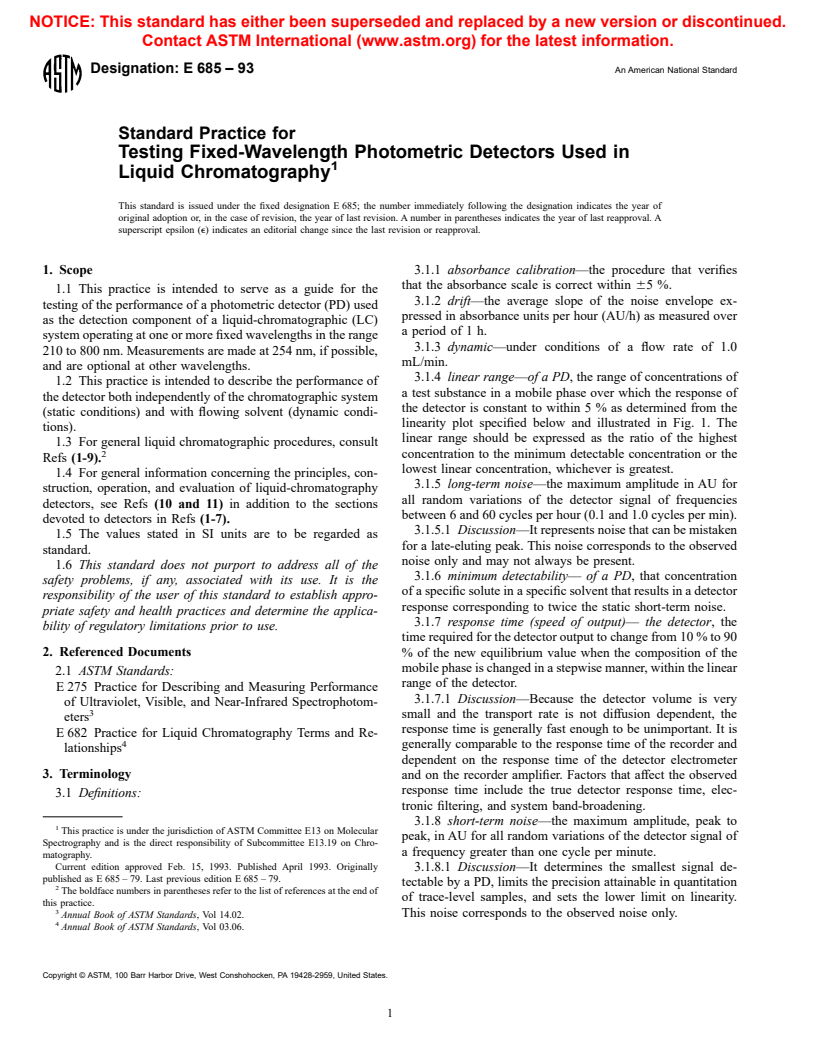

linearity plot specified below and illustrated in Fig. 1. The

tions).

linear range should be expressed as the ratio of the highest

1.3 For general liquid chromatographic procedures, consult

concentration to the minimum detectable concentration or the

Refs (1-9).

lowest linear concentration, whichever is greatest.

1.4 For general information concerning the principles, con-

3.1.5 long-term noise—the maximum amplitude in AU for

struction, operation, and evaluation of liquid-chromatography

all random variations of the detector signal of frequencies

detectors, see Refs (10 and 11) in addition to the sections

between 6 and 60 cycles per hour (0.1 and 1.0 cycles per min).

devoted to detectors in Refs (1-7).

3.1.5.1 Discussion—It represents noise that can be mistaken

1.5 The values stated in SI units are to be regarded as

for a late-eluting peak. This noise corresponds to the observed

standard.

noise only and may not always be present.

1.6 This standard does not purport to address all of the

3.1.6 minimum detectability— ofaPD, that concentration

safety problems, if any, associated with its use. It is the

of a specific solute in a specific solvent that results in a detector

responsibility of the user of this standard to establish appro-

response corresponding to twice the static short-term noise.

priate safety and health practices and determine the applica-

3.1.7 response time (speed of output)— the detector, the

bility of regulatory limitations prior to use.

time required for the detector output to change from 10 % to 90

2. Referenced Documents % of the new equilibrium value when the composition of the

mobile phase is changed in a stepwise manner, within the linear

2.1 ASTM Standards:

range of the detector.

E 275 Practice for Describing and Measuring Performance

3.1.7.1 Discussion—Because the detector volume is very

of Ultraviolet, Visible, and Near-Infrared Spectrophotom-

small and the transport rate is not diffusion dependent, the

eters

response time is generally fast enough to be unimportant. It is

E 682 Practice for Liquid Chromatography Terms and Re-

generally comparable to the response time of the recorder and

lationships

dependent on the response time of the detector electrometer

3. Terminology

and on the recorder amplifier. Factors that affect the observed

response time include the true detector response time, elec-

3.1 Definitions:

tronic filtering, and system band-broadening.

3.1.8 short-term noise—the maximum amplitude, peak to

This practice is under the jurisdiction of ASTM Committee E13 on Molecular

peak, in AU for all random variations of the detector signal of

Spectrography and is the direct responsibility of Subcommittee E13.19 on Chro-

a frequency greater than one cycle per minute.

matography.

Current edition approved Feb. 15, 1993. Published April 1993. Originally

3.1.8.1 Discussion—It determines the smallest signal de-

published as E 685 – 79. Last previous edition E 685 – 79.

tectable by a PD, limits the precision attainable in quantitation

The boldface numbers in parentheses refer to the list of references at the end of

of trace-level samples, and sets the lower limit on linearity.

this practice.

This noise corresponds to the observed noise only.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 685

5.2 Methods of Measurement:

5.2.1 Connect a suitable device (Note 1) between the pump

and the detector to provide at least 75 kPa (500 psi) back

pressure at 1.0 mL/min flow of methanol. Connect a short

length (about 100 mm) of 0.25-mm (0.01-in.) internal-diameter

stainless steel tubing to the outlet tube of the detector to retard

bubble formation. Connect the recorder to the proper detector

output channels.

NOTE 1—Suggested devices include (a)2to4mof 0.1-mm (0.004-in.)

internal-diameter stainless steel tubing, ( b) about 250 mm of 0.25 to

0.5-mm (0.01 to 0.02-in.) internal-diameter stainless steel tubing crimped

with pliers or cutters, or ( c) a constant back-pressure valve located

between the pump and the injector.

5.2.2 Repeatedly rinse the reservoir and chromatographic

system, including the detector, with degassed methanol to

remove from the system all other solvents, any soluble mate-

rial, and any entrained gasses. Fill the reservoir with methanol

and pump this solvent through the system for at least 30 min to

complete the system cleanup.

5.2.3 Air or nitrogen is used in the reference cell, if any.

FIG. 1 Example of a Linearity Plot for a Photometric Detector

Ensure that the cell is clean, free of dust, and completely dry.

5.2.4 To perform the static test, cease pumping and allow

3.1.9 static—under conditions of no flow.

the chromatographic system to stabilize for at least1hat room

4. Significance and Use temperature without flow. Set the attenuator at maximum

sensitivity (lowest attenuation), that is, the setting for the

4.1 Although it is possible to observe and measure each of

smallest value of absorbance units full-scale (AUFS). Adjust

the several characteristics of a detector under different and

the response time as close as possible to 2 s for a PD that has

unique conditions, it is the intent of this practice that a

a variable response time (Note 2). Record the response time

complete set of detector specifications should be obtained

used. Adjust the detector output to near midscale on the readout

under the same operating conditions. It should also be noted

device. Record at least1hof detector signal under these

that to completely specify a detector’s capability, its perfor-

conditions, during which time the ambient temperature should

mance should be measured at several sets of conditions within

not change by more than 2°C.

the useful range of the detector. The terms and tests described

in this practice are sufficiently general that they may be used

NOTE 2—Time constant is converted to response time by multiplying

regardless of the ultimate operating parameters.

by the factor 2.2. The effect of electronic filtering on observed noise may

4.2 Linearity and response time of the recorder or other be studied by repeating the noise measurements for a series of response-

time settings.

readout device used should be such that they do not distort or

otherwise interfere with the performance of the detector. This

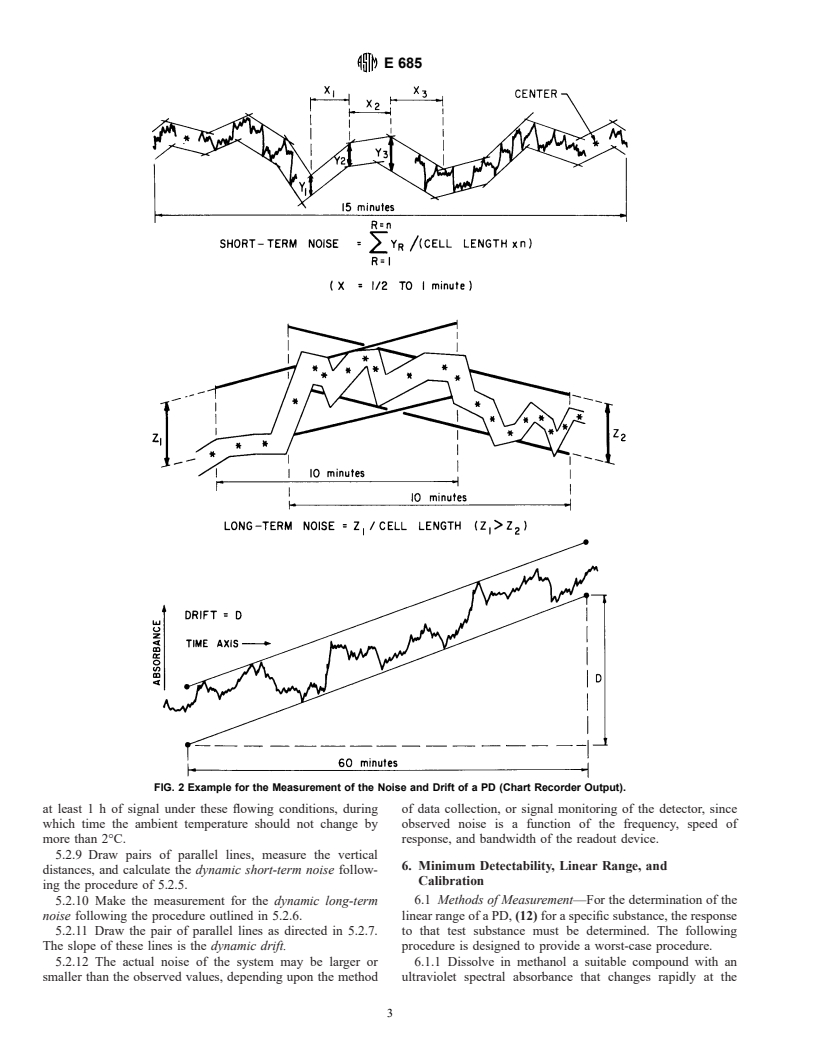

5.2.5 Draw pairs of parallel lines, each pair corresponding

requires adjusting the gain, damping, and calibration in accor-

to between 0.5 and 1 min in length, to form an envelope of all

dance with the manufacturer’s directions. If additional elec-

observed random variations over any 15-min period (see Fig.

tronic filters or amplifiers are used between the detector and the

2). Draw the parallel lines in such a way as to minimize the

final readout device, their characteristics should also first be

distance between them. Measure the vertical distance, in AU,

established.

between the lines. Calculate the average value over all the

segments. Divide this value by the cell length in centimetres to

5. Noise and Drift

obtain the static short-term noise.

5.1 Test Conditions—Pure, degassed methanol of suitable

5.2.6 Now mark the center of each segment over the 15-min

shall be used in the sample cell. Air or nitrogen shall be

grade

period of the static short-term noise measurement. Draw a

used in the reference cell if there is one. Nitrogen is preferred

series of parallel lines encompassing these centers, each pair

where the presence of high-voltage equipment makes it likely

corresponding to 10 min in length, and choose that pair of lines

that there is ozone in the air. Protect the entire system from

whose vertical distance apart is greatest (see Fig. 2). Divide

temperature fluctuations because these will lead to detectable

this distance in AU by the cell length in centimetres to obtain

drift.

the static long-term noise.

5.1.1 The detector should be located at the test site and

5.2.7 Draw the pair of parallel lines that minimizes the

turned on at least 24 h before the start of testing. Insufficient

vertical distance separating these lines over the1hof mea-

warm-up may result in drift in excess of the actual value for the

surement (see Fig. 2). The slope of either line is the static drift

detector.

expressed in AU/h.

5.2.8 Set the pump to deliver 1.0 mL/min under the same

conditions of tubing, solvent, and temperature as in 5.2.1

Distilled-in-glass or liquid-chromatography grade. Complete freedom from

particles may require filtration, for example, through a 0.45-μm membrane filter. through 5.2.3. Allow 15 min for the system to stabilize. Record

E 685

FIG. 2 Example for the Measurement of the Noise and Drift of a PD (Chart Recorder Output).

at least1hof signal under these flowing conditions, during of data collection, or signal monitoring of the detector, since

which time the ambient temperature should not change by observed noise is a function of the frequency, speed of

more than 2°C. response, and bandwidth of the readout device.

5.2.9 Draw pairs of parallel lines, measure the vertical

6. Minimum Detectability, Linear Range, and

distances, and calculate the dynamic short-term noise follow-

Calibration

ing the procedure of 5.2.5.

5.2.10 Make the measurement for the dynamic long-term 6.1 Methods of Measurement—For the determination of the

noise following the procedure outlined in 5.2.6. linear range of a PD, (12) for a specific substance, the response

5.2.11 Draw the pair of parallel lines as directed in 5.2.7. to that test substance must be determined. The following

The slope of these lines is the dynamic drift. procedure is designed to provide a worst-case procedure.

5.2.12 The actual noise of the system may be larger or 6.1.1 Dissolve in methanol a suitable compound with an

smaller than the observed values, depending upon the method ultraviolet spectral absorbance that changes rapidly at the

E 685

NOTE 3—For example, the values of molar absorptivity for uracil in

wavelength of interest. Choose a concentration that is ex-

3 3

methanol are 7.7 3 10 at 254 nm and 1.42 3 10 at 280 nm; for

pected to exceed the linear range, typically to give an absor-

potassium dichromate in 0.01 N sulfuric acid they are 4.22 3 10 at 254

bance above 2 AU. Dilute the solution accurately in a series to

nm and 3.60 3 10 at 280 nm.

cover the linear range, that is, down to the minimum detectable

concentration. Rinse the sample cell with methanol and zero 7. Response Time

the detector with methanol in the cell. Rinse the cell with the

7.1 The response time of the detector may become signifi-

solution of lowest concentration until a stable reading is

cant when a short micro-particle column and a high-speed

obtained; usually rinsing the cell with 1 mL is sufficient.

recorder are used. Also, it is possible, by using an intentionally

Record the detector output. After rinsing the syringe thor-

slow response time, to reduce the observed noise and hence

oughly with the next more concentrated solution, fill the cell

increase the apparent linear range. Although this would have

with the solution from each dilution in turn. Obtain a minimum

little effect on broad peaks, the signal from narrow peaks

of five on-scale measurements. Measure under static condi-

would be significantly degraded. Measure at the highest and

tions.

lowest values of the electronic filter if it is variable.

6.1.2 Calculate the ratio of detector response (AU) to

7.2 Method of Measurement:

concentration (μg/mL) for each solution and plot these ratios

7.2.1 The composition of the mobile phase is changed in a

versus log concentration (see Fig. 1). The region of linearity

stepwise manner and the output signal is recorded on the

will define a horizontal line of constant response ratio. At

highest-speed device available. If the recorder has a response

higher concentrations, there will typically be a negative devia-

time not significantly faster than the detector, only the response

tion from linearity, while at lower concentrations there may be

time of the detector-recorder combination will be obtained, as

deviation in either direction. Draw horizontal lines 5 % above

it would be when the combination is used to record chromato-

and below the line of constant response ratio. The upper limit

grams.

of linearity is the concentration at which the line of measured

7.2.2 Set a flow rate of 2.0 mL/min.

response ratio intersects one of the 5 % bracketing lines at the

7.2.3 A stepwise change may be obtained by means of a

high concentration end. The lower limit of linearity is either the

sample valve equipped with a 1-mL sample loop (or a loop

minimum detectable concentration (see 6.1.3) or the concen-

having at least four times the total volume from detector inlet

tration at which the line of measured response ratio intersects

to outlet) connected between the pump and the detector.

one of the bracketing lines at the low concentration end,

Observe the recorder trace and verify that a plateau has been

whichever is greater.

reached. If no plateau is reached, a larger sample volume is

6.1.3 Determine the minimum detectability (minimu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.