ASTM B900-04(2010)

(Practice)Standard Practice for Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

Standard Practice for Packaging of Copper and Copper Alloy Mill Products for U.S. Government Agencies

SIGNIFICANCE AND USE

This practice is applicable to packaging of copper alloy mill products for shipment to agencies of the U.S. Government.

It covers packaging of rod, bar, shapes, plate, sheet, strip, foil, wire, flat wire, rolled bar, forgings, pipe, and tube products.

SCOPE

1.1 This practice establishes requirements for packaging, packing, and marking intended to ensure proper and safe storage and transportation of copper and copper alloy mill products, both foreign and domestic, for direct shipment to government activities or shipment processed at a military activity or agency. This practice details the materials, methods, containers, and procedures for the preparation for shipment of copper and copper alloy mill products. Mill products wherein copper is the basic metal are within the scope of this practice. Commercial packaging establishes the minimum requirements that apply unless Level A or B packing is specified (see 6.1).

1.2 Units—The values stated in inch-pound units are regarded as standard. The SI values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B900 − 04(Reapproved 2010)

Standard Practice for

Packaging of Copper and Copper Alloy Mill Products for

U.S. Government Agencies

This standard is issued under the fixed designation B900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* PaperboardUsingConstant-Rate-of-ElongationApparatus

(Withdrawn 2009)

1.1 This practice establishes requirements for packaging,

D1974 Practice for Methods of Closing, Sealing, and Rein-

packing, and marking intended to ensure proper and safe

forcing Fiberboard Boxes

storage and transportation of copper and copper alloy mill

D3951 Practice for Commercial Packaging

products, both foreign and domestic, for direct shipment to

D4444 Test Method for Laboratory Standardization and

government activities or shipment processed at a military

Calibration of Hand-Held Moisture Meters

activity or agency.This practice details the materials, methods,

D5118/D5118M PracticeforFabricationofFiberboardShip-

containers, and procedures for the preparation for shipment of

ping Boxes

copper and copper alloy mill products. Mill products wherein

D5168 Practice for Fabrication and Closure of Triple-Wall

copper is the basic metal are within the scope of this practice.

Corrugated Fiberboard Containers

Commercial packaging establishes the minimum requirements

that apply unless Level A or B packing is specified (see 6.1). D5330/D5330M Specification for Pressure-Sensitive Tape

for Packaging, Filament-Reinforced

1.2 Units—The values stated in inch-pound units are re-

D6251/D6251M Specification forWood-Cleated Panelboard

garded as standard. The SI values given in parentheses are

Shipping Boxes

mathematical conversions to SI units that are provided for

information only and are not considered standard.

2.2 ANSI Standard:

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

1.3 This standard does not purport to address all of the

spection by Attributes

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2.3 Federal Specifications:

priate safety and health practices and determine the applica-

A-A-55057 Panels, Wood/Wood Base: Construction and

bility of regulatory limitations prior to use.

Decorative

PPP-B-585 Boxes, Wood, Wirebound

2. Referenced Documents

PPP-B-587 Boxes, Wood, Wirebound Pallet Type

2.1 ASTM Standards:

PPP-B-601 Boxes, Wood, Cleated-Plywood

B846 Terminology for Copper and Copper Alloys PPP-B-621 Boxes, Wood, Nailed and Lock-Corner

D143 Test Methods for Small Clear Specimens of Timber

PPP-B-1055 Barrier Material, Waterproofed, Flexible

D779 Test Method for Water Resistance of Paper,

PPP-D-705 Drum: Metal Shipping, Steel, (Over 12 and

Paperboard, and Other Sheet Materials by the Dry Indi-

Under 55 Gallon)

cator Method (Withdrawn 2011)

PPP-D-723 Drums, Fiber

D828 Test Method for Tensile Properties of Paper and

PPP-D-729 Drums: Metal, 55-Gallon (for Shipment of Non-

corrosive Material)

2.4 Military Standard:

This practice is under the jurisdiction ofASTM Committee B05 on Copper and

MIL-STD-129 Marking for Shipment and Storage

CopperAlloys and is the direct responsibility of Subcommittee B05.91 on Editorial

and Publications.

2.5 Military Publication:

Current edition approved Oct. 1, 2010. Published December 2010. Originally

MIL-HDBK-774 Palletized Unit Loads

approved in 1999. Last previous edition approved in 2004 as B900 – 04. DOI:

10.1520/B0900-04R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

3 5

The last approved version of this historical standard is referenced on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

www.astm.org. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B900 − 04 (2010)

3. Terminology 4.2 It covers packaging of rod, bar, shapes, plate, sheet,

strip, foil, wire, flat wire, rolled bar, forgings, pipe, and tube

3.1 For definitions of terms related to copper and copper

products.

alloys, refer to Terminology B846.

3.2 Definitions of Terms Specific to This Standard:

5. Classification

3.2.1 deckboard, n—piece or pieces of lumber fastened at

5.1 Shipping containers, for Levels A and B packing (see

right angles to the stringers or skids of a pallet to form a

7.6 and 7.8), having common characteristics are as follows:

load-bearing surface.

5.1.1 Category 1—Boxes, nailed wood, wire-bound wood,

3.2.2 gross weight, n—the bare-item weight and the weight

wood-cleated plywood, and wood cleated, veneer, paper over-

of all packaging and packing materials.

laid (see 7.6.1).

3.2.3 interleaving, n—the protective material placed be-

5.1.2 Category 2—Fiberand metal drums (see 7.6.2).

tween two adjacent pieces of metal.

5.1.3 Category 3—Pallets and pallet boxes (see 7.6.3).

3.2.4 net weight, n—the bare-item weight.

5.1.4 Category 4—Skidded lifts (see 7.6.4).

5.1.5 Category 5—Hand bundles (see 7.6.5).

3.2.5 nominal, adj—the rough–sawn, commercial size des-

5.1.6 Category 6—Secured lifts (without skids) (master

ignation for lumber common to the industry.

bundles) (see 7.6.6).

3.2.6 packing; Level A—the protection required to meet the

5.1.7 Category 7—Reels and spools (see 7.6.7).

most severe worldwide shipment, handling, and storage con-

5.1.8 Category 8—Fiberboard boxes (see 7.6.8).

ditions.

5.1.9 Category 9—Special containers (see 7.6.9).

3.2.6.1 Discussion—A Level A package must be capable of

protecting material from effects of direct exposure to extremes

6. Ordering Information

of climate, terrain, and operational transportation environ-

ments. 6.1 Orders for products shall specify the following packag-

ing information:

3.2.7 packing; Level B—the protection required to meet

6.1.1 ASTM designation and year of issue.

moderate worldwide shipment, handling, and storage condi-

6.1.2 Fiberboard box, if other than Class 1 (see 7.6.8).

tions.

6.1.3 Level of packaging and level of packing if other than

3.2.7.1 Discussion—ALevel B package must be capable of

commercial (see 7.4 and 7.6.9.1).

protectingmaterialnotdirectlyexposedtoextremesofclimate,

6.1.4 Maximum gross weight of container (see 7.6.1.6 –

terrain, and operational transportation environments.

7.6.1.8, 7.6.3 and 7.6.4).

3.2.8 packaging; commercial—although not specifically de-

6.1.5 When palletized drums are required (see 7.8.2.7).

fined by any government regulation or instruction, commercial

6.1.6 When bare welding rod in wire form is required in

packaging (preservation and packing) is understood to be those

fiber drums (see 7.8.2.7).

practices by manufacturers and contractors to protect and

6.1.7 When cores fitted with slinger ring attachment are

identify material and items packaged for retail and wholesale

required for shafting (see 7.8.2.7).

distribution purposes.

6.1.8 When coiled wire is required in lighter or heavier net

3.2.8.1 Discussion—Practice D3951 provides guidance in

weight (see 7.8.2.7).

the application of commercial packaging.

6.1.9 When saddles are required (see 7.8.3.1).

NOTE 1—It has been determined by joint DoD instructions that

6.1.10 Special marking required (see 7.9).

commercial, also in some areas addressed as industrial packaging, should

only be used or specified when such packaging is known to satisfy the

7. Detailed Requirements

DoD needs. Such use should be determined before a contract for supplies

isawardedorwithinthelifecycleofthecontractwhensubstantialsavings

7.1 Options—Unless otherwise specified, packaging and

to the government may result. Commercial (industrial) packaging should

packing requirements selection shall be at the option of the

notbespecifiedwheremultipleshipmentsandhandlingsareanticipatedor

contractor.

desired.

3.2.9 skid, n—one of a pair or series of parallel wood

7.2 Packaging and Packing Materials—Materials not cov-

runners affixed to the underside of boxes, crates, or an item

ered by applicable specifications or not specifically described

allowing entry of truck forks, or to facilitate sliding.

herein shall be of the best commercial quality and suitable for

the purpose intended.

3.2.10 sound woods, n—wood free of any form of decay,

7.2.1 Packaging—The use of packaging materials shall be

incipient or advanced, and from insert holes.

in accordance with 7.8.

3.2.11 stringer, n—a wooden member fastened at right

anglestotheload-bearingmembersofapalletorthedeckboard 7.3 Level A:

of a platform. 7.3.1 Waterproof Barrier Materials—The material shall

consist of 100 % sulfate paper suitably coated or laminated to

3.2.12 sulfate paper, n—wood-pulp paper made by the

meet the following tensile-strength requirement when tested in

sulfate process.

accordance with Test Method D828 and the following water-

4. Significance and Use

resistance requirement when tested in accordance with Test

4.1 This practice is applicable to packaging of copper alloy Method D779. If an asphalt laminate [base weight 30 lbs (13.6

millproductsforshipmenttoagenciesoftheU.S.Government. kg) minimum] is used, the paper shall have a minimum base

B900 − 04 (2010)

weight of 30 lbs per 500 sheets 24 by 36 in. (609.6 by 914.4 7.6 Container Construction Packing and Securing Methods

mm) (30-30-30-minimum). (Levels A and B):

Tensile strength per inch width (weaker direction) 15 lbs (16.8 kg)

7.6.1 Category 1 Boxes:

Water resistance (dry indicator method) 10 h

7.6.1.1 Nailed Wood Boxes (All Groups of Wood)—The

7.3.2 Alternatively, waterproof-barrier materials in accor-

construction and style of nailed wood boxes shall be in

dance with Specification PPP-B-1055 may be used at the

accordance with Figs. 1-6 and Tables 1-4. Side, top, and

contractor’s option.All wrapping material in contact with bare

bottom sections 9 ⁄2 in. (241.3 mm) or less in width shall be

metal surfaces shall be within the pH range from 5.0 to 10.0.

made of one piece, whenever possible. Spliced boards, when-

7.3.3 Interleaving Paper—Interleaving paper shall be

ever necessary, on nailed wood boxes are permissible. The

antitarnishing, noncorrosive, uncreped paper of 10-lbs (4.54-

boards shall be butted and the splicing board shall extend on

kg) minimum base weight.

each side of the joint at least three times the width of the board

7.3.4 Unit Containers—Fiberboard boxes and closure meth-

being spliced. The splicing board shall equal the width and

ods used for packaging wire on spools, wire and tube in coils,

thickness of the boards being spliced. Nails shall be clinched.

or similar products shall be in accordance with Practices

7.6.1.2 Skid (Runners)—Except as specified herein, boxes

D5118/D5118Mand D1974. Where specific container designs

having a gross weight exceeding 600 lbs (272 kg) shall be

are not described by the applicable specification, the manufac-

modified by the addition of nominal 2- by 4-in. (50.8- by

turer’s commercial practice shall apply.

101.6-mm) skids positioned flatwise across the width of the

7.4 Commercial—Unless Level A or B packing is specified

box and located approximately 4 in. (101.6 mm) from the ends

(see 6.1), the following shall apply.

of the box. In attaching skids, nailing shall be through the

7.4.1 Packaging material(s) shall be sufficient to afford

bottom boards and into the skids. When longitudinal, as well

adequate protection against physical damage during shipment

as, girthwise straps are required, the skids shall be notched to

from the supply source to the first receiving activity for

permit passage of the straps between the skids and the bottom

immediate use. This level may be in accordance with Practice

of the box. Skids are not required for boxes shipped on pallets,

D3951 when such meets the requirements of this level.

boxes in a skidded master shipping unit, or boxes 7 ft (2.13 m)

7.5 Packing (Levels A and B):

or over in length.

7.5.1 Wood—Requirements for wood for boxes, pallets,

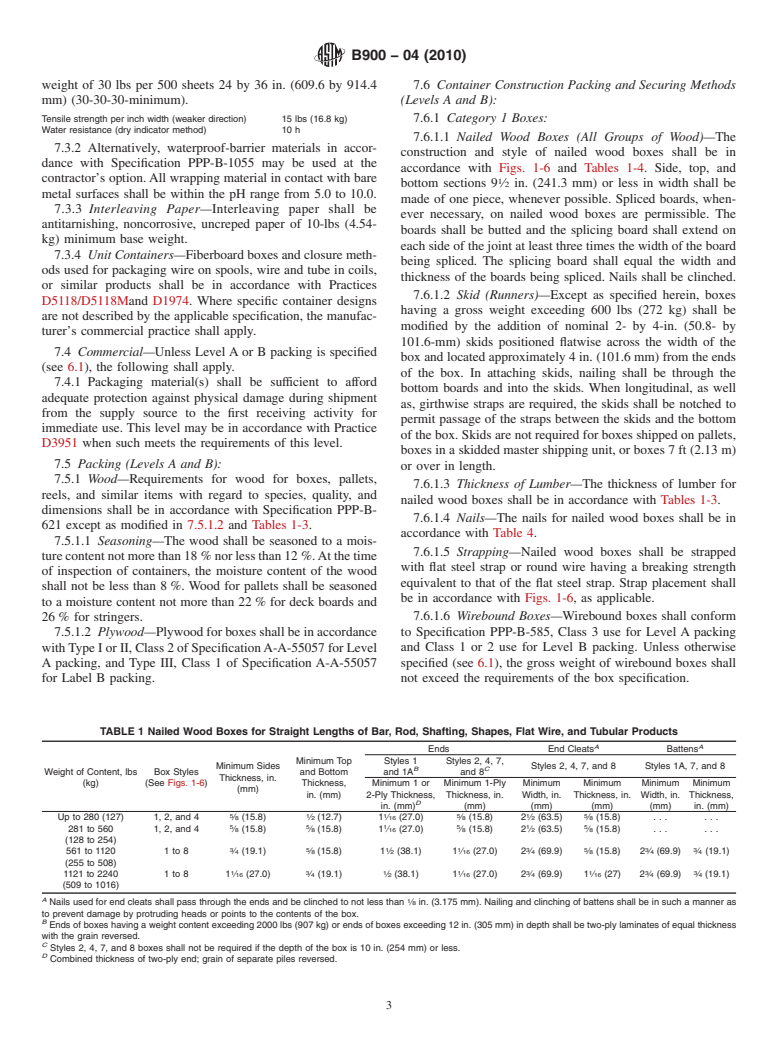

7.6.1.3 Thickness of Lumber—The thickness of lumber for

reels, and similar items with regard to species, quality, and

nailed wood boxes shall be in accordance with Tables 1-3.

dimensions shall be in accordance with Specification PPP-B-

7.6.1.4 Nails—The nails for nailed wood boxes shall be in

621 except as modified in 7.5.1.2 and Tables 1-3.

accordance with Table 4.

7.5.1.1 Seasoning—The wood shall be seasoned to a mois-

7.6.1.5 Strapping—Nailed wood boxes shall be strapped

turecontentnotmorethan18 %norlessthan12 %.Atthetime

with flat steel strap or round wire having a breaking strength

of inspection of containers, the moisture content of the wood

equivalent to that of the flat steel strap. Strap placement shall

shall not be less than 8 %. Wood for pallets shall be seasoned

be in accordance with Figs. 1-6, as applicable.

to a moisture content not more than 22 % for deck boards and

7.6.1.6 Wirebound Boxes—Wirebound boxes shall conform

26 % for stringers.

7.5.1.2 Plywood—Plywood for boxes shall be in accordance to Specification PPP-B-585, Class 3 use for Level A packing

and Class 1 or 2 use for Level B packing. Unless otherwise

withType I or II, Class 2 of SpecificationA-A-55057 for Level

A packing, and Type III, Class 1 of Specification A-A-55057 specified (see 6.1), the gross weight of wirebound boxes shall

for Label B packing. not exceed the requirements of the box specification.

TABLE 1 Nailed Wood Boxes for Straight Lengths of Bar, Rod, Shafting, Shapes, Flat Wire, and Tubular Products

A A

Ends End Cleats Battens

Minimum Top Styles 1 Styles 2, 4, 7,

Minimum Sides Styles 2, 4, 7, and 8 Styles 1A, 7, and 8

B C

Weight of Content, lbs Box Styles and Bottom and 1A and 8

Thickness, in.

(kg) (See Figs. 1-6) Thickness, Minimum 1 or Minimum 1-Ply Minimum Minimum Minimum Minimum

(mm)

in. (mm) 2-Ply Thickness, Thickness, in. Width, in. Thickness, in. Width, in. Thickness,

D

in. (mm) (mm) (mm) (mm) (mm) in. (mm)

5 1 1 5 1 5

Up to 280 (127) 1, 2, and 4 ⁄8 (15.8) ⁄2 (12.7) 1 ⁄16 (27.0) ⁄8 (15.8) 2 ⁄2 (63.5) ⁄8(15.8) . .

5 5 1 5 1 5

281 to 560 1, 2, and 4 ⁄8 (15.8) ⁄8 (15.8) 1 ⁄16 (27.0) ⁄8 (15.8) 2 ⁄2 (63.5) ⁄8(15.8) . .

(128 to 254)

3 5 1 1 3 5 3 3

561 to 1120 1to8 ⁄4 (19.1) ⁄8 (15.8) 1 ⁄2 (38.1) 1 ⁄16 (27.0) 2 ⁄4 (69.9) ⁄8 (15.8) 2 ⁄4 (69.9) ⁄4 (19.1)

(255

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.