ASTM D6504-11(2016)e1

(Practice)Standard Practice for On-Line Determination of Cation Conductivity in High Purity Water

Standard Practice for On-Line Determination of Cation Conductivity in High Purity Water

SIGNIFICANCE AND USE

5.1 Cation conductivity provides one of the most sensitive and dependable on-line means of detecting anionic contamination in the boiler/steam cycle, such as chlorides, sulfates, nitrates, bicarbonates, and organic acids, such as formic and acetic.

5.2 High sensitivity is provided by intentionally eliminating the pH adjusting treatment chemical(s), for example, ammonia and amines, from the sample and converting remaining salt contaminants into their acid forms which are approximately three times as conductive.

5.3 Guidelines on cation conductivity limits for various cycle chemistry and boiler types have been established by EPRI (2-4) and by ASME (5 and 6).

5.4 The sample effluent from the cation exchange column also may be used, and in some cases is preferred, for ion chromatography or other anion measurements.

SCOPE

1.1 This practice describes continuous sample conditioning by hydrogen ion exchange and measurement by electrolytic conductivity. It is commonly known as cation conductivity measurement in the power industry although it is actually an indication of anion contamination in high purity water samples. Measurements are typically in a range less than 1 μS/cm.

1.2 The actual conductivity measurements are made using Test Method D5391.

1.3 This practice does not provide for separate determination of dissolved carbon dioxide. Refer to Test Method D4519.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D6504 − 11 (Reapproved 2016)

Standard Practice for

On-Line Determination of Cation Conductivity in High Purity

Water

This standard is issued under the fixed designation D6504; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial corrections were made throughout in February 2016.

1. Scope D1193 Specification for Reagent Water

D3370 Practices for Sampling Water from Closed Conduits

1.1 This practice describes continuous sample conditioning

D3864 Guide for On-Line Monitoring Systems for Water

by hydrogen ion exchange and measurement by electrolytic

Analysis

conductivity. It is commonly known as cation conductivity

D4519 Test Method for On-Line Determination of Anions

measurement in the power industry although it is actually an

and Carbon Dioxide in High Purity Water by Cation

indicationofanioncontaminationinhighpuritywatersamples.

Exchange and Degassed Cation Conductivity

Measurements are typically in a range less than 1 µS/cm.

D5391 Test Method for Electrical Conductivity and Resis-

1.2 The actual conductivity measurements are made using

tivity of a Flowing High Purity Water Sample

Test Method D5391.

D5540 Practice for Flow Control and Temperature Control

1.3 This practice does not provide for separate determina- for On-Line Water Sampling and Analysis

tion of dissolved carbon dioxide. Refer to Test Method D4519.

3. Terminology

1.4 The values stated in SI units are to be regarded as

3.1 Definitions—For definitions of terms used in this

standard. The values given in parentheses are mathematical

practice, refer to Test Methods D1125, Terminology D1129,

conversions to inch-pound units that are provided for informa-

and Guide D3864.

tion only and are not considered standard.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard does not purport to address all of the

3.2.1 cation conductivity, n—the parameter obtained by

safety concerns, if any, associated with its use. It is the

conditioning a sample by passing it through a hydrogen form

responsibility of the user of this standard to establish appro-

cation ion exchange resin column and then measuring its

priate safety and health practices and determine the applica-

electrolytic conductivity, on-line.

bility of regulatory limitations prior to use.

3.2.2 specific conductivity, n—direct electrolytic conductiv-

2. Referenced Documents

ity measurement of a power plant sample, usually dominated

by treatment chemicals, such as ammonia or amines.

2.1 ASTM Standards:

D1066 Practice for Sampling Steam

4. Summary of Practice

D1125 Test Methods for Electrical Conductivity and Resis-

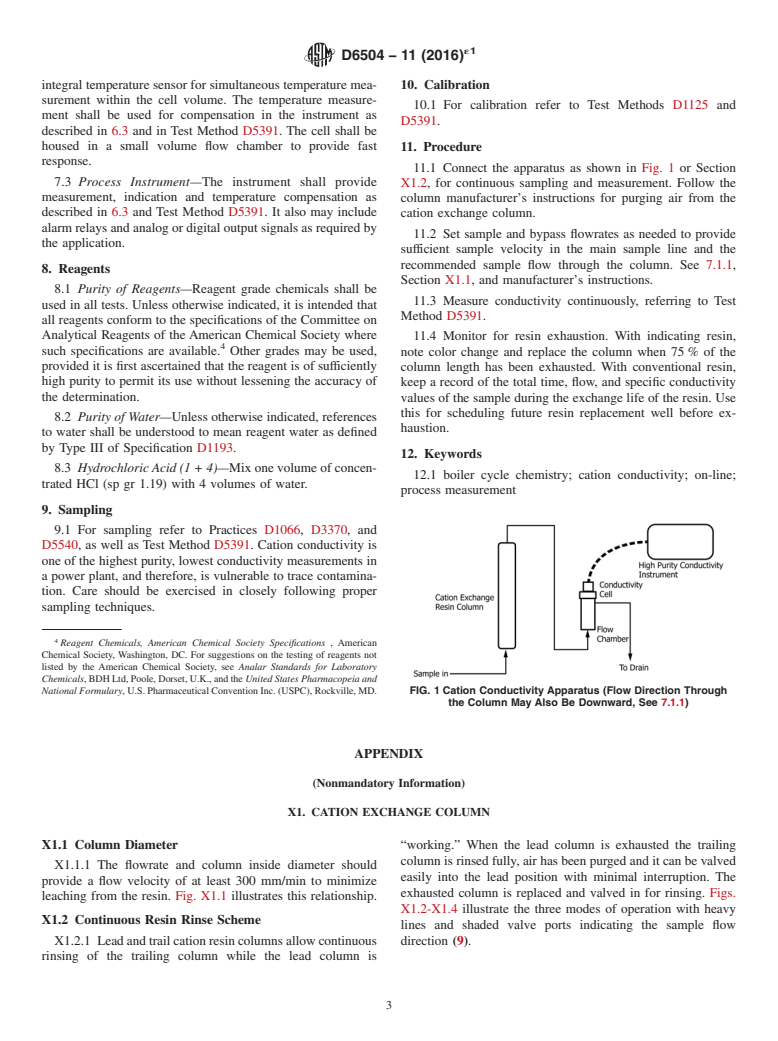

4.1 The sample is passed continuously through a small

tivity of Water

cation exchange column in the hydrogen form, which ex-

D1129 Terminology Relating to Water

+

changes all cations for H . In this process, pH adjusting

treatment chemicals, such as ammonia and amines are re-

This practice is under the jurisdiction ofASTM Committee D19 on Water and

moved.

is the direct responsibility of Subcommittee D19.03 on Sampling Water and

4.2 Measurement is made continuously on the conditioned

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

On-Line Water Analysis, and Surveillance of Water.

sample with a process high purity conductivity analyzer/

Current edition approved Feb. 15, 2016. Published March 2016. Originally

transmitter.

approved in 1999. Last previous edition approved in 2011 as D6504 – 11. DOI:

10.1520/D6504-11R16E01.

4.3 Temperature conditioning of the sample and specialized

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

compensation of the measurement are used to minimize

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

temperature effects on the performance of the ion exchange

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. resin and the measurement.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6504 − 11 (2016)

4.4 Few studies have been published on the performance of desirable to obtain a cation conductivity measurement with

cation conductivity measurement but one collaborative effort carbon dioxide removed (see Test Method D4519.)

provides some background (1).

6.5 Carbondioxidemayalsobeaspiratedasacomponentof

air, into the sample line through loose fittings in the exchange

5. Significance and Use

column,flowmeter,valves,etc.Thisisnotrepresentativeofthe

5.1 Cation conductivity provides one of the most sensitive

actual sampling point and produces positive errors.

and dependable on-line means of detecting anionic contamina-

6.6 Incompletely regenerated or inadequately rinsed resin

tion in the boiler/steam cycle, such as chlorides, sulfates,

will release trace ionic impurities that produce positive errors.

nitrates, bicarbonates, and organic acids, such as formic and

The use of fresh resin completely in the hydrogen form and

acetic.

thoroughlyrinsedisrecommended.Anexhaustedresincolumn

5.2 High sensitivity is provided by intentionally eliminating

will have the same effect but with more rapidly increasing

the pH adjusting treatment chemical(s), for example, ammonia

errors.

and amines, from the sample and converting remaining salt

6.7 Fouled resin can leach conductive components even

contaminants into their acid forms which are approximately

with an absolutely pure influent sample. Fresh resin is recom-

three times as conductive.

mended.

5.3 Guidelines on cation conductivity limits for various

6.8 Some cation resins contain leachables which can raise

cycle chemistry and boiler types have been established by

background conductivity and reduce sensitivity to sample

EPRI (2-4) and by ASME (5 and 6).

impurities. Extensive rinsing usually is required.Acontinuous

5.4 The sample effluent from the cation exchange column

rinsingschemeisgiveninSectionX1.2.Somesuccessalsohas

also may be used, and in some cases is preferred, for ion

been achieved with a hydrochloric acid (1 + 4) pre-rinse.

chromatography or other anion measurements.

6.9 For interferences with basic high purity conductivity

measurements, refer to Test Method D5391.

6. Interferences

6.1 Some weakly ionized cations may not be completely

7. Apparatus

exchanged by the resin. This will produce positive or negative

errors in the measurement depending on the sample composi- 7.1 Cation Exchange Column:

tion. These errors can reduce sensitivity to corrosive contami- 7.1.1 The cation exchange column shall have an inside

nants. diameter of less than 60 mm (2.4 in.) and produce a flow

velocity greater than 300 mm/min (1 ft/min) at the sample flow

6.2 Temperature effects on the cation resin may alter its

rate (see Appendix X1). The column shall have end screens to

equilibrium properties. Control sample temperature within the

distribute flow across the cross-section of the column and to

resin manufacturers’ temperature limits to obtain consistent

prevent resin beads and fines from escaping. The column may

results.

be piped for upward or downward flow. Upward flow provides

6.3 Thelargetemperatureeffectsofhighpurityconductivity

automatic purging of air at startup which is helpful in cycling

measurement must be minimized by sample conditioning and

plants. However, the resin must be packed full to prevent

temperature compensation. Although sample temperature may

fluidizing and channeling. Downward flow eliminates the

be controlled closely, it may be significantly influenced by the

possibility of fluidizing but requires the means to vent air from

ambient temperature as it passes through the column, tubing

the column at startup. Care must be exercised to eliminate all

and flow chamber. The temperature coefficient of pure water is

air pockets which could cause channeling. The column should

near 5 % of measurement per °C at 25°C, which can contribute

be constructed of nonleaching material, such as polycarbonate

substantial errors if not compensated properly. Temperature

or polypropylene. Materials, such as polyvinylchloride, may

compensation must be appropriate for the unique acidic com-

leachchloridesandarenotrecommended.Flexibletubingused

position of cation conductivity samples. Conventional high

tomakeconnectionstothecolumnshouldhaveminimallength

purity temperature compensation for neutral mineral contami-

and diameter to minimize the amount of leaching and air

nants is not suitable for this application (7 and 8). The user is

(carbon dioxide) permeation.

cautioned that the accuracy of algorithms for cation conduc-

7.1.2 The resin shall be a sulfonated styrene-divinylbenzene

tivity compensation may vary widely. The u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.