ASTM D4786-00(2005)

(Test Method)Standard Test Method for Stitch Tear Strength, Single Hole

Standard Test Method for Stitch Tear Strength, Single Hole

SIGNIFICANCE AND USE

This test method is intended to be used to rate leathers as to their stitch tear strengths.

SCOPE

1.1 This test method is intended for determining the stitch-tearing strength of leather with a tear originating from one hole. It is particularly applicable to heavy leather. This test method does not apply to wet blue.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D4786–00(Reapproved2005)

Standard Test Method for

Stitch Tear Strength, Single Hole

This standard is issued under the fixed designation D4786; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method is intended for determining the stitch-

tearing strength of leather with a tear originating from one

hole. It is particularly applicable to heavy leather. This test

method does not apply to wet blue.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1813 Test Method for Measuring Thickness of Leather

Test Specimens

D2209 Test Method for Tensile Strength of Leather

3. Significance and Use

3.1 This test method is intended to be used to rate leathers

as to their stitch tear strengths.

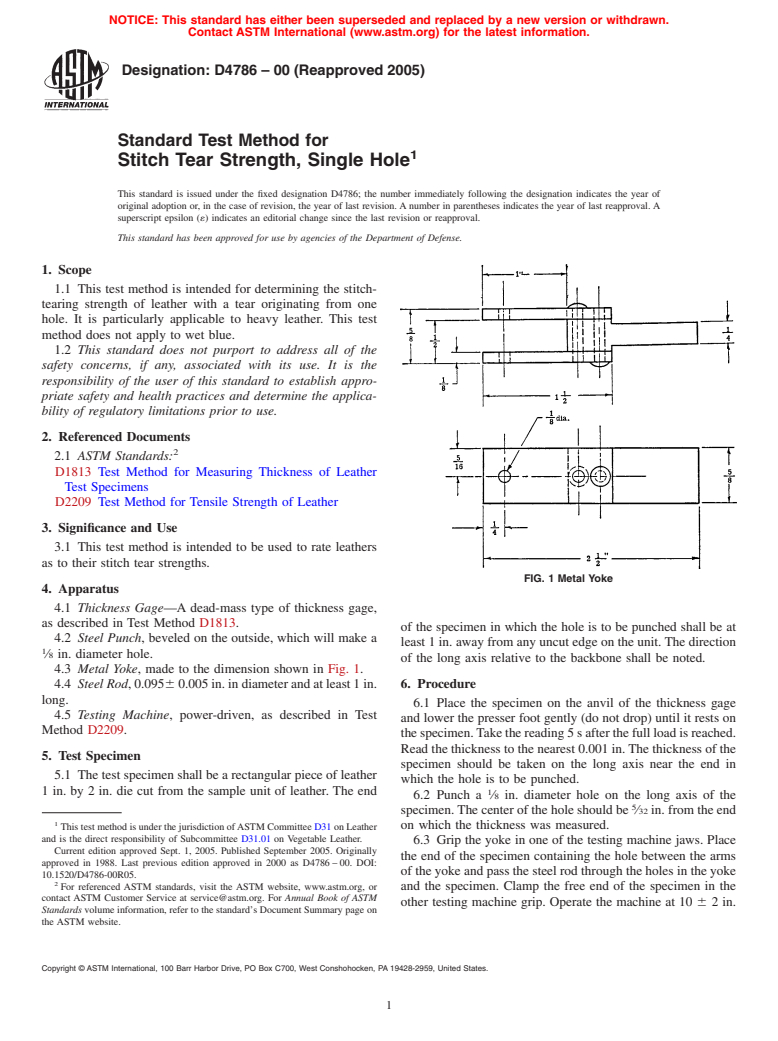

FIG. 1 Metal Yoke

4. Apparatus

4.1 Thickness Gage—A dead-mass type of thickness gage,

as described in Test Method D1813.

of the specimen in which the hole is to be punched shall be at

4.2 Steel Punch, beveled on the outside, which will make a

least 1 in. away from any uncut edge on the unit. The direction

⁄8 in. diameter hole.

of the long axis relative to the backbone shall be noted.

4.3 Metal Yoke, made to the dimension shown in Fig. 1.

4.4 SteelRod, 0.0956 0.005 in. in diameter and at least 1 in. 6. Procedure

long.

6.1 Place the specimen on the anvil of the thickness gage

4.5 Testing Machine, power-driven, as described in Test

and lower the presser foot gently (do not drop) until it rests on

Method D2209.

the specimen.Take the reading 5 s after the full load is reached.

Read the thickness to the nearest 0.001 in. The thickness of the

5. Test Specimen

specimen should be taken on the long axis near the end in

5.1 The test specimen shall be a rectangular piece of leather

which the hole is to be punched.

1 in. by 2 in. die cut from the sample unit of leather. The end 1

6.2 Punch a ⁄8 in. diameter hole on the long axis of the

specimen. The center of the hole should be ⁄32 in. from the end

This test method is under the jurisdiction ofASTM Committee D31 on Leather on which the thickness was measured.

and is the direct responsibility of Subcommittee D31.01 on Vegetable Leather.

6.3 Grip the yoke in one of the testing machine jaws. Place

Current edition approved Sept. 1, 2005. Published September 2005. Originally

the end of the specimen containing the hole between the arms

approved in 1988. Last previous edition approved in 2000 as D4786 – 00. DOI:

of the yoke and pass the steel rod through the holes in the yoke

10.1520/D4786-00R05.

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 This test method is intended to be used to rate leathers as to their stitch tear strengths.

SCOPE

1.1 This test method is intended for determining the stitch-tearing strength of leather with a tear originating from one hole. It is particularly applicable to heavy leather. This test method does not apply to wet blue.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments since current estimates of between-laboratory precision are acceptable, and the test method is used extensively in the trade for acceptance testing.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of fabric of the type in question. Test specimens then should be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using the appropriate statistical analysis and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected, or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

5.2 The force registered in a tear test is irregular, and as a consequence, empirical methods have had to be developed to obtain usable values related to tear strength. In spite of the empirical nature of the reported values, the values are considered to reflect comparative performance of similar fabrics tested and measured in the same way. No known procedure is available that can be used with all fabrics to determine the minimum tearing strength.

5.3 Depending on the nature of the specimen, the data recording devices will show the tearing force in the form of a peak or peaks. The highest peaks appear to reflect the strength of the yarn components, fiber bonds, or fiber interlocks, individually or in combination, needed to stop a te...

SCOPE

1.1 This test method covers the measurement of the tearing strength of textile fabrics by the tongue (single rip) procedure using a recording constant-rate-of-extension-type (CRE) tensile testing machine.

1.1.1 The CRE-type tensile testing machine has become the preferred test apparatus for determining tongue tearing strength. It is recognized that some constant-rate-of-traverse-type (CRT) tensile testing machines continue to be used. As a consequence, these test instruments may be used when agreed upon between the purchaser and the supplier. The conditions for use of the CRT-type tensile tester are included in Appendix X1.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knit fabrics, layered fabrics, pile fabrics and non-wovens. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing specimens with or without wetting.

1.3 Tear strength, as measured in this test method, requires that the tear be initiated before testing. The reported value obtained is not directly related to the force required to initiate or start a tear.

1.4 Two calculations for tongue tearing strength are provided: the single-peak force and the average of five highest peak forces.

1.5 The values stated in either SI units or inch-pound units are to be regarded as the standard. The inch-pound units may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of I...

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method can be used for acceptance testing of commercial shipments but comparisons should be made with caution because estimates of between-laboratory precision are incomplete.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use samples for such comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing, and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.2 Elongation is an indication of the ability of a fiber to absorb energy. The elongation of textile materials must be great enough to withstand strains experienced in processing and end use, and to absorb the energies of applied forces repeatedly.

SCOPE

1.1 This test method covers the determination of the breaking strength and elongation of textile webbing, tape and braided materials using a split-drum type specimen clamp.

1.2 This test method is limited to materials with a maximum width of 90 mm (3.5 in.) and a maximum breaking strength of no more than 89000 N (20000 lb).

1.3 The values stated in either SI units or U.S. Customary units are to be regarded separately as standard. Within the text, the U.S. Customary units are given in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 These test methods may be used for acceptance testing of commercial shipments; however, caution is advised because information about between interlaboratory precision is incomplete. Comparative tests as directed in 5.1.1 may be advisable.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is statistical bias between them using competent statistical assistance. As a minimum, use test samples for such comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in the disparate results during initial testing, and that are randomly assigned in equal numbers to each laboratory for testing. The test results from the laboratories should be compared using statistical test for unpaired data at a probability level chosen prior to the testing series. If a bias is found either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.2 These test methods are useful to evaluate quality and cost control during the manufacture of pile yarn floor covering.

5.3 The significance and uses of particular properties and test methods are discussed in the appropriate sections of the specified test methods.

SCOPE

1.1 This guide covers the procedures listed as follows for testing woven, knitted and nonwoven backing fabrics designed for use in the manufacture of pile yarn floor coverings. The procedures appear in the following order:

Section

Bow and Skewness of Woven Fabrics

8

Breaking Force of Woven and Nonwoven Fabrics

15

Breaking Force After Tufting of Woven and Nonwoven Fabrics

16

Extractable Matter

9

Fabric Count of Woven Fabrics

12

Fabric Count of Knitted Fabrics

13

Length of Woven Fabrics

11

Mass per Unit Area (Weight) of Woven Fabrics

14

Width of Woven Fabrics

10

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide3 pagesEnglish languagesale 15% off

- Guide3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of between-laboratory precision are acceptable, and this test method is used extensively in the trade for acceptance testing.

5.2 If there are differences of practical significance between test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative test that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing. Randomly assign the samples in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.3 The trapezoid tear produces tension along a reasonably defined course such that the tear propagates across the width of the specimen. It is useful for estimating the relative tear resistance of different fabrics or different directions in the same fabric.

5.4 Depending on the nature of the specimen, the data recording devices will show the tearing force in the form of a peak or peaks. The highest peaks appear to reflect the strength of the yarn components, individually or in combination, needed to stop a tear in fabrics of the same construction. The valleys recorded between the peaks have no specific significance. The minimum tearing force, however, is indicated to be above the lowest valleys.

5.5 Most textile fabrics can be tested by this test method. Some modification of clamping techniques may be necessary for a given fabric, depending upon its structure. Strong fabrics or fabrics...

SCOPE

1.1 This test method covers the measurement of the tearing strength of textile fabrics by the trapezoid procedure using a recording constant-rate-of-extension-type (CRE) tensile testing machine.

1.1.1 The CRE-type tensile testing machine has become the preferred test apparatus for determining trapezoid tearing strength. It is recognized that some constant-rate-of-traverse-type (CRT) tensile testing machines continue to be used. Consequently, these test instruments may be used when agreed upon between the purchaser and the supplier. The conditions for use of the CRT-type tensile tester are included in Appendix X1.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, pile, and nonwoven fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing specimens with or without wetting.

1.3 Tearing strength, as measured in this test method, requires that the tear be initiated before testing. The reported value obtained is not directly related to the force required to initiate or start a tear.

1.4 Two calculations for trapezoid tearing strength are provided: the single-peak force and the average of five highest peak forces.

1.5 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International ...

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 The guide, as now constituted, is not suitable for ranking of detergent products since no basis is available at this time for correlation of the detergency performance of any particular soiled cloth or clothes with detergency of naturally soiled articles.

4.2 A suggested procedure for comparing the performance of any two laundry detergents on naturally soiled family items in home laundry equipment under controlled conditions on a paired comparison basis is described in Method D2960.

SCOPE

1.1 This is a guide for measuring the ability of detergents to remove artificially applied soils from fabrics. It is intended as a laboratory screening test to aid in the formulation of detergent products, for quality control and as a basis between the purchaser and seller in standardizing specific products' performance.

1.2 The relative ranking of detergent products will vary greatly depending on the type of soiled fabrics used in the test. Therefore, selection of the standard soiled fabric to be used in a test shall be made by agreement between the interested parties on the basis of experience.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide2 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the general and physical requirements for greige fabrics woven from “E” electrical glass fiber yarns. The yarn shall be a continuous filament, free of any free alkali metal salts, such as soda or potash, and foreign particles, dirt, and other impurities. The fabric shall be furnished in rolls and shall be wound in spiral tubes. The materials shall be tested and shall conform to the following requirements: fabric count; yarn numbers for both the warp and filling yarns; filament diameter; strand construction; twist direction wherein the primary twist in the singles strands shall be “Z” twist and the final twist in the plied yarns shall be “S” twist; twist level; fabric weave type which shall include crowfoot, leno, mock leno, plain, eight-harness satin, and twelve-harness satin; mass per unit area; thickness; breaking strength; width including both selvages but excluding any feathered edges; fabric roll length, length between splices, and number of splices per roll; and ignition loss. The fabrics shall also be examined for defects such as bias or bowed filling; baggy, ridged, or wavy cloth; cut or tear; hole; spots, streaks, or stains; foreign inclusions; tender or weak spot; smash; broken, missing ends or picks; floats and skips; light and heavy marks; crease; waste; weave separation; brittle or fused area; selvage defects; selvage leno ends out; and feather edges.

SCOPE

1.1 This practice covers greige fabrics woven from “E” electrical glass fiber yarns. This practice can also be applied to fabrics made of other glass fiber types as agreed upon between the purchaser and the supplier.

1.2 This practice specifies the terminology, definitions, general requirements and physical requirements for greige glass fiber fabrics. This practice permits the application of organic materials to the glass fiber yarn during manufacture that helps facilitate weaving.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This practice is one of a series to provide a substitute for Military Specifications: MIL-Y-1140 Yarn, Cord, Sleeving, Cloth, and Tape-Glass and MIL-C-9084 Cloth, Glass Finished for Resin Laminates.

1.5 Additional ASTM practices in this series have been drafted and appear in current editions of the Annual Book of ASTM Standards. These include finished glass fabrics, unfinished glass fabrics, glass tapes, glass sleevings, glass cords, glass sewing threads, and finished laminates made from finished glass fabrics.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard18 pagesEnglish languagesale 15% off

- Standard18 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This is a guide to help a manufacturer distributor, or importer establish a reasonable basis for care information.

4.1.1 The manufacturer, distributor, or importer should possess, prior to sale, reliable evidence that the product was not harmed when refurbished reasonably often according to the instructions. Additionally, they should possess reliable evidence that the product, or a fair sample of the product, would be harmed when refurbished by methods warned against on the label.

4.2 This guide is intended for general use by those who wish to evaluate whether apparel or other textile products will perform in an acceptable manner when refurbished according to particular care instructions.

4.3 Refurbished products are evaluated against previously selected product specifications to determine whether the products can be refurbished successfully by following the instructions on the care label or other care instructions.

SCOPE

1.1 This guide may be used to determine and confirm the appropriate care label instructions for apparel, piece goods, and other textile products excluding textile floor coverings and upholstery.

1.2 This guide encompasses the following care procedures: home laundering, professional textile care, and other alternative cleaning methods.

1.3 This guide includes provision for evaluating the complete textile product and the product components.

1.4 This guide covers the performance characteristics as a result of refurbishing that are important in determining the acceptability of a textile product.

1.5 This guide is appropriate for the evaluation of all garments and household textiles that are sold with care labels.

1.5.1 This guide may also be used in connection with the evaluation of similar materials that do not have a care label.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This guide is intended to serve as a reference for the testing of textile composite materials.

4.2 The use of this guide ensures that proper consideration is given to the unique characteristics of these materials in testing. In addition, this guide also assists the user in selecting the best currently available ASTM test method for measurement of commonly evaluated material properties.

SCOPE

1.1 This guide is applicable to the testing of textile composites fabricated using fabric preforms, such as weaves, braids, stitched preforms, and so forth, as the reinforcement. The purpose of this guide is to:

1.1.1 Ensure that proper consideration is given to the unique characteristics of these materials in testing.

1.1.2 Assist the user in selecting the best currently available ASTM test method for the measurement of commonly evaluated material properties for this class of materials.

1.2 Areas where current ASTM test methods do not meet the needs for testing of textile composites are indicated.

1.3 It is not the intent of this guide to cover all test methods which could possibly be used for textile composites. Only the most commonly used and most applicable standards are included.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4.1 Within the text the inch-pound units are shown in brackets.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory requirements prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide9 pagesEnglish languagesale 15% off

- Guide9 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 In general, these procedures are more suitable for testing woven fabrics than knit fabrics.

5.2 Both test options in this test method are considered satisfactory for acceptance testing of commercial shipments since current estimates of between-laboratory precision are acceptable and the method is used extensively in the trade for acceptance testing.

5.2.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. Test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using the appropriate statistical analysis and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

5.3 The stiffness of a fabric may change with storage.

5.4 No evidence has been found showing that bending length is dependent on the width of the test specimen. The tendency for specimens to curl or twist will affect the result, because of the rigidity provided at the edge of the specimen. Consequently, the wider the strip, the less important is the edge effect. For fabrics having only a slight tendency to curl, a 2.5 cm wide strip has been found to be satisfactory. As the tendency to curl increases, this width may be increased (see Note 10).

5.5 This method differs from Test Method F3260 which requires tracking of...

SCOPE

1.1 This test method covers the measurement of stiffness properties of fabrics. Bending length is measured and flexural rigidity is calculated. Two procedures are provided.

1.1.1 Option A—Cantilever Test, employing the principle of cantilever bending of the fabric under its own mass.

1.1.2 Option B—Heart Loop Test, employing the principle of a loop formed in a fabric strip and hung vertically.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, pile fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated.

1.2.1 This method may be used to determine the stiffness of nonwoven materials (for example, hydroentangled, dry laid, needlepunch, resin bonded, thermal, and wet laid) or refer to Test Method D5732. To determine the stiffness of medical textiles (for example, surgical mesh, films, and membranes), refer to Test Method F3260.

Note 1: The formula to calculate flexural rigidity in D5732-95 (2001) is incorrect and should not be used. Utilize the formula presented in 11.5 of Test Method D1388.

1.3 Units—The values stated in SI units are to be regarded as the standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers...

- Standard8 pagesEnglish languagesale 15% off

- Standard8 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.