ASTM D2993-98

(Specification)Standard Specification for Acrylonitrile-Butadiene Rubberized Tar (Withdrawn 2003)

Standard Specification for Acrylonitrile-Butadiene Rubberized Tar (Withdrawn 2003)

SCOPE

1.1 This specification covers one grade of rubberized tar for use in construction of rubberized tar concrete pavement.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: D 2993 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Acrylonitrile-Butadiene Rubberized Tar

This standard is issued under the fixed designation D 2993; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

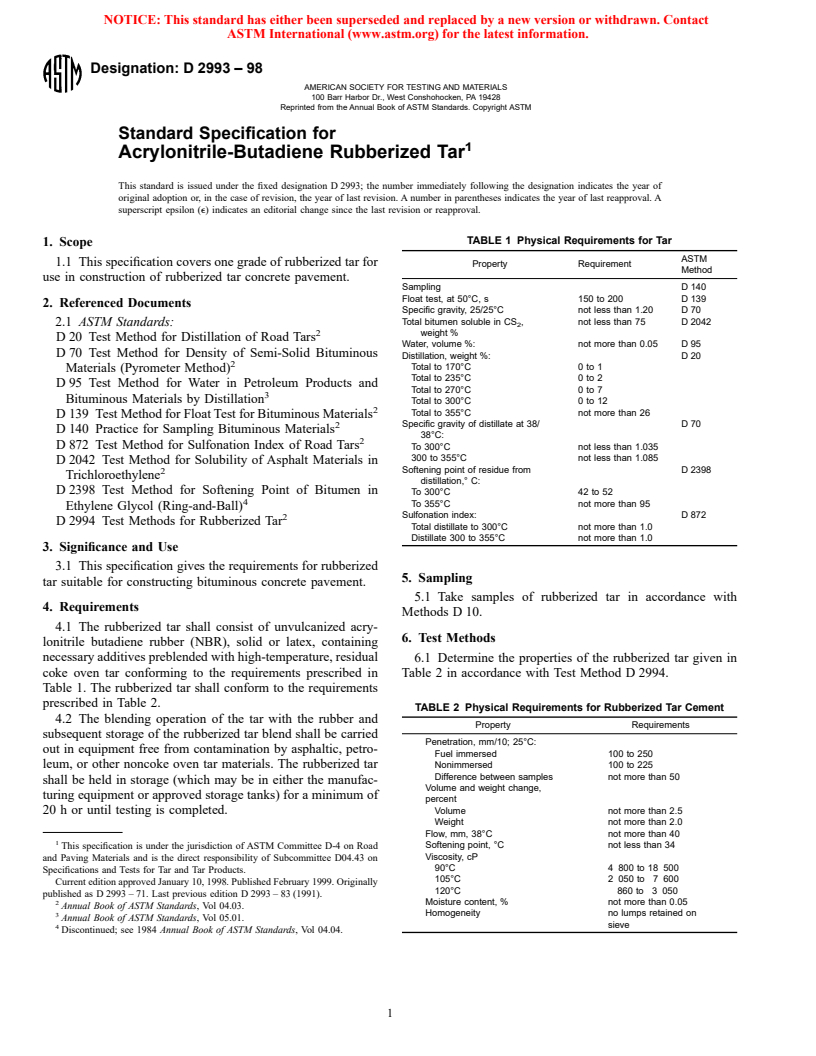

TABLE 1 Physical Requirements for Tar

1. Scope

ASTM

1.1 This specification covers one grade of rubberized tar for

Property Requirement

Method

use in construction of rubberized tar concrete pavement.

Sampling D 140

Float test, at 50°C, s 150 to 200 D 139

2. Referenced Documents

Specific gravity, 25/25°C not less than 1.20 D 70

Total bitumen soluble in CS , not less than 75 D 2042

2.1 ASTM Standards: 2

weight %

2

D 20 Test Method for Distillation of Road Tars

Water, volume %: not more than 0.05 D 95

D 70 Test Method for Density of Semi-Solid Bituminous

Distillation, weight %: D20

2

Total to 170°C 0 to 1

Materials (Pyrometer Method)

Total to 235°C 0 to 2

D 95 Test Method for Water in Petroleum Products and

Total to 270°C 0 to 7

3

Bituminous Materials by Distillation

Total to 300°C 0 to 12

2

Total to 355°C not more than 26

D 139 Test Method for Float Test for Bituminous Materials

Specific gravity of distillate at 38/ D70

2

D 140 Practice for Sampling Bituminous Materials

38°C:

2

D 872 Test Method for Sulfonation Index of Road Tars

To 300°C not less than 1.035

300 to 355°C not less than 1.085

D 2042 Test Method for Solubility of Asphalt Materials in

Softening point of residue from D 2398

2

Trichloroethylene

distillation,° C:

D 2398 Test Method for Softening Point of Bitumen in

To 300°C 42 to 52

4

To 355°C not more than 95

Ethylene Glycol (Ring-and-Ball)

Sulfonation index: D 872

2

D 2994 Test Methods for Rubberized Tar

Total distillate to 300°C not more than 1.0

Distillate 300 to 355°C not more than 1.0

3. Significance and Use

3.1 This specification gives the requirements for rubberized

5. Sampling

tar suitable for constructing bituminous concrete pavement.

5.1 Take samples of rubberized tar in accordance with

4. Requirements

Methods D 10.

4.1 The rubberized tar shall consist of unvulcanized acry-

6. Test Methods

lonitrile butadiene rubber (NBR), solid or latex, containing

necessary additives preblended with high-temperature, residual 6.1 Determine the properties of the rubberized tar given in

coke oven tar conforming to the requirements prescribed in Table 2 in accordance with

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 This test method provides a measure of rheological non-linearity for filled rubber compounds under oscillatory shear conditions: the normalized 3rd harmonic of the torque I3/1.

3.2 Rheological linearity means that the modulus is a function of frequency only. The shear modulus dependency on both frequency and amplitude of a dynamic deformation is a non-linear, rheological effect. Filled rubbers show a strain dependency of the modulus known as Payne effect. A test method for evaluating the Payne effect can be found in Test Method D8059.

3.3 One of the main contributions to the Payne effect is the so-called polymer-filler interaction in the range of mid amplitude oscillation shear, MAOS. The MAOS amplitude range is defined as the range where I3/1 is already measurable and increases according to a scaling law, for example, I3/1 ~ γ2. It has been shown that FT rheological measurements are very sensitive to changes in this interaction, and that it is possible to quantify the influence of the filler type and content on the nonlinearity. Interactions between the polymer and particle surface and between the filler particles create a network structure in the compound that not only increases the elasticity of the system but also introduces nonlinear contributions to the stress response.3

SCOPE

1.1 This test method provides a measure of rheological non-linearity of a rubber compound filled with rCB to assess its reinforcement capabilities. This test method requires the use of a sealed cavity rotorless oscillating shear rheometer for the measurement of the torque with increasing sinusoidal strain applied to an uncured rubber compound containing significant amounts of colloidal fillers, such as recovered carbon black, alone or as blend with virgin carbon black.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Weight loss through volatilization of components of a sealant in a building joint may affect sealant appearance because of shrinkage, and sealant performance because of the loss of functional sealant components. Exposure to high-temperature environments will accelerate the loss of volatiles.

5.2 This test method measures weight loss. It can be used in combination with a knowledge of sealant density to estimate shrinkage. In addition, when compared to sealant theoretical weight solids, it provides an estimate of the extent to which functional sealant components can be volatilized when exposed to high service temperatures. Substantial losses of this type may help predict early failures in durability. Also, development of cracks or chalking, or both, lessens sealant service life. However, a sealant that develops no cracks or chalking, or low weight loss in this test method, does not necessarily assure good durability.

SCOPE

1.1 This test method covers a laboratory procedure for determining the effects of heat aging on weight loss, cracking, and chalking of cured-in-place elastomeric joint sealants (single- and multi-component) for use in building construction.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 There is no known ISO equivalent to this test method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 It is known that solar radiation contributes to the degradation of sealants in exterior building joints. The use of a laboratory accelerated weathering machine with actinic radiation, moisture and heat appears to be a feasible means to give indications of early degradation by the appearance of sealant cracking. However, simulated weather factors in combination with extension may produce more severe degradation than weather factors only. Therefore, the effect of the weathering test is made more sensitive by the addition of the bending of the specimen at cold temperature.

SCOPE

1.1 This test method covers a laboratory procedure for determining the effects of accelerated weathering on cured-in-place elastomeric joint sealants (single- and multicomponent) for use in building construction.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other ASTM committees or other organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method is used to determine if there is any heavy material in the butadiene. It is possible that these materials could be deleterious to a polymerization reaction.

SCOPE

1.1 This test method covers the determination of nonvolatile material in polymerization-grade butadiene.

1.2 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use Caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability of regulatory limitations prior to use.

1.4.1 The user is advised to obtain LPG safety training for the safe operation of this test method procedure and related activities.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers nonvulcanized (uncured) rubber sheet made of ethylene-propylene-diene terpolymer (EPDM) or polychloroprene (CR) intended for use as watertight roof flashing exposed to the weather. In-place roof system design criteria such as fire resistance, field seaming strength, material compatibility, and uplift resistance, among others, are beyond the scope of this specification. The flashing material shall be formulated from the appropriate polymer type and other compounding ingredients, and shall be capable of being bonded to itself, to the roofing membrane, and to substrate for making watertight field splices and repairs. Property requirements for flashing before vulcanization include thickness, Green strength modulus, ultimate elongation, shelf stability, vulcanizability, tensile strength and set, dimensional stability, and weatherability. Consequently, the property requirements for flashing after vulcanization includes tensile strength and set, elongation, tear resistance, brittle point, ozone resistance, air oven heat aging, water absorption and weight change, linear dimension change, and weatherability.

SCOPE

1.1 This specification covers nonvulcanized (uncured) rubber sheet made of EPDM (ethylene-propylene-diene terpolymer) or CR (polychloroprene) intended for use as watertight roof flashing exposed to the weather.

1.2 The tests and property limits used to characterize these flashing materials are specific for each classification and are minimum values to make the product fit for its intended purpose.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 In-place roof system design criteria, such as fire resistance, field seaming strength, material compatibility, and uplift resistance, among others, are beyond the scope of this specification.

1.5 The following precautionary caveat pertains to the test methods portion only, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 This test method provides a measure of rheological non-linearity for filled rubber compounds under oscillatory shear conditions: the normalized 3rd harmonic of the torque I3/1.

3.2 Rheological linearity means that the modulus is a function of frequency only. The shear modulus dependency on both frequency and amplitude of a dynamic deformation is a non-linear, rheological effect. Filled rubbers show a strain dependency of the modulus known as Payne effect. A test method for evaluating the Payne effect can be found in Test Method D8059.

3.3 One of the main contributions to the Payne effect is the so-called polymer-filler interaction in the range of mid amplitude oscillation shear, MAOS. The MAOS amplitude range is defined as the range where I3/1 is already measurable and increases according to a scaling law, for example, I3/1 ~ γ2. It has been shown that FT rheological measurements are very sensitive to changes in this interaction, and that it is possible to quantify the influence of the filler type and content on the nonlinearity. Interactions between the polymer and particle surface and between the filler particles create a network structure in the compound that not only increases the elasticity of the system but also introduces nonlinear contributions to the stress response.3

SCOPE

1.1 This test method provides a measure of rheological non-linearity of a rubber compound filled with rCB to assess its reinforcement capabilities. This test method requires the use of a sealed cavity rotorless oscillating shear rheometer for the measurement of the torque with increasing sinusoidal strain applied to an uncured rubber compound containing significant amounts of colloidal fillers, such as recovered carbon black, alone or as blend with virgin carbon black.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Permittivity—Insulating materials are used in general in two distinct ways, (1) to support and insulate components of an electrical network from each other and from ground, and (2) to function as the dielectric of a capacitor. For the first use, it is generally desirable to have the capacitance of the support as small as possible, consistent with acceptable mechanical, chemical, and heat-resisting properties. A low value of permittivity is thus desirable. For the second use, it is desirable to have a high value of permittivity, so that the capacitor is able to be physically as small as possible. Intermediate values of permittivity are sometimes used for grading stresses at the edge or end of a conductor to minimize ac corona. Factors affecting permittivity are discussed in Appendix X3.

5.2 AC Loss—For both cases (as electrical insulation and as capacitor dielectric) the ac loss generally needs to be small, both in order to reduce the heating of the material and to minimize its effect on the rest of the network. In high frequency applications, a low value of loss index is particularly desirable, since for a given value of loss index, the dielectric loss increases directly with frequency. In certain dielectric configurations such as are used in terminating bushings and cables for test, an increased loss, usually obtained from increased conductivity, is sometimes introduced to control the voltage gradient. In comparisons of materials having approximately the same permittivity or in the use of any material under such conditions that its permittivity remains essentially constant, it is potentially useful to consider also dissipation factor, power factor, phase angle, or loss angle. Factors affecting ac loss are discussed in Appendix X3.

5.3 Correlation—When adequate correlating data are available, dissipation factor or power factor are useful to indicate the characteristics of a material in other respects such as dielectric breakdown, moisture content, degree o...

SCOPE

1.1 These test methods cover the determination of relative permittivity, dissipation factor, loss index, power factor, phase angle, and loss angle of specimens of solid electrical insulating materials when the standards used are lumped impedances. The frequency range addressed extends from less than 1 Hz to several hundred megahertz.

Note 1: In common usage, the word relative is frequently dropped.

1.2 These test methods provide general information on a variety of electrodes, apparatus, and measurement techniques. A reader interested in issues associated with a specific material needs to consult ASTM standards or other documents directly applicable to the material to be tested.2,3

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 10.2.1.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard20 pagesEnglish languagesale 15% off

- Standard20 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 There are differences in opinion among those concerned with sealant technology whether or not this adhesion-in-peel test simulates the type of strain and e-tensile stresses encountered by a sealant in normal use. Nevertheless, this test provides a valuable measurement of the ability of the cured sealant to maintain a bond to the substrate under severe peel conditions.

5.2 Many sealant manufacturers utilize the adhesion-in-peel test for determining the adhesive characteristics of sealant/primer combinations with unusual or proprietary substrates. This test is especially useful for quality measurements comparing batches of the same sealant relative to adhesion or for studying adhesion of a given sealant to a variety of substrates.

5.3 This test method alone is not appropriate for comparing the overall performance of different sealants in a given application. The adhesive force that determines if a given sealant is useful in a given application also depends on the modulus of elasticity and the degree to which the sealant will be strained. This test, as it exists, does not consider the modulus of elasticity, nor amount of stress that will be produced by a given strain in an actual sealant in a moving joint. No known correlations are given to relate and apply modulus values to the peel values.

5.4 This test requires that the results indicate whether the failure mode is primarily adhesive or cohesive. It is important to note that a cohesive failure is not necessarily better than an adhesive failure, if the adhesive value is sufficient for the application. Having adhesive failure allows one to study the change of adhesion with time and with the various stress conditions.

SCOPE

1.1 This test method covers a laboratory procedure for determining the strength and characteristics of the peel properties of a cured-in-place elastomeric joint sealant, single- or multicomponent, for use in building construction.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

ABSTRACT

This specification describes the properties of applied, flat shaped precured elastomeric silicone joint sealants that bridge joint openings and are adhered to joint substrates utilizing a liquid applied silicone adhesive sealant to seal building openings such as panel joints, metal flashing joints, or other building openings in place of conventional liquid applied sealants. Seals are applied in three different configurations, as follows: as a bridge joint, the seal is applied flat on the surface to cover a joint opening; as a beveled bridge joint, the seal is applied on the beveled edge of a substrate to bridge a joint opening.; as a U-joint, the seal is applied in a U-configuration within a joint. Seals are classified into Movement Classes on the basis of movement capability, and Tear Class on the basis of tear propagation. Seals should adhere to specified requirements as to stability, color and texture, application, adhesion and cohesion, and movement, modulus, and tear characteristics.

SCOPE

1.1 Precured elastomeric silicone joint sealants, hereinafter referred to as seal, are manufactured in flat, cured, extruded shapes and are primarily used to span joint openings in construction. This specification describes the properties of applied, flat shaped precured elastomeric silicone joint sealants, hereinafter referred to as applied seal, that bridge joint openings and are adhered to joint substrates utilizing a liquid applied silicone adhesive sealant, specified by the manufacturer, hereinafter referred to as adhesive to construction substrates, to seal building openings such as panel joints, metal flashing joints, or other building openings in place of conventional liquid applied sealants.

1.2 Seals are applied in three different configurations:

1.2.1 As a bridge joint, the seal is applied flat on the surface to cover a joint opening. See Fig. 1.

FIG. 1 Bridge Joint Configuration

1.2.2 As a beveled bridge joint, the seal is applied on the beveled edge of a substrate to bridge a joint opening. See Fig. 2.

FIG. 2 Beveled Bridge Joint Configuration

1.2.3 As a U-joint, the seal is applied in a U-configuration within a joint. See Fig. 3.

FIG. 3 U-Joint Configuration

1.3 This specification is for a flat extruded shape.

1.4 An applied seal meeting the requirements of this specification shall be designated by the manufacturer as to movement class and tear class as described in Section 5.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers test methods and performance requirements for loose-fill rubber playground-surfacing products and is intended to complement existing ASTM International standards for determining the shock attenuation and accessibility of a playground surface. The objective of this specification is to assist playground designers and specifiers, owner/operators, and playground-surfacing suppliers in evaluating loose-fill rubber products for playground use. The test methods and performance requirements cover particle size distribution, extractable hazardous metal content, total lead content, tramp metal content, and sharp tramp metal content. It does not address the accessibility of loose-fill rubber playground surfacing, or the release of organic chemicals from loose-fill rubber intended to be used as a playground surface. Included are tables that designate a sample of loose-fill rubber in the form of nuggets; a sample of loose-fill rubber in form of buffings tested; maximum allowable soluble concentration in mg/L; and analytical correction for antimony, arsenic, barium, cadmium, chromium, lead, mercury, and selenium.

SCOPE

1.1 This specification establishes test methods and performance requirements for particle size distribution, extractable hazardous metal content, total lead content, tramp metal content, and sharp tramp metal content for loose-fill rubber that is intended to be used as a playground surface.

1.2 This specification does not contain test methods or performance requirements for the accessibility of loose-fill rubber playground surfacing. The specification also does not establish test methods or performance requirements to characterize the release of organic chemicals from loose-fill rubber intended to be used as a playground surface. Appendix X1 and Appendix X2 contain additional information on these topics.

1.3 If loose-fill rubber which meets the requirements of this standard is to be installed in the use zone of playground equipment, it must also comply with Specification F1292.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification9 pagesEnglish languagesale 15% off

- Technical specification9 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.