ASTM D7488-11(2016)

(Test Method)Standard Test Method for Open Time of Latex Paints

Standard Test Method for Open Time of Latex Paints

SIGNIFICANCE AND USE

5.1 Latex paints dry very quickly which often causes difficulty in final appearance of painted areas, especially paints formulated below 100g/L VOC where lower amounts of solvents are in the formulated latex paint. This method is a means of determining the time available before a test paint cannot be worked into a previously painted area.

SCOPE

1.1 This test method covers a procedure to determine the length of time a latex paint remains “wet” or “open” enough to allow for brush-in and repair.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7488 − 11 (Reapproved 2016)

Standard Test Method for

Open Time of Latex Paints

This standard is issued under the fixed designation D7488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope temperature / humidity room (23 6 2°C (73.5 6 3.5°F)) / 50

65 %relativehumidity.Testpaintsareappliedtothecenterof

1.1 This test method covers a procedure to determine the

a sealed chart with a 76 microns (3 mil) wet film thickness. X

length of time a latex paint remains “wet” or “open” enough to

marks are made immediately. The number of X marks will

allow for brush-in and repair.

dependonhowmanycanfitononedrawdown(seeFig.1).The

1.2 This standard does not purport to address all of the

test paint is then applied in perpendicular sections, brushing

safety concerns, if any, associated with its use. It is the

each section across the initial painted section. The perpendicu-

responsibility of the user of this standard to establish appro-

lar sections are repeated at agreed upon time intervals. After

priate safety and health practices and determine the applica-

drying,wetedgeisrecordedasthelasttimethetestpaintcould

bility of regulatory limitations prior to use.

be brushed into the initial painted section without the edges of

the first coat being visible. The time at which the X marks

2. Referenced Documents

become visible is also noted.

2.1 ASTM Standards:

D3924 Specification for Environment for Conditioning and

5. Significance and Use

Testing Paint, Varnish, Lacquer, and Related Materials

5.1 Latex paints dry very quickly which often causes

D5068 Practice for Preparation of Paint Brushes for Evalu-

difficulty in final appearance of painted areas, especially paints

ation

formulated below 100g/L VOC where lower amounts of

D5301 Practice for Physical Characterization of Paint

solvents are in the formulated latex paint. This method is a

Brushes

means of determining the time available before a test paint

E177 Practice for Use of the Terms Precision and Bias in

cannot be worked into a previously painted area.

ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to

6. Apparatus

Determine the Precision of a Test Method

6.1 Constant Temperature/Humidity Room (23 6 2°C (73.5

3. Terminology

6 3.5°F)) / 50 6 5 % relative humidity in accordance with

3.1 Definitions:

Specification D3924.

3.1.1 open time, n—the length of time a coating remains wet

6.2 Contrasting Sealed Chart (that is, black sealed chart for

or open enough to allow for brush-in without the edges of the

white paints or white sealed chart for tinted paints), typically

first coat becoming visible and allowing for repair within the

30 by 60 cm (1 by 2 ft.).

previously painted area.

6.3 Glass Plate, 30 by 60 cm (1 by 2 ft.) or vacuum plate.

4. Summary of Test Method

6.3.1 If using a glass plate, tape to secure sealed chart to

glass plate.

4.1 Since environmental conditions such as temperature,

humidity and air flow can result in variable results, it is

6.4 Good Quality Brush, 50 mm (2 in.) wide with straight

recommended that this test method be performed in a constant

edge, polyester bristles in accordance with Practice D5301.

6.5 Timer or Clock to record time intervals.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.6 Film Applicator, capable of applying a film with a width

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

of 7.5 cm (3 in.) and approximate wet film thickness of 75

Current edition approved April 1, 2016. Published April 2016. Originally

microns (3 mil).

approved in 2010. Last previous edition approved in 2011 as D7488 – 11. DOI:

10.1520/D7488-11R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Procedure

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Condition the brush in with the test paint accordance

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. with Practice D5068.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7488 − 11 (2016)

7.7 At agreed upon time intervals between each X mark,

start brushing the first X mark in perpendicular direction to the

initial drawdown using ten strokes back and forth (1 stroke =

1 back and forth motion) to work the brush-applied paint into

thedrawdownarea.Thelengthofthestrokesshouldbeslightly

less than the width of the chart and moving across and pass the

initial drawdown to determine the time elapsed when the edges

of the first coat become visible.

7.8 Repeat 7.6 and 7.7 by moving sequentially down the

chart to each X mark at the agreed upon time interval. (For

example, 2 minute intervals from 8 to 14 minutes.)

7.9 Dry the chart in a horizontal position overnight.

7.10 After drying overnight, observe each panel to deter-

mine the time elapsed when the edges of the first coat become

visible and the time elapsed when the X marks become visible.

8. Report

8.1 The time elapsed when the edges of the first coat

become visible.

8.2 The time elapsed when the X marks become visible.

8.3 Any deviations from this test metho

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7488 − 11 (Reapproved 2016)

Standard Test Method for

Open Time of Latex Paints

This standard is issued under the fixed designation D7488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope temperature / humidity room (23 6 2°C (73.5 6 3.5°F)) / 50

6 5 % relative humidity. Test paints are applied to the center of

1.1 This test method covers a procedure to determine the

a sealed chart with a 76 microns (3 mil) wet film thickness. X

length of time a latex paint remains “wet” or “open” enough to

marks are made immediately. The number of X marks will

allow for brush-in and repair.

depend on how many can fit on one drawdown (see Fig. 1). The

1.2 This standard does not purport to address all of the

test paint is then applied in perpendicular sections, brushing

safety concerns, if any, associated with its use. It is the

each section across the initial painted section. The perpendicu-

responsibility of the user of this standard to establish appro-

lar sections are repeated at agreed upon time intervals. After

priate safety and health practices and determine the applica-

drying, wet edge is recorded as the last time the test paint could

bility of regulatory limitations prior to use.

be brushed into the initial painted section without the edges of

the first coat being visible. The time at which the X marks

2. Referenced Documents

become visible is also noted.

2.1 ASTM Standards:

D3924 Specification for Environment for Conditioning and

5. Significance and Use

Testing Paint, Varnish, Lacquer, and Related Materials

5.1 Latex paints dry very quickly which often causes

D5068 Practice for Preparation of Paint Brushes for Evalu-

difficulty in final appearance of painted areas, especially paints

ation

formulated below 100g/L VOC where lower amounts of

D5301 Practice for Physical Characterization of Paint

solvents are in the formulated latex paint. This method is a

Brushes

means of determining the time available before a test paint

E177 Practice for Use of the Terms Precision and Bias in

cannot be worked into a previously painted area.

ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to

6. Apparatus

Determine the Precision of a Test Method

6.1 Constant Temperature/Humidity Room (23 6 2°C (73.5

3. Terminology

6 3.5°F)) / 50 6 5 % relative humidity in accordance with

3.1 Definitions:

Specification D3924.

3.1.1 open time, n—the length of time a coating remains wet

6.2 Contrasting Sealed Chart (that is, black sealed chart for

or open enough to allow for brush-in without the edges of the

white paints or white sealed chart for tinted paints), typically

first coat becoming visible and allowing for repair within the

30 by 60 cm (1 by 2 ft.).

previously painted area.

6.3 Glass Plate, 30 by 60 cm (1 by 2 ft.) or vacuum plate.

4. Summary of Test Method

6.3.1 If using a glass plate, tape to secure sealed chart to

glass plate.

4.1 Since environmental conditions such as temperature,

humidity and air flow can result in variable results, it is

6.4 Good Quality Brush, 50 mm (2 in.) wide with straight

recommended that this test method be performed in a constant

edge, polyester bristles in accordance with Practice D5301.

6.5 Timer or Clock to record time intervals.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.6 Film Applicator, capable of applying a film with a width

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings. of 7.5 cm (3 in.) and approximate wet film thickness of 75

Current edition approved April 1, 2016. Published April 2016. Originally

microns (3 mil).

approved in 2010. Last previous edition approved in 2011 as D7488 – 11. DOI:

10.1520/D7488-11R16.

7. Procedure

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Condition the brush in with the test paint accordance

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. with Practice D5068.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7488 − 11 (2016)

7.7 At agreed upon time intervals between each X mark,

start brushing the first X mark in perpendicular direction to the

initial drawdown using ten strokes back and forth (1 stroke =

1 back and forth motion) to work the brush-applied paint into

the drawdown area. The length of the strokes should be slightly

less than the width of the chart and moving across and pass the

initial drawdown to determine the time elapsed when the edges

of the first coat become visible.

7.8 Repeat 7.6 and 7.7 by moving sequentially down the

chart to each X mark at the agreed upon time interval. (For

example, 2 minute intervals from 8 to 14 minutes.)

7.9 Dry the chart in a horizontal position overnight.

7.10 After drying overnight, observe each panel to deter-

mine the time elapsed when the edges of the first coat become

visible and the time elapsed when the X marks become visible.

8. Report

8.1 The time elapsed when the edges of the first coat

become visible.

8.2 The time elapsed when the X marks become visible.

8.3 Any deviations from this test method.

9. Precision and Bias

9.1 The precision of this test method is based on an

interla

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7488 − 11 D7488 − 11 (Reapproved 2016)

Standard Test Method for

Open Time of Latex Paints

This standard is issued under the fixed designation D7488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure to determine the length of time a latex paint remains “wet” or “open” enough to allow

for brush-in and repair.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3924 Specification for Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials

D5068 Practice for Preparation of Paint Brushes for Evaluation

D5301 Practice for Physical Characterization of Paint Brushes

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 open time, n—the length of time a coating remains wet or open enough to allow for brush-in without the edges of the first

coat becoming visible and allowing for repair within the previously painted area.

4. Summary of Test Method

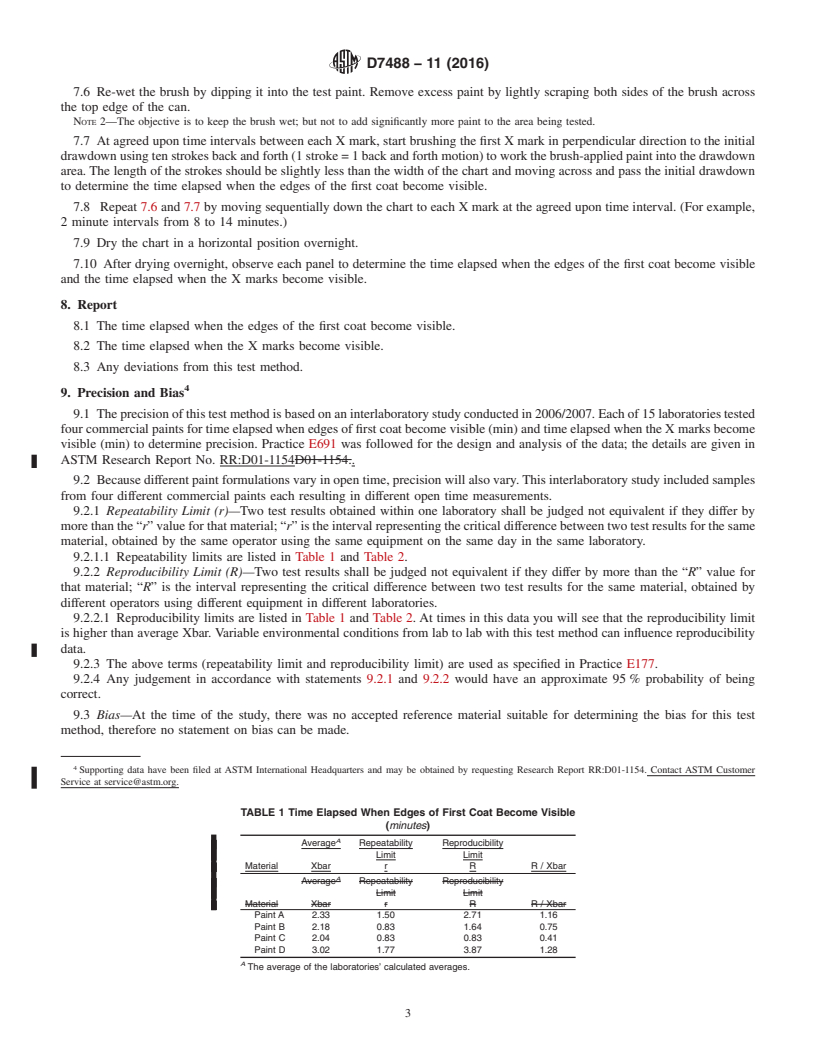

4.1 Since environmental conditions such as temperature, humidity and air flow can result in variable results, it is recommended

that this test method be performed in a constant temperature / humidity room (23 6 2°C (73.5 6 3.5°F)) / 50 6 5 % relative

humidity. Test paints are applied to the center of a sealed chart with a 76 microns (3 mil) wet film thickness. X marks are made

immediately. The number of X marks will depend on how many can fit on one drawdown (see Fig. 1). The test paint is then applied

in perpendicular sections, brushing each section across the initial painted section. The perpendicular sections are repeated at agreed

upon time intervals. After drying, wet edge is recorded as the last time the test paint could be brushed into the initial painted section

without the edges of the first coat being visible. The time at which the X marks become visible is also noted.

5. Significance and Use

5.1 Latex paints dry very quickly which often causes difficulty in final appearance of painted areas, especially paints formulated

below 100g/L VOC where lower amounts of solvents are in the formulated latex paint. This method is a means of determining the

time available before a test paint cannot be worked into a previously painted area.

6. Apparatus

6.1 Constant Temperature/Humidity Room (23 6 2°C (73.5 6 3.5°F)) / 50 6 5 % relative humidity in accordance with

Specification D3924.

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

Current edition approved July 1, 2011April 1, 2016. Published August 2011April 2016. Originally approved in 2010. Last previous edition approved in 20102011 as

D7488 - 10.D7488 – 11. DOI: 10.1520/D7488–11.10.1520/D7488-11R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7488 − 11 (2016)

FIG. 1 Illustration

6.2 Contrasting Sealed Chart (that is, black sealed chart for white paints or white sealed chart for tinted paints), typically 30

by 60 cm (1 by 2 ft.).

6.3 Glass Plate, 30 by 60 cm (1 by 2 ft.) or vacuum plate.

6.3.1 If using a glass plate, tape to secure sealed chart to glass plate.

6.4 Good Quality Brush, 50 mm (2 in.) wide with straight edge, polyester bristles in accordance with Practice D5301.

6.5 Timer or Clock to record time intervals.

6.6 Film Applicator, capable of applying a film with a width of 7.5 cm (3 in.) and approximate wet film thickness of 75 microns

(3 mil).

7. Procedure

7.1 Condition the brush in with the test paint accordance with Practice D5068.

7.2 Tape the edges of the chart to a smooth glass plate or use a vacuum plate.

7.3 Along the length of the panel, drawdown 76 microns (3 mil) wet film thickness of the test paint (see Fig. 1). The drawdown

must be free of ridges, craters, or other imperfections.

7.4 Start the timer or record the time.

1 1

7.5 Immediately make X marks approximately in 4 cm (1 ⁄2 in.) wide and 4 cm (1 ⁄2 in.) long in four to five different areas on

the drawdown, as shown in Fig. 1.

NOTE 1—The wide curved end of a wooden tongue blade/paint brush or the end of a tongue depressor/metal spatula has been found suitable for this

purpose. Depending on the type of instrument used to make the X mark, ensure that the X marks are consistent in size down the chart and throughout

your testing.

It is suggested that you wrap the brush in a disposable plastic wrap between timed intervals to prevent the paint from drying on the brush.

D7488 − 11 (2016)

7.6 Re-wet the brush by dipping it into the test paint. Remove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.