ASTM D5101-12(2017)

(Test Method)Standard Test Method for Measuring the Filtration Compatibility of Soil-Geotextile Systems

Standard Test Method for Measuring the Filtration Compatibility of Soil-Geotextile Systems

SIGNIFICANCE AND USE

5.1 This test method is recommended for the evaluation of the performance of water-saturated soil-geotextile systems under unidirectional flow conditions. The results obtained may be used as an indication of the compatibility of the soil-geotextile system with respect to both particle retention and flow capacity.

5.2 This test method is intended to evaluate the performance of specific on-site soils and geotextiles at the design stage of a project, or to provide qualitative data that may help identify causes of failure (for example, clogging, particle loss). It is not appropriate for acceptance testing of geotextiles. It is also improper to utilize the results from this test for job specifications or manufacturers' certifications.

5.3 This test method is intended for site-specific investigation therefore is not an index property of the geotextile, and thus is not intended to be requested of the manufacturer or supplier of the geotextile.

SCOPE

1.1 This test method covers performance tests applicable for determining the compatibility of geotextiles with various types of water-saturated soils under unidirectional flow conditions.

1.2 Two evaluation methods may be used to investigate soil-geotextile filtration behavior, depending on the soil type:

1.2.1 For soils with a plasticity index lower than 5, the systems compatibility shall be evaluated per this standard.

1.2.2 For soils with a plasticity index of 5 or more, it is recommended to use Test Method D5567 (‘HCR,’ Hydraulic Conductivity Ratio) instead of this test method.

1.2.3 If the plasticity index of the soil is close to 5, the involved parties shall agree on the selection of the appropriate method prior to conducting the test. This task may require comparison of the permeability of the soil-geotextile system to the detection limits of the HCR and Gradient Ratio Test (GRT) test apparatus being used.

1.3 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5101 − 12 (Reapproved 2017)

Standard Test Method for

Measuring the Filtration Compatibility of Soil-Geotextile

Systems

This standard is issued under the fixed designation D5101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D653 Terminology Relating to Soil, Rock, and Contained

Fluids

1.1 Thistestmethodcoversperformancetestsapplicablefor

D698 Test Methods for Laboratory Compaction Character-

determining the compatibility of geotextiles with various types

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

of water-saturated soils under unidirectional flow conditions.

kN-m/m ))

1.2 Two evaluation methods may be used to investigate

D737 Test Method for Air Permeability of Textile Fabrics

soil-geotextile filtration behavior, depending on the soil type:

D854 Test Methods for Specific Gravity of Soil Solids by

1.2.1 For soils with a plasticity index lower than 5, the

Water Pycnometer

systems compatibility shall be evaluated per this standard.

D1587 Practice for Thin-Walled Tube Sampling of Fine-

1.2.2 For soils with a plasticity index of 5 or more, it is

Grained Soils for Geotechnical Purposes

recommended to use Test Method D5567 (‘HCR,’ Hydraulic

D2216 Test Methods for Laboratory Determination of Water

Conductivity Ratio) instead of this test method.

(Moisture) Content of Soil and Rock by Mass

1.2.3 If the plasticity index of the soil is close to 5, the

D2487 Practice for Classification of Soils for Engineering

involved parties shall agree on the selection of the appropriate

Purposes (Unified Soil Classification System)

method prior to conducting the test. This task may require

D2488 Practice for Description and Identification of Soils

comparison of the permeability of the soil-geotextile system to

(Visual-Manual Procedure)

the detection limits of the HCR and Gradient Ratio Test (GRT)

D4220 Practices for Preserving and Transporting Soil

test apparatus being used.

Samples

1.3 The values stated in SI units are to be regarded as

D4318 Test Methods for Liquid Limit, Plastic Limit, and

standard. The values in parentheses are for information only.

Plasticity Index of Soils

D4354 Practice for Sampling of Geosynthetics and Rolled

1.4 This standard does not purport to address all of the

Erosion Control Products (RECPs) for Testing

safety concerns, if any, associated with its use. It is the

D4439 Terminology for Geosynthetics

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- D4491 Test Methods for Water Permeability of Geotextiles

by Permittivity

bility of regulatory limitations prior to use.

D4647 Test Method for Identification and Classification of

2. Referenced Documents

Dispersive Clay Soils by the Pinhole Test

D4751 Test Methods for Determining Apparent Opening

2.1 ASTM Standards:

Size of a Geotextile

D123 Terminology Relating to Textiles

D5084 Test Methods for Measurement of Hydraulic Con-

D422 Test Method for Particle-SizeAnalysis of Soils (With-

ductivity of Saturated Porous Materials Using a Flexible

drawn 2016)

Wall Permeameter

D5101 Test Method for Measuring the Filtration Compat-

This test method is under the jurisdiction of ASTM Committee D35 on ibility of Soil-Geotextile Systems

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

D5567 Test Method for Hydraulic Conductivity Ratio

ability and Filtration.

(HCR) Testing of Soil/Geotextile Systems

Current edition approved Feb. 15, 2017. Published February 2017. Originally

approved in 1990. Last previous edition approved in 2012 as D5101 – 12. DOI:

10.1520/D5101-12R17.

3. Terminology

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1 Definitions:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.1.1 clogging, n—in geotextiles, the tendency for a given

the ASTM website.

geotextile to lose permeability due to soil particles that have

The last approved version of this historical standard is referenced on

www.astm.org. eitherbecomeembeddedinthefabricopeningsorhavebuiltup

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5101 − 12 (2017)

on the geotextile surface to form a layer with lower permeabil-

ity than that of the bulk soil specimen.

3.1.2 piping, n—the tendency of the geotextile to let a

quantity of soil pass through its plane that may potentially lead

to stability concerns in the soil or internal clogging of the

geotextile.

3.1.3 gradient ratio, n—in geotextiles, ratio of the hydraulic

gradient across a soil-geotextile interface to the hydraulic

gradient through the soil alone.

3.1.4 hydraulic gradient, i, s (D)—thelossofhydraulichead

per unit distance of flow, dH/dL.

3.1.5 For definitions of other textile terms, refer to Termi-

nology D123. For definitions of other terms related to

geotextiles, refer to Terminology D4439 and Terminology

D653.

3.2 Symbols and Acronyms:

3.2.1 CHD—the acronym for constant head device

3.2.2 GRT—the acronym for gradient ratio test

3.2.3 HCR—the acronym for hydraulic conductivity ratio

4. Summary of Test Method

4.1 This method is intended for use in the observation of

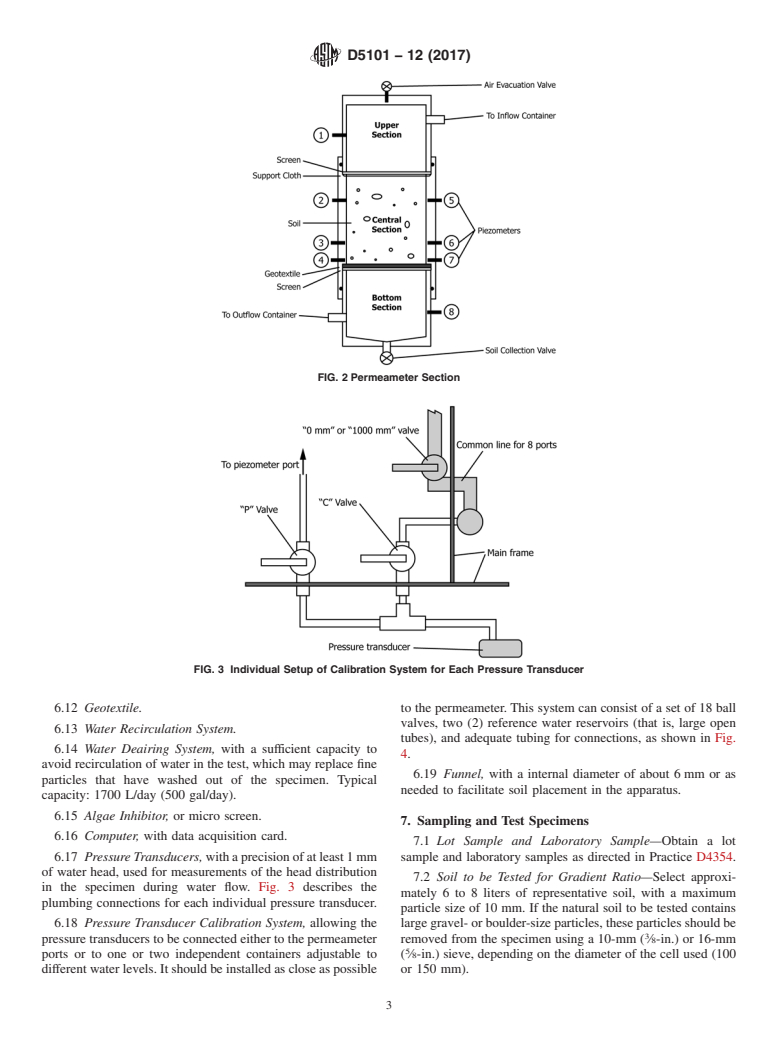

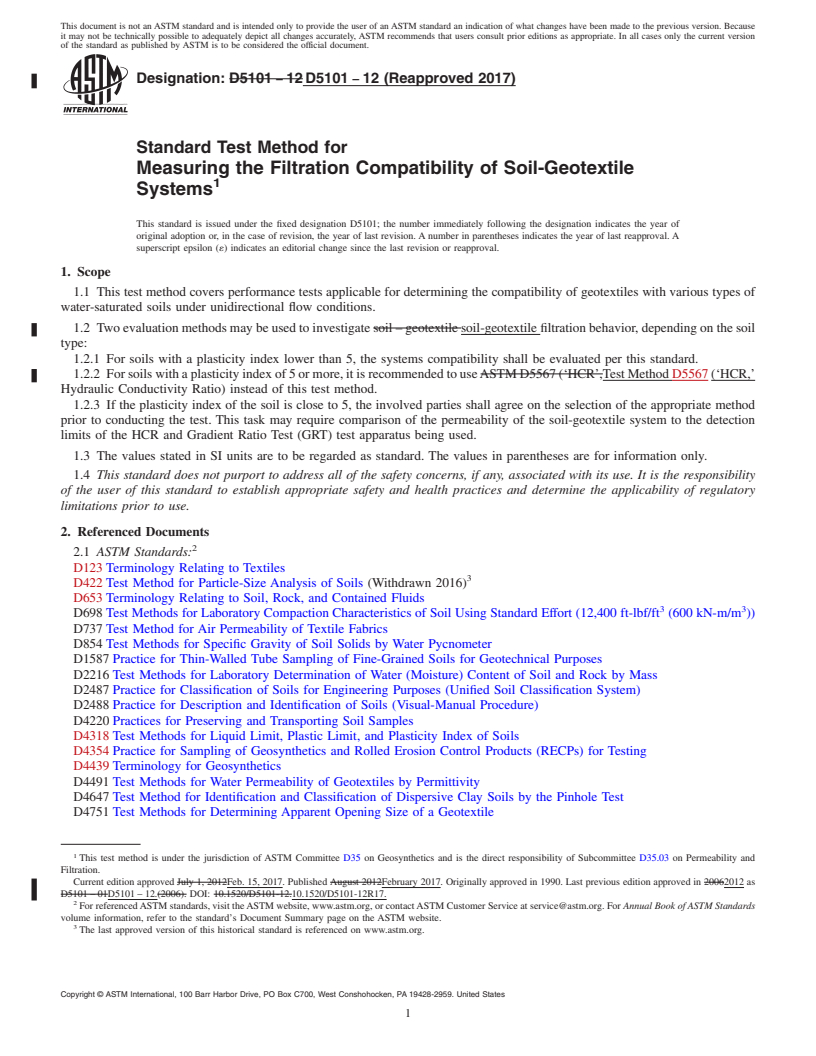

change in the permeability of a soil-geotextile interface over FIG. 1 Gradient Ratio Test Setup

timeunderarangeofappliedhydraulicgradients.Attheendof

the test, the weight of soil passing through the geotextile is

caulk) along the interface between the geotextile and the

measured. The distribution of hydraulic gradients in the vicin-

permeameter walls. The geotextile support screen opening size

ity of the soil-geotextile interface is also observed.

shall be greater than ten times the measured AOS of the

geotextile. The upper unit will permit application of a constant

5. Significance and Use

head boundary condition to the top of the specimen. The

5.1 This test method is recommended for the evaluation of

permeameter should also be equipped with a support stand,

the performance of water-saturated soil-geotextile systems

clamping brackets, and plastic tubing to connect with an

under unidirectional flow conditions. The results obtained may

external pressure head monitoring system.

be used as an indication of the compatibility of the soil-

NOTE 1—the diameter of the permeameter shall be at least 10 x d100,

geotextile system with respect to both particle retention and

where d100 is the largest particle of soil placed in the permeameter. In the

flow capacity. 5

case soils with particles larger than 16 mm (mesh # ⁄8 in.) were to be

evaluated, only the fraction smaller than 16 mm shall be used for testing.

5.2 Thistestmethodisintendedtoevaluatetheperformance

NOTE 2—Some permeameters allow application of a normal load on the

of specific on-site soils and geotextiles at the design stage of a

soil-geotextile interface. If so, the loading system shall be designed in

project, or to provide qualitative data that may help identify

such a way that it will not influence the system’s hydraulic behavior.

causes of failure (for example, clogging, particle loss). It is not

6.2 Two Constant Water Head Devices, one mounted on a

appropriate for acceptance testing of geotextiles. It is also

jack stand (adjustable) and one stationary (Fig. 3).

improper to utilize the results from this test for job specifica-

6.3 Soil Leveling Device (Fig. 4).

tions or manufacturers’ certifications.

6.4 Manometer Board,ofparallelglasstubesandmeasuring

5.3 This test method is intended for site-specific investiga-

rulers.

tion therefore is not an index property of the geotextile, and

thus is not intended to be requested of the manufacturer or

6.5 Two Soil Support Screens, of approximately 5 mm

supplier of the geotextile.

(No. 4) mesh.

6.6 Soil Support Cloth, of 150 µm (No. 100) mesh, or

6. Apparatus and Supplies

equivalent geotextile.

6.1 Soil-Geotextile Permeameter—A typical permeameter

6.7 Thermometer (0 to 50 6 1 °C).

will consist of three units, shown in Fig. 1, set-up on a frame

6.8 Graduated Cylinder, 100 6 1-cm capacity.

incorporating the other components such as the structure

shown in Fig. 2. The lower unit will contain a soil-geotextile

6.9 Stopwatch.

support screen and an outflow reservoir that permits collection

6.10 Balance, or scale of at least 2-kg capacity and accurate

of the particles passing through the geotextile during different

to 61g.

stages of the test. The middle unit will hold the soil specimen

and should be equipped with a piping barrier (for example, 6.11 Carbon Dioxide, (CO ), gas supply and regulator.

D5101 − 12 (2017)

FIG. 2 Permeameter Section

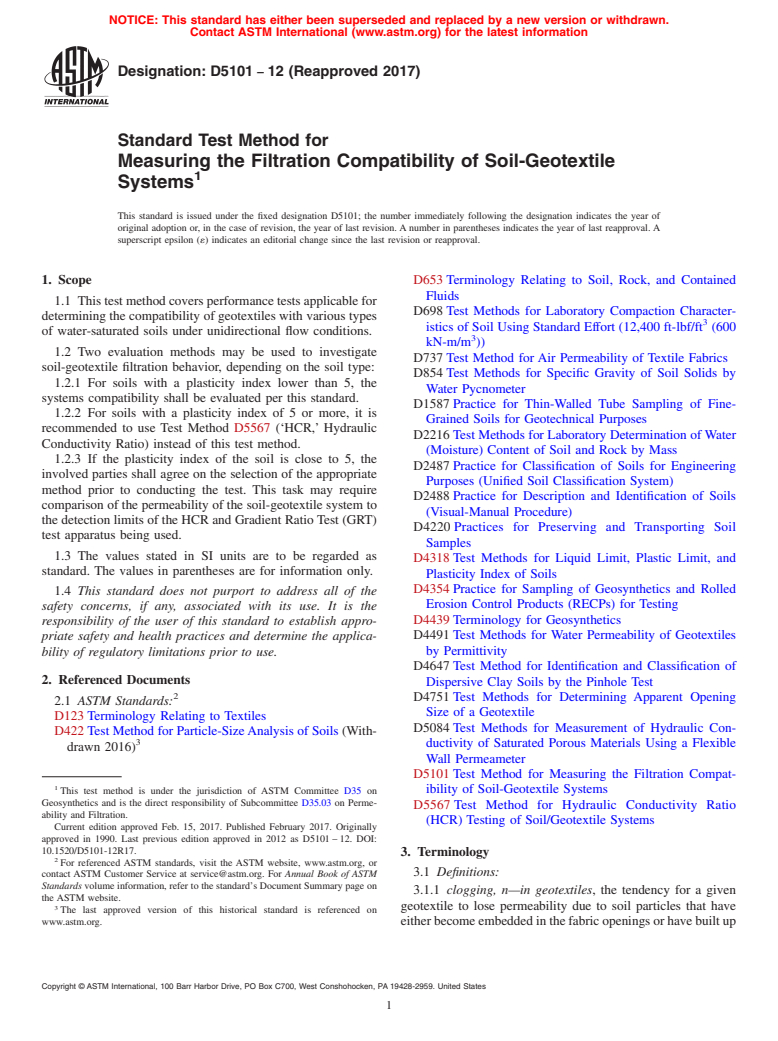

FIG. 3 Individual Setup of Calibration System for Each Pressure Transducer

6.12 Geotextile. to the permeameter. This system can consist of a set of 18 ball

valves, two (2) reference water reservoirs (that is, large open

6.13 Water Recirculation System.

tubes), and adequate tubing for connections, as shown in Fig.

6.14 Water Deairing System, with a sufficient capacity to

4.

avoid recirculation of water in the test, which may replace fine

6.19 Funnel, with a internal diameter of about 6 mm or as

particles that have washed out of the specimen. Typical

needed to facilitate soil placement in the apparatus.

capacity: 1700 L/day (500 gal/day).

6.15 Algae Inhibitor, or micro screen.

7. Sampling and Test Specimens

6.16 Computer, with data acquisition card.

7.1 Lot Sample and Laboratory Sample—Obtain a lot

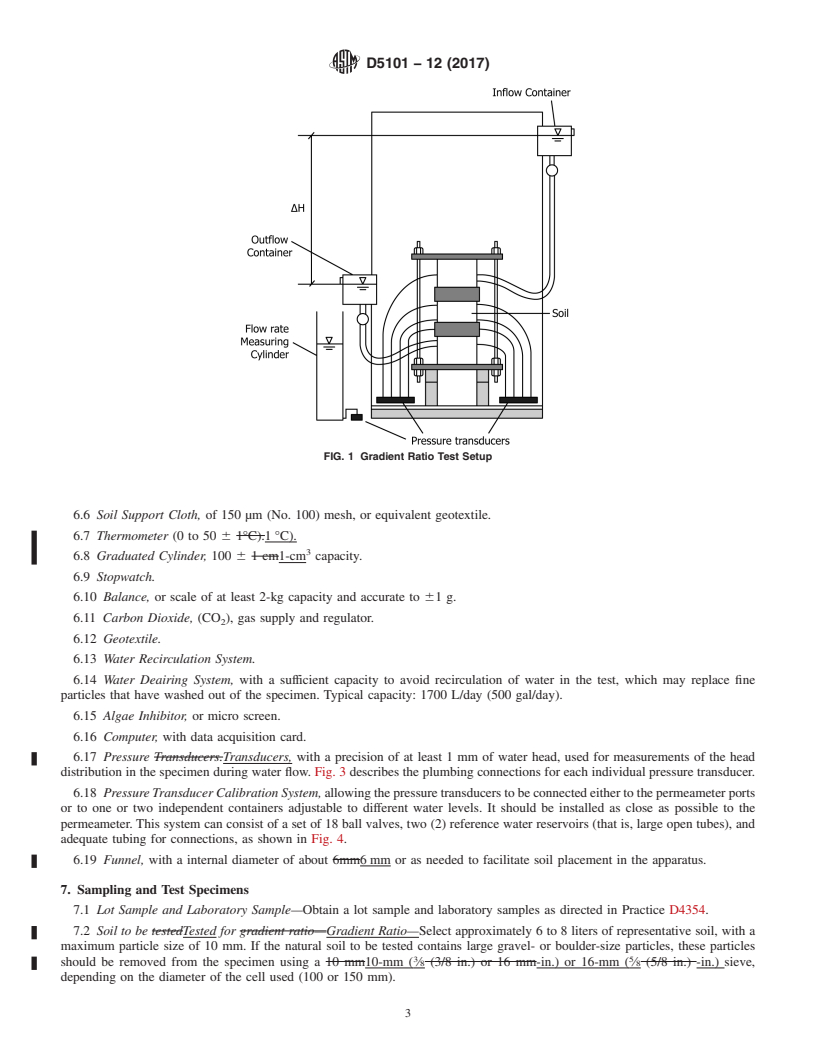

6.17 PressureTransducers,withaprecisionofatleast1mm sample and laboratory samples as directed in Practice D4354.

of water head, used for measurements of the head distribution

7.2 Soil to be Tested for Gradient Ratio—Select approxi-

in the specimen during water flow. Fig. 3 describes the

mately 6 to 8 liters of representative soil, with a maximum

plumbing connections for each individual pressure transducer.

particle size of 10 mm. If the natural soil to be tested contains

6.18 Pressure Transducer Calibration System, allowing the large gravel- or boulder-size particles, these particles should be

pressure transducers to be connected either to the permeameter removed from the specimen using a 10-mm ( ⁄8-in.) or 16-mm

ports or to one or two independent containers adjustable to ( ⁄8-in.) sieve, depending on the diameter of the cell used (100

different water levels. It should be installed as close as possible or 150 mm).

D5101 − 12 (2017)

FIG. 4 General Setup of Calibration Board

8. Conditioning permeability, additional investigations shall be considered to

determine whether GRT or HCR shall be used.

8.1 Test Water Preparation:

9.1.1.3 The soil installation technique is determined as

8.1.1 Test water should be maintained between 16 and

follows:

27 °C (60 to 80 °F) and deaired to a dissolved oxygen content

–3

(1) For silty soils, with permeabilities less than 10 cm/s,

of 2 ppm before being introduced into the apparatus. In

use of the ‘slurry’ deposition technique is preferred as dis-

addition, the deaired water shall be stored at a temperature

cussed in 9.4.3.

within 6 2 °C of the tested soil-geotextile system.

(2) For sandy soils, with permeabilities greater than

–3

NOTE 3—Use of deaired water is essential to reduce or eliminate

10 cm⁄s, use of the ‘water pluviation’ technique is preferred

problems associated with air bubbles forming within the test apparatus or

as discussed in 9.4.2.

in the soil.The dissolved air content will be lower, and chances to observe

(3) For well-graded soils or unstable soils that easily

air clogging will be decreased

segregate, the dry method presented in 9.4.4 is preferred.

8.1.2 An algae inhibitor or micro screen should be used to

9.1.2 Preparation of the Apparatus:

eliminate any algae buildup in the system.

9.1.2.1 Thoroughly clean and dry all permeameter sections.

9.1.2.2 Close all valves and cover the inside openings of all

9. Procedure

manometer ports with fine wire mesh or lightweight nonwoven

9.1 Preparation of the Test:

fabric (having an equivalent percent open area to that of a No.

9.1.1 Determination of the Soil’s Properties:

100 mesh sieve).

9.1.1.1 Measure the following properties of the soil under

9.1.2.3 Lubricate all O-ring gaskets.

investigation:

9.2 Permeameter Preassembly:

(1) Particle size distribution per Test Method D422.

9.2.1 Stand center section of the permeameter on its bottom

(2) Plasticity index per Test Method D4318, when appli-

end and place the geotextile specimen on the recessed per-

cable.

meameter flanges.

9.1.1.2 For silty soils with plasticity indices in the vicinity

9.2.2 Insert the support screen on top of the geotextile with

of 5, estimate the permeability of the soil (that is, using the

particle size distribution determined in 9.1.1.1) and compare the mesh side down.

this value to the detection limit of the apparatus. If the 9.2.3 Align and insert the bottom section of the permeame-

detection limit of the apparatus is close to the soil’s ter onto the center section and press until there is a tight fit that

D5101 − 12 (2017)

secures the geotextile and support screen in place. Ensure that

all gasket edges are secure against the geotextile, support

bracket, and the interface between the center and top per-

meameter sections.

9.2.4 Place permeameter into holding stand.

9.3 Process Soil—The test is to be performed on a soil

specimen having particle sizes which are <10 mm (< ⁄8 in.) in

size. The material passing the 10 mm ( ⁄8 in.) and retained on

the No. 10 sieve is subject to a second round of grinding.

However, this second grinding shall be done gently to ensure

that agglomerates of particles will be maintained, as they

reflect the field condition.

Select a representative sample of the amount required,

approximately 1500 g, to perform the test by the method of

quartering or by the use of a soil splitter.

9.4 Soil Placement—Soil placement shall be conducted

keeping in mind that the following goals have to be achieved:

(1) Uniformity of the soil from the top to the bottom of the

test specimen at the beginning of the test. Particular attention

shall be given to the soil located at the interface.

(2) Saturation of the system at the beginning of the test.

9.4.1 The placement proc

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5101 − 12 (Reapproved 2017)

Standard Test Method for

Measuring the Filtration Compatibility of Soil-Geotextile

Systems

This standard is issued under the fixed designation D5101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D653 Terminology Relating to Soil, Rock, and Contained

Fluids

1.1 This test method covers performance tests applicable for

D698 Test Methods for Laboratory Compaction Character-

determining the compatibility of geotextiles with various types

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

of water-saturated soils under unidirectional flow conditions.

kN-m/m ))

1.2 Two evaluation methods may be used to investigate

D737 Test Method for Air Permeability of Textile Fabrics

soil-geotextile filtration behavior, depending on the soil type:

D854 Test Methods for Specific Gravity of Soil Solids by

1.2.1 For soils with a plasticity index lower than 5, the

Water Pycnometer

systems compatibility shall be evaluated per this standard.

D1587 Practice for Thin-Walled Tube Sampling of Fine-

1.2.2 For soils with a plasticity index of 5 or more, it is

Grained Soils for Geotechnical Purposes

recommended to use Test Method D5567 (‘HCR,’ Hydraulic

D2216 Test Methods for Laboratory Determination of Water

Conductivity Ratio) instead of this test method.

(Moisture) Content of Soil and Rock by Mass

1.2.3 If the plasticity index of the soil is close to 5, the

D2487 Practice for Classification of Soils for Engineering

involved parties shall agree on the selection of the appropriate

Purposes (Unified Soil Classification System)

method prior to conducting the test. This task may require

D2488 Practice for Description and Identification of Soils

comparison of the permeability of the soil-geotextile system to

(Visual-Manual Procedure)

the detection limits of the HCR and Gradient Ratio Test (GRT)

D4220 Practices for Preserving and Transporting Soil

test apparatus being used.

Samples

1.3 The values stated in SI units are to be regarded as

D4318 Test Methods for Liquid Limit, Plastic Limit, and

standard. The values in parentheses are for information only.

Plasticity Index of Soils

D4354 Practice for Sampling of Geosynthetics and Rolled

1.4 This standard does not purport to address all of the

Erosion Control Products (RECPs) for Testing

safety concerns, if any, associated with its use. It is the

D4439 Terminology for Geosynthetics

responsibility of the user of this standard to establish appro-

D4491 Test Methods for Water Permeability of Geotextiles

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. by Permittivity

D4647 Test Method for Identification and Classification of

2. Referenced Documents

Dispersive Clay Soils by the Pinhole Test

D4751 Test Methods for Determining Apparent Opening

2.1 ASTM Standards:

Size of a Geotextile

D123 Terminology Relating to Textiles

D5084 Test Methods for Measurement of Hydraulic Con-

D422 Test Method for Particle-Size Analysis of Soils (With-

ductivity of Saturated Porous Materials Using a Flexible

drawn 2016)

Wall Permeameter

D5101 Test Method for Measuring the Filtration Compat-

This test method is under the jurisdiction of ASTM Committee D35 on ibility of Soil-Geotextile Systems

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

D5567 Test Method for Hydraulic Conductivity Ratio

ability and Filtration.

(HCR) Testing of Soil/Geotextile Systems

Current edition approved Feb. 15, 2017. Published February 2017. Originally

approved in 1990. Last previous edition approved in 2012 as D5101 – 12. DOI:

10.1520/D5101-12R17.

3. Terminology

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1 Definitions:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.1.1 clogging, n—in geotextiles, the tendency for a given

the ASTM website.

3 geotextile to lose permeability due to soil particles that have

The last approved version of this historical standard is referenced on

www.astm.org. either become embedded in the fabric openings or have built up

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5101 − 12 (2017)

on the geotextile surface to form a layer with lower permeabil-

ity than that of the bulk soil specimen.

3.1.2 piping, n—the tendency of the geotextile to let a

quantity of soil pass through its plane that may potentially lead

to stability concerns in the soil or internal clogging of the

geotextile.

3.1.3 gradient ratio, n—in geotextiles, ratio of the hydraulic

gradient across a soil-geotextile interface to the hydraulic

gradient through the soil alone.

3.1.4 hydraulic gradient, i, s (D)—the loss of hydraulic head

per unit distance of flow, dH/dL.

3.1.5 For definitions of other textile terms, refer to Termi-

nology D123. For definitions of other terms related to

geotextiles, refer to Terminology D4439 and Terminology

D653.

3.2 Symbols and Acronyms:

3.2.1 CHD—the acronym for constant head device

3.2.2 GRT—the acronym for gradient ratio test

3.2.3 HCR—the acronym for hydraulic conductivity ratio

4. Summary of Test Method

4.1 This method is intended for use in the observation of

change in the permeability of a soil-geotextile interface over FIG. 1 Gradient Ratio Test Setup

time under a range of applied hydraulic gradients. At the end of

the test, the weight of soil passing through the geotextile is

caulk) along the interface between the geotextile and the

measured. The distribution of hydraulic gradients in the vicin-

permeameter walls. The geotextile support screen opening size

ity of the soil-geotextile interface is also observed.

shall be greater than ten times the measured AOS of the

geotextile. The upper unit will permit application of a constant

5. Significance and Use

head boundary condition to the top of the specimen. The

5.1 This test method is recommended for the evaluation of

permeameter should also be equipped with a support stand,

the performance of water-saturated soil-geotextile systems

clamping brackets, and plastic tubing to connect with an

under unidirectional flow conditions. The results obtained may

external pressure head monitoring system.

be used as an indication of the compatibility of the soil-

NOTE 1—the diameter of the permeameter shall be at least 10 x d100,

geotextile system with respect to both particle retention and

where d100 is the largest particle of soil placed in the permeameter. In the

flow capacity.

case soils with particles larger than 16 mm (mesh # ⁄8 in.) were to be

evaluated, only the fraction smaller than 16 mm shall be used for testing.

5.2 This test method is intended to evaluate the performance

NOTE 2—Some permeameters allow application of a normal load on the

of specific on-site soils and geotextiles at the design stage of a

soil-geotextile interface. If so, the loading system shall be designed in

project, or to provide qualitative data that may help identify

such a way that it will not influence the system’s hydraulic behavior.

causes of failure (for example, clogging, particle loss). It is not

6.2 Two Constant Water Head Devices, one mounted on a

appropriate for acceptance testing of geotextiles. It is also

jack stand (adjustable) and one stationary (Fig. 3).

improper to utilize the results from this test for job specifica-

6.3 Soil Leveling Device (Fig. 4).

tions or manufacturers’ certifications.

6.4 Manometer Board, of parallel glass tubes and measuring

5.3 This test method is intended for site-specific investiga-

rulers.

tion therefore is not an index property of the geotextile, and

thus is not intended to be requested of the manufacturer or

6.5 Two Soil Support Screens, of approximately 5 mm

supplier of the geotextile.

(No. 4) mesh.

6.6 Soil Support Cloth, of 150 µm (No. 100) mesh, or

6. Apparatus and Supplies

equivalent geotextile.

6.1 Soil-Geotextile Permeameter—A typical permeameter

6.7 Thermometer (0 to 50 6 1 °C).

will consist of three units, shown in Fig. 1, set-up on a frame

incorporating the other components such as the structure 6.8 Graduated Cylinder, 100 6 1-cm capacity.

shown in Fig. 2. The lower unit will contain a soil-geotextile

6.9 Stopwatch.

support screen and an outflow reservoir that permits collection

6.10 Balance, or scale of at least 2-kg capacity and accurate

of the particles passing through the geotextile during different

to 61 g.

stages of the test. The middle unit will hold the soil specimen

and should be equipped with a piping barrier (for example, 6.11 Carbon Dioxide, (CO ), gas supply and regulator.

D5101 − 12 (2017)

FIG. 2 Permeameter Section

FIG. 3 Individual Setup of Calibration System for Each Pressure Transducer

6.12 Geotextile. to the permeameter. This system can consist of a set of 18 ball

valves, two (2) reference water reservoirs (that is, large open

6.13 Water Recirculation System.

tubes), and adequate tubing for connections, as shown in Fig.

6.14 Water Deairing System, with a sufficient capacity to

4.

avoid recirculation of water in the test, which may replace fine

6.19 Funnel, with a internal diameter of about 6 mm or as

particles that have washed out of the specimen. Typical

needed to facilitate soil placement in the apparatus.

capacity: 1700 L/day (500 gal/day).

6.15 Algae Inhibitor, or micro screen.

7. Sampling and Test Specimens

6.16 Computer, with data acquisition card.

7.1 Lot Sample and Laboratory Sample—Obtain a lot

6.17 Pressure Transducers, with a precision of at least 1 mm sample and laboratory samples as directed in Practice D4354.

of water head, used for measurements of the head distribution

7.2 Soil to be Tested for Gradient Ratio—Select approxi-

in the specimen during water flow. Fig. 3 describes the

mately 6 to 8 liters of representative soil, with a maximum

plumbing connections for each individual pressure transducer.

particle size of 10 mm. If the natural soil to be tested contains

6.18 Pressure Transducer Calibration System, allowing the large gravel- or boulder-size particles, these particles should be

pressure transducers to be connected either to the permeameter removed from the specimen using a 10-mm ( ⁄8-in.) or 16-mm

ports or to one or two independent containers adjustable to ( ⁄8-in.) sieve, depending on the diameter of the cell used (100

different water levels. It should be installed as close as possible or 150 mm).

D5101 − 12 (2017)

FIG. 4 General Setup of Calibration Board

8. Conditioning permeability, additional investigations shall be considered to

determine whether GRT or HCR shall be used.

8.1 Test Water Preparation:

9.1.1.3 The soil installation technique is determined as

8.1.1 Test water should be maintained between 16 and

follows:

27 °C (60 to 80 °F) and deaired to a dissolved oxygen content

–3

(1) For silty soils, with permeabilities less than 10 cm/s,

of 2 ppm before being introduced into the apparatus. In

use of the ‘slurry’ deposition technique is preferred as dis-

addition, the deaired water shall be stored at a temperature

cussed in 9.4.3.

within 6 2 °C of the tested soil-geotextile system.

(2) For sandy soils, with permeabilities greater than

–3

NOTE 3—Use of deaired water is essential to reduce or eliminate

10 cm ⁄s, use of the ‘water pluviation’ technique is preferred

problems associated with air bubbles forming within the test apparatus or

as discussed in 9.4.2.

in the soil. The dissolved air content will be lower, and chances to observe

(3) For well-graded soils or unstable soils that easily

air clogging will be decreased

segregate, the dry method presented in 9.4.4 is preferred.

8.1.2 An algae inhibitor or micro screen should be used to

9.1.2 Preparation of the Apparatus:

eliminate any algae buildup in the system.

9.1.2.1 Thoroughly clean and dry all permeameter sections.

9.1.2.2 Close all valves and cover the inside openings of all

9. Procedure

manometer ports with fine wire mesh or lightweight nonwoven

9.1 Preparation of the Test:

fabric (having an equivalent percent open area to that of a No.

9.1.1 Determination of the Soil’s Properties:

100 mesh sieve).

9.1.1.1 Measure the following properties of the soil under

9.1.2.3 Lubricate all O-ring gaskets.

investigation:

9.2 Permeameter Preassembly:

(1) Particle size distribution per Test Method D422.

9.2.1 Stand center section of the permeameter on its bottom

(2) Plasticity index per Test Method D4318, when appli-

end and place the geotextile specimen on the recessed per-

cable.

meameter flanges.

9.1.1.2 For silty soils with plasticity indices in the vicinity

of 5, estimate the permeability of the soil (that is, using the 9.2.2 Insert the support screen on top of the geotextile with

the mesh side down.

particle size distribution determined in 9.1.1.1) and compare

this value to the detection limit of the apparatus. If the 9.2.3 Align and insert the bottom section of the permeame-

detection limit of the apparatus is close to the soil’s ter onto the center section and press until there is a tight fit that

D5101 − 12 (2017)

secures the geotextile and support screen in place. Ensure that

all gasket edges are secure against the geotextile, support

bracket, and the interface between the center and top per-

meameter sections.

9.2.4 Place permeameter into holding stand.

9.3 Process Soil—The test is to be performed on a soil

specimen having particle sizes which are <10 mm (< ⁄8 in.) in

size. The material passing the 10 mm ( ⁄8 in.) and retained on

the No. 10 sieve is subject to a second round of grinding.

However, this second grinding shall be done gently to ensure

that agglomerates of particles will be maintained, as they

reflect the field condition.

Select a representative sample of the amount required,

approximately 1500 g, to perform the test by the method of

quartering or by the use of a soil splitter.

9.4 Soil Placement—Soil placement shall be conducted

keeping in mind that the following goals have to be achieved:

(1) Uniformity of the soil from the top to the bottom of the

test specimen at the beginning of the test. Particular attention

shall be given to the soil located at the interface.

(2) Saturation of the system at the beginning of the test.

9.4.1 The placement procedure is a critical aspect of the test

and may significantly influen

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5101 − 12 D5101 − 12 (Reapproved 2017)

Standard Test Method for

Measuring the Filtration Compatibility of Soil-Geotextile

Systems

This standard is issued under the fixed designation D5101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers performance tests applicable for determining the compatibility of geotextiles with various types of

water-saturated soils under unidirectional flow conditions.

1.2 Two evaluation methods may be used to investigate soil – geotextile soil-geotextile filtration behavior, depending on the soil

type:

1.2.1 For soils with a plasticity index lower than 5, the systems compatibility shall be evaluated per this standard.

1.2.2 For soils with a plasticity index of 5 or more, it is recommended to use ASTM D5567 (‘HCR’,Test Method D5567 (‘HCR,’

Hydraulic Conductivity Ratio) instead of this test method.

1.2.3 If the plasticity index of the soil is close to 5, the involved parties shall agree on the selection of the appropriate method

prior to conducting the test. This task may require comparison of the permeability of the soil-geotextile system to the detection

limits of the HCR and Gradient Ratio Test (GRT) test apparatus being used.

1.3 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D422 Test Method for Particle-Size Analysis of Soils (Withdrawn 2016)

D653 Terminology Relating to Soil, Rock, and Contained Fluids

3 3

D698 Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft (600 kN-m/m ))

D737 Test Method for Air Permeability of Textile Fabrics

D854 Test Methods for Specific Gravity of Soil Solids by Water Pycnometer

D1587 Practice for Thin-Walled Tube Sampling of Fine-Grained Soils for Geotechnical Purposes

D2216 Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass

D2487 Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)

D2488 Practice for Description and Identification of Soils (Visual-Manual Procedure)

D4220 Practices for Preserving and Transporting Soil Samples

D4318 Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils

D4354 Practice for Sampling of Geosynthetics and Rolled Erosion Control Products (RECPs) for Testing

D4439 Terminology for Geosynthetics

D4491 Test Methods for Water Permeability of Geotextiles by Permittivity

D4647 Test Method for Identification and Classification of Dispersive Clay Soils by the Pinhole Test

D4751 Test Methods for Determining Apparent Opening Size of a Geotextile

This test method is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Permeability and

Filtration.

Current edition approved July 1, 2012Feb. 15, 2017. Published August 2012February 2017. Originally approved in 1990. Last previous edition approved in 20062012 as

D5101 – 01D5101 – 12.(2006). DOI: 10.1520/D5101-12.10.1520/D5101-12R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5101 − 12 (2017)

D5084 Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall

Permeameter

D5101 Test Method for Measuring the Filtration Compatibility of Soil-Geotextile Systems

D5567 Test Method for Hydraulic Conductivity Ratio (HCR) Testing of Soil/Geotextile Systems

3. Terminology

3.1 Definitions:

3.1.1 clogging, n—in geotextiles, the tendency for a given geotextile to lose permeability due to soil particles that have either

become embedded in the fabric openings or have built up on the geotextile surface to form a layer with lower permeability than

that of the bulk soil specimen.

3.1.2 piping, n—the tendency of the geotextile to let a quantity of soil pass through its plane that may potentially lead to stability

concerns in the soil or internal clogging of the geotextile.

3.1.3 gradient ratio, n—in geotextiles, ratio of the hydraulic gradient across a soil-geotextile interface to the hydraulic gradient

through the soil alone.

3.1.4 hydraulic gradient, i, s (D)—the loss of hydraulic head per unit distance of flow, dH/dL.

3.1.5 For definitions of other textile terms, refer to Terminology D123. For definitions of other terms related to geotextiles, refer

to Terminology D4439 and Terminology D653.

3.2 Symbols and Acronyms:

3.2.1 CHD—the acronym for constant head device.device

3.2.2 GRT—the acronym for Gradient Ratio Testgradient ratio test

3.2.3 HCR—the acronym for Hydraulic Conductivity Ratiohydraulic conductivity ratio

4. Summary of Test Method

4.1 This method is intended for use in the observation of change in the permeability of a soil-geotextile interface over time under

a range of applied hydraulic gradients. At the end of the test, the weight of soil passing through the geotextile is measured. The

distribution of hydraulic gradients in the vicinity of the soil-geotextile interface is also observed.

5. Significance and Use

5.1 This test method is recommended for the evaluation of the performance of water-saturated soil-geotextile systems under

unidirectional flow conditions. The results obtained may be used as an indication of the compatibility of the soil-geotextile system

with respect to both particle retention and flow capacity.

5.2 This test method is intended to evaluate the performance of specific on-site soils and geotextiles at the design stage of a

project, or to provide qualitative data that may help identify causes of failure (that is,(for example, clogging, particle loss). It is

not appropriate for acceptance testing of geotextiles. It is also improper to utilize the results from this test for job specifications

or manufacturers’ certifications.

5.3 This test method is intended for site-specific investigation therefore is not an index property of the geotextile, and thus is

not intended to be requested of the manufacturer or supplier of the geotextile.

6. Apparatus and Supplies

6.1 Soil-Geotextile Permeameter—A typical permeameter will consist of three units, shown in Fig. 1, set-up on a frame

incorporating the other components such as the structure shown in Fig. 2. The lower unit will contain a soil-geotextile support

screen and an outflow reservoir that permits collection of the particles passing through the geotextile during different stages of the

test. The middle unit will hold the soil specimen and should be equipped with a piping barrier (i.e., (for example, caulk) along the

interface between the geotextile and the permeameter walls. The geotextile support screen opening size shall be greater than ten

times the measured AOS of the geotextile. The upper unit will permit application of a constant head boundary condition to the top

of the specimen. The permeameter should also be equipped with a support stand, clamping brackets, and plastic tubing to connect

with an external pressure head monitoring system.

NOTE 1—the diameter of the permeameter shall be at least 10 x d100, where d100 is the largest particle of soil placed in the permeameter. In the case

soils with particles larger than 16 mm (mesh #5/8”)# ⁄8 in.) were to be evaluated, only the fraction smaller than 16 mm shall be used for testing.

NOTE 2—Some permeameters allow application of a normal load on the soil-geotextile interface. If so, the loading system shall be designed in such

a way that it will not influence the system’s hydraulic behavior.

6.2 Two Constant Water Head Devices, one mounted on a jack stand (adjustable) and one stationary (Fig. 3).

6.3 Soil Leveling Device (Fig. 4).

6.4 Manometer Board, of parallel glass tubes and measuring rulers.

6.5 Two Soil Support Screens, of approximately 5 mm (No. 4) mesh.

D5101 − 12 (2017)

FIG. 1 Gradient Ratio Test Setup

6.6 Soil Support Cloth, of 150 μm (No. 100) mesh, or equivalent geotextile.

6.7 Thermometer (0 to 50 6 1°C).1 °C).

6.8 Graduated Cylinder, 100 6 1 cm1-cm capacity.

6.9 Stopwatch.

6.10 Balance, or scale of at least 2-kg capacity and accurate to 61 g.

6.11 Carbon Dioxide, (CO ), gas supply and regulator.

6.12 Geotextile.

6.13 Water Recirculation System.

6.14 Water Deairing System, with a sufficient capacity to avoid recirculation of water in the test, which may replace fine

particles that have washed out of the specimen. Typical capacity: 1700 L/day (500 gal/day).

6.15 Algae Inhibitor, or micro screen.

6.16 Computer, with data acquisition card.

6.17 Pressure Transducers.Transducers, with a precision of at least 1 mm of water head, used for measurements of the head

distribution in the specimen during water flow. Fig. 3 describes the plumbing connections for each individual pressure transducer.

6.18 Pressure Transducer Calibration System, allowing the pressure transducers to be connected either to the permeameter ports

or to one or two independent containers adjustable to different water levels. It should be installed as close as possible to the

permeameter. This system can consist of a set of 18 ball valves, two (2) reference water reservoirs (that is, large open tubes), and

adequate tubing for connections, as shown in Fig. 4.

6.19 Funnel, with a internal diameter of about 6mm6 mm or as needed to facilitate soil placement in the apparatus.

7. Sampling and Test Specimens

7.1 Lot Sample and Laboratory Sample—Obtain a lot sample and laboratory samples as directed in Practice D4354.

7.2 Soil to be testedTested for gradient ratio—Gradient Ratio—Select approximately 6 to 8 liters of representative soil, with a

maximum particle size of 10 mm. If the natural soil to be tested contains large gravel- or boulder-size particles, these particles

3 5

should be removed from the specimen using a 10 mm10-mm ( ⁄8 (3/8 in.) or 16 mm-in.) or 16-mm ( ⁄8 (5/8 in.) -in.) sieve,

depending on the diameter of the cell used (100 or 150 mm).

D5101 − 12 (2017)

FIG. 2 Permeameter Section

FIG. 3 Individual Setup of Calibration System for Each Pressure Transducer

8. Conditioning

8.1 Test Water Preparation:

8.1.1 Test water should be maintained between 16 and 27°C27 °C (60 to 80°F)80 °F) and deaired to a dissolved oxygen content

of 2 ppm 2 ppm before being introduced into the apparatus. In addition, the deaired water shall be stored at a temperature within

6 2°C2 °C of the tested soil/geotextilesoil-geotextile system.

NOTE 3—Use of deaired water is essential to reduce or eliminate problems associated with air bubbles forming within the test apparatus or in the soil.

The dissolved air content will be lower, and chances to observe air clogging will be decreased

8.1.2 An algae inhibitor or micro screen should be used to eliminate any algae buildup in the system.

9. Procedure

9.1 Preparation of the test:Test:

9.1.1 Determination of the soils properties:Soil’s Properties:

9.1.1.1 Measure the following properties of the soil under investigation:

(1) Particle size distribution per Test Method D422.

(2) Plasticity index per Test Method D4318D4318,, when applicableapplicable.

D5101 − 12 (2017)

FIG. 4 General Setup of Calibration Board

9.1.1.2 For silty soils with plasticity indices in the vicinity of 5, estimate the permeability of the soil that(that is, using the

particle size distribution determined in 9.1.1.1) and compare this value to the detection limit of the apparatus. If the detection limit

of the apparatus is close to the soilssoil’s permeability, additional investigations shall be considered to determine whether GRT or

HCR shall be used.

9.1.1.3 The soil installation technique is determined as follows:

–3

(1) For silty soils, with permeabilities less than 10-310 cm/s, use of the ‘slurry’ deposition technique is preferred as discussed

in 9.4.3Section 9.4.2;.

–3

(2) For sandy soils, with permeabilities greater than 10-310 cm cm/s, ⁄s, use of the ‘water pluviation’ technique is preferred

as discussed in 9.4.2Section 9.4.3.

(3) For well graded well-graded soils or unstable soils that easily segregate, the dry method presented in section9.4.4 9.4.4 is

preferred.

9.1.2 Preparation of the Apparatus:

9.1.2.1 Thoroughly clean and dry all permeameter sections.

9.1.2.2 Close all valves and cover the inside openings of all manometer ports with fine wire mesh or lightweight nonwoven

fabric (having an equivalent percent open area to that of a No. 100 mesh sieve).

9.1.2.3 Lubricate all O-ring gaskets.

9.2 Permeameter Preassembly:

9.2.1 Stand center section of the permeameter on its bottom end and place the geotextile specimen on the recessed permeameter

flanges.

9.2.2 Insert the support screen on top of the geotextile with the mesh side down.

9.2.3 Align and insert the bottom section of the permeameter onto the center section and press until there is a tight fit that

secures the geotextile and support screen in place. Ensure that all gasket edges are secure against the geotextile, support bracket,

and the interface between the center and top permeameter sections.

9.2.4 Place permeameter into holding stand.

9.3 Process Soil: Soil—The test is to be performed on a soil specimen having particle sizes which are <10 mm (< ⁄8 in.) in size.

The material passing the 10 mm ( ⁄8 in.) and retained on the No. 10 sieve is subject to a second round of grinding. However, this

second grinding shall be done gently to ensure that agglomerates of particles will be maintained, as they refl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.