ASTM C623-92(2015)

(Test Method)Standard Test Method for Young's Modulus, Shear Modulus, and Poisson's Ratio for Glass and Glass-Ceramics by Resonance

Standard Test Method for Young's Modulus, Shear Modulus, and Poisson's Ratio for Glass and Glass-Ceramics by Resonance

SIGNIFICANCE AND USE

3.1 This test system has advantages in certain respects over the use of static loading systems in the measurement of glass and glass-ceramics:

3.1.1 Only minute stresses are applied to the specimen, thus minimizing the possibility of fracture.

3.1.2 The period of time during which stress is applied and removed is of the order of hundreds of microseconds, making it feasible to perform measurements at temperatures where delayed elastic and creep effects proceed on a much-shortened time scale, as in the transformation range of glass, for instance.

3.2 The test is suitable for detecting whether a material meets specifications, if cognizance is given to one important fact: glass and glass-ceramic materials are sensitive to thermal history. Therefore the thermal history of a test specimen must be known before the moduli can be considered in terms of specified values. Material specifications should include a specific thermal treatment for all test specimens.

SCOPE

1.1 This test method covers the determination of the elastic properties of glass and glass-ceramic materials. Specimens of these materials possess specific mechanical resonance frequencies which are defined by the elastic moduli, density, and geometry of the test specimen. Therefore the elastic properties of a material can be computed if the geometry, density, and mechanical resonance frequencies of a suitable test specimen of that material can be measured. Young's modulus is determined using the resonance frequency in the flexural mode of vibration. The shear modulus, or modulus of rigidity, is found using torsional resonance vibrations. Young's modulus and shear modulus are used to compute Poisson's ratio, the factor of lateral contraction.

1.2 All glass and glass-ceramic materials that are elastic, homogeneous, and isotropic may be tested by this test method.2 The test method is not satisfactory for specimens that have cracks or voids that represent inhomogeneities in the material; neither is it satisfactory when these materials cannot be prepared in a suitable geometry.

Note 1: Elastic here means that an application of stress within the elastic limit of that material making up the body being stressed will cause an instantaneous and uniform deformation, which will cease upon removal of the stress, with the body returning instantly to its original size and shape without an energy loss. Glass and glass-ceramic materials conform to this definition well enough that this test is meaningful.

Note 2: Isotropic means that the elastic properties are the same in all directions in the material. Glass is isotropic and glass-ceramics are usually so on a macroscopic scale, because of random distribution and orientation of crystallites.

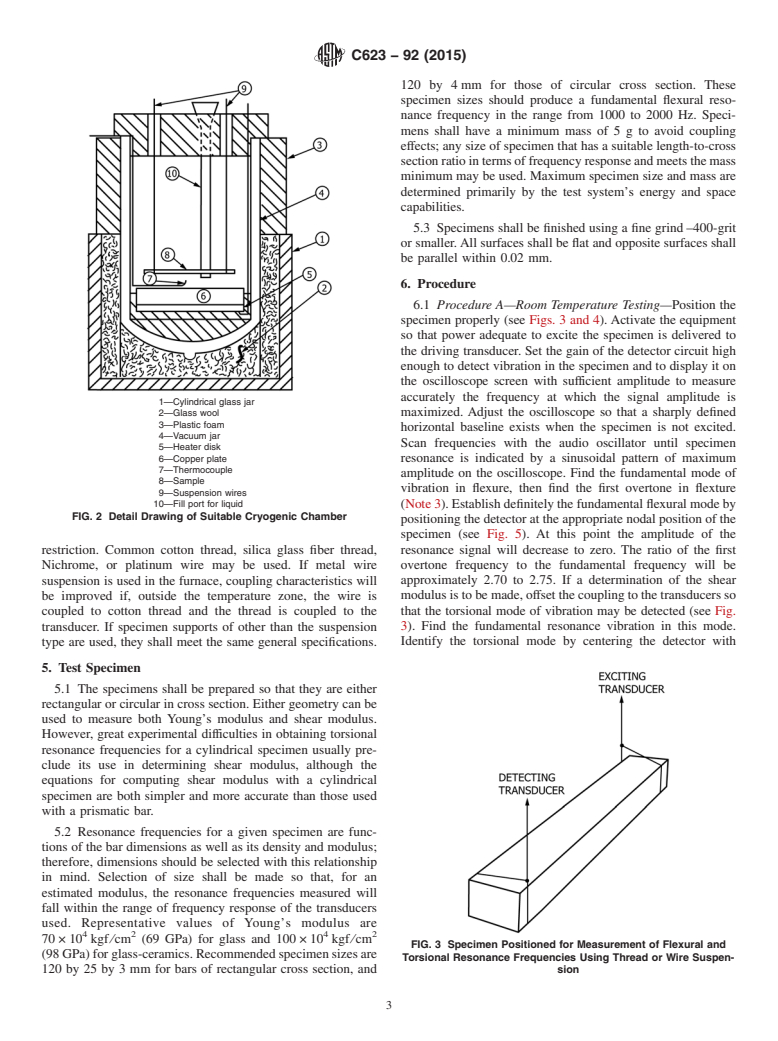

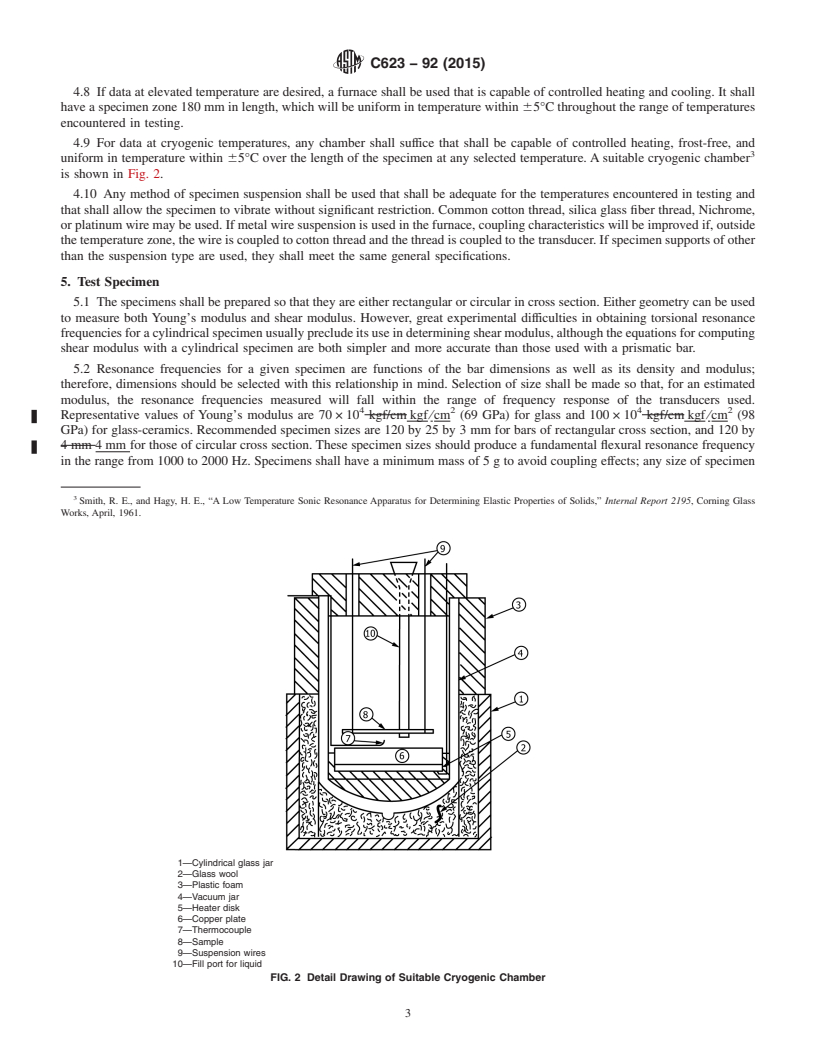

1.3 A cryogenic cabinet and high-temperature furnace are described for measuring the elastic moduli as a function of temperature from –195 to 1200°C.

1.4 Modification of the test for use in quality control is possible. A range of acceptable resonance frequencies is determined for a piece with a particular geometry and density. Any specimen with a frequency response falling outside this frequency range is rejected. The actual modulus of each piece need not be determined as long as the limits of the selected frequency range are known to include the resonance frequency that the piece must possess if its geometry and density are within specified tolerances.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C623 − 92 (Reapproved 2015)

Standard Test Method for

Young’s Modulus, Shear Modulus, and Poisson’s Ratio for

1

Glass and Glass-Ceramics by Resonance

This standard is issued under the fixed designation C623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 Modification of the test for use in quality control is

possible. A range of acceptable resonance frequencies is

1.1 This test method covers the determination of the elastic

determined for a piece with a particular geometry and density.

properties of glass and glass-ceramic materials. Specimens of

Any specimen with a frequency response falling outside this

thesematerialspossessspecificmechanicalresonancefrequen-

frequency range is rejected. The actual modulus of each piece

cies which are defined by the elastic moduli, density, and

need not be determined as long as the limits of the selected

geometry of the test specimen. Therefore the elastic properties

frequency range are known to include the resonance frequency

of a material can be computed if the geometry, density, and

that the piece must possess if its geometry and density are

mechanical resonance frequencies of a suitable test specimen

within specified tolerances.

of that material can be measured. Young’s modulus is deter-

1.5 The values stated in SI units are to be regarded as

mined using the resonance frequency in the flexural mode of

standard. No other units of measurement are included in this

vibration. The shear modulus, or modulus of rigidity, is found

standard.

using torsional resonance vibrations. Young’s modulus and

shear modulus are used to compute Poisson’s ratio, the factor

1.6 This standard does not purport to address all of the

of lateral contraction.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.2 All glass and glass-ceramic materials that are elastic,

2

priate safety and health practices and determine the applica-

homogeneous,andisotropicmaybetestedbythistestmethod.

bility of regulatory limitations prior to use.

The test method is not satisfactory for specimens that have

cracks or voids that represent inhomogeneities in the material;

2. Summary of Test Method

neither is it satisfactory when these materials cannot be

2.1 This test method measures the resonance frequencies of

prepared in a suitable geometry.

test bars of suitable geometry by exciting them at continuously

NOTE 1—Elastic here means that an application of stress within the

variable frequencies. Mechanical excitation of the specimen is

elastic limit of that material making up the body being stressed will cause

provided through use of a transducer that transforms an initial

aninstantaneousanduniformdeformation,whichwillceaseuponremoval

electrical signal into a mechanical vibration. Another trans-

ofthestress,withthebodyreturninginstantlytoitsoriginalsizeandshape

without an energy loss. Glass and glass-ceramic materials conform to this

ducer senses the resulting mechanical vibrations of the speci-

definition well enough that this test is meaningful.

men and transforms them into an electrical signal that can be

NOTE 2—Isotropic means that the elastic properties are the same in all

displayed on the screen of an oscilloscope to detect resonance.

directionsinthematerial.Glassisisotropicandglass-ceramicsareusually

The reasonance frequencies, the dimensions, and the mass of

so on a macroscopic scale, because of random distribution and orientation

the specimen are used to calculate Young’s modulus and the

of crystallites.

shear modulus.

1.3 A cryogenic cabinet and high-temperature furnace are

described for measuring the elastic moduli as a function of

3. Significance and Use

temperature from–195 to 1200°C.

3.1 This test system has advantages in certain respects over

the use of static loading systems in the measurement of glass

and glass-ceramics:

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass

3.1.1 Only minute stresses are applied to the specimen, thus

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

minimizing the possibility of fracture.

Physical and Mechanical Properties.

3.1.2 The period of time during which stress is applied and

Current edition approved May 1, 2015. Published May 2015. Originally

approved in 1969. Last previous edition approved in 2010 as C623–92(2010).

removed is of the order of hundreds of microseconds, making

DOI: 10.1520/C0623-92R15.

it feasible to perform measurements at temperatures where

2

Spinner, S., and Tefft, W. E., “A Method for Determining M

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C623 − 92 (Reapproved 2010) C623 − 92 (Reapproved 2015)

Standard Test Method for

Young’s Modulus, Shear Modulus, and Poisson’s Ratio for

1

Glass and Glass-Ceramics by Resonance

This standard is issued under the fixed designation C623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the elastic properties of glass and glass-ceramic materials. Specimens of these

materials possess specific mechanical resonance frequencies which are defined by the elastic moduli, density, and geometry of the

test specimen. Therefore the elastic properties of a material can be computed if the geometry, density, and mechanical resonance

frequencies of a suitable test specimen of that material can be measured. Young’s modulus is determined using the resonance

frequency in the flexural mode of vibration. The shear modulus, or modulus of rigidity, is found using torsional resonance

vibrations. Young’s modulus and shear modulus are used to compute Poisson’s ratio, the factor of lateral contraction.

2

1.2 All glass and glass-ceramic materials that are elastic, homogeneous, and isotropic may be tested by this test method. The

test method is not satisfactory for specimens that have cracks or voids that represent inhomogeneities in the material; neither is

it satisfactory when these materials cannot be prepared in a suitable geometry.

NOTE 1—Elastic here means that an application of stress within the elastic limit of that material making up the body being stressed will cause an

instantaneous and uniform deformation, which will cease upon removal of the stress, with the body returning instantly to its original size and shape

without an energy loss. Glass and glass-ceramic materials conform to this definition well enough that this test is meaningful.

NOTE 2—Isotropic means that the elastic properties are the same in all directions in the material. Glass is isotropic and glass-ceramics are usually so

on a macroscopic scale, because of random distribution and orientation of crystallites.

1.3 A cryogenic cabinet and high-temperature furnace are described for measuring the elastic moduli as a function of

temperature from −195°Cfrom –195 to 1200°C.

1.4 Modification of the test for use in quality control is possible. A range of acceptable resonance frequencies is determined for

a piece with a particular geometry and density. Any specimen with a frequency response falling outside this frequency range is

rejected. The actual modulus of each piece need not be determined as long as the limits of the selected frequency range are known

to include the resonance frequency that the piece must possess if its geometry and density are within specified tolerances.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Summary of Test Method

2.1 This test method measures the resonance frequencies of test bars of suitable geometry by exciting them at continuously

variable frequencies. Mechanical excitation of the specimen is provided through use of a transducer that transforms an initial

electrical signal into a mechanical vibration. Another transducer senses the resulting mechanical vibrations of the specimen and

transforms them into an electrical signal that can be displayed on the screen of an oscilloscope to detect resonance. The reasonance

frequencies, the dimensions, and the mass of the specimen are used to calculate Young’s modulus and the shear modulus.

3. Significance and Use

3.1 This test system has advantages in certain respects over the use of static loading systems in the measurement of glass and

glass-ceramics:

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.04 on Physical

and Mechanical Properties.

Current edition approved April 1, 2010May 1, 2015. Published May 2010May 2015. Originally approved in 1969. Last previous edition approved in 20052010 a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.