ASTM E1338-09(2021)e1

(Guide)Standard Guide for Identification of Metals and Alloys in Computerized Material Property Databases

Standard Guide for Identification of Metals and Alloys in Computerized Material Property Databases

SIGNIFICANCE AND USE

4.1 This guide describes the types of information that are indispensable for uniquely identifying a metal or alloy in a computerized database. The purpose is to facilitate standardized storage and retrieval of the information with a computer, and allow meaningful comparison of data from different sources.

4.2 Many numbering systems for metals and alloys have been developed which are based on their chemical compositions. Separate systems have also evolved to describe the thermomechanical condition of metals and alloys in order to narrow their description. It is the separation into logical data elements from these complex, historically significant, and overlapping systems of identification that is the challenge in the identification of metals and alloys within computerized databases.

4.3 This guide is intended to provide a common starting point for designers and builders of materials property databases. This guide generally identifies the contents of the database in terms of data elements, but does not recommend any particular logical or physical database design. A database builder has considerable flexibility in designing a database schema, and it is intended that this guide support that flexibility.

4.4 It is recognized that material property databases will be designed for different levels of material information and for different purposes. For example, a database developed by an industry trade group might only identify typical properties generally representative of those for a particular metal or alloy, and not actual values measured on a specific sample. On the other hand, a business might desire to manage data on specific lots it procures, or even properties of a specific piece or sample from a lot. Consequently, some of the data elements identified in this guide might not be applicable in every database instance.

4.5 The extent of material identification implemented in a particular database depends on its specific purpose. A single organization may i...

SCOPE

1.1 This guide covers the identification of metals and alloys in computerized material property databases. It establishes essential and desirable data elements that serve to uniquely identify and describe a particular metal or alloy sample as well as properties that identify a given metal or alloy in general.

1.1.1 This guide does not necessarily provide sufficient data elements to describe weld metal, metal matrix composites, or joined metals.

1.1.2 The data element identified herein are not all germane to every metal or alloy group.

1.1.3 Different sets of data elements may also be applied within a given metal or alloy group depending on conditions or applications specific to that metal or alloy group. Further, within a particular metal or alloy group, different sets of data elements may be used to identify specific material conditions.

1.1.4 Table 1 on Recommended Data Elements and Tables 2-17 on values for specific data elements appear at the end of this guide.

1.2 Some of the data elements in this guide may be useful for other purposes. However, this guide does not attempt to document the essential and desirable data element for any purpose except for the identification of metals and alloys in computerized material property databases. Other purposes, such as material production, material procurement, and material processing, each may have different material data reporting requirements distinct from those covered in this guide. A specific example is the contractually required report for a material property testing series. Such a report may not contain all the data elements considered essential for a specific computerized database; conversely, this guide may not contain all the data elements considered essential for a contracted test report.

1.3 Results from material tests conducted as part of the procurement process are often used to determine adherence to a specification. While thi...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation:E1338 −09 (Reapproved 2021)

Standard Guide for

Identification of Metals and Alloys in Computerized Material

Property Databases

This standard is issued under the fixed designation E1338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The Referenced Documents list was updated editorially in March 2022.

1. Scope computerized database; conversely, this guide may not contain

all the data elements considered essential for a contracted test

1.1 This guide covers the identification of metals and alloys

report.

in computerized material property databases. It establishes

essential and desirable data elements that serve to uniquely

1.3 Results from material tests conducted as part of the

identify and describe a particular metal or alloy sample as well procurement process are often used to determine adherence to

as properties that identify a given metal or alloy in general. a specification. While this guide includes a number of test

1.1.1 This guide does not necessarily provide sufficient data result data elements, such data elements are included in this

elements to describe weld metal, metal matrix composites, or guide only for the purposes of material identification.

joined metals.

1.4 Reporting of contracted test results, such as certification

1.1.2 The data element identified herein are not all germane

test results, shall follow the requirements described in the

to every metal or alloy group.

materialspecification,orasagreeduponbetweenthepurchaser

1.1.3 Different sets of data elements may also be applied

and the manufacturer.

withinagivenmetaloralloygroupdependingonconditionsor

1.5 This guide contains a limited number of data elements

applications specific to that metal or alloy group. Further,

related to material test results. These data elements are for

within a particular metal or alloy group, different sets of data

material identification purposes and are not intended to replace

elements may be used to identify specific material conditions.

the more detailed sets of data elements listed in guides such as

1.1.4 Table 1 on Recommended Data Elements and Tables

Guide E1313 covering data recording formats for mechanical

2-17 on values for specific data elements appear at the end of

testing of metals. For material identification purposes, the data

this guide.

elements in this guide include typical, nominal, or summary

1.2 Some of the data elements in this guide may be useful

properties normally derived from a population of individual

for other purposes. However, this guide does not attempt to

specimen tests. If warranted by the scope of a particular

document the essential and desirable data element for any

database system, the system might provide links between the

purpose except for the identification of metals and alloys in

material identification data elements given in this guide, and

computerized material property databases. Other purposes,

the individual specimen test results recorded in accordance

such as material production, material procurement, and mate-

with other guides corresponding to particular test methods.

rialprocessing,eachmayhavedifferentmaterialdatareporting

1.6 Material Classes—See ANSI/AWS A9.1-92 for arc

requirements distinct from those covered in this guide. A

welds, Guide E527 for Metal and Alloys in the Unified

specific example is the contractually required report for a

Numbering System (UNS), Guide E1308 for polymers, Guide

material property testing series. Such a report may not contain

E1309 for composite material, and Guide E1471 for fibers,

all the data elements considered essential for a specific

fillers, and core materials.

1.7 This international standard was developed in accor-

This guide is under the jurisdiction ofASTM Committee B08 on Metallic and

dance with internationally recognized principles on standard-

Inorganic Coatings and is the direct responsibility of Subcommittee B08.01 on

AncillaryActivities. This guide was developed in cooperation with Committee B07

ization established in the Decision on Principles for the

on Light Metals and Alloys.

Development of International Standards, Guides and Recom-

Current edition approved April 1, 2021. Published May 2021. Originally

mendations issued by the World Trade Organization Technical

approved in 1990. Last previous edition approved in 2015 as E1338 – 09(2015).

DOI: 10.1520/E1338-09R21E01. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1338−09 (2021)

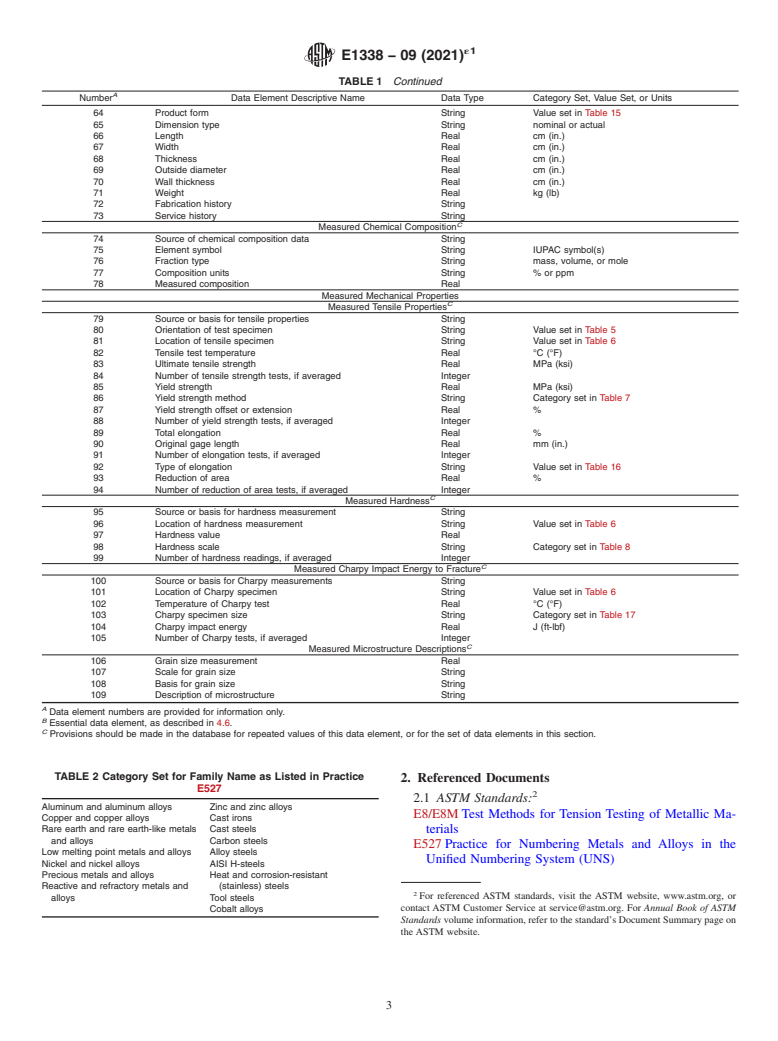

TABLE 1 Recommended Data Elements for the Identification of Metals and Alloys

A

Number Data Element Descriptive Name Data Type Category Set, Value Set, or Units

Primary Identifiers

1 Material class String metal

2 Family name String Category set in Table 2

3 Family subclass String Value set in Table 3

B C

4 Common name String

C

5 Application group String

C

6 Product group String

C

Material Specification

B

7 UNS Number String Category set defined in Practice E527

B

8 Specification organization String

B

9 Specification number String

B

10 Specification version String

B C

11 Designation keyword String Category set in Table 4

B C

12 Designation value String

C

Composition Requirements

13 Element symbol String IUPAC symbol(s)

14 Fraction type String mass, volume, or mole

15 Composition units String % or ppm

16 Minimum specified composition Real

17 Maximum specified composition Real

Mechanical Properties Requirements

C

Tensile Test Requirements

18 Orientation of tensile specimen for certification String Value set in Table 5

19 Location of tensile specimen for certification String Values set in Table 6

20 Tensile test temperature for certification Real °C (°F)

21 Minimum ultimate tensile strength Real MPa (ksi)

22 Maximum ultimate tensile strength Real MPa (ksi)

23 Minimum yield strength Real MPa (ksi)

24 Maximum yield strength Real MPa (ksi)

25 Yield strength determination method String Category set in Table 7

26 Yield strength offset or extension Real %

27 Minimum elongation Real %

28 Maximum elongation Real %

29 Original gage length Real mm (in.)

30 Minimum reduction of area Real %

31 Maximum reduction of area Real %

C

Hardness Requirements

32 Location of hardness measurement for certification String Value set in Table 6

33 Minimum hardness Real

34 Maximum hardness Real

35 Hardness scale String Category set in Table 8

C

Charpy Impact Energy to Fracture Requirements

36 Location of Charpy specimen for certification String Value set in Table 6

37 Temperature of Charpy test for certification Real °C (°F)

38 Minimum Charpy impact energy Real J (ft-lbf)

39 Maximum Charpy impact energy Real J (ft-lbf)

Primary Material Producer

40 Original producer String

41 Country of origin String

42 Producer’s facility String

43 Production date Date

44 Primary process type String

45 Melt practice String Value set in Table 9

46 Cast practice String Value set in Table 10

B

47 Heat number String

C

Material Processing

48 Processor’s name String

49 Processor’s country String see ISO 3166

50 Processor’s facility name String

51 Processor’s assigned production date Date

B

52 Process type String

53 Process lot number String

C

Heat Treatment

54 Thermal step type String

55 Time of thermal step Real h

56 Thermal step temperature Real °C (°F)

57 Heating environment String Values set in Table 11

58 Heating rate Real °C/h (°F/h)

59 Cooling environment String Value set in Table 12

60 Cooling rate Real °C/h (°F/h)

Product Detail

61 Product forming method String Value set in Table 13

62 Product identifier String

63 Product shape String Value set in Table 14

´1

E1338−09 (2021)

TABLE1 Continued

A

Number Data Element Descriptive Name Data Type Category Set, Value Set, or Units

64 Product form String Value set in Table 15

65 Dimension type String nominal or actual

66 Length Real cm (in.)

67 Width Real cm (in.)

68 Thickness Real cm (in.)

69 Outside diameter Real cm (in.)

70 Wall thickness Real cm (in.)

71 Weight Real kg (lb)

72 Fabrication history String

73 Service history String

C

Measured Chemical Composition

74 Source of chemical composition data String

75 Element symbol String IUPAC symbol(s)

76 Fraction type String mass, volume, or mole

77 Composition units String % or ppm

78 Measured composition Real

Measured Mechanical Properties

C

Measured Tensile Properties

79 Source or basis for tensile properties String

80 Orientation of test specimen String Value set in Table 5

81 Location of tensile specimen String Value set in Table 6

82 Tensile test temperature Real °C (°F)

83 Ultimate tensile strength Real MPa (ksi)

84 Number of tensile strength tests, if averaged Integer

85 Yield strength Real MPa (ksi)

86 Yield strength method String Category set in Table 7

87 Yield strength offset or extension Real %

88 Number of yield strength tests, if averaged Integer

89 Total elongation Real %

90 Original gage length Real mm (in.)

91 Number of elongation tests, if averaged Integer

92 Type of elongation String Value set in Table 16

93 Reduction of area Real %

94 Number of reduction of area tests, if averaged Integer

C

Measured Hardness

95 Source or basis for hardness measurement String

96 Location of hardness measurement String Value set in Table 6

97 Hardness value Real

98 Hardness scale String Category set in Table 8

99 Number of hardness readings, if averaged Integer

C

Measured Charpy Impact Energy to Fracture

100 Source or basis for Charpy measurements String

101 Location of Charpy specimen String Value set in Table 6

102 Temperature of Charpy test Real °C (°F)

103 Charpy specimen size String Category set in Table 17

104 Charpy impact energy Real J (ft-lbf)

105 Number of Charpy tests, if averaged Integer

C

Measured Microstructure Descriptions

106 Grain size measurement Real

107 Scale for grain size String

108 Basis for grain size String

109 Description of microstructure String

A

Data element numbers are provided for information only.

B

Essential data element, as described in 4.6.

C

Provisions should be made in the database for repeated values of this data element, or for the set of data elements in this section.

TABLE 2 Category Set for Family Name as Listed in Practice

2. Referenced Documents

E527

2.1 ASTM Standards:

Aluminum and aluminum alloys Zinc and zinc alloys

E8/E8M Test Methods for Tension Testing of Metallic Ma-

Copper and copper alloys Cast irons

Rare earth and rare earth-like metals Cast steels

terials

and alloys Carbon steels

E527 Practice for Numbering Metals and Alloys in the

Low melting point metals and alloys Alloy steels

Unified Numbering System (UNS)

Nickel and nickel alloys AISI H-steels

Precious metals and alloys Heat and corrosion-resistant

Reactive and refractory metals and (stainless) steels

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

alloys Tool steels

Cobalt alloys contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

´1

E1338−09 (2021)

TABLE 3 Example Value Sets for Family Subclass Name for TABLE 8 Category Set for Hardness Scale

Aluminum, Copper, Steel, and Other Metals and Alloys

Brinell

Knoop

Aluminum: Copper:

Rockwell A

Commercially pure aluminum Copper

Rockwell B

Aluminum-copper alloy High copper alloy

Rockwell C

Aluminum-manganese alloy Beryllium copper

Rockwell E

Aluminum-silicon alloy Chromium copper

Rockwell F

Aluminum-manganese-silicon alloy Copper-zinc alloy (brass)

Shore

Aluminum-magnesium alloy Copper-zinc-lead-alloy (leaded

Vickers

Aluminum-magnesium-silicon alloy brass)

Rockwell 15t

Aluminum-zinc alloy Copper-zinc-tin alloy (tin brass)

Rockwell 30t

Other aluminum alloy Copper-tin-phosphorus alloy

Rockwell 45t

(phosphor bronze)

Steel: Copper-tin-lead-phosphorus alloy Rockwell 15N

Rockwell 30N

Chromium-molybdenum (leaded phosphor bronze)

Rockwell 45N

Low carbon

High carbon

Austenitic

Ferritic

TABLE 9 Value Set for Melt Practice

Martensitic

Precipitation hardening

Argon oxygen decarburization

Basic oxygen furnace

Open hearth

Electric furnace

TABLE 4 Category Set for Designation Keyword

Remelt

Ladle refining

Grade

Vacuum degassing

Type

Vacuum arc remelt

Composition

Vacuum oxygen decarburization

Temper

Vacuum induction melting

Condition

Air induction melting

Class

Electroslag remelt

Electroflux remelt

Electron beam melting

TABLE 5 Value Set for Specimen Orientation

Reverbatory furnace

Unnotched Specimen:

Longitudinal (parallel to working direction)

Transverse (perpendicular to working direction)

TABLE 10 Value Set for Cast Practice

Long transverse

Continuous

Short transverse

Ingot

Tangenital

Powder metallurgy

Radial

Spin

Diagonal (to rolling direction)

Cracked or Notched Specimen:

See Terminology E616 for orientation codes

TABLE 11 Value Set for Heating Environment

Air

TABLE 6 Value Set for Location Within Product

Vacuum

Inert gas

Outer surface

Internal Hydrogen

Other reducing gas

Inside surface

Oxidizing gas atmosphere

Surface

Quarter thickness

Center of thickness

Leading edge

TABLE 12 Value Set for Cooling Environment

Trailing edge

Quenched in oil

Air-cooled

Inert gas-cooled

TABLE 7 Category Set for Yield Strength Method (as explained in

Quenched in water

Test Methods E8/E8M)

Quenched in brine

Quenched in polymer

Offset

Quenched in air and water

Extension under load

Upper

Lower

E1308 Guide for Identification of Polymers (Excludes Ther-

E616 Terminology Relating to Fracture Testing (Withdrawn

moset Elastomers) in Computerized Material Property

1996)

Databases (Withdrawn 2000)

E1309 Guide for Identification of Fiber-Reinforced

Polymer-Matrix Composite Materials in Databases (With-

The last approved version of this historical standard is referenced on

www.astm.org. drawn 2015)

´1

E1338−09 (2021)

TABLE 13 Value Set for Forming Method

ANSI/AWS A9.1-92 Standard Guide for Describing Arc

Forging Welds in Computerized Material Property and Nonde-

Casting

structive Examination Databases

Extrusion

Hot rolling

3. Terminology

Cold rolling

Powder compaction

3.1 Computer-related technical terms in this guide are

Drawing/coining

defined in Terminology E1443.

Bending

4. Significance and Use

TABLE 14 Value Set for Product Shape

4.1 This guide describes the types of information that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.