ASTM E1471-92(2004)

(Guide)Standard Guide for Identification of Fibers, Fillers, and Core Materials in Computerized Material Property Databases

Standard Guide for Identification of Fibers, Fillers, and Core Materials in Computerized Material Property Databases

SIGNIFICANCE AND USE

This guide defines the information which is considered essential to uniquely describe a fiber, filler, or core material in a computerized database. A format is recommended for placing these data in fields suitable for a computerized database. Additional fields which are considered desirable, but not essential, are also defined. The purpose is to facilitate efficient storage and retrieval of the information with a computer and to allow meaningful comparison of data from different sources.

Comparison of property data from different sources will be most meaningful if all the essential information defined by the guidelines is present. Comparison may still be possible if essential information is omitted, but the value of the comparison may be greatly reduced.

While at this time there is no generally accepted numbering system for these materials, analogous to those for metals and alloys, a field for an identifying number (Material Reference Number) is included should such a system be developed in the future.

This information should not be considered restrictive. For example, a database designer may find it useful to aggregate several fields, such as the material and chemical class fields, into a single field. This may affect search strategies and other database operations. These considerations are beyond the scope of this guide.

SCOPE

1.1 This guide establishes the essential and desirable elements of data required for the identification in computerized material property databases of fibers, fillers, and core materials used in composite materials. A recommended format for entry of these fields into a computerized database is provided. Examples of the application of this guide are also included.

1.2 The recommended format described in this guide is suggested for use in recording data in a database, which is different from contractural reporting of actual test results. The latter type of information is described in materials specifications shown in business transactions and is subject to agreement between vendor and purchaser.

1.3 The materials covered by this guide include fibers, both continuous and discontinuous, and fillers of various geometries which are used as reinforcements in composite materials, as well as core materials used in sandwich composites. Cores may be foam, honeycomb, or naturally occurring materials such as balsa wood. These materials are distinguished from bulk materials by the importance of their specialized geometric forms to their properties. This difference is reflected in the use of geometry, along with chemistry, as a primary basis for classification. Identification of composite materials is discussed in Guide E 1309.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1471 – 92 (Reapproved 2004)

Standard Guide for

Identification of Fibers, Fillers, and Core Materials in

Computerized Material Property Databases

This standard is issued under the fixed designation E 1471; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1443 Terminology Relating to Building and Accessing

Material and Chemical Databases

1.1 This guide establishes the essential and desirable ele-

ments of data required for the identification in computerized

3. Terminology

material property databases of fibers, fillers, and core materials

3.1 Definitions—Terminology D 3878 shall be used where

used in composite materials. A recommended format for entry

applicable.

of these fields into a computerized database is provided.

3.2 Definitions of Terms Specific to This Standard:

Examples of the application of this guide are also included.

3.2.1 core, n—a generally, centrally located layer or com-

1.2 The recommended format described in this guide is

posite component of a sandwich construction, usually low

suggested for use in recording data in a database, which is

density, which separates and stabilizes the facings and trans-

different from contractural reporting of actual test results. The

mits shear between them and provides most of the shear

latter type of information is described in materials specifica-

rigidity of the construction (see Terminology C 274).

tions shown in business transactions and is subject to agree-

3.2.2 essential field, n—a field in a record which must be

ment between vendor and purchaser.

filled to meet the requirements of a stated type of database (see

1.3 The materials covered by this guide include fibers, both

Terminology E 1443).

continuous and discontinuous, and fillers of various geometries

3.2.2.1 Discussion—Fields are considered essential if they

which are used as reinforcements in composite materials, as

are required to make a meaningful comparison of property data

wellascorematerialsusedinsandwichcomposites.Coresmay

from different sources. A comparison of data from different

be foam, honeycomb, or naturally occurring materials such as

sourcesmaystillbepossibleifessentialinformationisomitted,

balsa wood. These materials are distinguished from bulk

but the value of the comparison may be greatly reduced.

materials by the importance of their specialized geometric

3.2.3 fiber, n—in textiles, the general term for a filamentary

forms to their properties. This difference is reflected in the use

material having a length at least ten times its nominal diameter.

of geometry, along with chemistry, as a primary basis for

3.2.4 field, n—an elementary unit of a record that may

classification. Identification of composite materials is dis-

contain a data item, a data aggregate, a pointer, or a link (see

cussed in Guide E 1309.

E 1443).

2. Referenced Documents 3.2.5 field name, n—a name or code associated with a field

and used for identification (see Terminology E 1443).

2.1 ASTM Standards:

3.2.6 filler, n—a relatively inert material added to a plastic

C 274 Terminology of Structural Sandwich Constructions

to modify its strength, permanence, working properties, or

D 123 Terminology Relating to Textiles

other qualities, or to lower cost (see Terminology D 883).

D 883 Terminology Relating to Plastics

3.2.7 strand, n—in textile fibers, a normally untwisted

D 3878 Terminology for Composite Materials

bundle of filaments.

E 1309 Guide for Identification of Fiber-Reinforced

3.2.8 value set, n—an open listing of representative, accept-

Polymer-Matrix Composite Materials in Computerized

able strings which could be included in a particular field of a

Material Property Databases

record (see Terminology E 1443).

4. Significance and Use

This guide is under the jurisdiction of ASTM Committee D30 on Composite

4.1 This guide defines the information which is considered

Materials and is the direct responsibility of Subcommittee D30.01 on Editorial and

Resource Standards. essential to uniquely describe a fiber, filler, or core material in

Current edition approved Mar. 1, 2004. Published March 2004. Originally

acomputerizeddatabase.Aformatisrecommendedforplacing

approved in 1992. Last previous edition approved in 1998 as E 1471 – 92 (1998).

these data in fields suitable for a computerized database.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1471 – 92 (2004)

Additional fields which are considered desirable, but not 5.2.4 Chemical Family—Classificationofthematerialbyits

essential, are also defined. The purpose is to facilitate efficient generic chemical composition family. See Table 1 for list.

storage and retrieval of the information with a computer and to 5.3 Commercial Specification:

allow meaningful comparison of data from different sources. 5.3.1 Common Name—Name by which the material is

4.2 Comparison of property data from different sources will known in the industry.

be most meaningful if all the essential information defined by 5.3.2 Additional Name Information—Additional informa-

the guidelines is present. Comparison may still be possible if tion on the name, such as chemical composition details on the

essential information is omitted, but the value of the compari- material.

son may be greatly reduced. 5.3.3 Specification Organization—A company, industry,

4.3 While at this time there is no generally accepted government, national, regional, or international organization

numbering system for these materials, analogous to those for issuing the specification; for example, ASTM.

metals and alloys, a field for an identifying number (Material 5.3.4 Specification Number—The specification number

Reference Number) is included should such a system be within the organization referenced.

developed in the future. 5.3.5 Specification Version—The year or revision code of

4.4 This information should not be considered restrictive. the specification.

For example, a database designer may find it useful to 5.3.6 Specification Designation—The designation used for

aggregate several fields, such as the material and chemical the material in the specification.

class fields, into a single field.This may affect search strategies 5.4 Characteristics:

and other database operations. These considerations are be- 5.4.1 Density.

yond the scope of this guide. 5.4.2 Cross-Section Type—Geometry of cross section of the

material. See Table 2 for list.

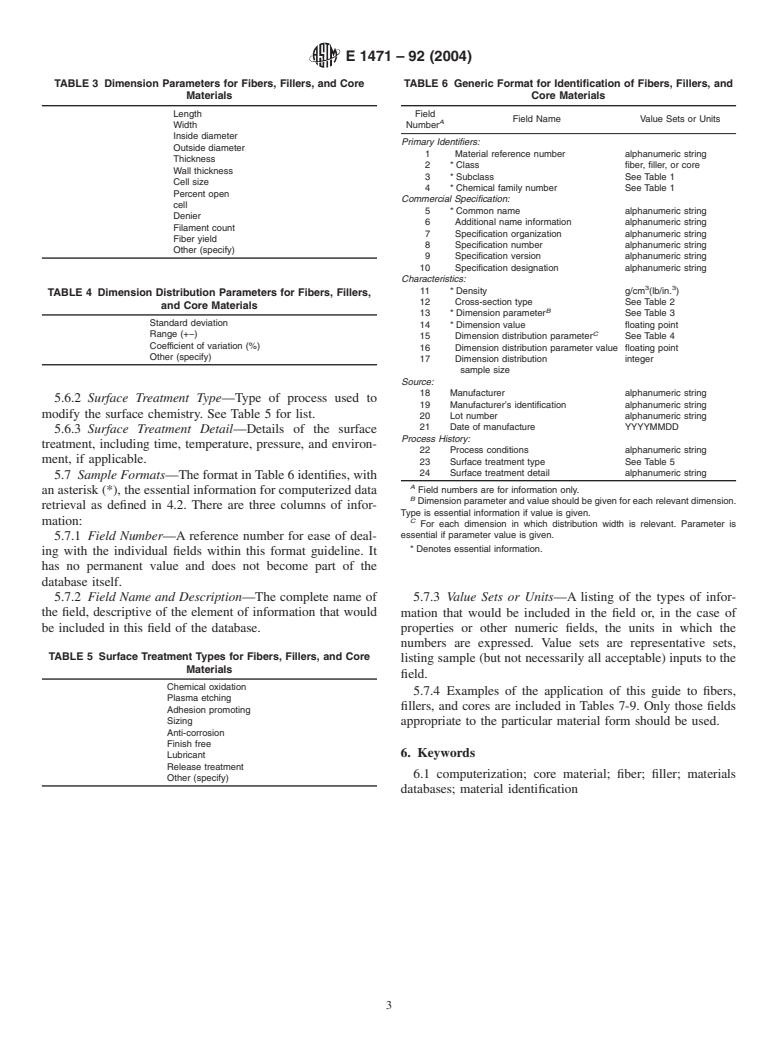

5. Guidelines 5.4.3 Dimension Parameter—Name of dimension charac-

teristic of the material; for example, diameter. Dimension

5.1 The following fields are recommended for identification

parameter, units, and value should be given for each charac-

of fibers, fillers, and core materials used in composites. For

teristic dimension. See Table 3 for list.

certain fields, lists of recommended entries are included.

5.4.4 Dimension Value—Mean or nominal numerical value

Where possible, entries should be chosen from these lists.

of the specified dimension in appropriate units.

However, these lists should not be regarded as exhaustive.

5.4.5 Dimension Distribution Parameter Type—Name of

5.2 Primary Identifiers:

the parameter used to characterize the distribution of values for

5.2.1 Material Reference Number—Identifying number or

the specified dimension. See Table 4 for list.

code, if any, for the particular material.

5.4.6 Dimension Distribution Parameter Value—Numerical

5.2.2 Class—Classification by form, either fiber, filler, or

value of the distribution parameter for the specified dimension.

core.

Units are assumed to be the same as those of the dimension

5.2.3 Subclass—Further subdivision by geometric form

itself.

within the class. See Table 1 for list.

5.4.7 Dimension Distribution Sample Size—The number of

samples from which the dimension distribution parameter

value is determined.

TABLE 1 Class, Subclass, Chemical Family, and Forms for

Fibers, Fillers, and Core Materials

5.5 Source:

5.5.1 Manufacturer.

NOTE 1—These are lists. The table is not intended to be read horizon-

5.5.2 Manufacturer’s Identification—Code, part number, or

tally.

other identification used by the manufacturer to identify this

Class Subclass Chemical Family Form

material.

Fiber continuous aramid tow or end or impreg-

5.5.3 Lot Number—Manufacturer’s reference for traceabil-

discontinuous, long glass nated tow strand

discontinuous, short silicon carbide plied yarn

ity of this lot of material.

staple aluminum oxide yarn roving

5.5.4 Date of Manufacture—YYYYMMDD.

milled aluminum mat

5.6 P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.