ASTM A789/A789M-13ae1

(Specification)Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

ABSTRACT

This specification covers standard requirements for grades of nominal wall thickness, stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures. Heat and product analyses shall be performed wherein the steel shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, nitrogen, copper, and others. All tubes shall be furnished in the heat-treated condition in accordance with the specified temperature and quench conditions. When the final heat treatment is in a continuous furnace, or when heat treated condition is obtained directly by quenching after hot forming, the number of tubes of the same size and from the same heat in a lot shall be determined from the prescribed sizes of the tubes. The material shall conform to the prescribed tensile and hardness properties. Mechanical tests such as tension test, flaring test (for seamless tubes), flange test (for welded tubes), hardness test, and reverse flattening test shall be performed on the steel tubing. Each tube shall also be subjected to the nondestructive electric test or the hydrostatic test.

SCOPE

1.1 This specification2 covers grades of average wall thickness, or, if specified on the order, minimum wall thickness, of stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. Within the text, the SI units are shown in brackets. The inch-pound units shall apply unless the M designation of this specification is specified in the order.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A789/A789M −13a

StandardSpecification for

Seamless and Welded Ferritic/Austenitic Stainless Steel

1

Tubing for General Service

This standard is issued under the fixed designationA789/A789M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Footnote A under Table 4 was editorially corrected in November 2013.

4

1. Scope* 2.2 SAE Standard:

2 SAE J 1086 Practice for Numbering Metals and Alloys

1.1 This specification covers grades of average wall

(UNS)

thickness, or, if specified on the order, minimum wall

thickness, of stainless steel tubing for services requiring

3. Ordering Information

general corrosion resistance, with particular emphasis on

3.1 Orders for product under this specification should in-

resistance to stress corrosion cracking.These steels are suscep-

clude the following, as required, to describe the desired

tible to embrittlement if used for prolonged periods at elevated

material adequately:

temperatures.

3.1.1 Quantity (feet, metres, or number of lengths),

1.2 The values stated in either SI units or inch-pound units

3.1.2 Name of product (seamless or welded tubes),

are to be regarded separately as standard. The values stated in

3.1.3 Grade (see Table 1),

each system may not be exact equivalents; therefore, each

3.1.4 Size (outside diameter and average wall thickness,

system shall be used independently of the other. Combining

unless minimum wall thickness is specified),

values from the two systems may result in non-conformance

3.1.5 Length (specific or random),

with the standard. Within the text, the SI units are shown in

3.1.6 Optional requirements (for product analysis, see Sec-

brackets. The inch-pound units shall apply unless the M

tion 8; for hydrostatic or nondestructive electric test, see

designation of this specification is specified in the order.

Section 10),

3.1.7 Test report required (see the Inspection section of

2. Referenced Documents

Specification A1016/A1016M),

3

2.1 ASTM Standards:

3.1.8 Specification designation, and

A480/A480M Specification for General Requirements for

3.1.9 Special requirements.

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

Sheet, and Strip 4. General Requirements

A1016/A1016M Specification for General Requirements for

4.1 Product furnished under this specification shall conform

Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless

to the applicable requirements of Specification A1016/

Steel Tubes

A1016M, unless otherwise provided herein.

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

5. Manufacture

5.1 The tubes shall be made by the seamless or welded

process with no filler metal added.

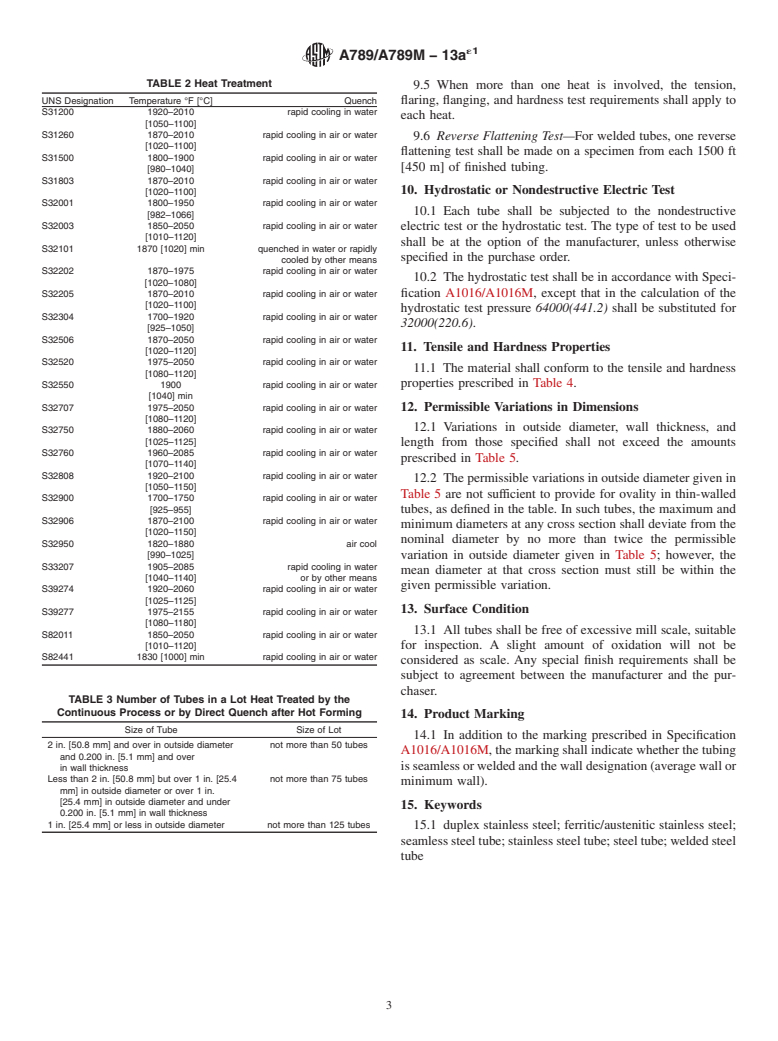

6. Heat Treatment

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

6.1 All tubes shall be furnished in the heat-treated condition

A01.10 on Stainless and Alloy Steel Tubular Products.

in accordance with the procedures shown in Table 2. For

Current edition approved Oct. 1, 2013. Published October 2013. Originally

approved in 1981. Last previous edition approved in 2013 as A789/A789M–13. seamless tubes, as an alternate to final heat treatment in a

DOI: 10.1520/A0789_A0789M-13AE01.

continuous furnace or batch-type furnace, immediately follow-

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

ing hot forming while the temperature of the tubes is not less

cation SA–789 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A789/A789M−13a

A

TABLE 1 Chemical Requirements

UNS

C Mn P S Si Ni Cr Mo N Cu Others

B

Designation

S31200 0.030 2.00 0.045 0.030 1.00 5.5–6.5 24.0–26.0 1.20–2.00 0.14–0.20 . . . . . .

S31260 0.030 1.00 0.030 0.030 0.75 5.5–7.5 24.0–26.0 2.5–3.5 0.10–0.30 0.20–0.80 W 0.10–0.50

S31500 0.030 1.20–2.00 0.030 0.030 1.40–2.00 4.3–5.2 18.0–19.0 2.50–3.00 0.05–0.1 . . . . . .

S31803 0.030 2.00 0.030 0.020 1.00 4.5–6.5 21.0–23.0 2.5–3.5 0.08–0.20 . . . . . .

S32001 0.030 4.00–6.00 0.040 0.030 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.