ASTM D4754-98(2003)

(Test Method)Standard Test Method for Two-Sided Liquid Extraction of Plastic Materials Using FDA Migration Cell

Standard Test Method for Two-Sided Liquid Extraction of Plastic Materials Using FDA Migration Cell

SIGNIFICANCE AND USE

Knowledge of migrants from plastic materials may serve many useful purposes, such as testing for compliance with food additive regulations. The procedure described in this test method is recommended as suitable for obtaining such data on many migrant(s)/plastic(s) combinations.

SCOPE

1.1 This test method covers the use of the FDA migration cell in the extraction of components and permits quantitation of individual migrants from plastic materials by suitable extracting liquids, including liquid foods and food-stimulating solvents.

1.2 This test method provides a two-sided, liquid extraction test for plastic materials that can be formed into film, sheet, or disks.

1.3 This test method has been applied to a variety of migrant/polymer systems in contact with numerous foods and food simulants. Though most of the migrants examined were radiolabeled, the use of the FDA cell has been validated for migration studies of unlabeled sytrene from polystyrene.

1.4 This test method has been shown to yield reproducible results under the conditions for migration tests requested by the FDA. However, if the data is to be submitted to the FDA, it is suggested that their guidelines be consulted.

1.5 Because it employs two-sided extraction, this test method may not be suitable for multi-layered plastics intended for single-sided food contact use.

1.6 The size of the FDA migration cell as described may preclude its use in determining total nonvolatile extractives in some cases.

Note 1—For more information, see Practice D 1898, the AOAC Methods of Analysis on Flexible Barrier Materials Exposed for Extraction, and the 1995 Recommendations for Chemistry Data for Indirect Food Additive Petitions.

1.7 Analytical procedures must be available to quantitate the migrant(s) generated by this test method.

1.8 The values stated in SI units are to be regarded as the standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

Note 2—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4754–98 (Reapproved 2003)

Standard Test Method for

Two-Sided Liquid Extraction of Plastic Materials Using FDA

Migration Cell

This standard is issued under the fixed designation D4754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This test method covers the use of the FDA migration

bility of regulatory limitations prior to use. Specific hazards

cellintheextractionofcomponentsandpermitsquantitationof

statements are given in Section 8.

individual migrants from plastic materials by suitable extract-

ing liquids, including liquid foods and food-stimulating sol-

NOTE 2—There is no similar or equivalent ISO standard.

vents.

2. Referenced Documents

1.2 This test method provides a two-sided, liquid extraction

test for plastic materials that can be formed into film, sheet, or

2.1 ASTM Standards:

disks.

D883 Terminology Relating to Plastics

1.3 This test method has been applied to a variety of

D1898 Practice for Sampling of Plastics

migrant/polymer systems in contact with numerous foods and

E691 Practice for Conducting an Interlaboratory Study to

food simulants. Though most of the migrants examined were

Determine the Precision of a Test Method

radiolabeled, the use of the FDA cell has been validated for

IEEE/ASTM SI 10 Standard for Use of the International

migration studies of unlabeled sytrene from polystyrene.

System of Units (SI): The Modernized Metric System

1.4 This test method has been shown to yield reproducible

2.2 Association of Offıcial Analytical Chemists (AOAC)

resultsundertheconditionsformigrationtestsrequestedbythe

Methods of Analysis:

FDA. However, if the data is to be submitted to the FDA, it is

Flexible Barrier Materials Exposed for Extraction

suggested that their guidelines be consulted.

2.3 Federal Document:

1.5 Because it employs two-sided extraction, this test

1995 Recommendations for Chemistry Data for Indirect

method may not be suitable for multi-layered plastics intended

Food Additive Petitions

for single-sided food contact use.

3. Terminology

1.6 The size of the FDA migration cell as described may

preclude its use in determining total nonvolatile extractives in

3.1 General—The units, symbols, and abbreviations used in

some cases. this test method are in accordance withTerminology D883 and

Practice IEEE/ASTM SI 10.

NOTE 1—For more information, see Practice D1898, theAOAC Meth-

ods ofAnalysis on Flexible Barrier Materials Exposed for Extraction, and

4. Summary of Test Method

the1995RecommendationsforChemistryDataforIndirectFoodAdditive

Petitions. 4.1 Specimens of plastic materials, formed in the shape of

disks, are threaded onto a stainless steel wire with alternating

1.7 Analytical procedures must be available to quantitate

glass bead spacers and placed in a glass vial. Solvent is added

the migrant(s) generated by this test method.

to the vial and the vial is capped and maintained at the desired

1.8 The values stated in SI units are to be regarded as the

extraction temperature. Aliquots of the liquid are removed at

standard.

various times and the migrant(s) in the liquid determined by

1.9 This standard does not purport to address all of the

suitable analytical methods.

safety concerns, if any, associated with its use. It is the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction ofASTM Committee D20 on Plastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 10, 2003. Published May 2003. Originally the ASTM website.

approved in 1987. Last previous edition approved in 1998 as D4754 – 98. DOI: Withdrawn.

10.1520/D4754-98R03. Available through theAssociation of OfficialAnalytical Chemists,Washington,

“A Study of Indirect Food Additive Migration,” Arthur D. Little, Inc., FDA DC.

Contract No. 223-77-2360. Available from Chemistry Review Branch, Office of Premarket Approval,

Supporting data have been filed at ASTM International Headquarters and may Center for Food Safety and Applied Nutrition, Food and Drug Administration,

be obtained by requesting Research Report D20-1141. Washington, DC 20204.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

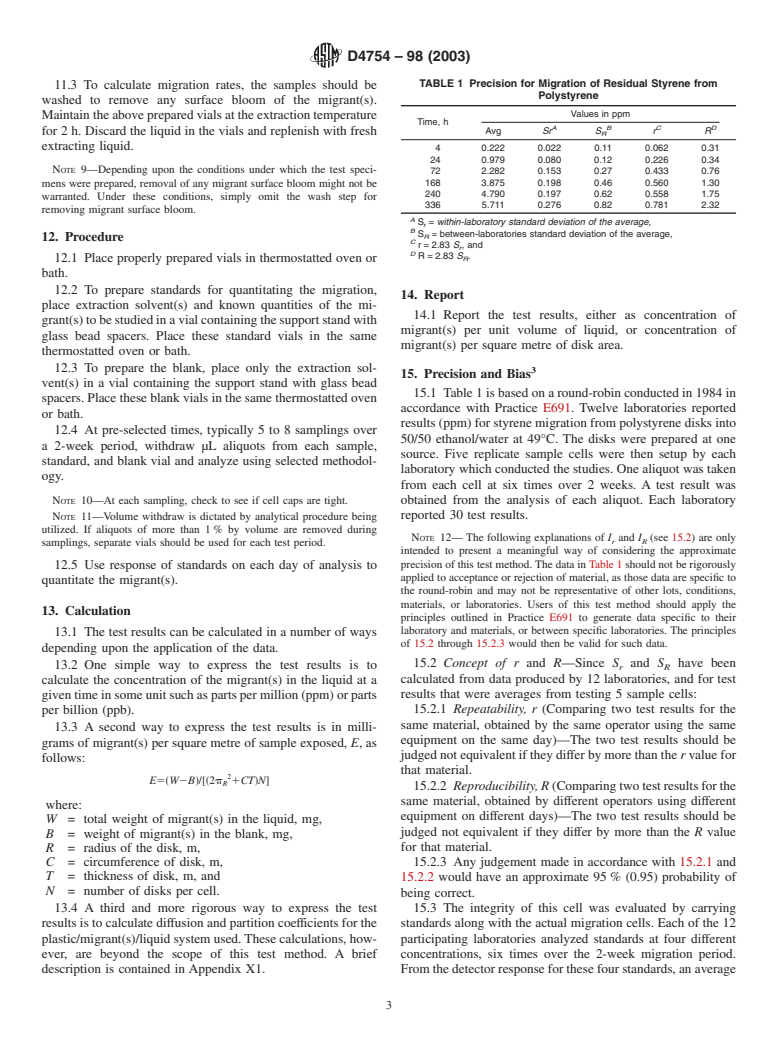

D4754–98 (2003)

,

8 10

6.3 Thermostatted Shaker Water Bath —Some migrant/

plastic/liquid combinations may involve significant partition-

ing and would benefit by having the cells shaken throughout

the migration study.

6.4 Liquid Syringes, for removing liquid aliquots from the

cells and transferring them to the analytical instrumentation.

6.5 Analytical Instrumentation, as required by the method

chosen to determine the migrant(s).

7. Reagents and Materials

7.1 Purity of Reagents—All solvents shall be HPLC or

chromatographicgradeandshowntobefreeofinterferencesin

the detection region of the migrant(s).

8. Hazards

8.1 The usual safety precautions for handling flammable

solvents are recommended when such solvents are used for

extraction.

FIG. 1 FDA Migration Cell

9. Sampling

9.1 Sample the plastic in accordance with Practice D1898.

NOTE 3— Significant migration loss due to volatility may occur if

9.2 Select representative samples of the plastic to be tested

migration is carried out at temperatures exceeding 50°C for periods

from available stock on hand. Film, pellets, powders, sheet,

greater than 2 weeks.

and, in some cases, actual end-use articles are suitable. Protect

the samples from exposure to liquids or contamination by

5. Significance and Use

migration from contact with other materials.

5.1 Knowledge of migrants from plastic materials may

NOTE 6—See D20-1141 for details regarding sample test specimens.

serve many useful purposes, such as testing for compliance

with food additive regulations. The procedure described in this

10. Test Specimen

testmethodisrecommendedassuitableforobtainingsuchdata

10.1 Test specimens in the form of round disks (11 by 1

on many migrant(s)/plastic(s) combinations.

mm) are prepared from the plastic to be tested. Disks can be

stamped out of sheets of actual end-use articles of non-brittle

6. Apparatus

plastic by means of the appropriate sized cork borer. Alterna-

6.1 FDA Migration Cell (Fig. 1), consisting of:

tively, disks can be formed by using a heated press and an

6.1.1 Glass Vials, 23-mL, appropriate shim or mold containing holes the size of the disk.

Holes can be put in the center of the disk by means of a drill

6.1.2 Mininertt Slide Valve Caps,

or a heated wire.

6.1.3 Stainless Steel Wire (20-gage), and

NOTE 7—Whenever possible, plastic from actual end-use articles

6.1.4 Glass Bead (5-mm diameter), containing hole slightly

should be tested.

larger than diameter of stainless steel wire. (Available at local

NOTE 8—When actual end-use articles are tested, the cut edges of the

hobby shops.)

disks may have a different structure than the surfaces, and henceforth the

migration rates may be altered. Because the area of the surfaces is much

NOTE 4—The apparatus, disk size, and number of disks are described

greater than that of the cut edges, the effect of the edges would be limited.

for the 23-mLvial.Alternative vial sizes and corresponding test specimen

If a significant edge effect is suspected, however, tests can be run

sizes may be substituted. (The volume-to-surface area ideally should be

2 comparing disks formed by using a heated press with disks cut from a

between 155 and 0.31 mL/cm .) Note that validation tests have only been

sheet formed under similar conditions.

conducted using the 23-mL vials.

NOTE 5—Recommend one-time use of mininert valve (that is, discard-

11. Preparation of Apparatus

ing it at completion of study).

11.1 Alternatelythreadglassbeadsand14plasticdisksonto

6.2 Hot-Air Oven or Static Thermostatted Water Bath, with

the stainless steel wire (see Fig. 1). Prepare at least 4 sets for

suitable safety provisions and capable of maintaining the

each liquid extractant used. Place resulting stacks of disks into

desired extraction temperature within 61°C.

23 mL glass vials. Add 22 mL of extraction liquid and screw

Mininertt caps tightly onto the vials.

11.2 Use the above prepared vials to determine the total

8 amount of migrant(s).

The sole source of supply of the FDAMigration Cell components known to the

committee at this time is Supelco, Inc., P.O. Box 628, 146 S. Water St., Bellefonte,

PA16823. If you are aware of alternative suppliers, please provide this information

to ASTM International Headquarters. Your comments will receive careful consid- The sole source of supply of the thermostatted shaker water bath known to the

erationatameetingoftheresponsibletechnicalcommittee ,whichyoumayattend. committee at this time is Precision Scientific, 3737 W. Cortland St.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.