ASTM G59-97(2003)

(Test Method)Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements

Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements

SCOPE

1.1 This test method describes an experimental procedure for polarization resistance measurements which can be used for the calibration of equipment and verification of experimental technique. The test method can provide reproducible corrosion potentials and potentiodynamic polarization resistance measurements.

1.2 This test method does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G59–97 (Reapproved 2003)

Standard Test Method for

Conducting Potentiodynamic Polarization Resistance

1

Measurements

ThisstandardisissuedunderthefixeddesignationG 59;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope rapid way to measure the general corrosion rate. Real time

corrosion monitoring is a common application. The technique

1.1 This test method describes an experimental procedure

canalsobeusedasawaytorankalloys,inhibitors,andsoforth

forpolarizationresistancemeasurementswhichcanbeusedfor

in order of resistance to general corrosion.

the calibration of equipment and verification of experimental

3.3 Inthistestmethod,asmallpotentialscan, DE(t),defined

technique. The test method can provide reproducible corrosion

with respect to the corrosion potential (DE=E–E ), is

potentials and potentiodynamic polarization resistance mea- corr

applied to a metal sample. The resultant currents are recorded.

surements.

The polarization resistance, R , of a corroding electrode is

1.2 This test method does not purport to address all of the P

defined from Eq 1 as the slope of a potential versus current

safety concerns, if any, associated with its use. It is the

4

density plot at i=0 (1-4):

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- ]DE

R 5 (1)

S D

p

] i

bility of regulatory limitations prior to use.

i50, dE/dt→0

The current density is given by i. The corrosion current

2. Referenced Documents

density, i , is related to the polarization resistance by the

corr

2.1 ASTM Standards:

Stern-Geary coefficient, B. (3),

G 3 PracticeforConventionsApplicabletoElectrochemical

B

2

6

Measurements in Corrosion Testing

i 5 10 (2)

corr

R

p

G 5 Test Method for Making Potentiostatic and Potentiody-

2 2

2

The dimension of R is ohm-cm , i is muA/cm , and B is

namic Anodic Polarization Measurements p corr

in V. The Stern-Geary coefficient is related to the anodic, b ,

a

G 102 Practice for Calculation of Corrosion Rates and

2

and cathodic, b , Tafel slopes as per Eq 3.

Related Information from Electrochemical Measurements c

2.2 Adjunct:

b b

a c

B 5 (3)

SamplesoftheStandardAISIType430StainlessSteel(UNS 2.303~b 1 b !

a c

3

S43000)

The units of the Tafel slopes are V. The corrosion rate, CR,

in mm per year can be determined from Eq 4 in which EW is

3. Significance and Use

the equivalent weight of the corroding species in grams and r

3.1 This test method can be utilized to verify the perfor- 3

is the density of the corroding material in g/cm .

mance of polarization resistance measurement equipment in-

i EW

corr

–3

cluding reference electrodes, electrochemical cells, poten-

CR 5 3.27 3 10 (4)

r

tiostats, scan generators, measuring and recording devices.The

Refer to Practice G 102 for derivations of the above equa-

test method is also useful for training operators in sample

tions and methods for estimating Tafel slopes.

preparation and experimental techniques for polarization resis-

3.4 The test method may not be appropriate to measure

tance measurements.

polarization resistance on all materials or in all environments.

3.2 Polarization resistance can be related to the rate of

See 8.2 for a discussion of method biases arising from solution

generalcorrosionformetalsatorneartheircorrosionpotential,

resistance and electrode capacitance.

E .Polarizationresistancemeasurementsareanaccurateand

corr

4. Apparatus

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

4.1 The apparatus is described in Test Method G 5. It

of Metals, and is the direct responsibility of Subcommittee G 01.11 on Electro-

includesa1L round bottom flask modified to permit the

chemical Measurements in Corrosion Testing.

Current edition approved Dec. 10, 1997. Published February 1998. Originally

approved in 1978. Last previous edition approved in 1991 as G 59 – 91.

2 4

Annual Book of ASTM Standards, Vol 03.02. The boldface numbers in parentheses refer to the list of references at the end of

3

Available from ASTM Headquarters. Order PCN 12-700050-00. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

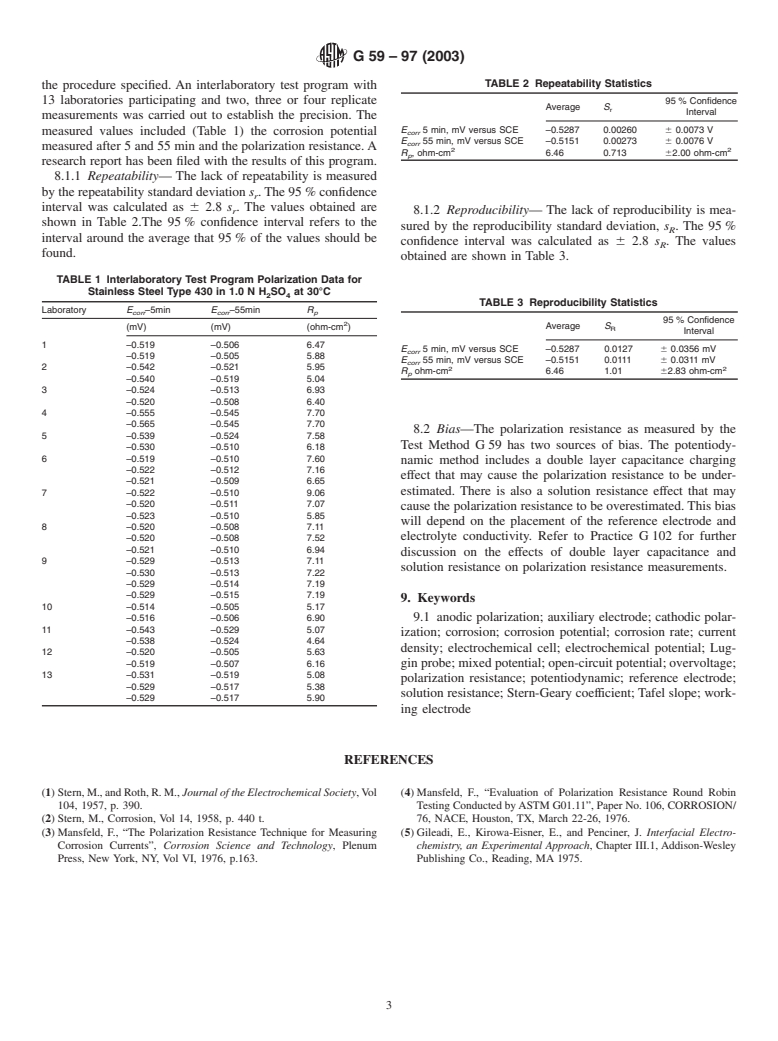

G59–97 (2003)

2

addition of inert gas, thermometer, and electrodes. This stan- surface area of the specimen to the nearest 0.01 cm and

dard cell or an equivalent cell can be used. An equivalent cell subtract for the area under the gasket (typically 0.20 to 0.25

2

must be constructed of inert materials and be able to reproduce cm ).

the standard c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.