ASTM B878-97(2019)

(Test Method)Standard Test Method for Nanosecond Event Detection for Electrical Contacts and Connectors

Standard Test Method for Nanosecond Event Detection for Electrical Contacts and Connectors

SIGNIFICANCE AND USE

4.1 The tests in this test method are designed to assess the resistance stability of electrical contacts or connections.

4.2 The described procedures are for the detection of events that result from short duration, high-resistance fluctuations, or of voltage variations that may result in improper triggering of high speed digital circuits.

4.3 In those procedures, the test currents are 100 mA (±20 mA) when the test sample has a resistance between 0 and 10 Ω. Since the minimum resistance change required to produce an event (defined in 3.2.1) is specified as 10 Ω (see 1.3), the voltage increase required to produce this event must be at least 1.0 V.

4.4 The detection of nanosecond-duration events is considered necessary when an application is susceptible to noise. However, these procedures are not capable of determining the actual duration of the event detected.

4.5 The integrity of nanosecond-duration signals can only be maintained with transmission lines; therefore, contacts in series are connected to a detector channel through coaxial cable. The detector will indicate when the resistance monitored exceeds the minimum event resistance for more than the specified duration.

4.6 The test condition designation corresponding to a specific minimum event duration of 1, 10, or 50 ns is listed in Table 1. These shall be specified in the referencing document.

SCOPE

1.1 This test method describes equipment and techniques for detecting contact resistance transients yielding resistances greater than a specified value and lasting for at least a specified minimum duration.

1.2 The minimum durations specified in this standard are 1, 10, and 50 nanoseconds (ns).

1.3 The minimum sample resistance required for an event detection in this standard is 10 Ω.

1.4 An ASTM guide for measuring electrical contact transients of various durations is available as Guide B854.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B878 − 97 (Reapproved 2019)

Standard Test Method for

Nanosecond Event Detection for Electrical Contacts and

Connectors

This standard is issued under the fixed designation B878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B542 Terminology Relating to Electrical Contacts and Their

Use

1.1 This test method describes equipment and techniques

B854 Guide for Measuring Electrical Contact Intermittences

for detecting contact resistance transients yielding resistances

2.2 Other Standards:

greater than a specified value and lasting for at least a specified

IEC 801-2 ed 2:91

minimum duration.

EN 50 082-1:94

1.2 The minimum durations specified in this standard are 1,

10, and 50 nanoseconds (ns). 3. Terminology

1.3 The minimum sample resistance required for an event 3.1 Definitions—Many terms used in this standard are de-

detection in this standard is 10 Ω. fined in Terminology B542.

1.4 An ASTM guide for measuring electrical contact tran- 3.2 Definitions of Terms Specific to This Standard:

sients of various durations is available as Guide B854. 3.2.1 event, n—a condition in which the sample resistance

increases by more than 10 Ω for more than a specified time

1.5 The values stated in SI units are to be regarded as

duration.

standard. No other units of measurement are included in this

standard.

4. Significance and Use

1.6 This standard does not purport to address all of the

4.1 The tests in this test method are designed to assess the

safety concerns, if any, associated with its use. It is the

resistance stability of electrical contacts or connections.

responsibility of the user of this standard to become familiar

4.2 The described procedures are for the detection of events

with all hazards including those identified in the appropriate

that result from short duration, high-resistance fluctuations, or

Material Safety Data Sheet (MSDS) for this product/material

of voltage variations that may result in improper triggering of

as provided by the manufacturer, to establish appropriate

high speed digital circuits.

safety, health, and environmental practices, and determine the

applicability of regulatory limitations prior to use.

4.3 In those procedures, the test currents are 100 mA (620

1.7 This international standard was developed in accor-

mA) when the test sample has a resistance between 0 and 10 Ω.

dance with internationally recognized principles on standard-

Since the minimum resistance change required to produce an

ization established in the Decision on Principles for the

event (defined in 3.2.1) is specified as 10 Ω (see 1.3), the

Development of International Standards, Guides and Recom-

voltage increase required to produce this event must be at least

mendations issued by the World Trade Organization Technical

1.0 V.

Barriers to Trade (TBT) Committee.

4.4 The detection of nanosecond-duration events is consid-

ered necessary when an application is susceptible to noise.

2. Referenced Documents

However, these procedures are not capable of determining the

2.1 ASTM Standards:

actual duration of the event detected.

4.5 The integrity of nanosecond-duration signals can only

This test method is under the jurisdiction of ASTM Committee B02 on be maintained with transmission lines; therefore, contacts in

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

series are connected to a detector channel through coaxial

B02.05 on Precious Metals and Electrical Contact Materials and Test Methods.

cable. The detector will indicate when the resistance monitored

Current edition approved Nov. 1, 2019. Published November 2019. Originally

exceeds the minimum event resistance for more than the

approved in 1997. Last previous edition approved in 2014 as B878 – 97 (2014).

DOI: 10.1520/B0878-97R19.

specified duration.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B878 − 97 (2019)

4.6 The test condition designation corresponding to a spe-

cific minimum event duration of 1, 10, or 50 ns is listed in

Table 1. These shall be specified in the referencing document.

5. Apparatus

5.1 Detector—The detector used shall be an AnaTech 64

EHD, 32 EHD, or equivalent. The detector shall meet the

following requirements:

5.1.1 Electromagnetic Interference (EMI)—The detector

shall pass the European Community (EC) electrostatic dis-

charge (ESD) requirement for computers (EN 50 082-1:94

based on IEC 801-2, ed. 2:91). The performance criteria is “1)

normal performance within the specification limits;” that is, no

FIG. 1 Equipment Setup for Amplitude Sensitivity Measurement

channel is allowed to trip. Air discharge voltages shall include

2, 4, 8, and 15 kV. Contact discharge voltages shall include 2,

4, 6, and 8 kV. Detector inputs shall be protected with coaxial

shorts.

5.1.2 dc Current—Each channel shall supply 100 6 20 mA

when the sample being tested has a resistance between 0 and 10

Ω.

5.1.3 Input Impedance:

5.1.3.1 Direct Current (dc)—The detector source resistance

(impedance) shall be 50 Ω when the sample resistance is

between 0 and 10 Ω.

5.1.3.2 RF Input Impedance—A Time Domain Reflectome-

ter (TDR) or Network Analyzer Time Domain Reflectometer

(NATDR) shall be used to measure the reflection in percent of

a (simulated) 0.5 ns risetime step when the sample direct

current resistance is 10 Ω and the detector current is 100 mA.

(The 10 Ω sample resistance is put on the bias port for

NATDR.) An acceptable detector shall reflect less than 30 %

amplitude.

5.1.4 Amplitude Sensitivity—Amplitude required to trip the

detector with a 1 nanosecond duration pulse shall be no more

than 120 % of the direct current trip amplitude. One nanosec-

ond pulse duration shall be measured at 90 % of the pulse

NOTE 1—

amplitude, and the rise and fall times shall be less than 0.5 ns. A One square meter EMI loop monitored at top center (see 6.1).

B Connection to series wired sample circuit with the greatest capacitance

Pulse low level shall be 0 V. These shall be measured with a 1

shell or other metal fixturing (see 6.1).

GHz bandwidth oscilloscope and a pulse generator (see Fig. 1).

C Miniature coaxial cable (50 Ω) (see 5.3.1.1).

5.1.4.1 The same requirements shall be met for the 10 and

D Patch panel, coaxial through-bulkhead RF connectors in metal panel.

50 ns detector settings, but the pulse rise and fall times can now

E Short flexible ground strap, 70 mm long and >25 mm wide (see 7.3).

be less than 2 ns. F Strain relief coaxial cable at these locations.

G Physical support for patch panel.

5.1.5 Accuracy—It shall be possible to adjust the detector to

H RG-223 double braid coaxial cable.

trip at 10 6 1 Ω for all channels in use.

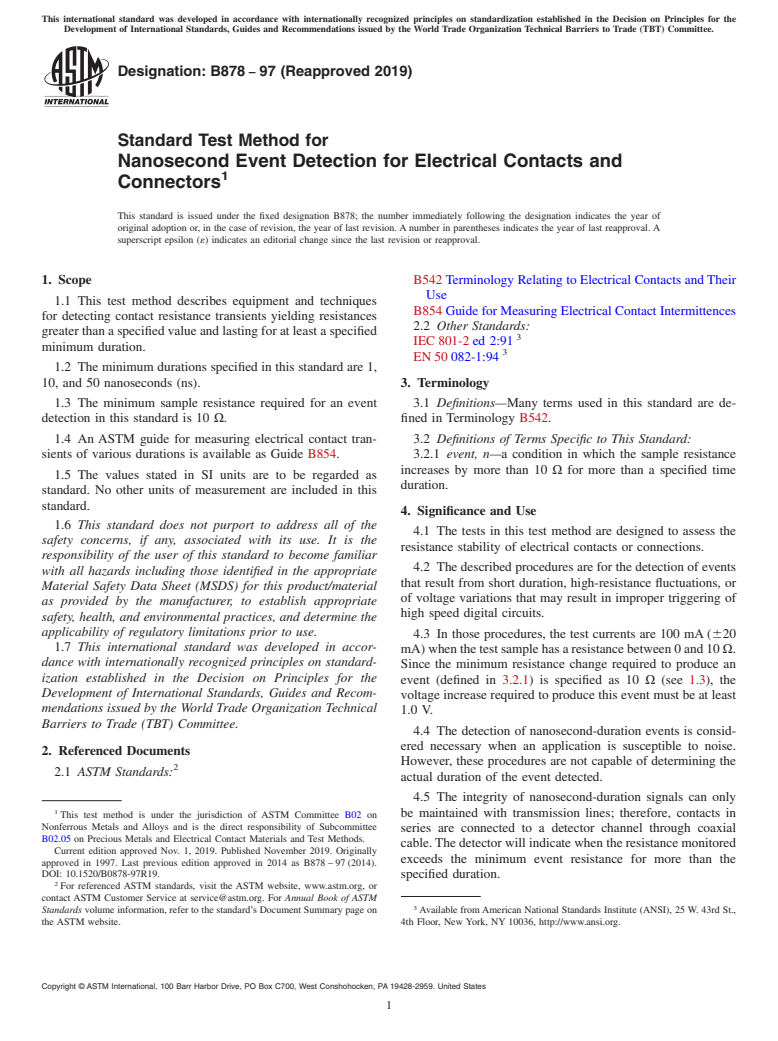

FIG. 2 Ten and Fifty Nanosecond Fixturing

5.2 Test Setup—Recommended equipment is as shown in

Fig. 2. A short flexible ground strap directs ground loop

5.3 Sample and EMI Loop Preparation—The sample circuit

currents away from the sample (see Fig. 2, Note E). The

shall have a resistance of less than 4 Ω.

RG-223 coaxial cable is well shielded whereas the short 50 Ω

5.3.1 Sample Wiring:

miniature coaxial cable is flexible. Each EMI loop is connected

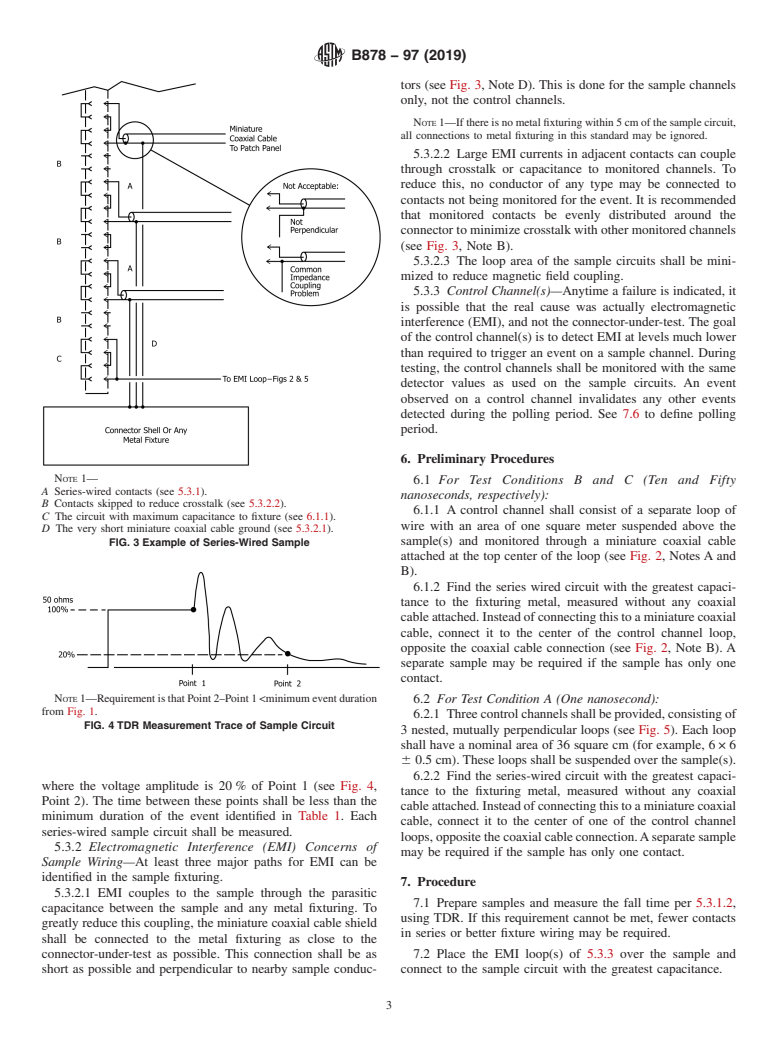

5.3.1.1 A contact or series-wired contacts (see Fig. 3, Note

to a detector channel and is used as a control.

A) shall be wired from the center conductor to the braid of

miniature 50-Ω coaxial cable (see Fig. 2, Note C).

5.3.1.2 The sample, as wired to the miniature coaxial cable

TABLE 1 Test Condition Designations for Specific Minimum

for testing, shall be capable of passing short duration pulses. A

Event Durations

time domain reflectometer (TDR) shall be used to measure the

Test Condition Event Duration, min

transition time of a fast risetime step (<60 ps) reflected from

A 1 nanosecond

the sample under test. On the waveform, find the point

B 10 nanoseconds

representing the far end of the miniature 50-Ω coaxial cable

C 50 nanoseconds

(see Fig. 4, Point 1). Also find the last point on the waveform

B878 − 97 (2019)

tors (see Fig. 3, Note D). This is done for the sample channels

only, not the control channels.

NOTE 1—If there is no metal fixturing within 5 cm of the sample circu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.