ASTM C12-01

(Practice)Standard Practice for Installing Vitrified Clay Pipe Lines

Standard Practice for Installing Vitrified Clay Pipe Lines

SCOPE

1.1 This practice covers the proper methods of installing vitrified clay pipe lines in order to fully utilize the structural properties of such pipe.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 12 – 01

Standard Practice for

1

Installing Vitrified Clay Pipe Lines

This standard is issued under the fixed designation C 12; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope dependent upon two factors: (1) the inherent strength of the

pipe and (2) the bedding of the pipe.

1.1 This practice covers the proper methods of installing

4.2 The minimum bearing strength requirement in accor-

vitrified clay pipe lines in order to fully utilize the structural

dance with Specification C 700, as determined by the 3-edge-

properties of such pipe.

bearing test of Test Methods C 301, is a measure of the

1.2 The values stated in inch-pound units are to be regarded

inherent strength of the pipe.

as the standard. The values given in parentheses are for

4.3 The tests used to measure bearing strength determine

information only.

relative pipe strengths but do not represent actual field condi-

1.3 This standard does not purport to address all of the

tions. Therefore, an adjustment called a load factor is intro-

safety concerns, if any, associated with its use. It is the

duced to convert minimum bearing strength to field supporting

responsibility of the user of this standard to establish appro-

strength. The magnitude of the load factor depends on how the

priate safety and health practices and determine the applica-

pipe is bedded. The relationship is:

bility of regulatory limitations prior to use.

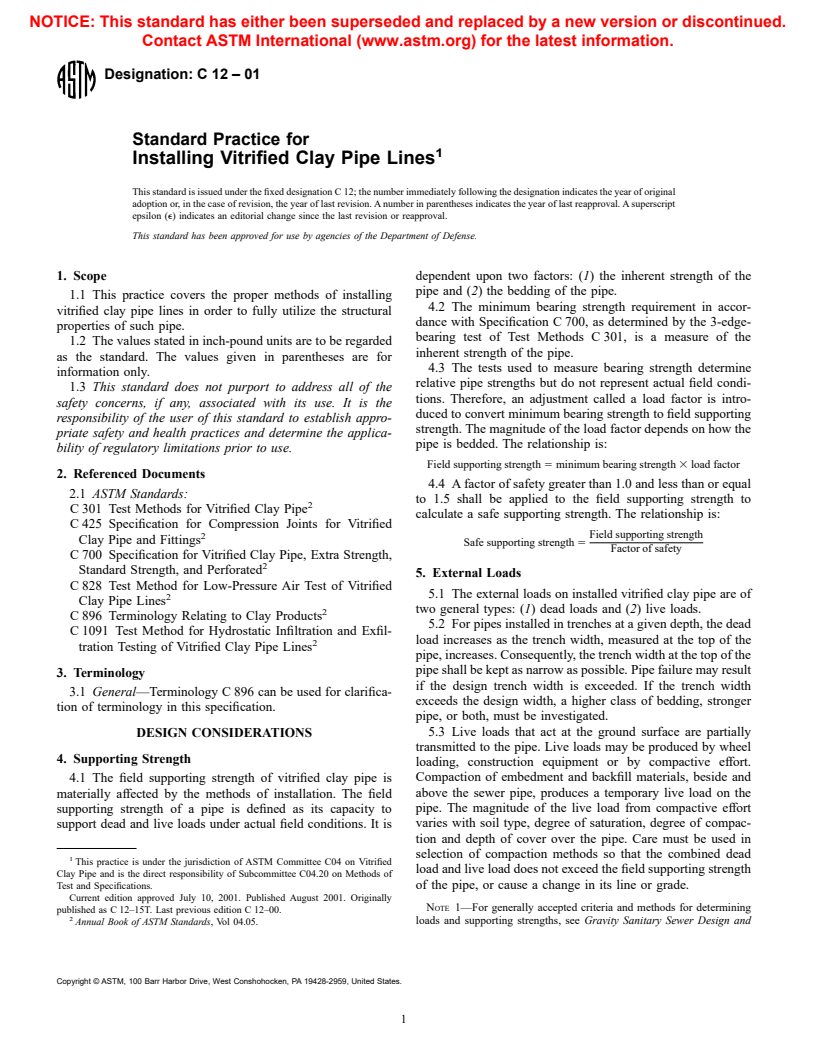

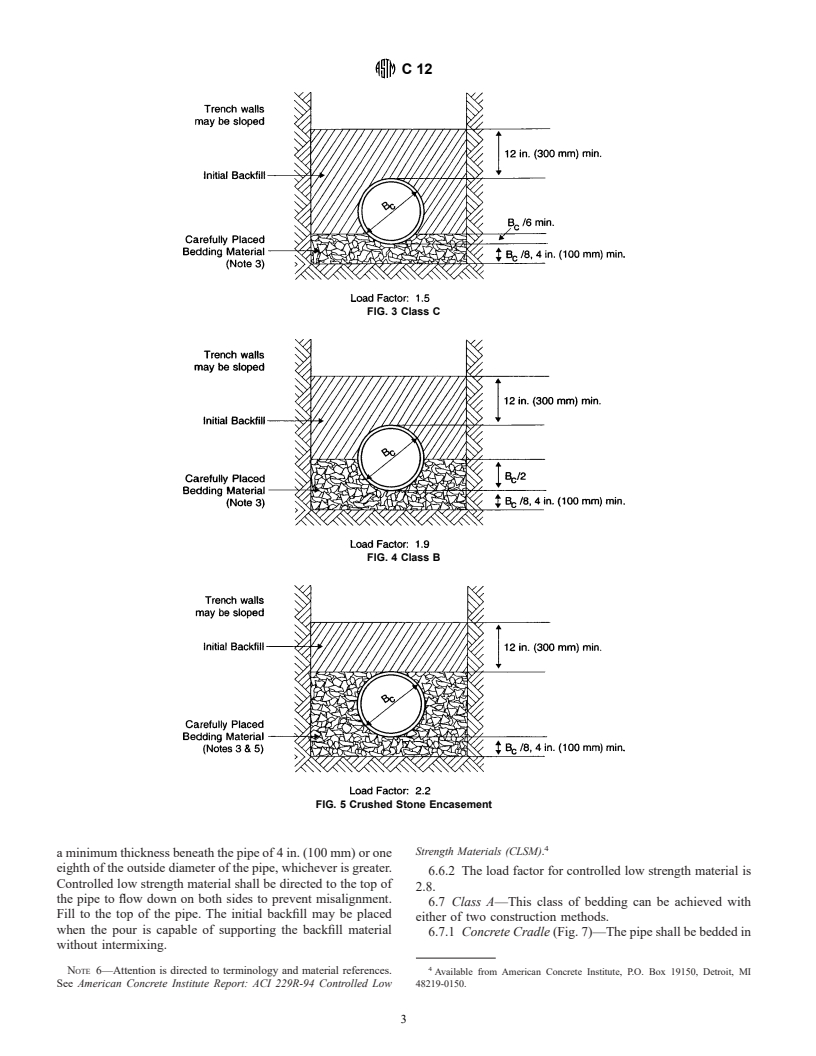

Field supporting strength 5 minimum bearing strength 3 load factor

2. Referenced Documents

4.4 A factor of safety greater than 1.0 and less than or equal

2.1 ASTM Standards:

to 1.5 shall be applied to the field supporting strength to

2

C 301 Test Methods for Vitrified Clay Pipe

calculate a safe supporting strength. The relationship is:

C 425 Specification for Compression Joints for Vitrified

2 Field supporting strength

Clay Pipe and Fittings

Safe supporting strength 5

Factor of safety

C 700 Specification for Vitrified Clay Pipe, Extra Strength,

2

Standard Strength, and Perforated

5. External Loads

C 828 Test Method for Low-Pressure Air Test of Vitrified

5.1 The external loads on installed vitrified clay pipe are of

2

Clay Pipe Lines

two general types: (1) dead loads and (2) live loads.

2

C 896 Terminology Relating to Clay Products

5.2 For pipes installed in trenches at a given depth, the dead

C 1091 Test Method for Hydrostatic Infiltration and Exfil-

load increases as the trench width, measured at the top of the

2

tration Testing of Vitrified Clay Pipe Lines

pipe, increases. Consequently, the trench width at the top of the

pipe shall be kept as narrow as possible. Pipe failure may result

3. Terminology

if the design trench width is exceeded. If the trench width

3.1 General—Terminology C 896 can be used for clarifica-

exceeds the design width, a higher class of bedding, stronger

tion of terminology in this specification.

pipe, or both, must be investigated.

5.3 Live loads that act at the ground surface are partially

DESIGN CONSIDERATIONS

transmitted to the pipe. Live loads may be produced by wheel

4. Supporting Strength

loading, construction equipment or by compactive effort.

4.1 The field supporting strength of vitrified clay pipe is Compaction of embedment and backfill materials, beside and

above the sewer pipe, produces a temporary live load on the

materially affected by the methods of installation. The field

supporting strength of a pipe is defined as its capacity to pipe. The magnitude of the live load from compactive effort

varies with soil type, degree of saturation, degree of compac-

support dead and live loads under actual field conditions. It is

tion and depth of cover over the pipe. Care must be used in

selection of compaction methods so that the combined dead

1

This practice is under the jurisdiction of ASTM Committee C04 on Vitrified

load and live load does not exceed the field supporting strength

Clay Pipe and is the direct responsibility of Subcommittee C04.20 on Methods of

of the pipe, or cause a change in its line or grade.

Test and Specifications.

Current edition approved July 10, 2001. Published August 2001. Originally

NOTE 1—For generally accepted criteria and methods for determining

published as C 12–15T. Last previous edition C 12–00.

2

loads and supporting strengths, see Gravity Sanitary Sewer Design and

Annual Book of ASTM Standards, Vol 04.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C12

6.2.1 The load factor for C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.