ASTM F2838-10

(Practice)Standard Practice for Accelerated Laboratory Aging of Radial Passenger Car and Light Truck Tires through Load Range E for the Laboratory Generation of Belt Separation

Standard Practice for Accelerated Laboratory Aging of Radial Passenger Car and Light Truck Tires through Load Range E for the Laboratory Generation of Belt Separation

SIGNIFICANCE AND USE

This standard practice establishes a method for conducting accelerated laboratory aging of radial passenger or light truck tires, or both, in an oven.

The goal of this practice is to define a scientifically valid protocol for the accelerated laboratory aging of a tire such that certain of its material properties correlate to those of in-service tires (see Appendix X1). This practice does not establish performance limits or tolerances for tire specifications.

SCOPE

1.1 This practice describes a method to laboratory age a new tire in an oven to produce changes in certain chemical and physical properties at the belt edges similar to those of tires in-service (see Appendix X1).

1.2 This practice is a precursor to conducting an ASTM standard roadwheel test method for laboratory generation of belt separation in radial passenger car and light truck tires.

1.3 This practice may not produce representative chemical and physical property changes in any part of the tire except the belt edge.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2838 − 10

Standard Practice for

Accelerated Laboratory Aging of Radial Passenger Car and

Light Truck Tires through Load Range E for the Laboratory

Generation of Belt Separation

This standard is issued under the fixed designation F2838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standards:

ANSI/ISO/IEC 17025 General requirements for the compe-

1.1 Thispracticedescribesamethodtolaboratoryageanew

tence of testing and calibration laboratories

tire in an oven to produce changes in certain chemical and

Compressed Gas Association (CGA) Standard for Valve

physical properties at the belt edges similar to those of tires

Connections V-1

in-service (see Appendix X1).

EIGA IGA 04/09/E Fire Hazards of Oxygen and Oxygen

1.2 This practice is a precursor to conducting an ASTM

Enriched Atmospheres

standard roadwheel test method for laboratory generation of

RMA Volume 4 Tire Service Manual

belt separation in radial passenger car and light truck tires. 6

Tire and Rim Association (T&RA) Year Book

European Tyre and Rim Technical Organisation (ETRTO)

1.3 This practice may not produce representative chemical

and physical property changes in any part of the tire except the Standards Manual

Japan Automobile Tyre Manufacturers Association Inc.

belt edge.

(JATMA) Year Book

1.4 The values stated in SI units are to be regarded as the

ISO 4000 Passenger Car Tyres and Rims

standard. The values given in parentheses are for information

only.

3. Terminology

1.5 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 age, v—toapplyconditionssoastopromotechangeof

responsibility of the user of this standard to establish appro-

material properties.

priate safety and health practices and determine the applica-

3.1.1.1 Discussion—For a tire, this can be done on a

bility of regulatory limitations prior to use. For specific

roadwheel, in a laboratory oven, in service, etc.

precautionary statements, see Section 8.

3.1.2 aging, accelerated laboratory (also: aging, labora-

tory) , n—increasedrateoftirematerialpropertychangesunder

2. Referenced Documents

specified conditions, including temperature, inflation pressure,

2.1 ASTM Standards:

oxygen concentration in the filling gas, and time.

ASTM SI10 - 02 IEEE/ASTM SI 10 American National

3.1.3 aging, in-service, n—materialpropertychangeswithin

StandardforUseoftheInternationalSystemofUnits(SI):

tires due to consumer usage.

The Modern Metric System

3.1.3.1 Discussion—See Appendix X1 for more details.

F538 Terminology Relating to the Characteristics and Per-

3.1.4 aging, oven, n—accelerated laboratory aging in an

formance of Tires

G128 Guide for Control of Hazards and Risks in Oxygen elevated temperature environment.

Enriched Systems

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

1 4

This practice is under the jurisdiction ofASTM Committee F09 on Tires and is Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular) Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

Testing. Available from Rubber Manufacturers Association (RMA), 1400 K St., NW,

Current edition approved May 1, 2010. Published June 2010. DOI: 10.1520/ Suite 900, Washington, DC 20005, http://www.rma.org.

F2838-10. AvailablefromTireandRimAssociation,Inc.(TRA),175MontroseWestAve.,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Suite 150, Copley, OH 44313, http://www.us-tra.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), 1, ch. de

Standards volume information, refer to the standard’s Document Summary page on la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

the ASTM website. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2838 − 10

3.1.5 aging, thermal oxidative, n—the process whereby 6.1.2 Autonomous oven temperature monitoring devices

chemical and physical material properties of a tire change with shall be located within the oven such that the thermal history

exposure to heat and oxygen. for each tire can be characterized.

6.1.3 Oven temperature control mechanisms (including the

3.1.6 belt, in a tire, n—a breaker that substantially restricts

thermostat) shall be calibrated within 61°C per the latest

the carcass in a circumferential direction. F538

requirements of ANSI/ISO/IEC 17025.

3.1.7 belt separation, n—a breakdown of bonding between

6.1.4 Ovens large enough for tires may have a temperature

the belts or plies or tread, or combination thereof. F538

gradientwithinthem.Athermalmapshallbedevelopedforthe

3.1.8 cold inflation pressure, n—thegaugepressureofatire,

oven intended to be used for the laboratory aging of tires, to

measured after equilibration at ambient temperature.

identify positions or regions which are too hot or cold to be

usable, or to identify the need to reduce the thermal gradient.

3.1.9 inflation gas, n—the specific filling medium used to

pressurize the tire cavity and maintain a specified gauge See 11.4 for temperature tolerances.

6.1.4.1 At steady-state conditions, the temperature gradient

pressure (for example, oxygen/nitrogen gas mixture, air).

within the usable oven space shall be stable.Astable tempera-

3.1.10 hot inflation pressure, n—the gauge pressure of a tire

ture gradient can be achieved by, amongst other things, having

after equilibration in an oven, measured between 60 and 80

proper thermal insulation in the oven, appropriate circulation,

min after removal from oven.

and having the door(s) adequately sealed.

3.1.11 measured inflation pressure, n—gauge pressure of a

tire measured at a given time under ambient temperature and

7. Reagents and Materials

barometric pressure source. F538

7.1 An oxygen/nitrogen gas mixture of (50.0 % O / 50.0 %

3.1.12 oven, n—a chamber designed for heating tires in a

N with a 62 % analytical uncertainty) shall be used with a

controlled manner.

maximum moisture content of 200 ppm.

3.1.13 tire, n—a load-bearing ground-contacting circumfer-

8. Hazards

ential attachment to a vehicle wheel. F538

3.1.14 tire, oven-aged, n—a tire that has been subjected to 8.1 Hazards During Tire Oven Aging—The possibility of a

accelerated laboratory aging in an elevated temperature envi- catastrophic loss of air pressure from the tire shall be antici-

pated throughout the procedure. (Warning—Such a pressure

ronment (see 3.1.2).

loss may be accompanied by fragments having a high energy

4. Summary of Practice level being thrown from the tire as well as a pressure wave

radiating from the tire. Adequate safeguards for fire and

4.1 This standard practice requires the use of an oven (as

personalprotectionaswellasover-pressureventilationshallbe

specified in 6.1) to conduct accelerated laboratory aging of a

provided at all times.)

tire. This requires a defined inflation pressure, inflation gas,

oven temperature, and time period.

8.2 Hazards During Tire Oxygen/Nitrogen Gas Mixture

Filling and Replenishment:

4.2 This standard practice was developed to be used to

8.2.1 Regulators and Fittings—Oxygen rated hoses and

prepare tires for conducting anASTM standard test method for

fittings shall be used. The fittings and regulators shall conform

laboratory generation of belt separation in radial passenger car

to the Compressed GasAssociation StandardV-1 requirements

and light truck tires. Use of this practice for other applications

for compressed gases with enriched oxygen concentrations, for

would require validation.

example CGA-296. The hose shall have a working pressure

above the tire inflation pressure specified in this standard. The

5. Significance and Use

hose shall be kept clean and undamaged and should be

5.1 This standard practice establishes a method for conduct-

compatible with the specified oxygen concentration.

ing accelerated laboratory aging of radial passenger or light

8.2.2 Storage of Gas Cylinders—Gas cylinders shall be

truck tires, or both, in an oven.

stored per OSHA guidelines.

5.2 Thegoalofthispracticeistodefineascientificallyvalid

8.2.3 Filling and Venting of Tires—Venting and filling tires

protocol for the accelerated laboratory aging of a tire such that

shall be done in a well ventilated area, away from any ignition

certain of its material properties correlate to those of in-service

sources. Persons who have been exposed to oxygen enriched

tires (see Appendix X1). This practice does not establish

atmosphere should avoid ignition sources until well ventilated,

performance limits or tolerances for tire specifications.

at least 15 min, per EIGA IGA 04/09/E recommendation.

8.2.4 Static Electrical Isolation of Tire/Wheel Assemblies—

6. Apparatus

The tire/wheel assembly shall be electrically grounded during

fill/vent to prevent any static discharge.

6.1 Use of an oven is specified in this section, defining the

requirements such that tires may be exposed to a controlled

9. Sampling and Specimens

temperature. Provisions for monitoring other environmental

conditions (for example, humidity) are also recommended. 9.1 All of the tires in a sample lot shall have the desired

6.1.1 Oven configuration shall be such that tires may be production plant and date codes and similar storage and

positioned without contacting other tires or oven walls, ceiling temperature history exposure.Tires must be free of molding or

or floor. other defects.

F2838 − 10

9.2 New tires (not previously used or inflated) shall be used pressure, shall remain at the ambient temperature of the test

in this standard practice and shall be selected so that they are room for at least 24 h prior to testing.

no less than 2 weeks and no greater than 39 weeks from time 11.1.7 Testing for leaks is suggested. Leak checks can be

of manufacture. conducted by either submersion in a water tank for at least 30

min or by carefully checking both beads and fittings for leaks

9.3 Test tires shall be mounted on wheels for testing, of the

with leak detection fluid. If a light alloy wheel is used, the

measuring rim width, if available. The same wheel should be

entire wheel assembly must be checked for leaks.

used for both oven aging and roadwheel testing without

11.1.8 Using the oxygen/nitrogen gas mixture, inflate the

dismounting, to prevent any damage incurred through removal

tires as follows:

of the tire from the wheel. If the appropriate rim size is not

11.1.8.1 Vent air-filled tire to atmospheric pressure,

available, the operator shall use an alternate size per current

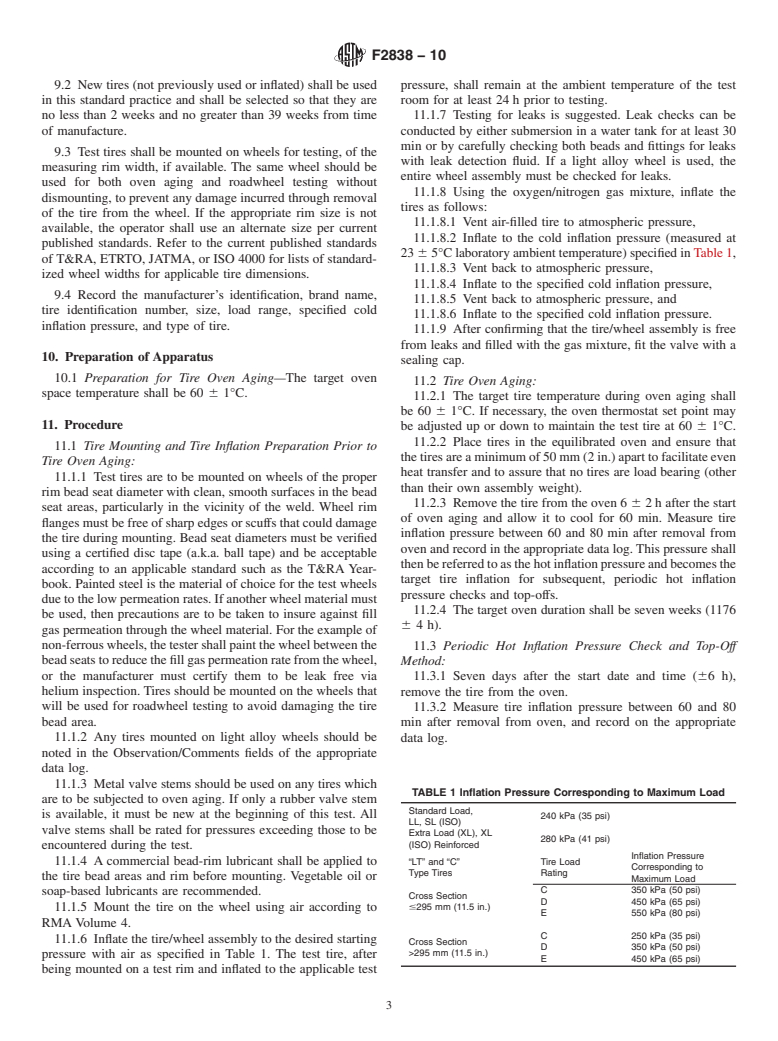

11.1.8.2 Inflate to the cold inflation pressure (measured at

published standards. Refer to the current published standards

23 65°Claboratoryambienttemperature)specifiedinTable1,

of T&RA, ETRTO, JATMA, or ISO 4000 for lists of standard-

11.1.8.3 Vent back to atmospheric pressure,

ized wheel widths for applicable tire dimensions.

11.1.8.4 Inflate to the specified cold inflation pressure,

9.4 Record the manufacturer’s identification, brand name,

11.1.8.5 Vent back to atmospheric pressure, and

tire identification number, size, load range, specified cold

11.1.8.6 Inflate to the specified cold inflation pressure.

inflation pressure, and type of tire.

11.1.9 After confirming that the tire/wheel assembly is free

from leaks and filled with the gas mixture, fit the valve with a

10. Preparation of Apparatus

sealing cap.

10.1 Preparation for Tire Oven Aging—The target oven

11.2 Tire Oven Aging:

space temperature shall be 60 6 1°C.

11.2.1 The target tire temperature during oven aging shall

be 60 6 1°C. If necessary, the oven thermostat set point may

11. Procedure

be adjusted up or down to maintain the test tire at 60 6 1°C.

11.2.2 Place tires in the equilibrated oven and ensure that

11.1 Tire Mounting and Tire Inflation Preparation Prior to

thetiresareaminimumof50mm(2in.)aparttofacilitateeven

Tire Oven Aging:

heat transfer and to assure that no tires are load bearing (other

11.1.1 Test tires are to be mounted on wheels of the proper

than their own assembly weight).

rim bead seat diameter with clean, smooth surfaces in the bead

11.2.3 Remove the tire from the oven 6 6 2 h after the start

seat areas, particularly in the vicinity of the weld. Wheel rim

of oven aging and allow it to cool for 60 min. Measure tire

flangesmustbefreeofsharpedgesorscuffsthatcoulddamage

inflation pressure between 60 and 80 min after removal from

the tire during mounting. Bead seat diameters must be verified

oven and record in the appropriate data log.This pressure shall

using a certified disc tape (a.k.a. ball tape) and be acceptable

thenbereferredtoasthehotinflationpressureandbecomesthe

according to an applicable standard such as the T&RA Year-

target tire inflation for subsequent, periodic hot inflation

book. Painted steel is the material of choice for the test wheels

pressure checks and top-offs.

duetothelowpermeationrates.Ifanotherwheelmaterialmust

11.2.4 The target oven duration shall be seven weeks (1176

be used, then precautions are to be taken to insure against fill

6 4 h).

gas permeation through the wheel material. For the example of

non-ferrouswheels,thetestershallpaintthewheelbetweenthe 11.3 Periodic Hot Inflation Pressure Check and Top-Off

beadseatstoreducethefillgaspermeationratefromthewheel,

Method:

or the manufacturer must certify them to be leak free via 11.3.1 Seven days after the start date and time (66 h),

helium inspection. Tires should be mounted on the wheels that

remove the tire from the oven.

will be used for roadwheel testing to avoid damaging the tire 11.3.2 Measure tire inflation pressure between 60 and 80

bead area.

min after removal from oven, and record on the appropriate

11.1.2 Any tires mounted on light alloy wheels should be data log.

noted in the Observation/Comments fields of the appropriate

data log.

11.1.3 Metal valve stems should be used on any tires which

TABLE 1 Inflation Pressure Corresponding to Maximum Load

are to be subjected to oven aging. If only a rubber valve stem

Standard Load,

is available, it must be new at the beginning of this test. All

240 kPa (35 psi)

LL, SL (ISO)

valve stems shall be rated for pressures exceeding those to be

Extra Load (XL), XL

280 kPa (41 psi)

(ISO) Reinforced

encountered during the test.

Inflation Pressure

11.1.4 A commercial bead-rim lubricant shall be applied to “LT”

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.