ASTM D1250-08(2013)e1

(Guide)Standard Guide for Use of the Petroleum Measurement Tables

Standard Guide for Use of the Petroleum Measurement Tables

SIGNIFICANCE AND USE

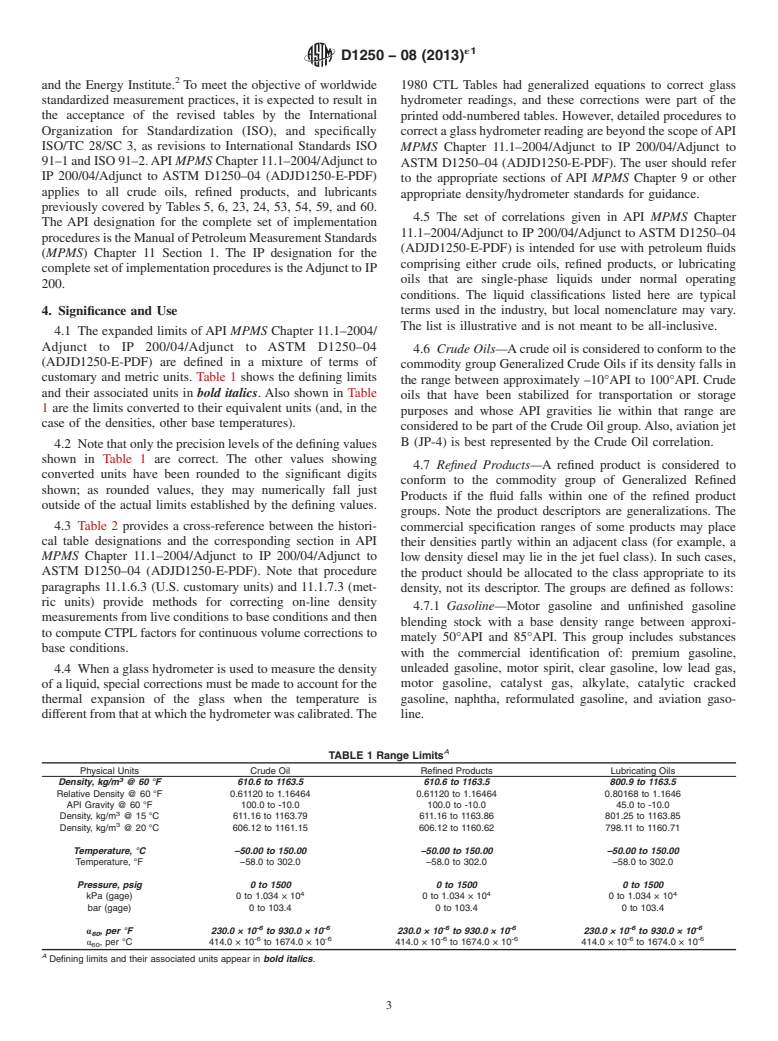

4.1 The expanded limits of API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF) are defined in a mixture of terms of customary and metric units. Table 1 shows the defining limits and their associated units in bold italics. Also shown in Table 1 are the limits converted to their equivalent units (and, in the case of the densities, other base temperatures).

4.2 Note that only the precision levels of the defining values shown in Table 1 are correct. The other values showing converted units have been rounded to the significant digits shown; as rounded values, they may numerically fall just outside of the actual limits established by the defining values.

4.3 Table 2 provides a cross-reference between the historical table designations and the corresponding section in API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF). Note that procedure paragraphs 11.1.6.3 (U.S. customary units) and 11.1.7.3 (metric units) provide methods for correcting on-line density measurements from live conditions to base conditions and then to compute CTPL factors for continuous volume corrections to base conditions.

4.4 When a glass hydrometer is used to measure the density of a liquid, special corrections must be made to account for the thermal expansion of the glass when the temperature is different from that at which the hydrometer was calibrated. The 1980 CTL Tables had generalized equations to correct glass hydrometer readings, and these corrections were part of the printed odd-numbered tables. However, detailed procedures to correct a glass hydrometer reading are beyond the scope of API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF). The user should refer to the appropriate sections of API MPMS Chapter 9 or other appropriate density/hydrometer standards for guidance.

4.5 The set of correlations given in API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to AST...

SCOPE

1.1 The API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF) for temperature and pressure volume correction factors for generalized crude oils, refined products, and lubricating oils, provides the algorithm and implementation procedure for the correction of temperature and pressure effects on density and volume of liquid hydrocarbons. Natural gas liquids (NGLs) and liquefied petroleum gases (LPGs) are excluded from consideration. The combination of density and volume correction factors for both temperature and pressure is collectively referred to in the standard/adjunct(s) as a Correction for Temperature and Pressure of a Liquid (CTPL). The temperature portion of this correction is termed the Correction for the effect of Temperature on Liquid (CTL), also historically known as VCF (Volume Correction Factor). The pressure portion is termed the Correction for the effect of Pressure on Liquid (CPL). As this standard will be applied to a variety of applications, the output parameters specified in this standard/adjunct(s) (CTL, Fp, CPL, and CTPL) may be used as specified in other standards.

1.2 Including the pressure correction in API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF) represents an important change from the “temperature only” correction factors given in the 1980 Petroleum Measurement Tables. However, if the pressure is one atmosphere (the standard pressure) then there is no pressure correction and the standard/adjunct(s) will give CTL values consistent with the 1980 Petroleum Measurement Tables.

1.3 API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF) covers general procedures for the conversion of input data to generate CTL, Fp, CPL, and CTPL values at the user specified base temperature and pressure (Tb, Pb). Two sets of procedures are included for computing volume correction factor: one set for...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D1250 − 08 (Reapproved 2013)

Designation: 200/08

Standard Guide for

Use of the Petroleum Measurement Tables

This standard is issued under the fixed designation D1250; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Adjunct ADJD1250-E-PDF information was corrected editorially in October 2015.

INTRODUCTION

This guide discusses the use of temperature and pressure volume correction factors for generalized

crude oils, refined products, and lubricating oils, developed jointly by ASTM International, the

American Petroleum Institute (API) and the Energy Institute.

The volume correction factors, in their basic form, are the output of a set of equations derived from,

and based on, empirical data relating to the volumetric change of hydrocarbons over a range of

temperatures and pressures. Traditionally, the factors have been listed in tabular format called the

Petroleum Measurement Tables (hence the appearance of this term in the title), and published as an

API Standard/Adjunct to IP 200/Adjunct to ASTM D1250. However, since the 1980 revision the

actual standard has been a set of implementation procedures, not printed tables nor simply a set of

equations.

This revised standard, API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM

D1250–04 (ADJD1250-E-PDF), establishes procedures for crude oils, liquid refined products, and

lubricating oils, by which volume measurements taken at any temperature and pressure (within the

range of the standard) can be corrected to an equivalent volume at base/standard conditions, normally

15°C, 60°F or 20°C, by use of a volume correction factor (VCF). The standard, API MPMS Chapter

11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF), also provides

methods for making conversions to alternate conditions from base conditions and to alternate base

temperatures. Densities can be corrected by using the inverse of the VCF.

See Section 5 for a list of significant changes from Guide D1250–80 (provided in its entirety in

Annex A1 ).

USAGE GUIDELINES

The revised standard, API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM

D1250–04 (ADJD1250-E-PDF), is effective upon the date of publication and supersedes the previous

edition of the standard/adjunct(s). However, due to the nature of the changes in the revised

standard/adjunct(s), it is recognized that guidance concerning an implementation period may be

needed in order to avoid disruptions within the industry and ensure proper application. As a result, it

is recommended that the revised standard/adjunct(s) be used on all new applications no later than two

years after the publication date (May 2004). An application for this purpose is defined as the point

where the calculation is applied.

Once the revised standard/adjunct(s) is implemented in a particular application, the previous

standard will no longer be used in that application.

If an existing application complies with the previous standard/adjunct(s) (as referenced in Annex

A1 ), then it shall be considered in compliance with the revised standard/adjunct(s).

However, the use of the API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM

D1250–04 (ADJD1250-E-PDF) remains voluntary, and the decision on when to utilize a standard is

an issue that is subject to the negotiations between the parties involved in the transaction.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1250 − 08 (2013)

2007 UPDATE

Some minor modifications to the API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to

ASTM D1250–04 (ADJD1250-E-PDF) have been issued in Addendum 1-2007. These modifications

totheadjunctnecessitatedarealignmentwithASTMStandardGuideD1250,hencean-07versionhas

been approved and published.

This guide is under the jurisdiction ofASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and theAPI Committee on Petroleum Measurement,

and is the direct responsibility of Subcommittee D02.02 /COMQ the joint ASTM-API Committee on Hydrocarbon Measurement for Custody Transfer (Joint ASTM-API).

This guide has been approved by the sponsoring committees and was accepted by the Cooperating Societies in accordance with established procedures.

Current edition approved Oct. 1, 2013. Published October 2013. Originally approved in 1952, replacing former D206 and D1090. Last previous edition approved in 2008

as D1250 – 08. DOI: 10.1520/D1250-08R13E01.

The organization that publishes IP test methods and guides.

The 1980 edition of the Petroleum Measurement Tables may still be in use (see the Introduction and Usage Guidelines). For that reason, Guide D1250–80 has been

included as this mandatory annex.

1. Scope 1.4 The procedures recognize three distinct commodity

groups: crude oil, refined products, and lubricating oils. A

1.1 The API MPMS Chapter 11.1–2004/Adjunct to IP 200/

procedure is also provided for determining volume correction

04/Adjunct toASTM D1250–04 (ADJD1250-E-PDF) for tem-

for special applications where the generalized commodity

peratureandpressurevolumecorrectionfactorsforgeneralized

groups’ parameters may not adequately represent the thermal

crude oils, refined products, and lubricating oils, provides the

expansion properties of the liquid and a precise thermal

algorithm and implementation procedure for the correction of

expansion coefficient has been determined by experiment.

temperature and pressure effects on density and volume of

liquid hydrocarbons. Natural gas liquids (NGLs) and liquefied 2. Referenced Documents

petroleum gases (LPGs) are excluded from consideration. The

2.1 API Standards:

combination of density and volume correction factors for both

API Manual of Petroleum Measurement Standards (MPMS):

temperature and pressure is collectively referred to in the

Chapter 11.1–2004 Temperature and Pressure Volume Cor-

standard/adjunct(s) as a Correction for Temperature and Pres-

rection Factors for Generalized Crude Oils, Refined

sure of a Liquid (CTPL). The temperature portion of this

Products, and Lubricating Oils (including Addendum

correction is termed the Correction for the effect of Tempera-

1-2007)

ture on Liquid (CTL), also historically known asVCF (Volume

Chapter 11.2.1 Compressibility Factors for Hydrocarbons:

Correction Factor). The pressure portion is termed the Correc-

0–90° API Gravity Range

tionfortheeffectofPressureonLiquid(CPL).Asthisstandard

Chapter 11.2.1M Compressibility Factors for Hydrocarbons:

will be applied to a variety of applications, the output param-

638–1074 Kilograms per Cubic Meter Range

eters specified in this standard/adjunct(s) (CTL, F , CPL, and

p Chapter 11.5 Density/Weight/Volume Intraconversion

CTPL) may be used as specified in other standards.

2.2 ISO Standards:

ISO 91–1:1992 Petroleum measurement tables—Part 1:

1.2 Including the pressure correction inAPI MPMS Chapter

Tables based on reference temperatures of 15°C and 60°F

11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04

ISO 91–2:1991 Petroleum measurement tables—Part 2:

(ADJD1250-E-PDF) represents an important change from the

Tables based on a reference temperature of 20°C

“temperature only” correction factors given in the 1980 Petro-

2.3 ASTM Adjuncts:

leum Measurement Tables. However, if the pressure is one

Adjunct to ASTM D1250: ADJD1250-E-PDF—

atmosphere (the standard pressure) then there is no pressure

Temperature and Pressure Volume Correction Factors for

correction and the standard/adjunct(s) will give CTL values

Generalized Crude Oils, Refined Products, and Lubricat-

consistent with the 1980 Petroleum Measurement Tables.

ing Oils

1.3 API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/

Adjunct to ASTM D1250: ADJD1250CD2 – Density/

Adjunct to ASTM D1250–04 (ADJD1250-E-PDF) covers Weight/Volume Intraconversion

general procedures for the conversion of input data to generate

3. Sponsorship

CTL, F , CPL, and CTPL values at the user specified base

p

temperature and pressure (T , P ). Two sets of procedures are 3.1 The revision of the ASTM/API/IP set of implementa-

b b

included for computing volume correction factor: one set for tion procedures is the result of close cooperation between

data expressed in customary units (temperature in °F, pressure ASTM International, the American Petroleum Institute (API),

in psig); the other for the metric system of units (temperature

in°C,pressureinkPaorbar).Incontrasttothe1980Petroleum

Available on CD-ROM from API. Order Product Number H11013.

Measurement Tables, the metric procedures require the proce-

Available on CD-ROM from API. Order Product Number H1105CD.

Available from ASTM International Headquarters. Order Adjunct No.

dure for customary units be used first to compute density at

ADJD1250-E-PDF. Original adjunct produced in 2004. Adjunct last revised in

60°F. This value is then further corrected to give the metric

2007.

output. The metric procedures now incorporate the base 7

Available on CD-ROM fromASTM International Headquarters. OrderAdjunct

temperature of 20 °C in addition to 15 °C. No. ADJD1250CD2. Original adjunct produced in 2009.

´1

D1250 − 08 (2013)

and the Energy Institute. To meet the objective of worldwide 1980 CTL Tables had generalized equations to correct glass

standardized measurement practices, it is expected to result in hydrometer readings, and these corrections were part of the

the acceptance of the revised tables by the International

printed odd-numbered tables. However, detailed procedures to

Organization for Standardization (ISO), and specifically correctaglasshydrometerreadingarebeyondthescopeofAPI

ISO/TC 28/SC 3, as revisions to International Standards ISO

MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to

91–1 and ISO 91–2.API MPMS Chapter 11.1–2004/Adjunct to

ASTM D1250–04 (ADJD1250-E-PDF). The user should refer

IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250-E-PDF)

to the appropriate sections of API MPMS Chapter 9 or other

applies to all crude oils, refined products, and lubricants

appropriate density/hydrometer standards for guidance.

previously covered by Tables 5, 6, 23, 24, 53, 54, 59, and 60.

4.5 The set of correlations given in API MPMS Chapter

The API designation for the complete set of implementation

11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04

proceduresistheManualofPetroleumMeasurementStandards

(ADJD1250-E-PDF) is intended for use with petroleum fluids

(MPMS) Chapter 11 Section 1. The IP designation for the

comprising either crude oils, refined products, or lubricating

complete set of implementation procedures is theAdjunct to IP

oils that are single-phase liquids under normal operating

200.

conditions. The liquid classifications listed here are typical

4. Significance and Use terms used in the industry, but local nomenclature may vary.

The list is illustrative and is not meant to be all-inclusive.

4.1 The expanded limits ofAPI MPMS Chapter 11.1–2004/

Adjunct to IP 200/04/Adjunct to ASTM D1250–04

4.6 Crude Oils—Acrude oil is considered to conform to the

(ADJD1250-E-PDF) are defined in a mixture of terms of

commodity group Generalized Crude Oils if its density falls in

customary and metric units. Table 1 shows the defining limits

the range between approximately –10°API to 100°API. Crude

and their associated units in bold italics. Also shown in Table

oils that have been stabilized for transportation or storage

1 are the limits converted to their equivalent units (and, in the

purposes and whose API gravities lie within that range are

case of the densities, other base temperatures).

considered to be part of the Crude Oil group.Also, aviation jet

B (JP-4) is best represented by the Crude Oil correlation.

4.2 Note that only the precision levels of the defining values

shown in Table 1 are correct. The other values showing

4.7 Refined Products—A refined product is considered to

converted units have been rounded to the significant digits

conform to the commodity group of Generalized Refined

shown; as rounded values, they may numerically fall just

Products if the fluid falls within one of the refined product

outside of the actual limits established by the defining values.

groups. Note the product descriptors are generalizations. The

4.3 Table 2 provides a cross-reference between the histori-

commercial specification ranges of some products may place

cal table designations and the corresponding section in API

their densities partly within an adjacent class (for example, a

MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to

low density diesel may lie in the jet fuel class). In such cases,

ASTM D1250–04 (ADJD1250-E-PDF). Note that procedure

the product should be allocated to the class appropriate to its

paragraphs 11.1.6.3 (U.S. customary units) and 11.1.7.3 (met-

density, not its descriptor. The groups are defined as follows:

ric units) provide methods for correcting on-line density

4.7.1 Gasoline—Motor gasoline and unfinished gasoline

measurements from live conditions to base conditions and then

blending stock with a base density range between approxi-

to compute CTPLfactors for continuous volume corrections to

mately 50°API and 85°API. This group includes substances

base conditions.

with the commercial identification of: premium gasoline,

4.4 When a glass hydrometer is used to measure the density unleaded gasoline, motor spirit, clear gasoline, low lead gas,

of a liquid, special corrections must be made to account for the motor gasoline, catalyst gas, alkylate, catalytic cracked

thermal expansion of the glass when the temperature is gasoline, naphtha, reformulated gasoline, and aviation gaso-

differentfromthatatwhichthehydrometerwascalibrated.The line.

A

TABLE 1 Range Limits

Physical Units Crude Oil Refined Products Lubricating Oils

Density, kg/m @ 60 °F 610.6 to 1163.5 610.6 to 1163.5 800.9 to 1163.5

Relative Density @ 60 °F 0.61120 to 1.16464 0.61120 to 1.16464 0.80168 to 1.1646

API Gravity @ 60 °F 100.0 to -10.0 100.0 to -10.0 45.0 to -10.0

Density, kg/m @ 15 °C 611.16 to 1163.79 611.16 to 1163.86 801.25 to 1163.85

Density, kg/m @ 20 °C 606.12 to 1161.15 606.12 to 1160.62 798.11 to 1160.71

Temperature, °C –50.00 to 150.00 –50.00 to 150.00 –50.00 to 150.00

Temperature, °F –58.0 to 302.0 –58.0 to 302.0 –58.0 to 302.0

Pressure, psig 0 to 1500 0 to 1500 0 to 1500

4 4 4

kPa (gage) 0 to 1.034 × 10 0to1.034×10 0to1.034×10

bar (gage) 0 to 103.4 0 to 103.4 0 to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1250 − 08 (Reapproved 2013) D1250 − 08 (Reapproved 2013)

Designation: 200/08

Standard Guide for

Use of the Petroleum Measurement Tables

This standard is issued under the fixed designation D1250; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Adjunct ADJD1250-E-PDF information was corrected editorially in October 2015.

INTRODUCTION

This guide discusses the use of temperature and pressure volume correction factors for generalized

crude oils, refined products, and lubricating oils, developed jointly by ASTM International, the

American Petroleum Institute (API) and the Energy Institute.

The volume correction factors, in their basic form, are the output of a set of equations derived from,

and based on, empirical data relating to the volumetric change of hydrocarbons over a range of

temperatures and pressures. Traditionally, the factors have been listed in tabular format called the

Petroleum Measurement Tables (hence the appearance of this term in the title), and published as an

API Standard/Adjunct to IP 200/Adjunct to ASTM D1250. However, since the 1980 revision the

actual standard has been a set of implementation procedures, not printed tables nor simply a set of

equations.

This revised standard, API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM

D1250–04 (ADJD1250CD),(ADJD1250-E-PDF), establishes procedures for crude oils, liquid refined

products, and lubricating oils, by which volume measurements taken at any temperature and pressure

(within the range of the standard) can be corrected to an equivalent volume at base/standard

conditions, normally 15°C, 60°F or 20°C, by use of a volume correction factor (VCF). The standard,

API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250CD),

(ADJD1250-E-PDF), also provides methods for making conversions to alternate conditions from base

conditions and to alternate base temperatures. Densities can be corrected by using the inverse of the

VCF.

See Section 5 for a list of significant changes from Guide D1250–80 (provided in its entirety in

Annex A1 ).

USAGE GUIDELINES

The revised standard, API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM

D1250–04 (ADJD1250CD),(ADJD1250-E-PDF), is effective upon the date of publication and

supersedes the previous edition of the standard/adjunct(s). However, due to the nature of the changes

in the revised standard/adjunct(s), it is recognized that guidance concerning an implementation period

may be needed in order to avoid disruptions within the industry and ensure proper application. As a

result, it is recommended that the revised standard/adjunct(s) be used on all new applications no later

than two years after the publication date (May 2004). An application for this purpose is defined as the

point where the calculation is applied.

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on Petroleum Measurement,

and is the direct responsibility of Subcommittee D02.02 /COMQ the joint ASTM-API Committee on Hydrocarbon Measurement for Custody Transfer (Joint ASTM-API).

This guide has been approved by the sponsoring committees and was accepted by the Cooperating Societies in accordance with established procedures.

Current edition approved Oct. 1, 2013. Published October 2013. Originally approved in 1952, replacing former D206 and D1090. Last previous edition approved in 2008

as D1250 – 08. DOI: 10.1520/D1250-08R13.10.1520/D1250-08R13E01.

The organization that publishes IP test methods and guides.

The 1980 edition of the Petroleum Measurement Tables may still be in use (see the Introduction and Usage Guidelines). For that reason, Guide D1250–80 has been

included as this mandatory annex.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1250 − 08 (2013)

Once the revised standard/adjunct(s) is implemented in a particular application, the previous

standard will no longer be used in that application.

If an existing application complies with the previous standard/adjunct(s) (as referenced in Annex

A1 ), then it shall be considered in compliance with the revised standard/adjunct(s).

However, the use of the API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM

D1250–04 (ADJD1250CD)(ADJD1250-E-PDF) remains voluntary, and the decision on when to

utilize a standard is an issue that is subject to the negotiations between the parties involved in the

transaction.

´1

D1250 − 08 (2013)

2007 UPDATE

Some minor modifications to the API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to

ASTM D1250–04 (ADJD1250CD)(ADJD1250-E-PDF) have been issued in Addendum 1-2007.

These modifications to the adjunct necessitated a realignment with ASTM Standard Guide D1250,

hence an -07 version has been approved and published.

1. Scope

1.1 The API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250CD)(ADJD1250-E-

PDF) for temperature and pressure volume correction factors for generalized crude oils, refined products, and lubricating oils,

provides the algorithm and implementation procedure for the correction of temperature and pressure effects on density and volume

of liquid hydrocarbons. Natural gas liquids (NGLs) and liquefied petroleum gases (LPGs) are excluded from consideration. The

combination of density and volume correction factors for both temperature and pressure is collectively referred to in the

standard/adjunct(s) as a Correction for Temperature and Pressure of a Liquid (CTPL). The temperature portion of this correction

is termed the Correction for the effect of Temperature on Liquid (CTL), also historically known as VCF (Volume Correction

Factor). The pressure portion is termed the Correction for the effect of Pressure on Liquid (CPL). As this standard will be applied

to a variety of applications, the output parameters specified in this standard/adjunct(s) (CTL, F , CPL, and CTPL) may be used

p

as specified in other standards.

1.2 Including the pressure correction in API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04

(ADJD1250CD)(ADJD1250-E-PDF) represents an important change from the “temperature only” correction factors given in the

1980 Petroleum Measurement Tables. However, if the pressure is one atmosphere (the standard pressure) then there is no pressure

correction and the standard/adjunct(s) will give CTL values consistent with the 1980 Petroleum Measurement Tables.

1.3 API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250CD)(ADJD1250-E-PDF)

covers general procedures for the conversion of input data to generate CTL, F , CPL, and CTPL values at the user specified base

p

temperature and pressure (T ,P ). Two sets of procedures are included for computing volume correction factor: one set for data

b b

expressed in customary units (temperature in °F, pressure in psig); the other for the metric system of units (temperature in °C,

pressure in kPa or bar). In contrast to the 1980 Petroleum Measurement Tables, the metric procedures require the procedure for

customary units be used first to compute density at 60°F. This value is then further corrected to give the metric output. The metric

procedures now incorporate the base temperature of 20°C20 °C in addition to 15°C.15 °C.

1.4 The procedures recognize three distinct commodity groups: crude oil, refined products, and lubricating oils. A procedure is

also provided for determining volume correction for special applications where the generalized commodity groups’ parameters

may not adequately represent the thermal expansion properties of the liquid and a precise thermal expansion coefficient has been

determined by experiment.

2. Referenced Documents

2.1 API Standards:

API Manual of Petroleum Measurement Standards (MPMS):

Chapter 11.1–2004 Temperature and Pressure Volume Correction Factors for Generalized Crude Oils, Refined Products, and

Lubricating Oils (including Addendum 1-2007)

Chapter 11.2.1 Compressibility Factors for Hydrocarbons: 0–90° API Gravity Range

Chapter 11.2.1M Compressibility Factors for Hydrocarbons: 638–1074 Kilograms per Cubic Meter Range

Chapter 11.5 Density/Weight/Volume Intraconversion

2.2 ISO Standards:

ISO 91–1:1992 Petroleum measurement tables—Part 1: Tables based on reference temperatures of 15°C and 60°F

ISO 91–2:1991 Petroleum measurement tables—Part 2: Tables based on a reference temperature of 20°C

2.3 ASTM Adjuncts:

Adjunct to ASTM D1250: ADJD1250CDADJD1250-E-PDF—Temperature and Pressure Volume Correction Factors for

Generalized Crude Oils, Refined Products, and Lubricating Oils

Adjunct to ASTM D1250: ADJD1250CD2 – Density/Weight/Volume Intraconversion

3. Sponsorship

3.1 The revision of the ASTM/API/IP set of implementation procedures is the result of close cooperation between ASTM

International, the American Petroleum Institute (API), and the Energy Institute. To meet the objective of worldwide standardized

Available on CD-ROM from API. Order Product Number H11013.

Available on CD-ROM from API. Order Product Number H1105CD.

Available on CD-ROM from ASTM International Headquarters. Order Adjunct No. ADJD1250CDADJD1250-E-PDF. Original adjunct produced in 2004. Adjunct last

revised in 2007.

Available on CD-ROM from ASTM International Headquarters. Order Adjunct No. ADJD1250CD2. Original adjunct produced in 2009.

´1

D1250 − 08 (2013)

measurement practices, it is expected to result in the acceptance of the revised tables by the International Organization for

Standardization (ISO), and specifically ISO/TC 28/SC 3, as revisions to International Standards ISO 91–1 and ISO 91–2. API

MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250CD)(ADJD1250-E-PDF) applies to all

crude oils, refined products, and lubricants previously covered by Tables 5, 6, 23, 24, 53, 54, 59, and 60. The API designation for

the complete set of implementation procedures is the Manual of Petroleum Measurement Standards (MPMS) Chapter 11 Section

1. The IP designation for the complete set of implementation procedures is the Adjunct to IP 200.

4. Significance and Use

4.1 The expanded limits of API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04

(ADJD1250CD)(ADJD1250-E-PDF) are defined in a mixture of terms of customary and metric units. Table 1 shows the defining

limits and their associated units in bold italics. Also shown in Table 1 are the limits converted to their equivalent units (and, in

the case of the densities, other base temperatures).

4.2 Note that only the precision levels of the defining values shown in Table 1 are correct. The other values showing converted

units have been rounded to the significant digits shown; as rounded values, they may numerically fall just outside of the actual

limits established by the defining values.

4.3 Table 2 provides a cross-reference between the historical table designations and the corresponding section in API MPMS

Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250CD).(ADJD1250-E-PDF). Note that procedure

paragraphs 11.1.6.3 (U.S. customary units) and 11.1.7.3 (metric units) provide methods for correcting on-line density

measurements from live conditions to base conditions and then to compute CTPL factors for continuous volume corrections to base

conditions.

4.4 When a glass hydrometer is used to measure the density of a liquid, special corrections must be made to account for the

thermal expansion of the glass when the temperature is different from that at which the hydrometer was calibrated. The 1980 CTL

Tables had generalized equations to correct glass hydrometer readings, and these corrections were part of the printed odd-numbered

tables. However, detailed procedures to correct a glass hydrometer reading are beyond the scope of API MPMS Chapter

11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04 (ADJD1250CD).(ADJD1250-E-PDF). The user should refer to the

appropriate sections of API MPMS Chapter 9 or other appropriate density/hydrometer standards for guidance.

4.5 The set of correlations given in API MPMS Chapter 11.1–2004/Adjunct to IP 200/04/Adjunct to ASTM D1250–04

(ADJD1250CD)(ADJD1250-E-PDF) is intended for use with petroleum fluids comprising either crude oils, refined products, or

lubricating oils that are single-phase liquids under normal operating conditions. The liquid classifications listed here are typical

terms used in the industry, but local nomenclature may vary. The list is illustrative and is not meant to be all-inclusive.

4.6 Crude Oils—A crude oil is considered to conform to the commodity group Generalized Crude Oils if its density falls in the

range between approximately –10°API to 100°API. Crude oils that have been stabilized for transportation or storage purposes and

whose API gravities lie within that range are considered to be part of the Crude Oil group. Also, aviation jet B (JP-4) is best

represented by the Crude Oil correlation.

4.7 Refined Products—A refined product is considered to conform to the commodity group of Generalized Refined Products if

the fluid falls within one of the refined product groups. Note the product descriptors are generalizations. The commercial

A

TABLE 1 Range Limits

Physical Units Crude Oil Refined Products Lubricating Oils

Density, kg/m @ 60°F 610.6 to 1163.5 610.6 to 1163.5 800.9 to 1163.5

Density, kg/m @ 60 °F 610.6 to 1163.5 610.6 to 1163.5 800.9 to 1163.5

Relative Density @ 60°F 0.61120 to 1.16464 0.61120 to 1.16464 0.80168 to 1.1646

Relative Density @ 60 °F 0.61120 to 1.16464 0.61120 to 1.16464 0.80168 to 1.1646

API Gravity @ 60°F 100.0 to -10.0 100.0 to -10.0 45.0 to -10.0

API Gravity @ 60 °F 100.0 to -10.0 100.0 to -10.0 45.0 to -10.0

Density, kg/m @ 15°C 611.16 to 1163.79 611.16 to 1163.86 801.25 to 1163.85

Density, kg/m @ 15 °C 611.16 to 1163.79 611.16 to 1163.86 801.25 to 1163.85

Density, kg/m @ 20°C 606.12 to 1161.15 606.12 to 1160.62 798.11 to 1160.71

Density, kg/m @ 20 °C 606.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.