ASTM D5421-00

(Specification)Standard Specification for Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

Standard Specification for Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

SCOPE

1.1 This specification covers circular contact-molded fiberglass reinforced-thermosetting-resin flanges for use in pipe systems and tank nozzles. Included are requirements for materials, workmanship, performance, and dimensions.

1.2 Flanges (see Fig. 1 ) may be produced as integral flanges, Type A, or flange-on-pipe, Type B.

1.3 This specification is based on flange performance and does not cover design.

1.4 These flanges are designed for use with pipe and tanks that are manufactured to Specifications D2996, D2997, D3262, D3299, D3517, D3754, D3982, and D4097.

1.5 Selection of gaskets is not covered in this specification, refer to the manufacturer's recommendation.

Note 1--ISO Equivalent--There is no similar or equivalent ISO standard.

1.6 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

The following precautionary caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5421 – 00

Standard Specification for

Contact Molded “Fiberglass” (Glass-Fiber-Reinforced

1

Thermosetting Resin) Flanges

This standard is issued under the fixed designation D 5421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers circular contact-molded fiber-

glass reinforced-thermosetting-resin flanges for use in pipe

systems and tank nozzles. Included are requirements for

materials, workmanship, performance, and dimensions.

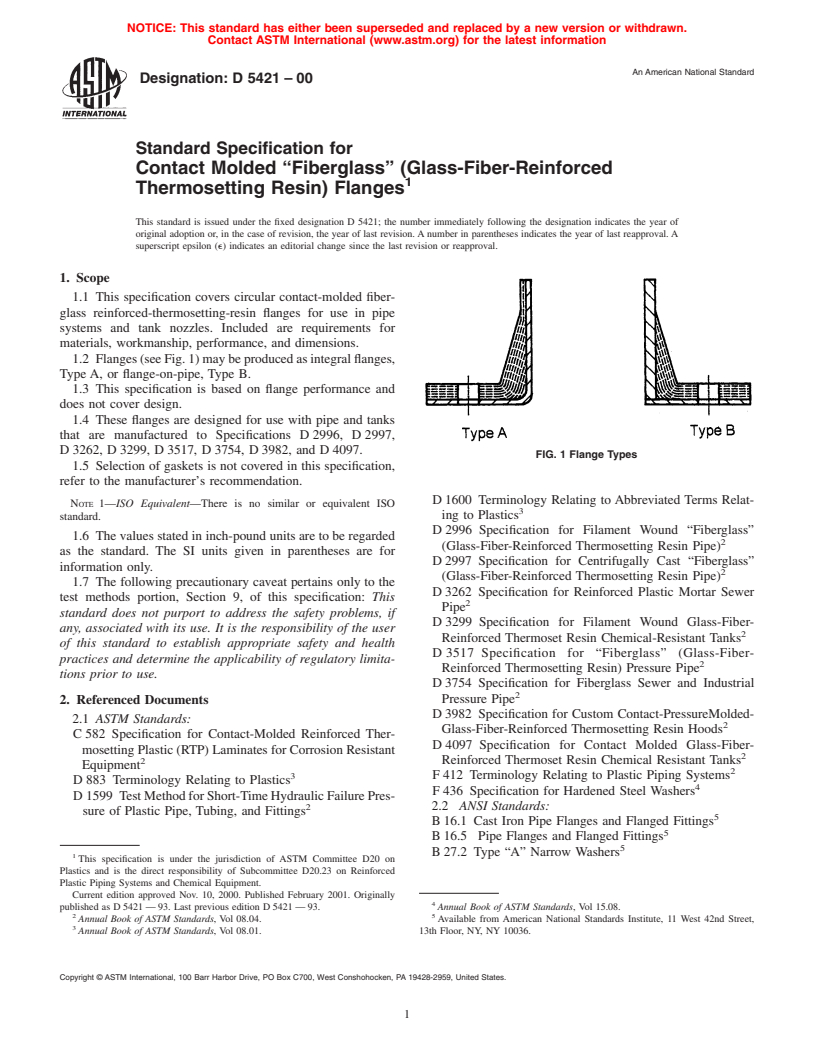

1.2 Flanges(seeFig.1)maybeproducedasintegralflanges,

Type A, or flange-on-pipe, Type B.

1.3 This specification is based on flange performance and

does not cover design.

1.4 These flanges are designed for use with pipe and tanks

that are manufactured to Specifications D 2996, D 2997,

D 3262, D 3299, D 3517, D 3754, D 3982, and D 4097.

FIG. 1 Flange Types

1.5 Selection of gaskets is not covered in this specification,

refer to the manufacturer’s recommendation.

D 1600 Terminology Relating to Abbreviated Terms Relat-

NOTE 1—ISO Equivalent—There is no similar or equivalent ISO

3

ing to Plastics

standard.

D 2996 Specification for Filament Wound “Fiberglass”

1.6 The values stated in inch-pound units are to be regarded

2

(Glass-Fiber-Reinforced Thermosetting Resin Pipe)

as the standard. The SI units given in parentheses are for

D 2997 Specification for Centrifugally Cast “Fiberglass”

information only.

2

(Glass-Fiber-Reinforced Thermosetting Resin Pipe)

1.7 The following precautionary caveat pertains only to the

D 3262 Specification for Reinforced Plastic Mortar Sewer

test methods portion, Section 9, of this specification: This

2

Pipe

standard does not purport to address the safety problems, if

D 3299 Specification for Filament Wound Glass-Fiber-

any, associated with its use. It is the responsibility of the user

2

Reinforced Thermoset Resin Chemical-Resistant Tanks

of this standard to establish appropriate safety and health

D 3517 Specification for “Fiberglass” (Glass-Fiber-

practices and determine the applicability of regulatory limita-

2

Reinforced Thermosetting Resin) Pressure Pipe

tions prior to use.

D 3754 Specification for Fiberglass Sewer and Industrial

2

2. Referenced Documents Pressure Pipe

D 3982 Specification for Custom Contact-PressureMolded-

2.1 ASTM Standards:

2

Glass-Fiber-Reinforced Thermosetting Resin Hoods

C 582 Specification for Contact-Molded Reinforced Ther-

D 4097 Specification for Contact Molded Glass-Fiber-

mosetting Plastic (RTP) Laminates for Corrosion Resistant

2

Reinforced Thermoset Resin Chemical Resistant Tanks

2

Equipment

2

3 F 412 Terminology Relating to Plastic Piping Systems

D 883 Terminology Relating to Plastics

4

F 436 Specification for Hardened Steel Washers

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

2 2.2 ANSI Standards:

sure of Plastic Pipe, Tubing, and Fittings

5

B 16.1 Cast Iron Pipe Flanges and Flanged Fittings

5

B 16.5 Pipe Flanges and Flanged Fittings

5

B 27.2 Type “A” Narrow Washers

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

Current edition approved Nov. 10, 2000. Published February 2001. Originally

4

published as D 5421 — 93. Last previous edition D 5421 — 93. Annual Book of ASTM Standards, Vol 15.08.

2 5

Annual Book of ASTM Standards, Vol 08.04. Available from American National Standards Institute, 11 West 42nd Street,

3

Annual Book of ASTM Standards, Vol 08.01. 13th Floor, NY, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5421

TABLE 1 Pressure Categories

3. Terminology

A

Pressure Rating

3.1 Definitions:

Designation

psi MPa

3.1.1 Definitions are in accordance with Terminology

A 25 0.173

D 883. Abbreviations are in accordance with Terminology

B 50 0.345

D 1600, unless otherwise indicated. The abbreviation for

C 75 0.517

reinforced-thermosetting-resin pipe is RTRP.

D 100 0.690

E 125 0.862

3.2 Definitions of Terms Specific to This Standard: Descrip-

F 150 1.034

tions of Terms Specific to This Standard:

A

Flanges with higher pressure ratings are available by agreement between the

3.2.1 contact molding (CM)—a method of fabrication

purchaser and the manufacturer.

wherein the glass fiber reinforcement is applied to the mold in

the form of all chopped-strand mat, or chopped-strand mat and

TABLE 2 Short-Term Rupture Pressure and Sealing-Test

woven roving, in alternate plies by hand with the res

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.